A Double Shear Plate Transfer Beam-Column Joint

A beam-column joint and conversion beam technology, which is applied to buildings and building structures, can solve problems such as increased construction costs, waste of structural steel bars, and increased stress-bearing steel bars for frame-supported beams. The effect of improving the shear capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

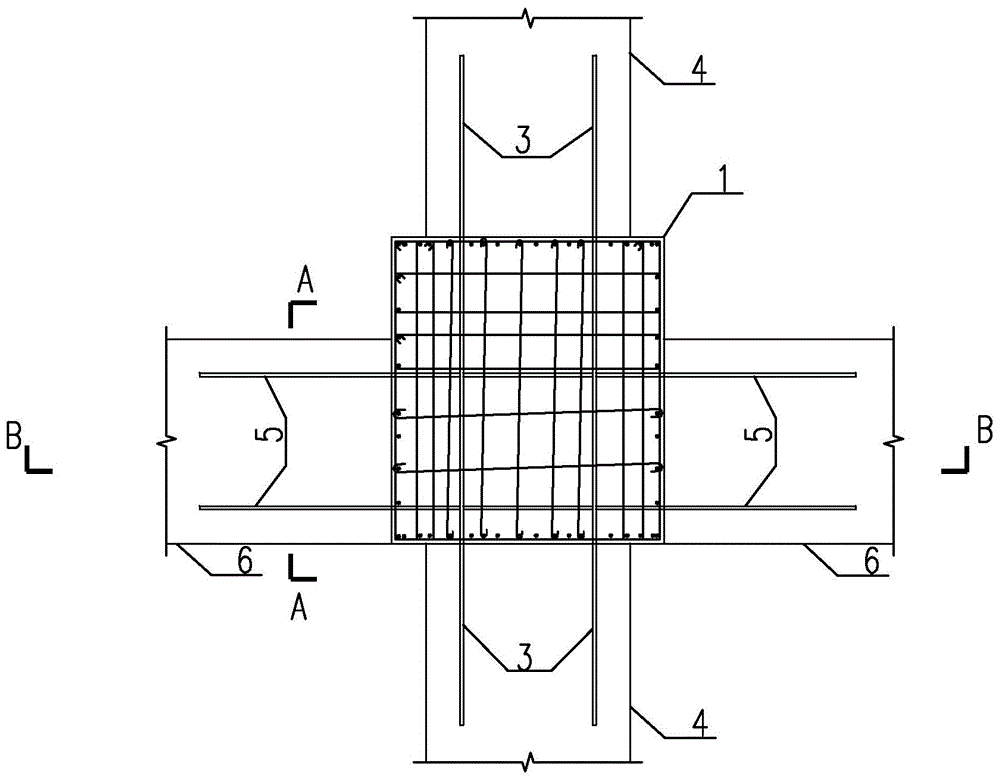

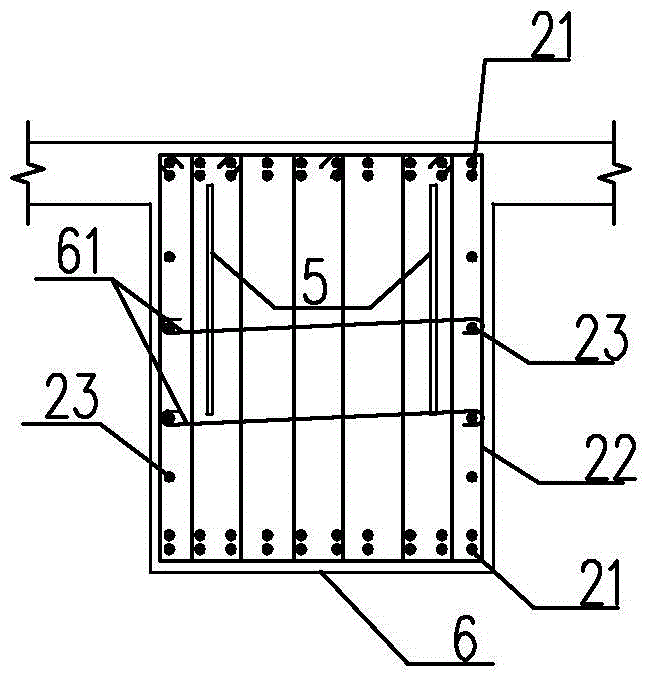

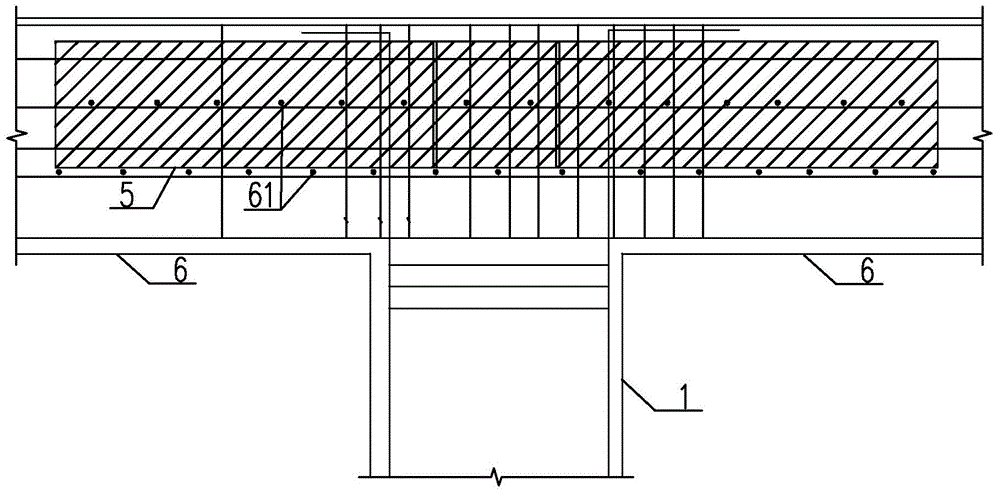

[0033] Such as Figure 1~3 As shown, a double shear plate transfer beam-column node of the present invention includes a transfer column 1 and a concrete transfer beam, the concrete transfer beam is composed of concrete and steel bars, and the steel bars include longitudinal bars 21, stirrups 22 and waist bars 23, and each A pair of parallel shear steel plates are vertically arranged in the beam end of a concrete transfer beam along its length direction, the thickness of the shear steel plates is 6-30 mm, and the distance between the shear steel plates and the beam side of the concrete transfer beam is at least 120 mm, The distance between the top surface of the shear steel plate and the beam top of the concrete transfer beam is at least 100mm, which can meet the minimum protective layer thickness requirements. The specific values of the length, height and thickness of the shear steel plate can be calculated according to the comprehensive shear envelope diagram of the structur...

Embodiment 2

[0036] The difference between this embodiment and Embodiment 1 is that the concrete transfer column and the concrete transfer beam intersect in an "L" shape, and there are two pairs of shear steel plates, of which one pair of shear steel plates is located in one of the concrete as the first shear steel plate. In the transfer beam, another shear steel plate is located in another concrete transfer beam as the second shear steel plate, and the second shear steel plate is cut by the first shear steel plate at the beam-column connection.

Embodiment 3

[0038] Such as Figure 4 As shown, the difference between this embodiment and Embodiment 1 is that the transfer column 1 is a steel-concrete transfer column, the steel frame of the steel-concrete transfer column is cross-shaped steel, and the steel-concrete transfer column intersects with the concrete transfer beam in the shape of a "cross" , there are two pairs of shear steel plates, one of which is located in a pair of opposite concrete transfer beams 8 as the first shear steel plate 7, and the pair of first shear steel plates 7 are respectively connected to a pair of flanges of cross-shaped steel butt joint, the flange is the first flange 12, and the other shear steel plate is located in another pair of opposite concrete transfer beams 10 as the second shear steel plate 9, and is cut by the first shear steel plate 7, one of which The second shear steel plate 9 is docked with one of the other pair of flanges 13 of the cross-shaped steel, and another second shear steel plate ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com