Tunnel face cavity processing method for shield tunnel construction

A technology of shield tunneling and treatment method, applied in tunnels, tunnel linings, earthwork drilling and other directions, can solve the problems of ineffective treatment of tunnel face voids, poor grouting reinforcement effect, etc., to avoid long-term exposure, delicate The effect of high bonding and bonding strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

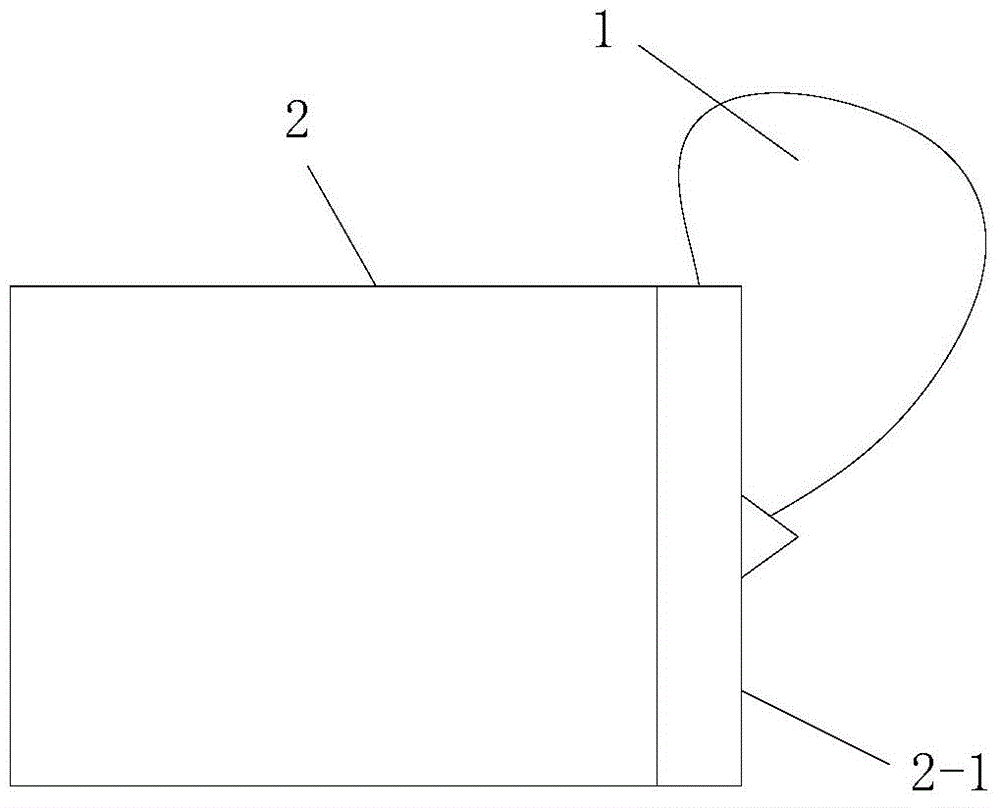

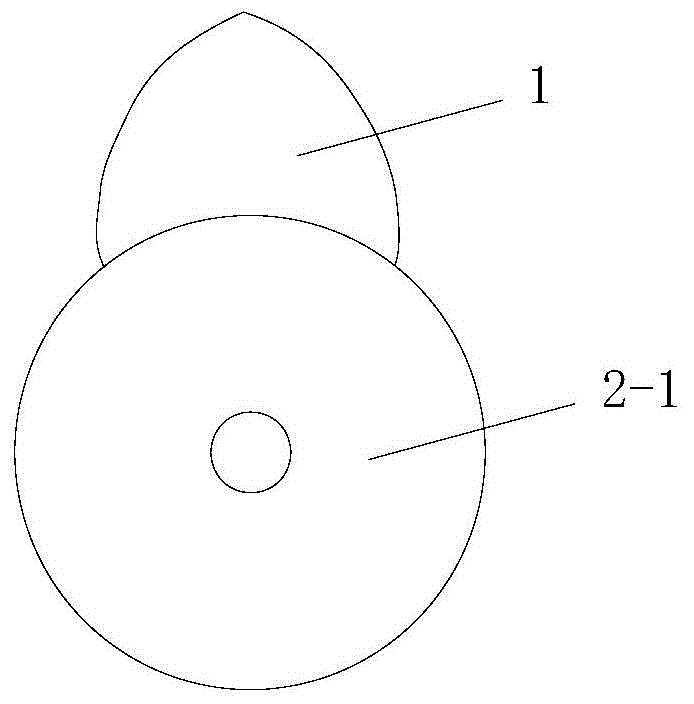

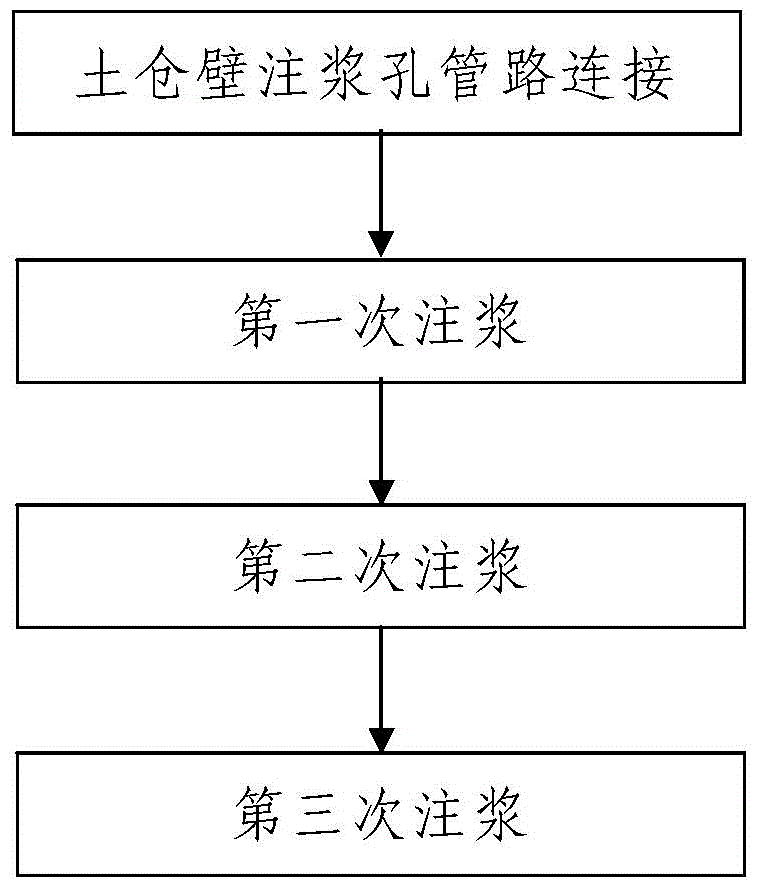

[0048] like figure 2 A method for treating tunnel face voids for shield tunnel construction is shown. The tunnel face voids to be processed are voids 1 located at the front and upper part of the cutter head 2-1 of the shield machine 2, including the following steps:

[0049] Step 1, the first grouting: the grouting system of the shield machine 2 is used, and the first cement mortar is injected into the lower part of the cavity 1 through the soil bin of the shield machine 2; during the first grouting process, the soil The internal pressure of the warehouse is controlled between 1.5bar and 3.5bar.

[0050] During the first grouting, inject the first grouting slurry into the soil bin from top to bottom; after the first grouting is completed, the inner upper part of the soil bin is filled with cement mortar, and the cement The bottom height of the mortar-filled section is lower than that of the cavity 1 .

[0051] The first grouting slurry is composed of cement, bentonite, fly ...

Embodiment 2

[0090] In this example, the difference from Example 1 is that the first grouting slurry described in step 1 is uniformly composed of cement, bentonite, fly ash, sand and water in a weight ratio of 48:52:195:580:410 Formed by mixing; the second cement mortar described in step 2 is formed by uniformly mixing cement, bentonite, fly ash, sand and water in a weight ratio of 95:78:235:580:470.

[0091] In this embodiment, the construction process of the remaining steps is the same as that of Embodiment 1.

Embodiment 3

[0093] In this example, the difference from Example 1 is that the first grouting slurry described in step 1 is uniformly composed of cement, bentonite, fly ash, sand and water in a weight ratio of 52:48:205:580:390 Formed by mixing; the second cement mortar described in step 2 is formed by uniformly mixing cement, bentonite, fly ash, sand and water in a weight ratio of 105:72:245:580:450.

[0094] In this embodiment, the construction process of the remaining steps is the same as that of Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com