Underground construction deformation joint waterproof structure and construction method thereof

A construction method and technology for underground engineering, applied in water conservancy projects, underwater structures, infrastructure engineering and other directions, can solve the problems of increasing cost, affecting the construction period, costing and laboring remedial measures, etc., and achieving reliable functions, simple waterproof structure, The effect of strong repairability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

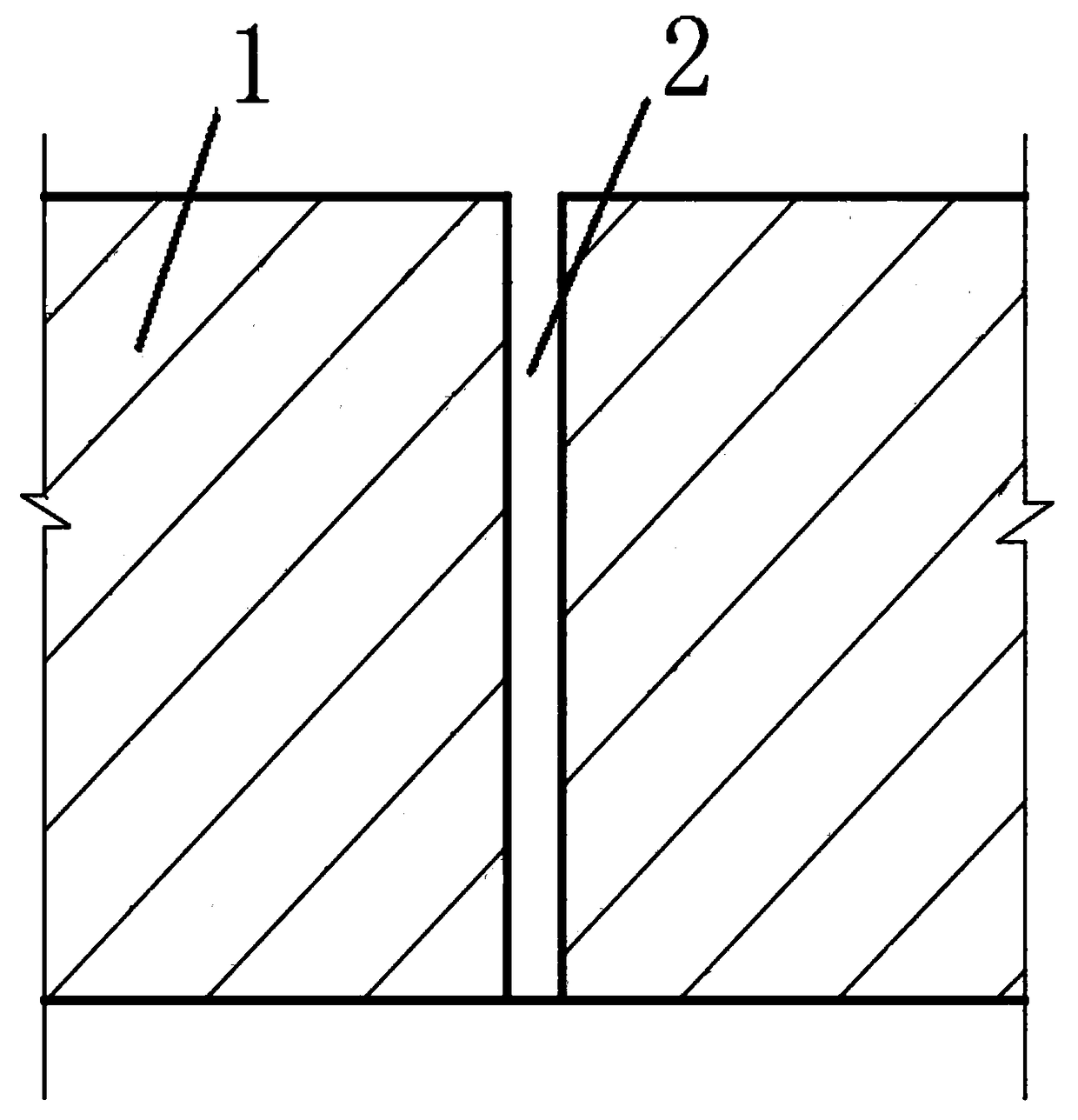

[0041] Embodiment 1 A kind of underground engineering deformation joint waterproof structure, see figure 1 , diagram 2-1 , Figure 2-2 , Figure 2-3 , Figure 2-4 , Figure 2-5 , Figure 2-6 , Figure 2-7 , image 3 , Figure 4 with Figure 5 , including the deformation seam 2, and an expansion chamber 3 located at a distance of 30-70 mm from the top of the deformation seam 2, filling the space between the expansion chamber 3 and the deformation seam 2 with a waterproof sealing material 7.

Embodiment 2

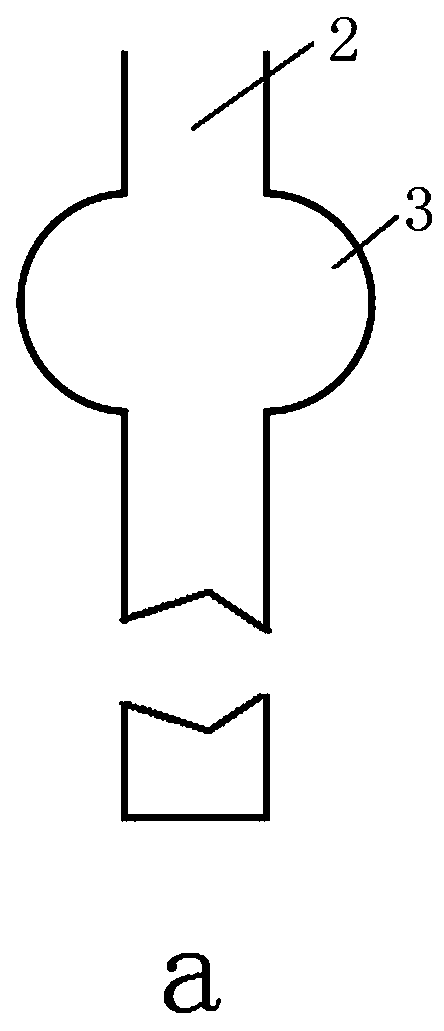

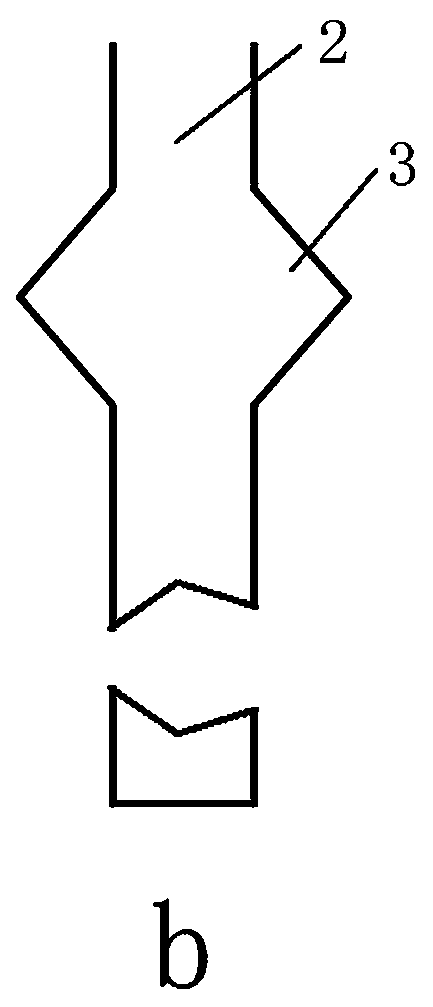

[0042] Embodiment 2 A kind of underground engineering deformation joint waterproof structure, see diagram 2-1 , Figure 2-2 , Figure 2-3 , Figure 2-4 with Figure 2-5 , including deformation seam 2, expansion cavity 3 and sealing material 7, the difference from embodiment 1 is that the cross section of expansion cavity 3 is circular (such as diagram 2-1 ), or oval, or triangular (such as Figure 2-2 ), or a polygon with sides ≥ 4 (such as Figure 2-3 , Figure 2-4 with Figure 2-5 ).

Embodiment 3

[0043] Embodiment 3 An underground engineering deformation joint waterproof structure, see diagram 2-1 , Figure 2-2 , Figure 2-3 , Figure 2-4 , Figure 2-5 , Figure 2-6 with Figure 2-7 , including deformation seam 2, expansion cavity 3 and sealing material 7, the difference from embodiment 1 is that: the cross section of expansion cavity 3 is a regular curved edge shape; the cross section of expansion cavity 3 is composed of two circles with the same radius ( Such as Figure 2-6 a1), or composed of multiple circles with the same radius (such as Figure 2-6 a2), or for two triangles (such as Figure 2-7 ).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com