Spliced-type integrated inspection well

An assembled and integrated technology, applied in water conservancy projects, artificial islands, underwater structures, etc., can solve problems such as waste of materials, poor operating environment of inspection wells, and delays in project duration, etc., to achieve clean operating environment, reasonable assembly structure, and airtight good performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

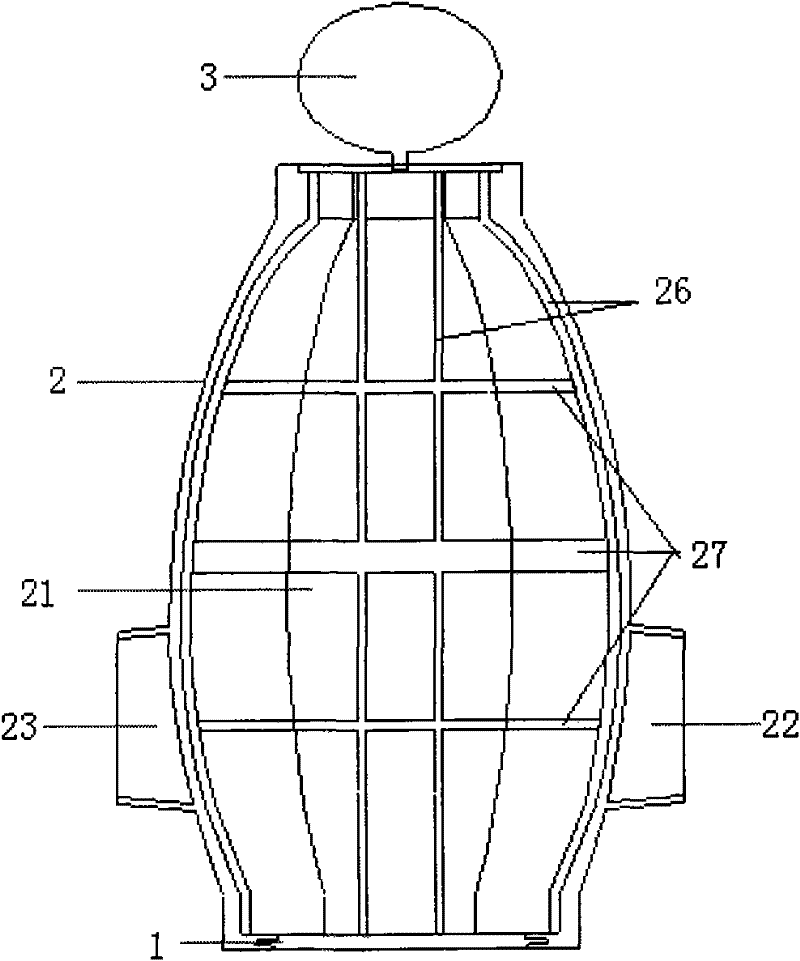

[0027] Such as Figure 1A as shown,

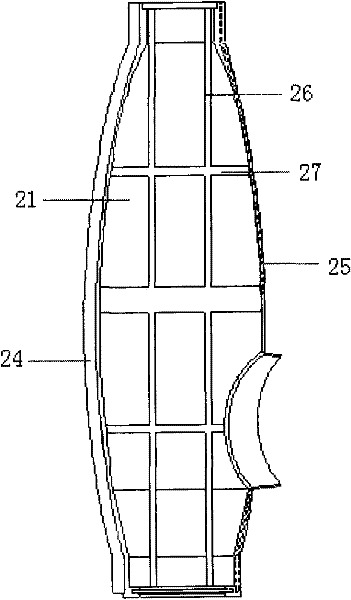

[0028] The said assembly type integral inspection well of the present invention is mainly made up of chassis 1, side wall 2 and cover plate 3. Wherein, the side wall is a barrel-shaped (huge in the middle) wall assembled by six wall panels 21 along the circumferential direction, and each piece of circumferential rotation is 60°; ; The inlet and outlet are respectively provided with protruding connecting nozzles.

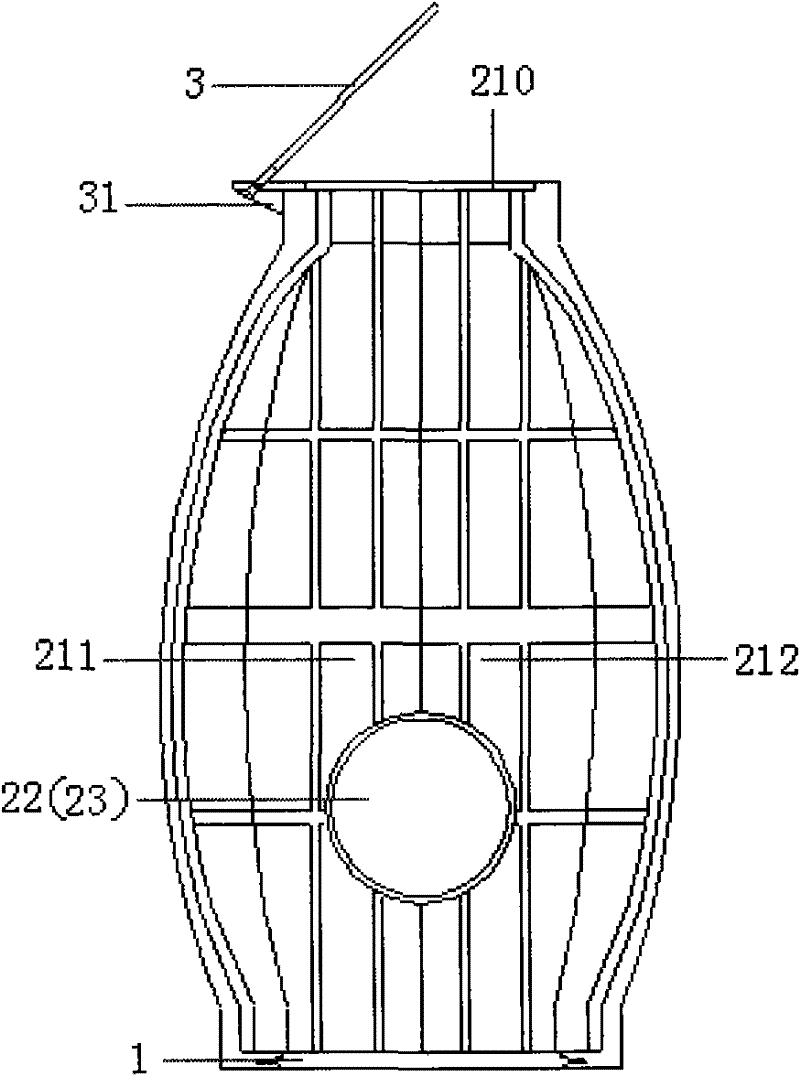

[0029] Such as Figure 1B as shown,

[0030] The cover plate 3 is connected to the upper end of the side wall through the cover plate provided on the side wall, and is connected to the upper end of the side wall with bolts, and the cover plate is located in the concave step circumferential surface formed by the wall plate concave step 210 on the top surface of the side wall; The inlet 22 and the outlet 23 of the manhole are formed by splicing two semi-circular arcs, and each semi-circular arc is respectively arranged on two ad...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com