Tunnel face breast wall filter cake construction process for shield compressed air operations

A construction technique and tunnel face technology, which is applied in mining equipment, earthwork drilling, tunnels, etc., can solve the problems of poor self-stabilization ability of the soil body on the tunnel face, impossibility of tool change, and harsh conditions for tool change, etc., to achieve improved Shield tunneling efficiency, high practical value, and short construction period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

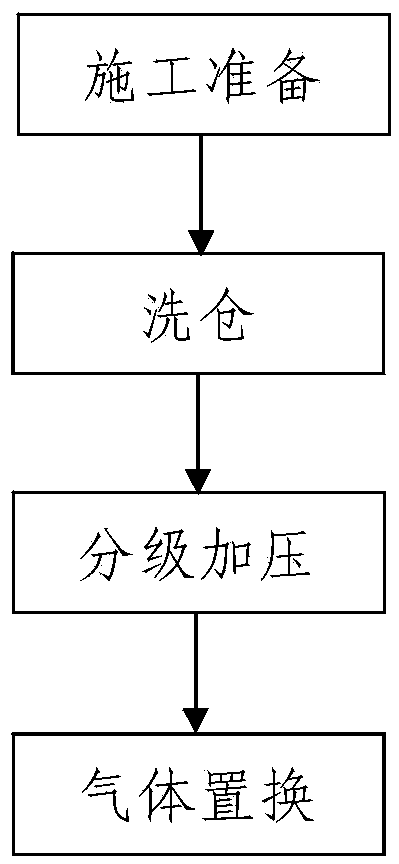

[0040] Such as figure 1 The construction process of mud film on the face of a tunnel face for air compression operation of a shield machine shown includes the following steps:

[0041] Step 1. Construction preparation: the grouting system is connected to a plurality of grouting holes through the grouting pipeline, and the plurality of grouting holes are all arranged on the outer wall of the middle and upper part of the soil bin 1 of the shield machine.

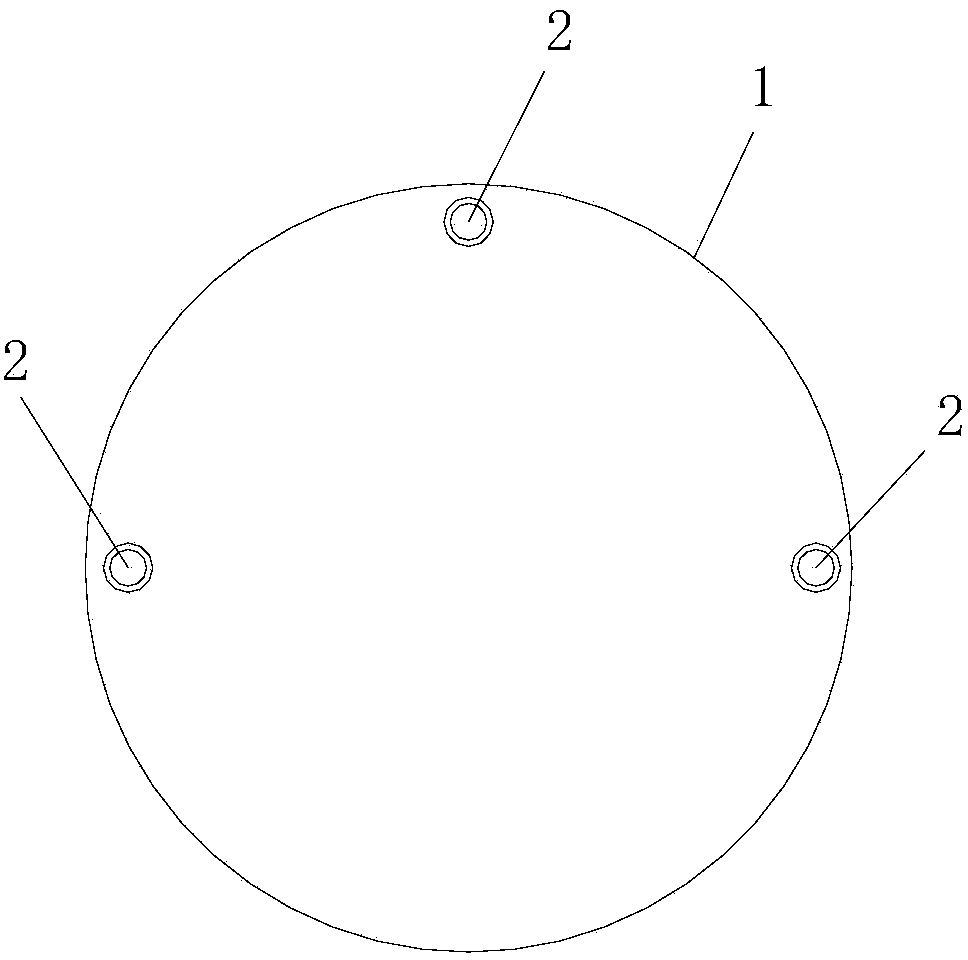

[0042] In this embodiment, a plurality of the grouting holes are arranged on the outer sidewall of the upper middle part of the soil bin 1 of the shield machine along the circumferential direction.

[0043] In this embodiment, the multiple grouting holes in step 1 are multiple balance valves 2 installed on the side wall of the soil bin 1 .

[0044] In this embodiment, the shield machine is a Herrenknecht shield machine and a plurality of balance valves 2 are arranged on the wall of the soil bin.

[0045] In actual constructi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com