Slidable construction stable annular beam

A technology with stable construction and ring beams, applied in joists, girders, trusses, etc., can solve the problems of cumbersome construction of cross braces between columns, affecting the construction period, increasing costs, etc., saving labor and material costs, saving costs, Easy to assemble and install

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

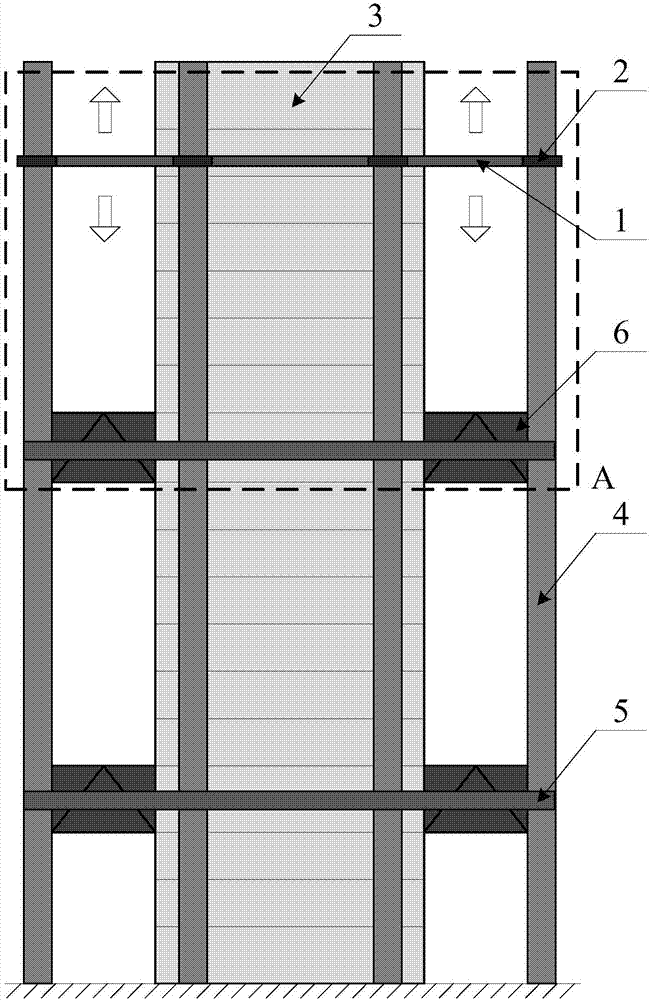

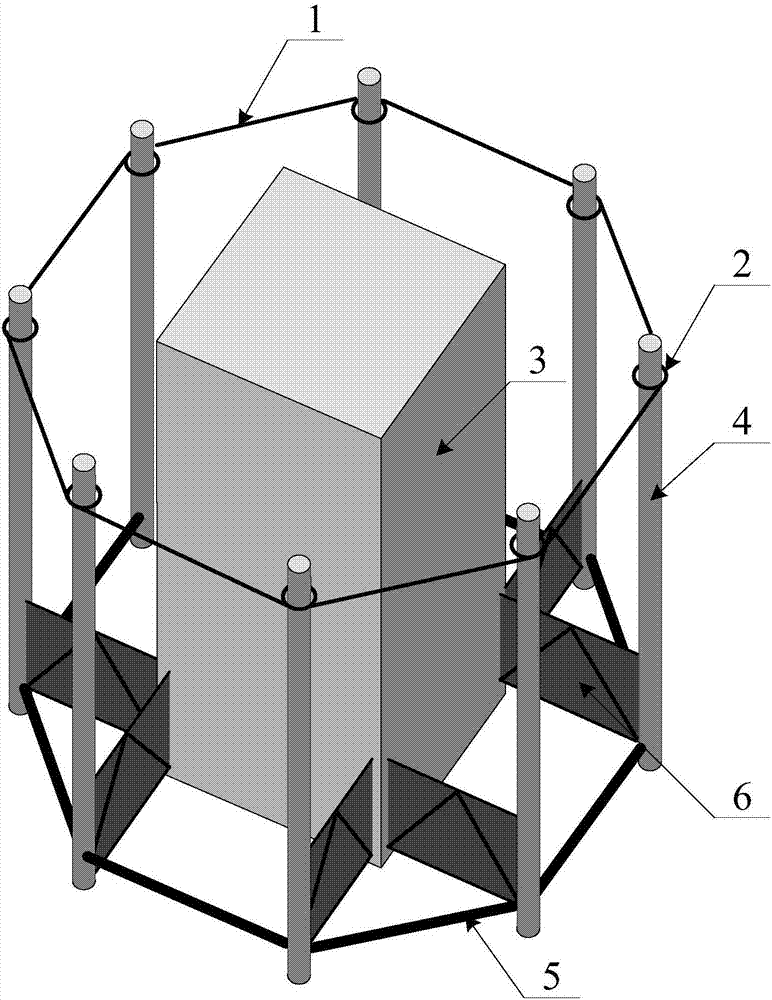

[0018] Embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

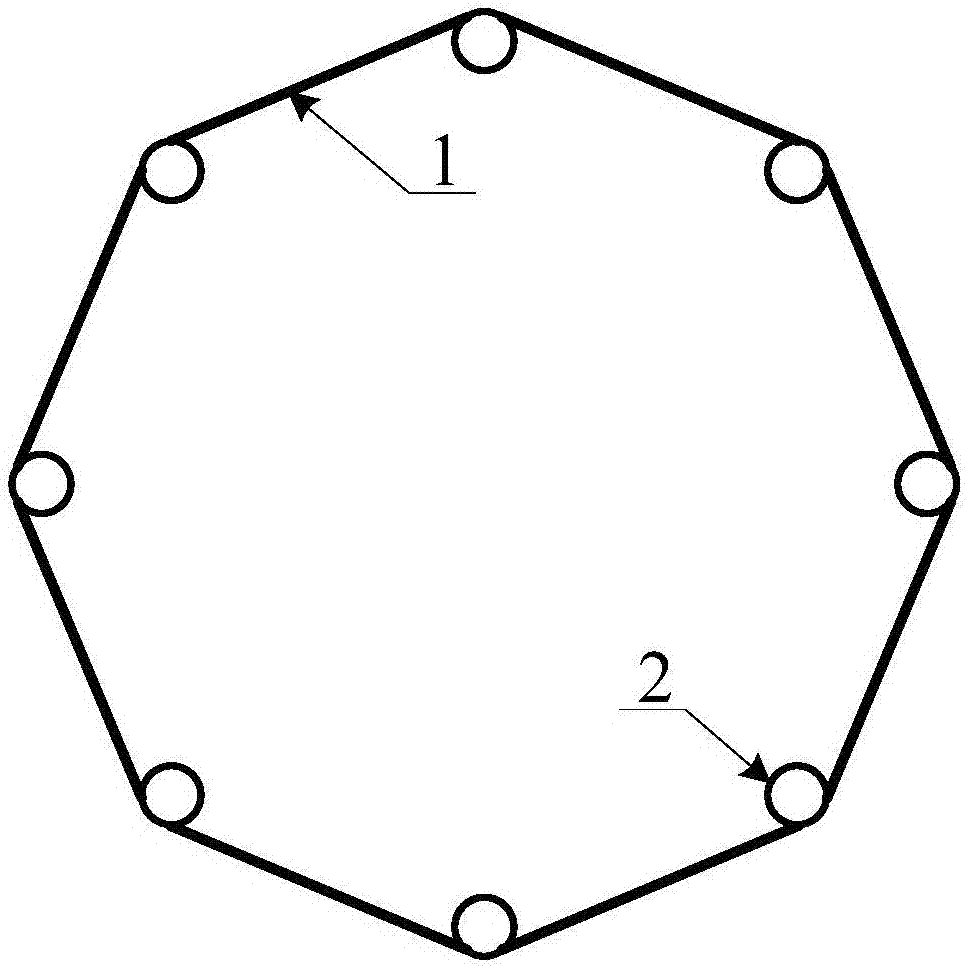

[0019] Such as Figure 1~2 As shown, the frame core tube structure system with sliding construction and stable ring beams includes the following components:

[0020] 1——steel ring beam;

[0021] 2 - fasteners;

[0022] 3 - core tube;

[0023] 4——frame column;

[0024] 5 - frame beam;

[0025] 6—Outrigger truss.

[0026] Such as Figure 1~2 As shown, the frame core tube structural system includes a core tube 3 , frame columns 4 , frame beams 5 , and outrigger trusses 6 . The steel ring beam 1 is placed horizontally between the adjacent frame columns 5, and the two ends are connected with fasteners 2. The fasteners 2 are ring-shaped steel members, which can be nested on the periphery of the frame columns 4 and connected with them. Fixed connection. Furthermore, the slidable construction-stabilizing ring beam composed of the steel ring beam 1 and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com