Cast-in-place concrete pile static load test unbalance loading monitoring method based on piezoelectric impedance frequency shift

A piezoelectric impedance, concrete technology, applied in the direction of applying stable tension/pressure to test the strength of materials, measuring devices, instruments, etc., can solve problems such as difficulty in monitoring eccentric load in static load tests, and achieve synchronization between monitoring and test process, avoiding Collapsing, low-cost effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

[0035] Specific embodiments of the present invention are described as follows:

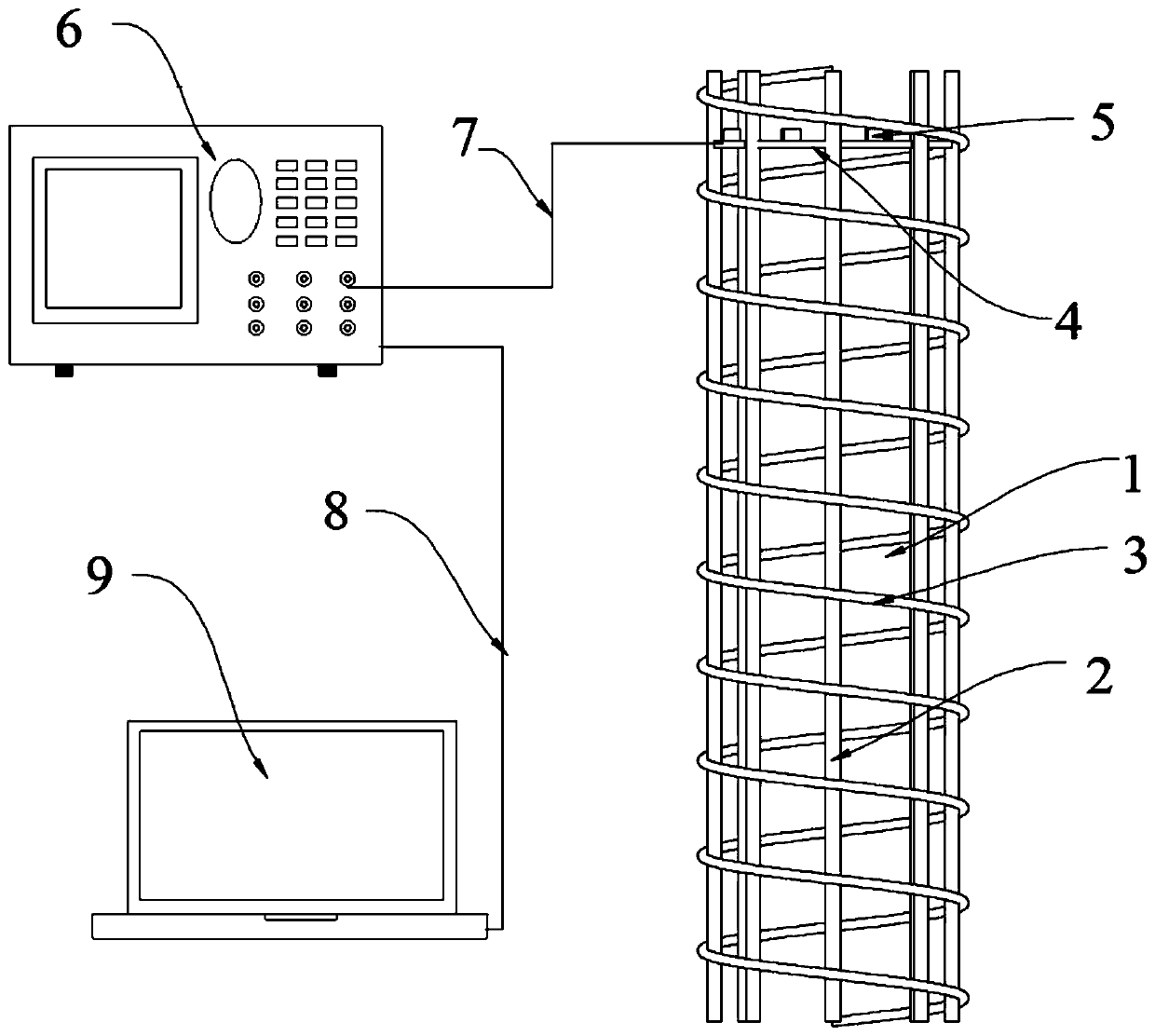

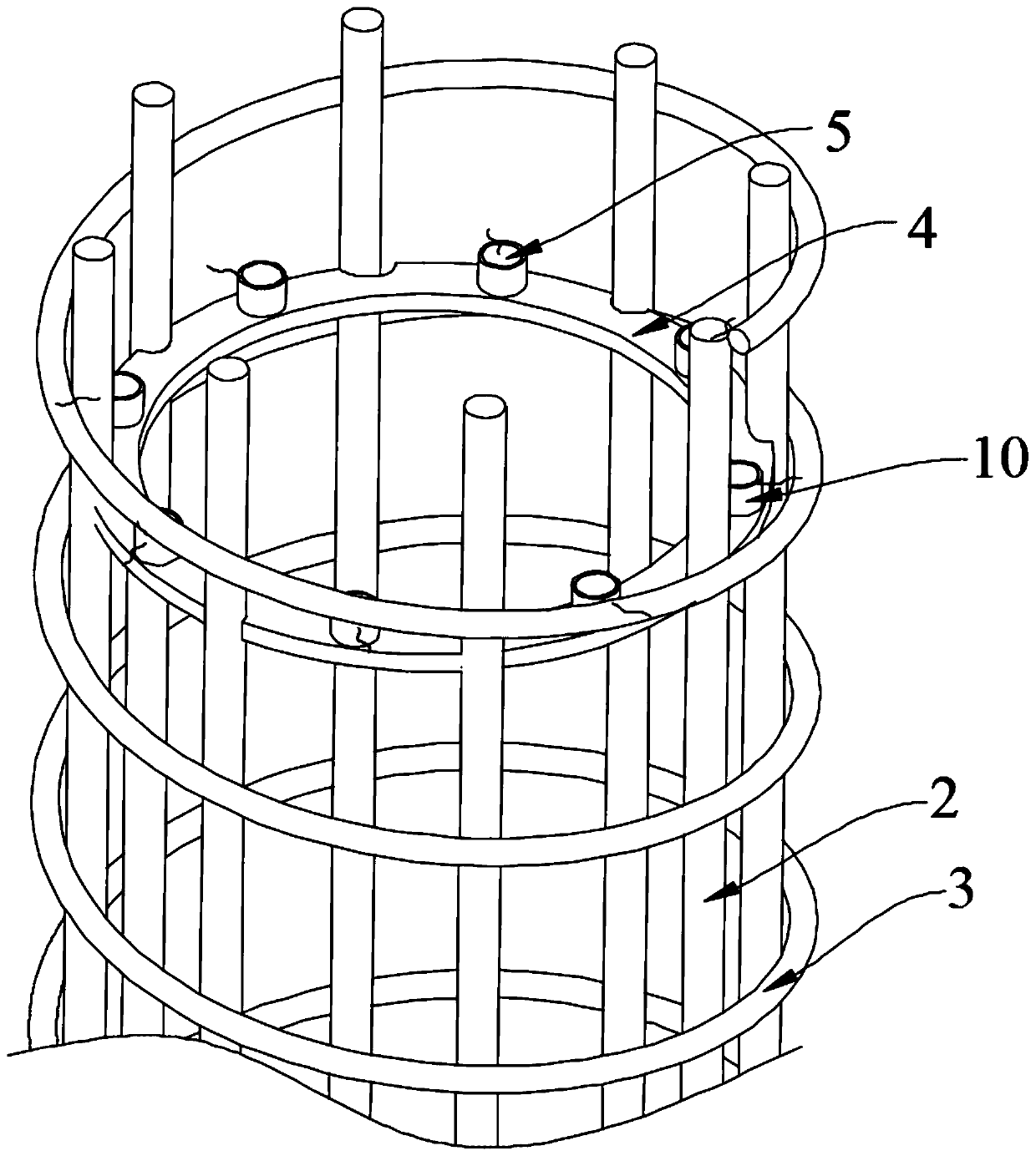

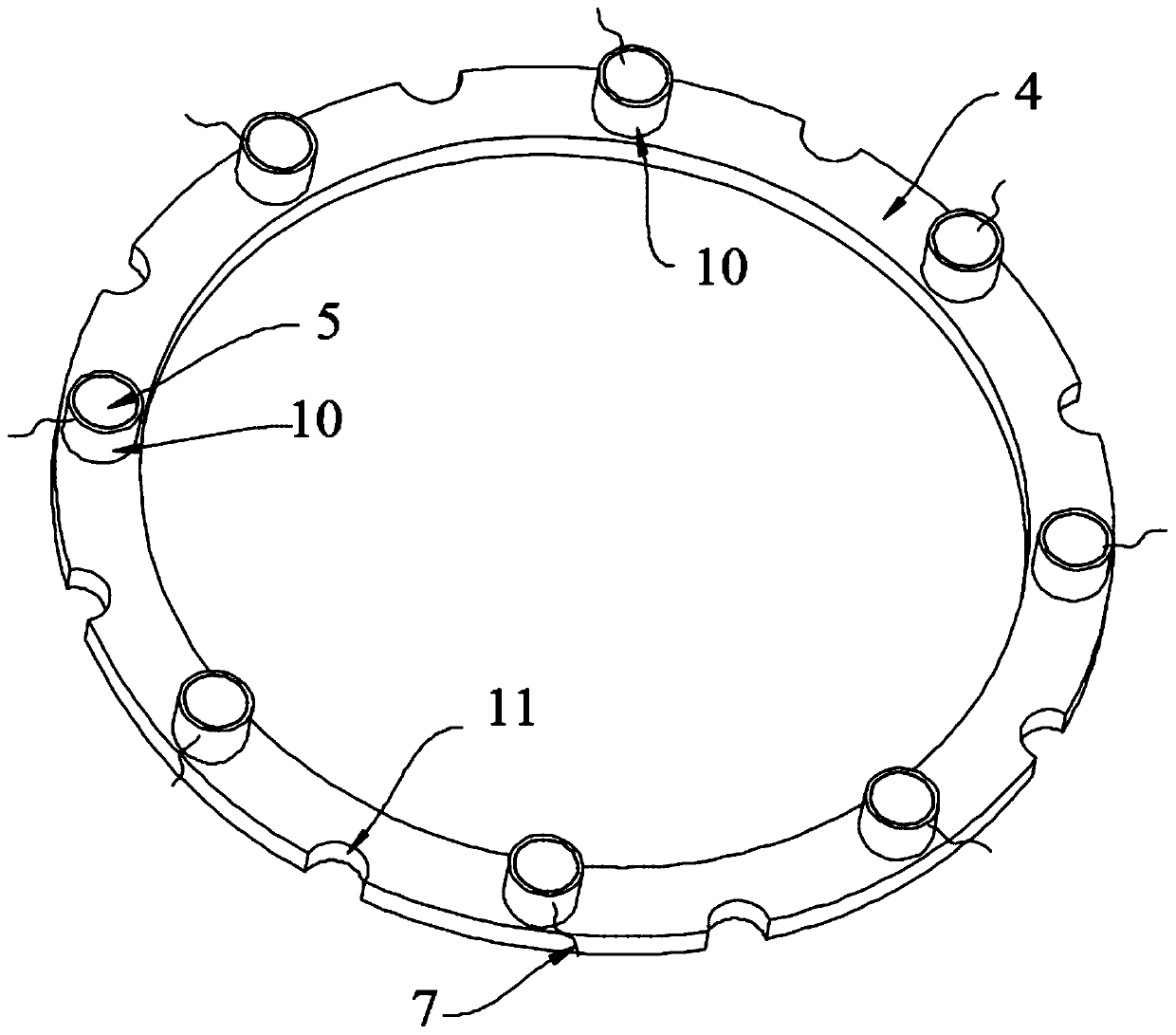

[0036] Such as Figure 1 to Figure 3 As shown, a static load test eccentric load monitoring device for concrete pouring piles based on piezoelectric impedance frequency shift includes a supporting plate 4, a number of piezoelectric ceramic sensors 5, an impedance analyzer 6 and a computer terminal 9, and the supporting plate 4 is an annular Steel plate, one side of supporting plate 4 is provided with a plurality of decks 10 that are evenly distributed in a ring, and the piezoelectric ceramic sensor 5 is fixed in the corresponding decking 10, and the main reinforcement of the steel cage is reserved on the outer side of the supporting plate 4 made of steel. 2. The number of bayonets 11 for connection is determined according to the number of reinforcements in the designed pile body, and the size is determined according to the type of the designed reinforcement bars. It can realize the occlusal connec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com