Occlusive pile construction method during encountering with deep layer underground obstacles

A construction method and obstacle technology, applied in excavation, sheet pile walls, foundation structure engineering, etc., can solve the problems of secondary obstacles encountered in the construction method of moving piles, prolong the construction period of key lines, and difficult control of construction quality, etc., to achieve Avoid pile anchorage with insufficient anchorage length, reduce construction workload, and reduce the effect of construction workload

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

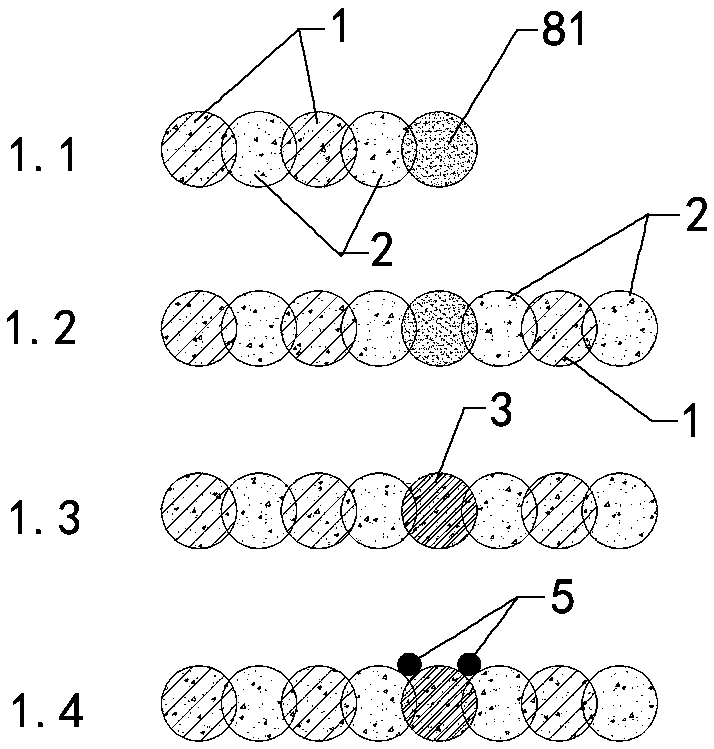

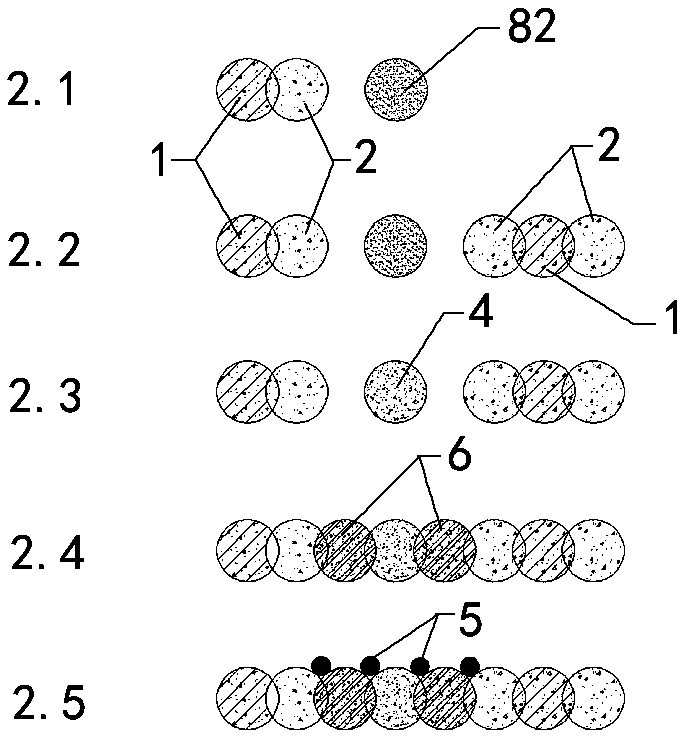

[0051] The construction method of the occlusal pile of the present invention in case of a deep underground obstacle specifically comprises the following steps:

[0052] Step 1. Site leveling and shallow surface old foundation removal:

[0053] According to the construction design requirements, carry out pre-setting, determine the occlusal pile construction area with shallow old foundations, and then remove the shallow old foundations with a depth of no more than 5m in the area. The specific removal steps are as follows:

[0054] First, excavate the miscellaneous soil in the area with an excavator, and excavate on both sides of the work area to avoid soil subsidence. The slope angle is 60° until the obstacles are completely exposed;

[0055]Then use a pickaxe machine to break shallow obstacles;

[0056] Finally, remove the broken garbage;

[0057] Step 2, guide wall construction: specifically include the following steps:

[0058] A) Pile position measurement: according to th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com