A construction method for rapid silo-type roller compacted concrete dam with overflow gap concrete

A technology of roller compacted concrete and construction method, applied in marine engineering, water conservancy engineering, infrastructure engineering and other directions, can solve the problems of low construction efficiency, slow construction progress, high construction cost, and achieve construction quality assurance, construction convenience, and construction. Efficient effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

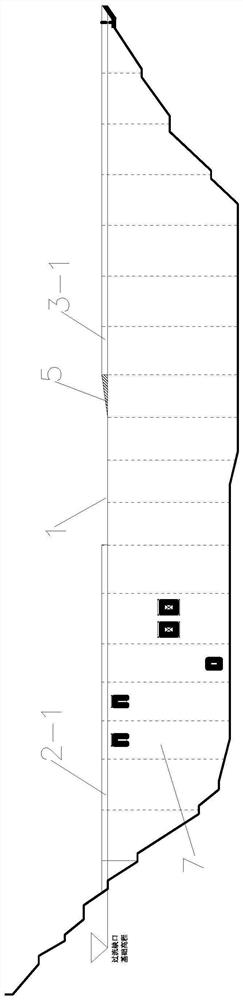

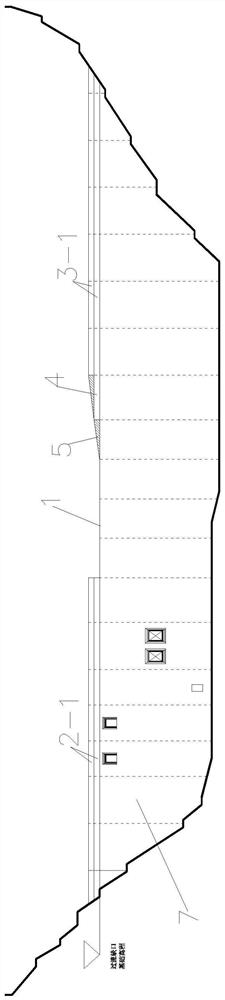

[0052] Such as Figure 1 to Figure 11 Shown, a kind of overflow gap concrete of the present invention enters the warehouse type roller compacted concrete dam construction method fast, comprises the following steps:

[0053] Step 1, construction of the foundation dam section: according to the design requirements of the foundation dam section 7, construct the foundation dam section 7 of the design elevation;

[0054] In this embodiment, the foundation dam section is provided with a water inlet hole, a diversion bottom hole and a discharge bottom hole.

[0055] In actual construction, roller compacted concrete dams are built between the two banks of rivers for flood control, water storage, water supply, and power generation.

[0056] Step 2: Construction of the transitional dam section, the process is as follows:

[0057] Step 201, determining the position of the overflow gap 1 at the top of the foundation dam section 7;

[0058] Step 202, constructing a conventional dam secti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com