Track climbing type monolithic architecture construction scaffold

A building construction and climbing technology, which is applied to the scaffolding supported by the house structure, buildings, building structures, etc., can solve the problems of slow lifting speed of electric hoists, increased construction time, and difficult dismantling of the construction site, so as to improve the overall building safety factor , Improve production efficiency and shorten the construction period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with the examples, the purpose is only to better understand the contents of the present invention, therefore, the examples given do not limit the protection scope of the present invention.

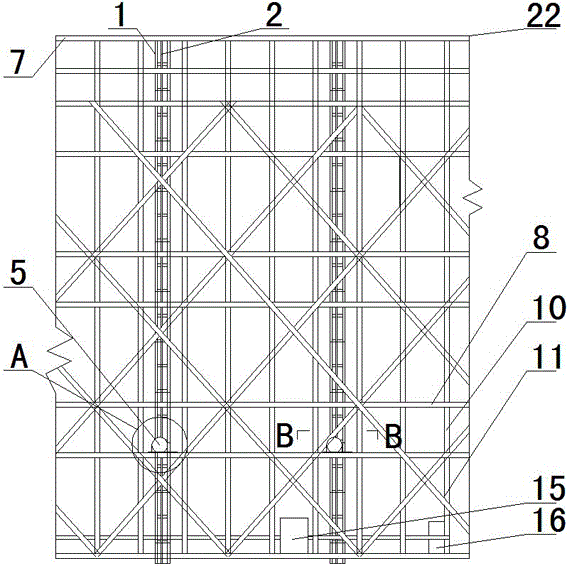

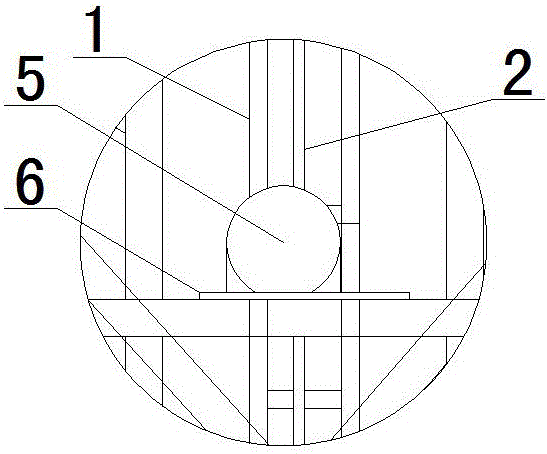

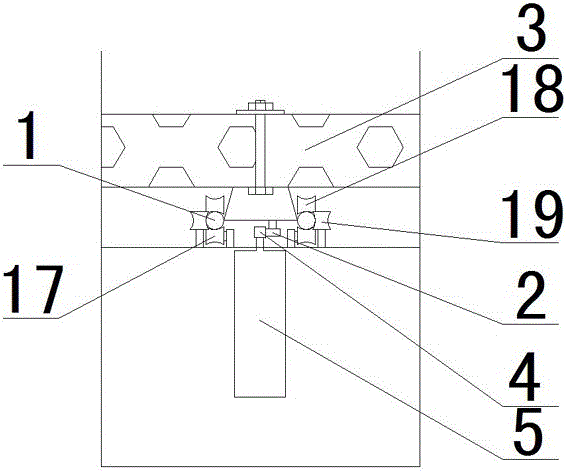

[0022] see figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , the rack bracket 1 is fixed on the wall body 3 by bolts through the bolt holes on the wall body 3, and the frame body 22 is slidingly connected with the rack bracket 1 through a fixed pulley, and the fixed pulley is installed on the frame body 22, including the Bar support 1 supports the front back wheel 17, the back wheel 18 and the side back wheel 19 of the beam front side, rear side and outside, and the frame body 22 passes the front back wheel 17, the back back wheel 18 and the side back wheel 19 on the rack support 1 slide up and down, the function of the fixed pulley is to realize the sliding connection between the rack body 22 and the r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com