Method for rapidly evaluating crack resistance of cement-based material

A technology of cement-based materials and anti-crack performance, which is applied in the field of building materials and can solve the problems of no evaluation method for the anti-crack performance of cement-based materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] 1. Test raw materials

[0035] P.O 42.5 cement (Fujian Taiwan Cement Plant), Minjiang river sand (medium sand), gravel (Tongkou gravel), fly ash (Huaneng Power Plant Class II fly ash), water reducer (Xiamen Hongfa Xianke Polycarboxylate superplasticizer produced by Chemical Building Materials Co., Ltd.), tap water.

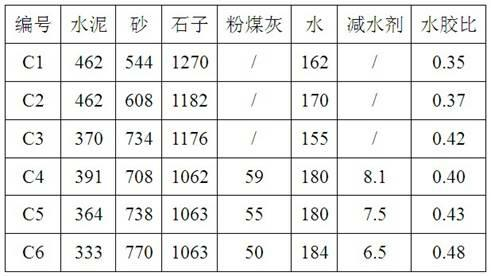

[0036] 2. Concrete mix ratio

[0037] The designed concrete mix ratio is shown in Table 1.

[0038] Concrete mix ratio ( )

[0039]

[0040] 3. Test piece production

[0041] Adopt the method of patent CN1932512 to carry out mechanical performance and anti-crack performance test. According to the "Standards for Test Methods of Mechanical Properties of Ordinary Concrete" (GB / T50081-2002), standard specimens were prepared, and their 7d and 28d compressive strengths were tested. The test results are shown in Table 2.

[0042] Table 2 Concrete cube test results (MPa)

[0043]

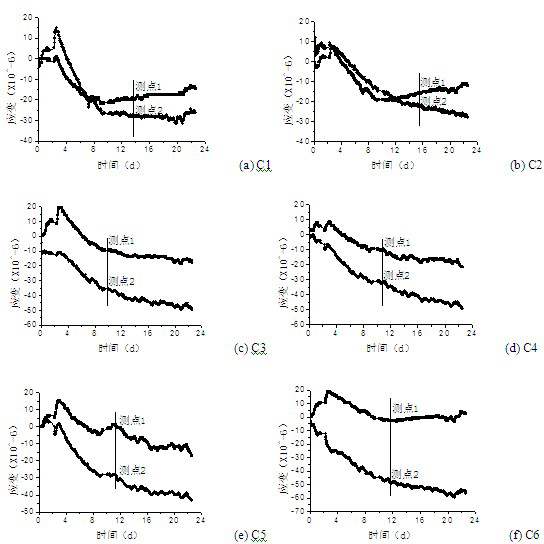

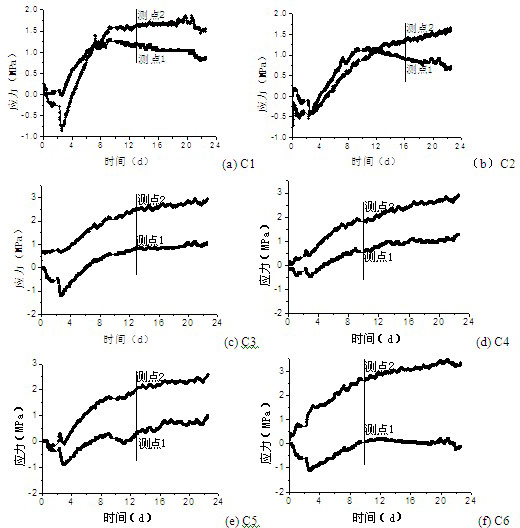

[0044] . According to the collected strain of the inner steel ring...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com