Complete-section tunnel boring machine disk cutter management method

A technology of tunnel boring machine and disc hob, which is applied in tunnels, earth-moving drilling, mining equipment, etc., can solve the problems of reducing the construction cost of full-section tunnel boring machines and improving the utilization rate, so as to improve the service life and the efficiency of tool change. , The effect of improving utilization rate and reducing construction cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0069] A where A and I intersect 1 Take area as an example, set this area as the first area, that is, i=1, set the life limit size L of the tool max =397mm, the nominal diameter of the cutter dpD=432mm, the allowable gap between the cutters l=15mm, first replace the cutters with hob diameters d432mm with cutters with diameters 397mm≤d≤432mm.

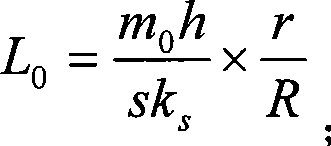

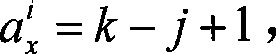

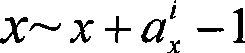

[0070] A 1 There are 7 knives in the area, arranged in descending order of diameter, numbered 1 to 7 respectively, and the diameters are 430mm, 425mm, 417mm, 414mm, 409mm, 408mm, 398mm. according to d j -d k ≤ l and d j -d k+1 >l, 1≤ji , to find one or more of the largest values a x i = k - j + 1 , 1≤x≤N i -1 criterion, get a 3 1 = 4 , That is to say, for tools numbered 3 to 6, the tools whose diameters d are 417mm, 4...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com