Patents

Literature

49results about How to "Good at propagating" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

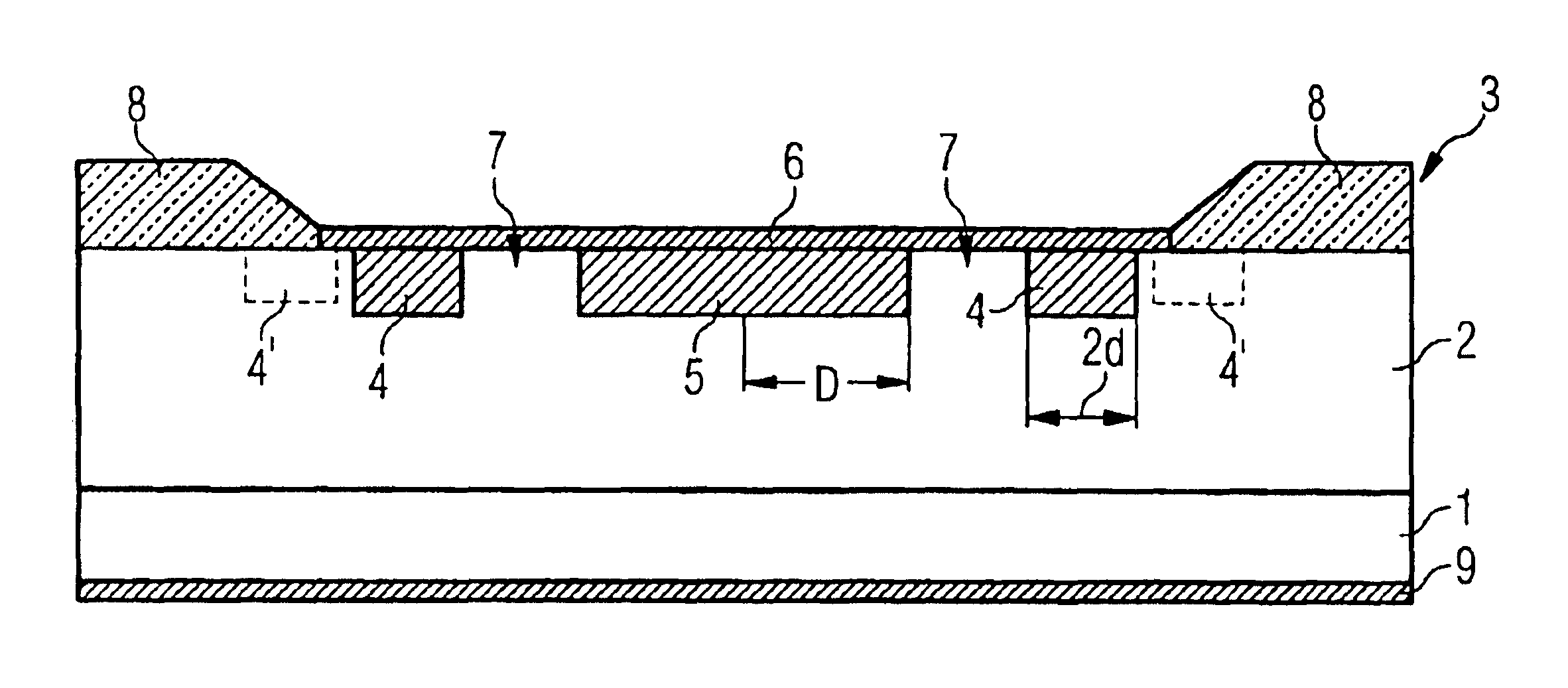

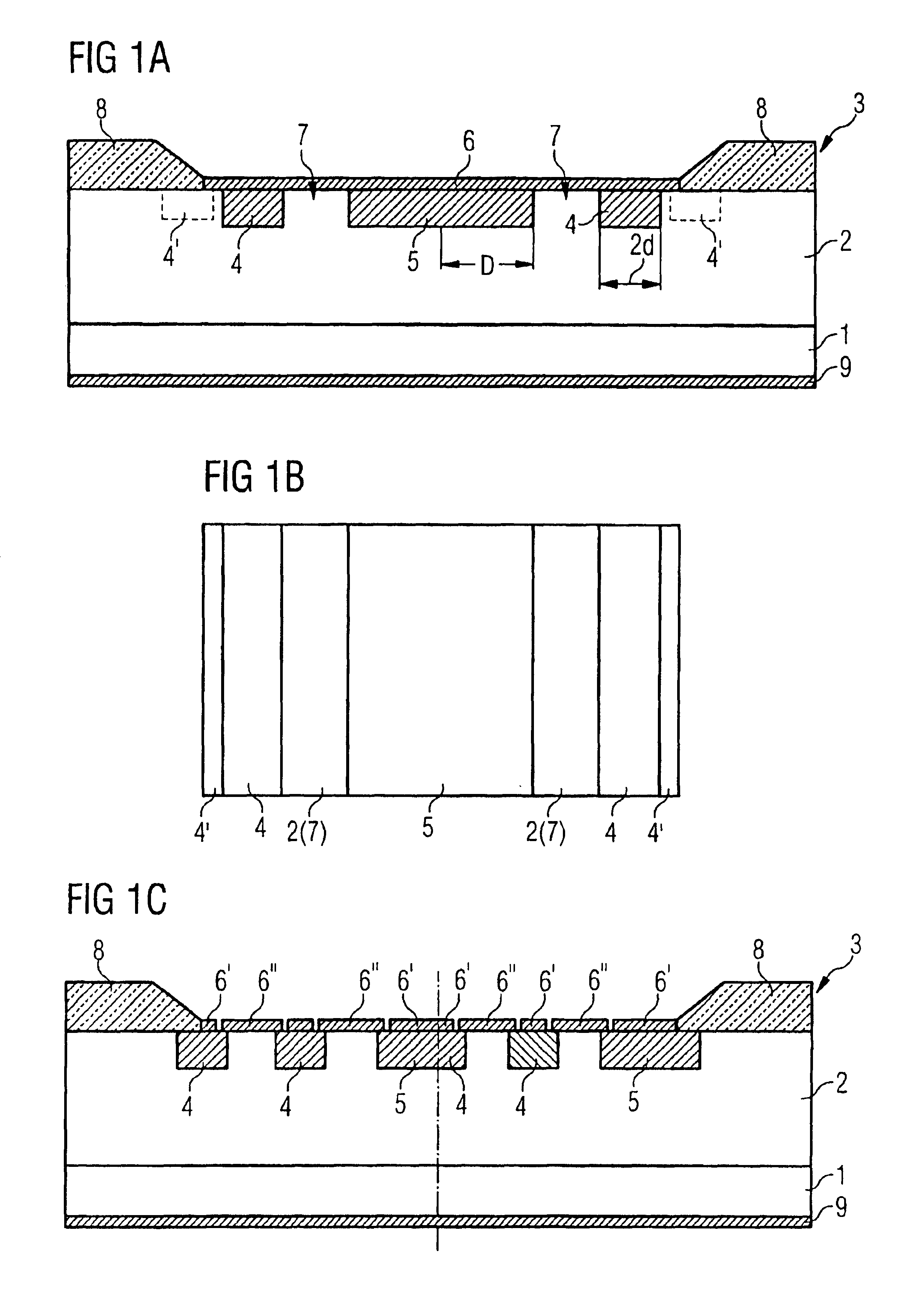

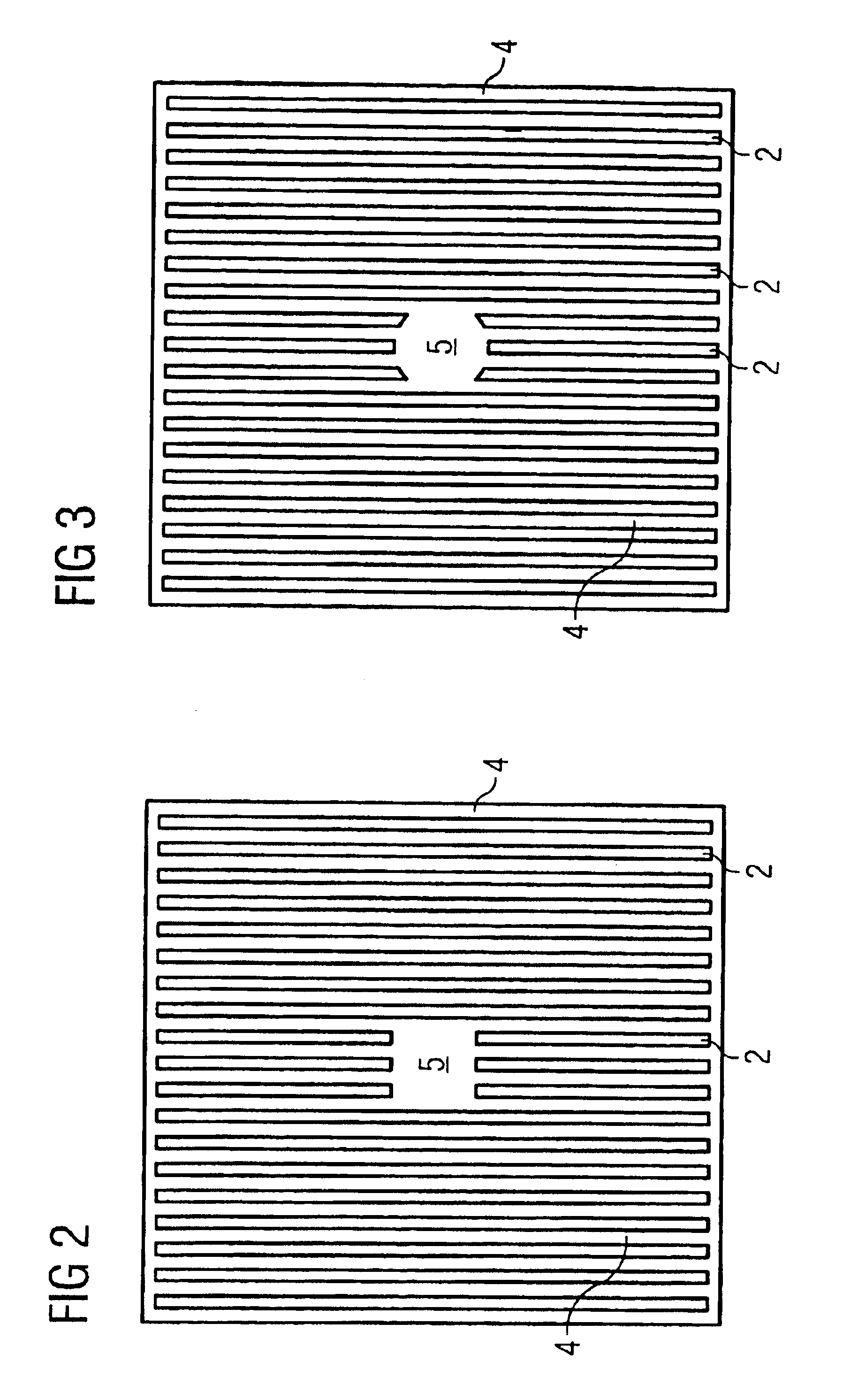

Schottky diode having overcurrent protection and low reverse current

ActiveUS6861723B2Good resistance to overcurrentsLower forward voltageTransistorReverse currentEngineering

The invention relates to a Schottky diode in which p-doped regions (4, 5) are incorporated in the Schottky contact area. At least one (5) of these regions (4, 5) has a greater minimum extent, in order to initiate a starting current.

Owner:INFINEON TECH AG

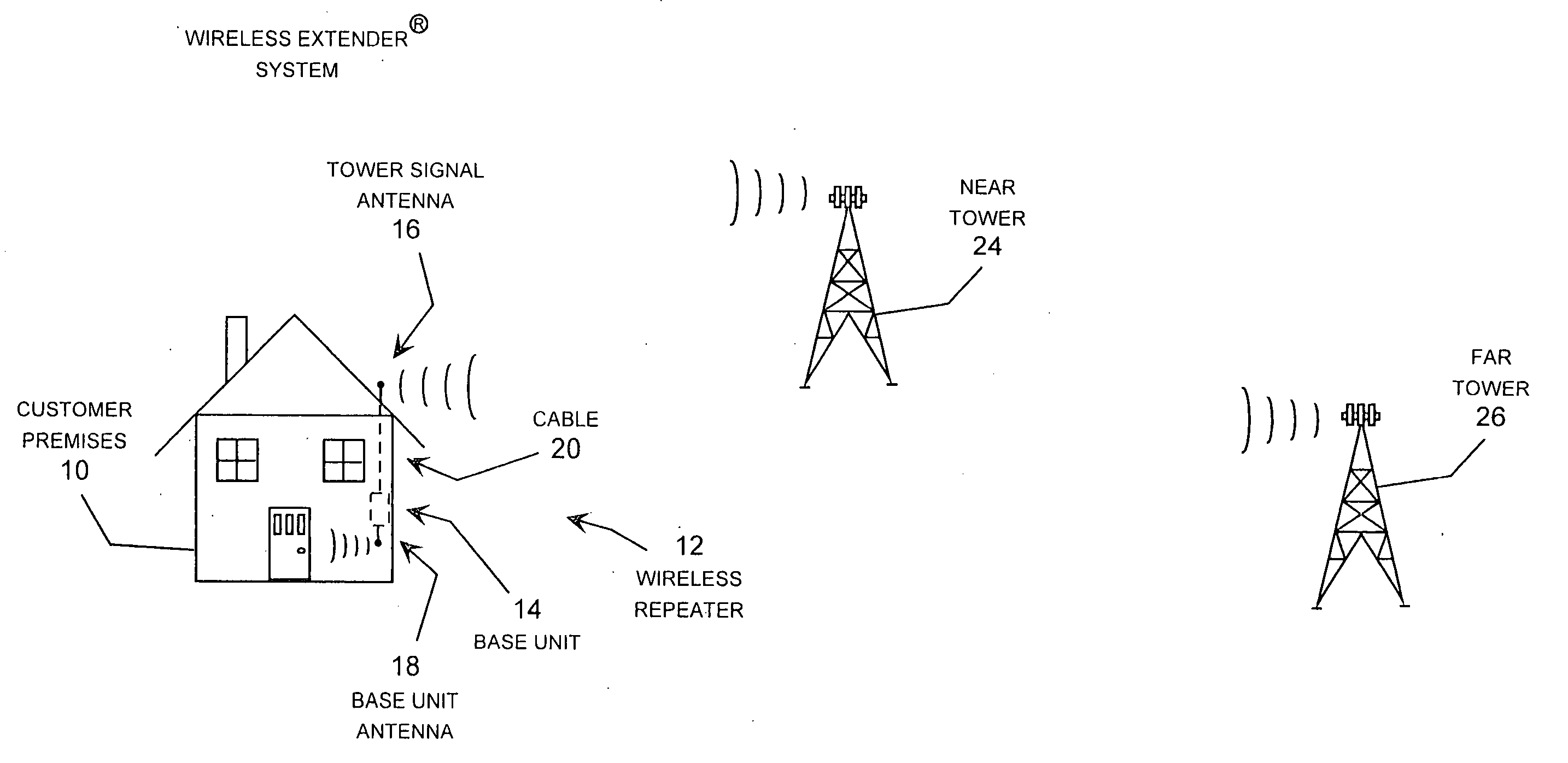

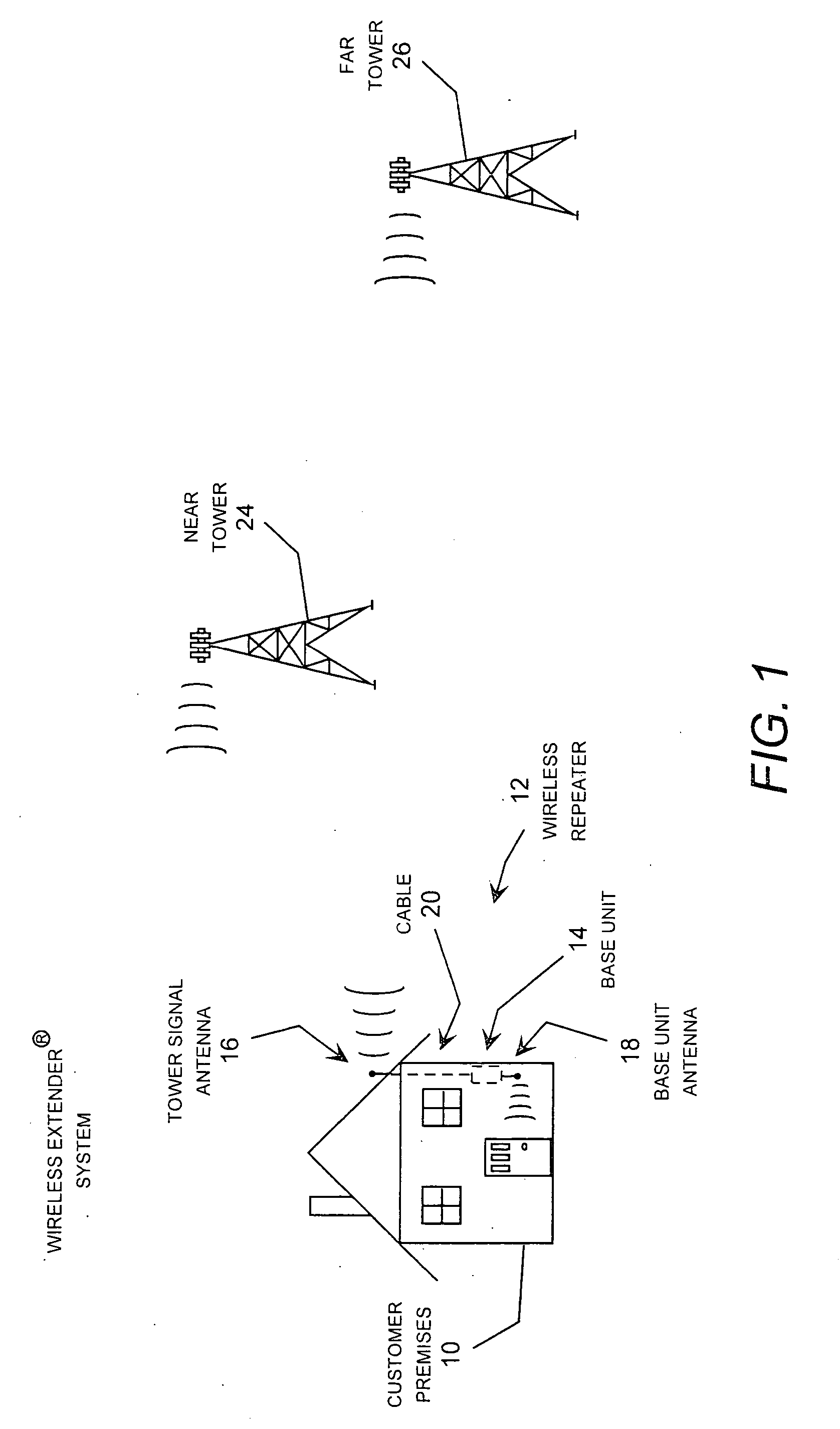

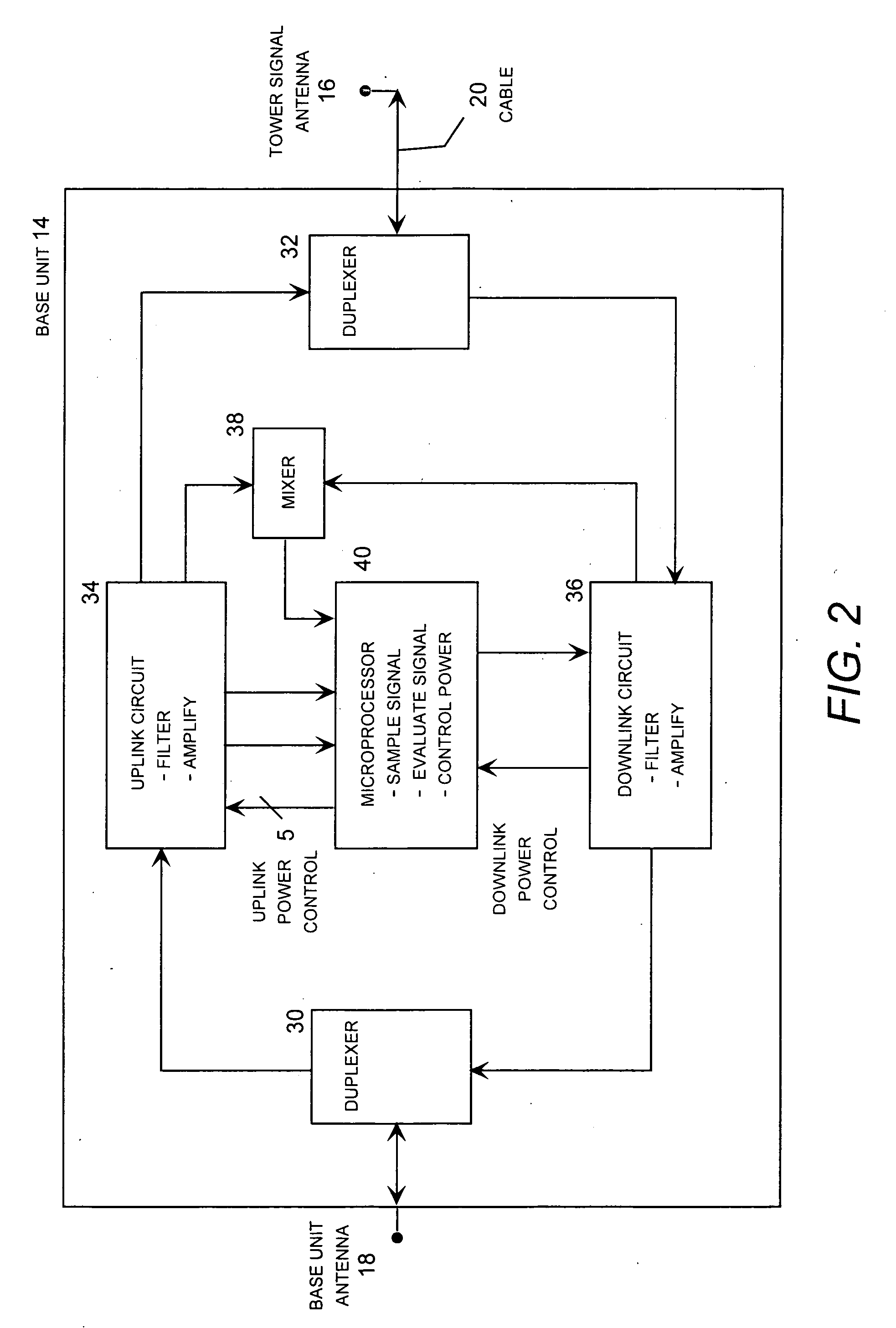

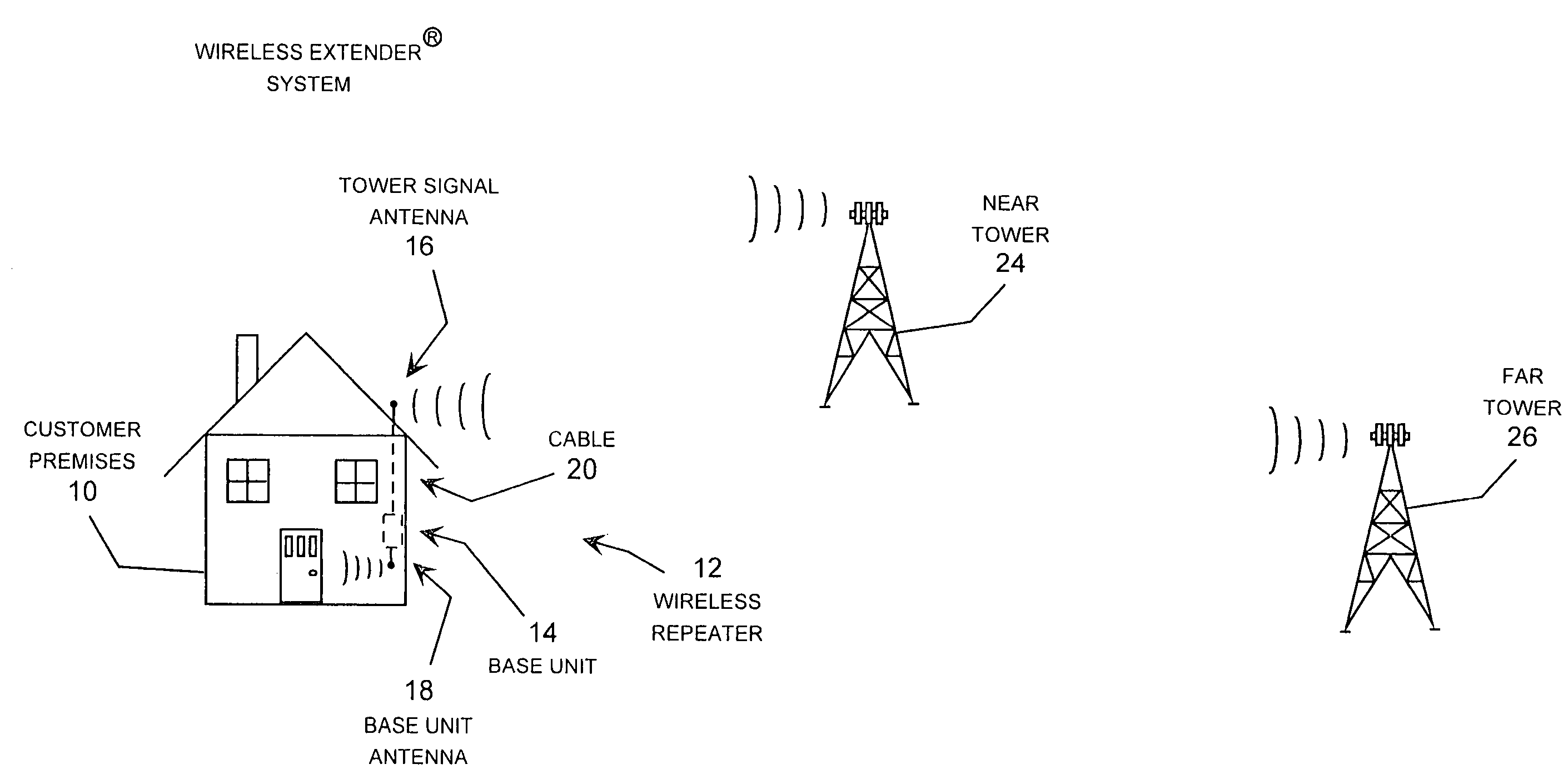

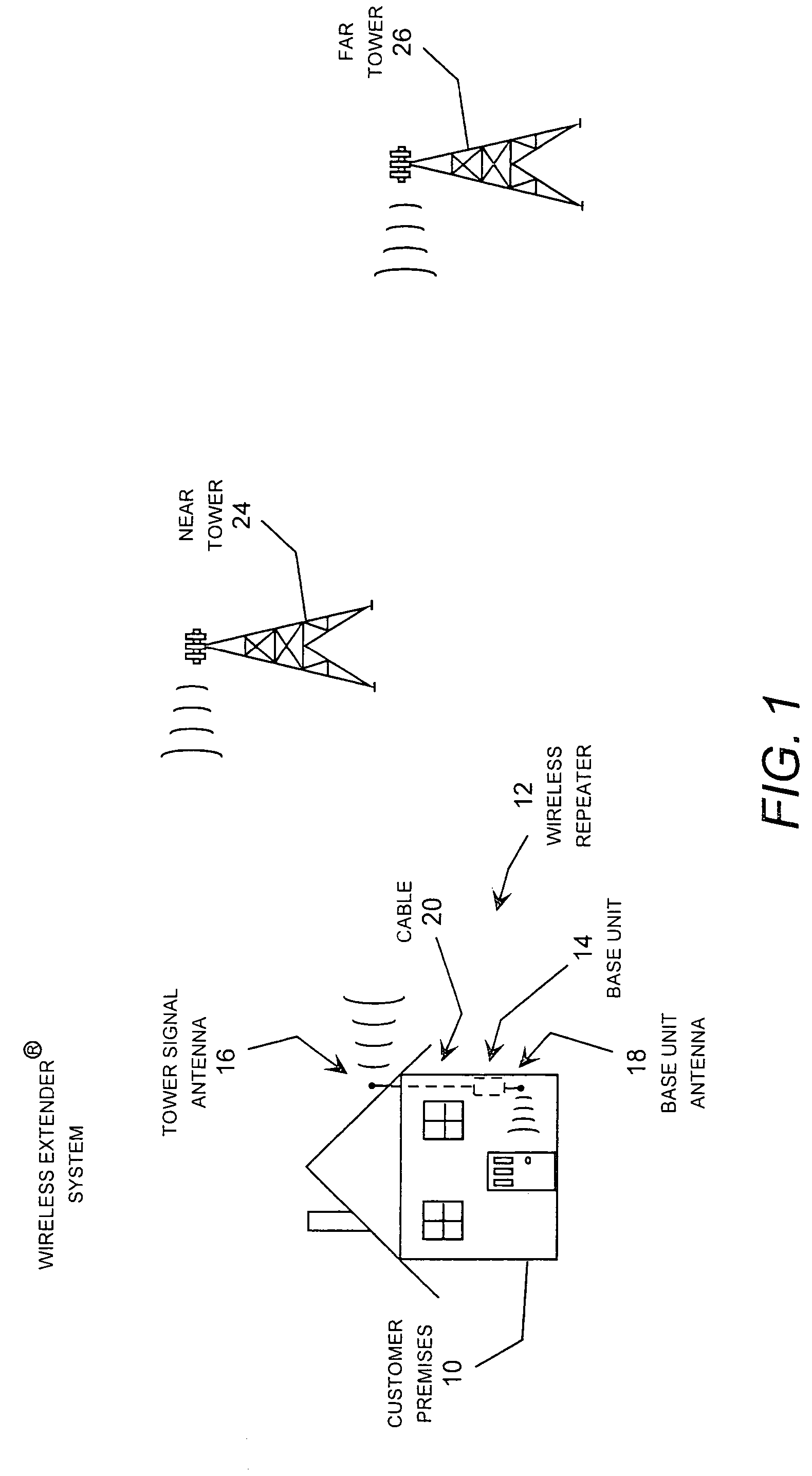

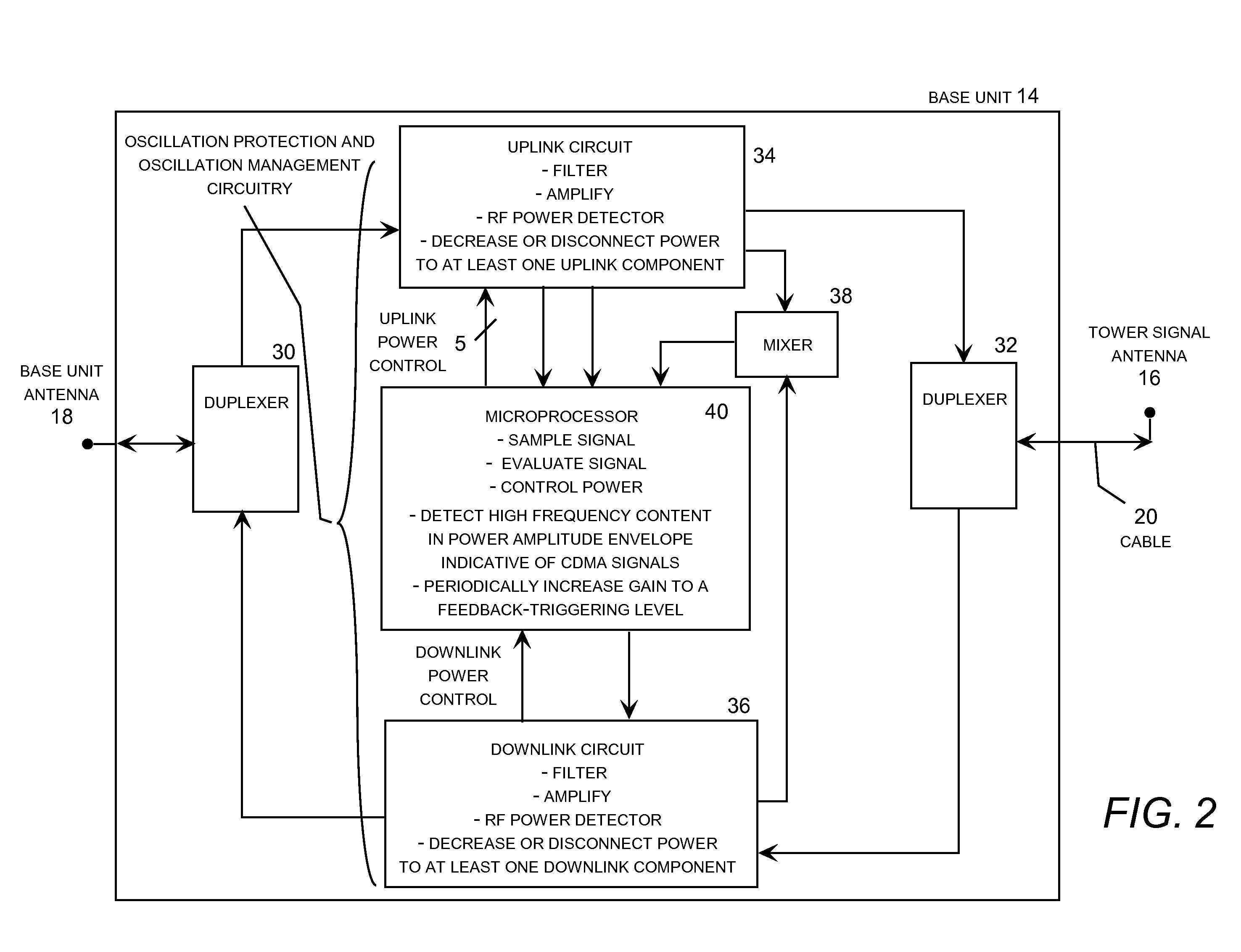

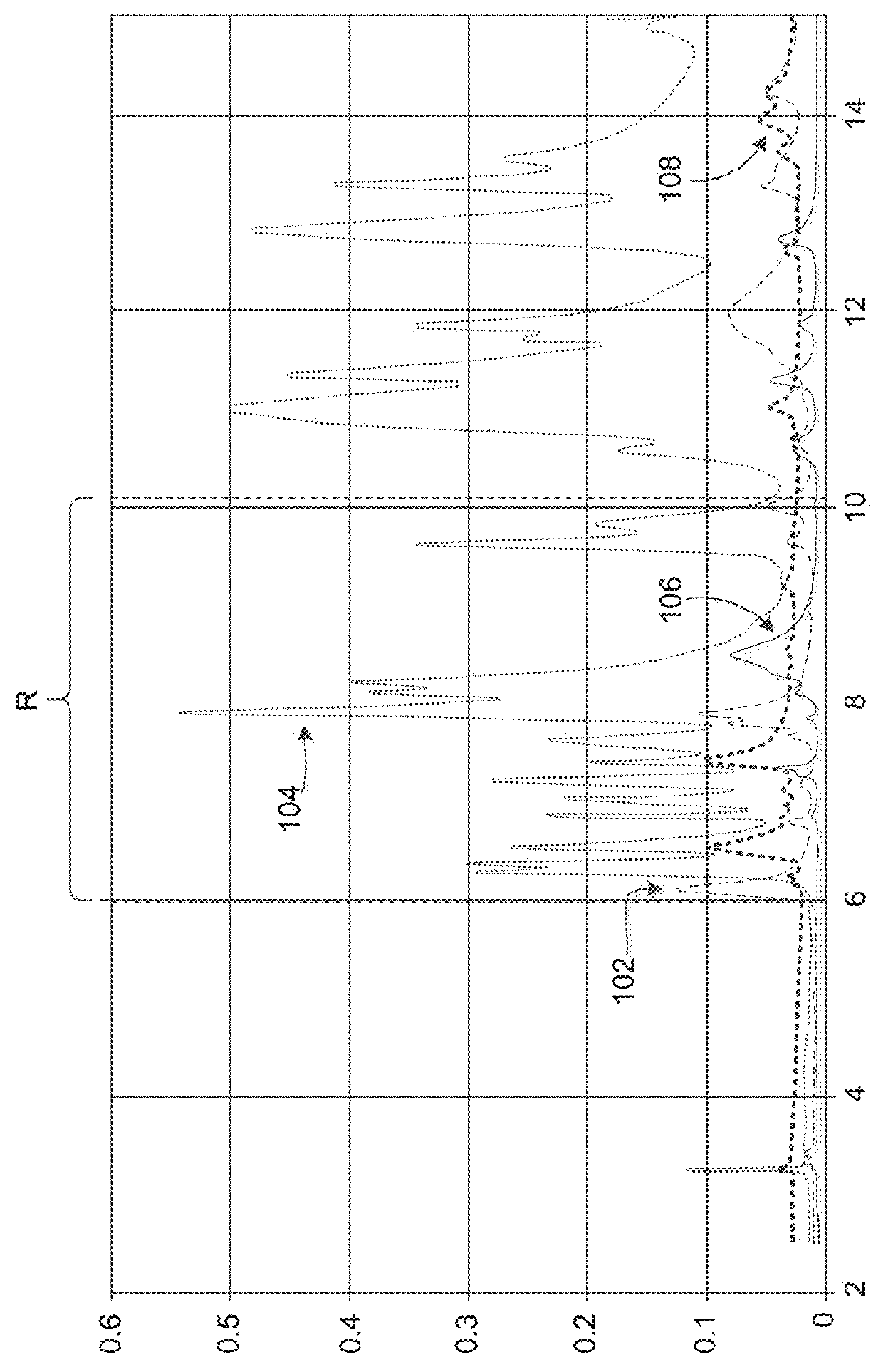

Wireless repeater implementing low-level oscillation detection and protection for a duplex communication system

ActiveUS20050272367A1Maximize coverage gainGood serviceActive radio relay systemsSubstation equipmentCommunications systemCoaxial cable

A modular wireless repeater typically deployed with a roof-mounted tower-signal antenna and a base unit with a base unit antenna located within the building, to which the tower-signal antenna and the base unit are connected by the user or a satellite TV installer using a 75 Ω coaxial cable. The system allows a customer to purchase a unit for all wireless service providers in a given frequency band, such as Cellular, PCS, GSM900, or DCS, etc., and then add on modules for additional types of service that the customer may desire in the future. The system also detects and prevents low-level oscillations. The wireless repeater also performs intelligent power control allowing it to function properly with near and far base unit antennas as well as near and far mobile stations.

Owner:WILSON ELECTRONICS

Wireless repeater implementing low-level oscillation detection and protection for a duplex communication system

ActiveUS7706744B2Good serviceReducing the BDA gainActive radio relay systemsSubstation equipmentCoaxial cableCommunications system

A modular wireless repeater typically deployed with a roof-mounted tower-signal antenna and a base unit with a base unit antenna located within the building, to which the tower-signal antenna and the base unit are connected by the user or a satellite TV installer using a 75Ω coaxial cable. The system allows a customer to purchase a unit for all wireless service providers in a given frequency band, such as Cellular, PCS, GSM900, or DCS, etc., and then add on modules for additional types of service that the customer may desire in the future. The system also detects and prevents low-level oscillations. The wireless repeater also performs intelligent power control allowing it to function properly with near and far base unit antennas as well as near and far mobile stations.

Owner:WILSON ELECTRONICS

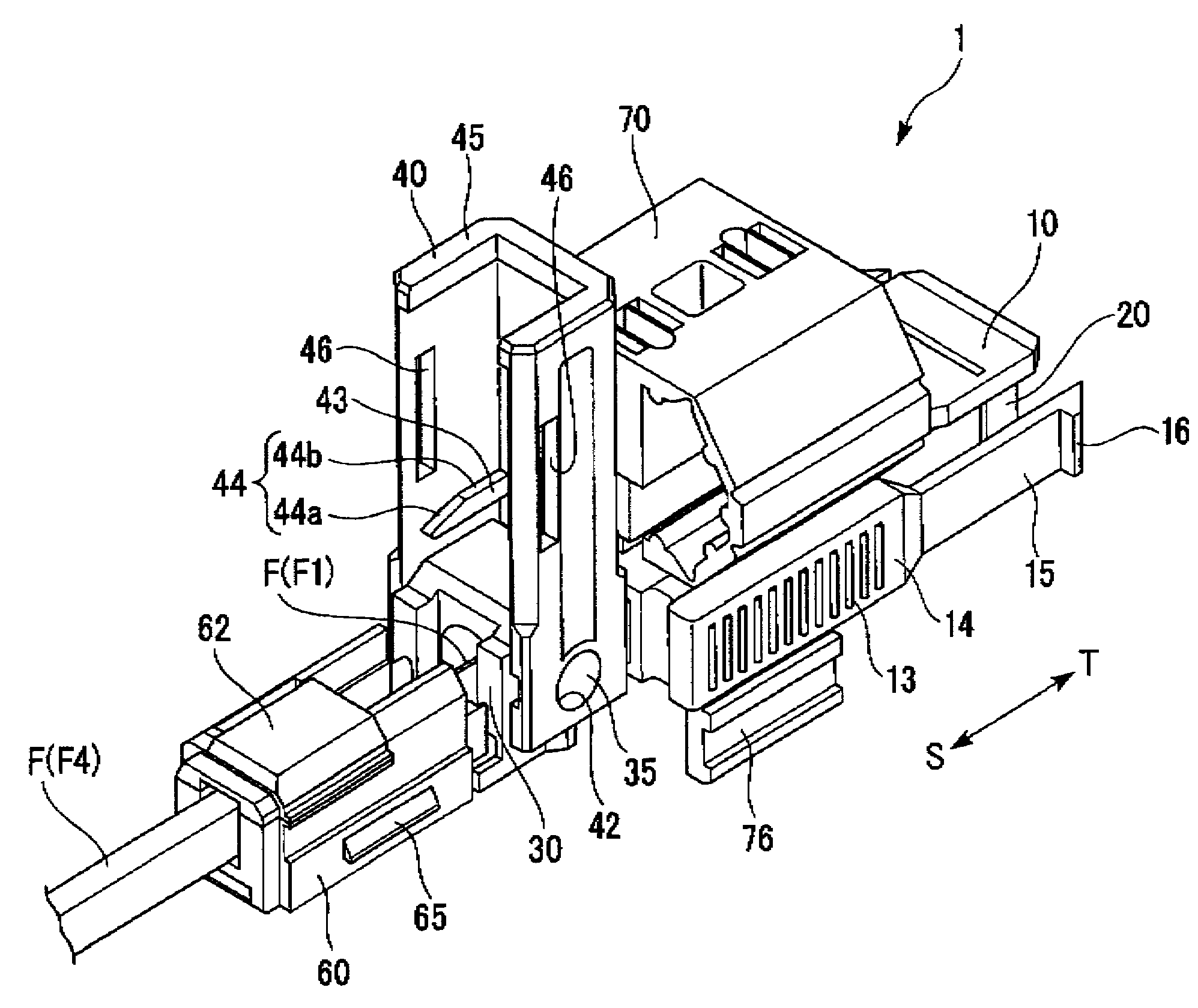

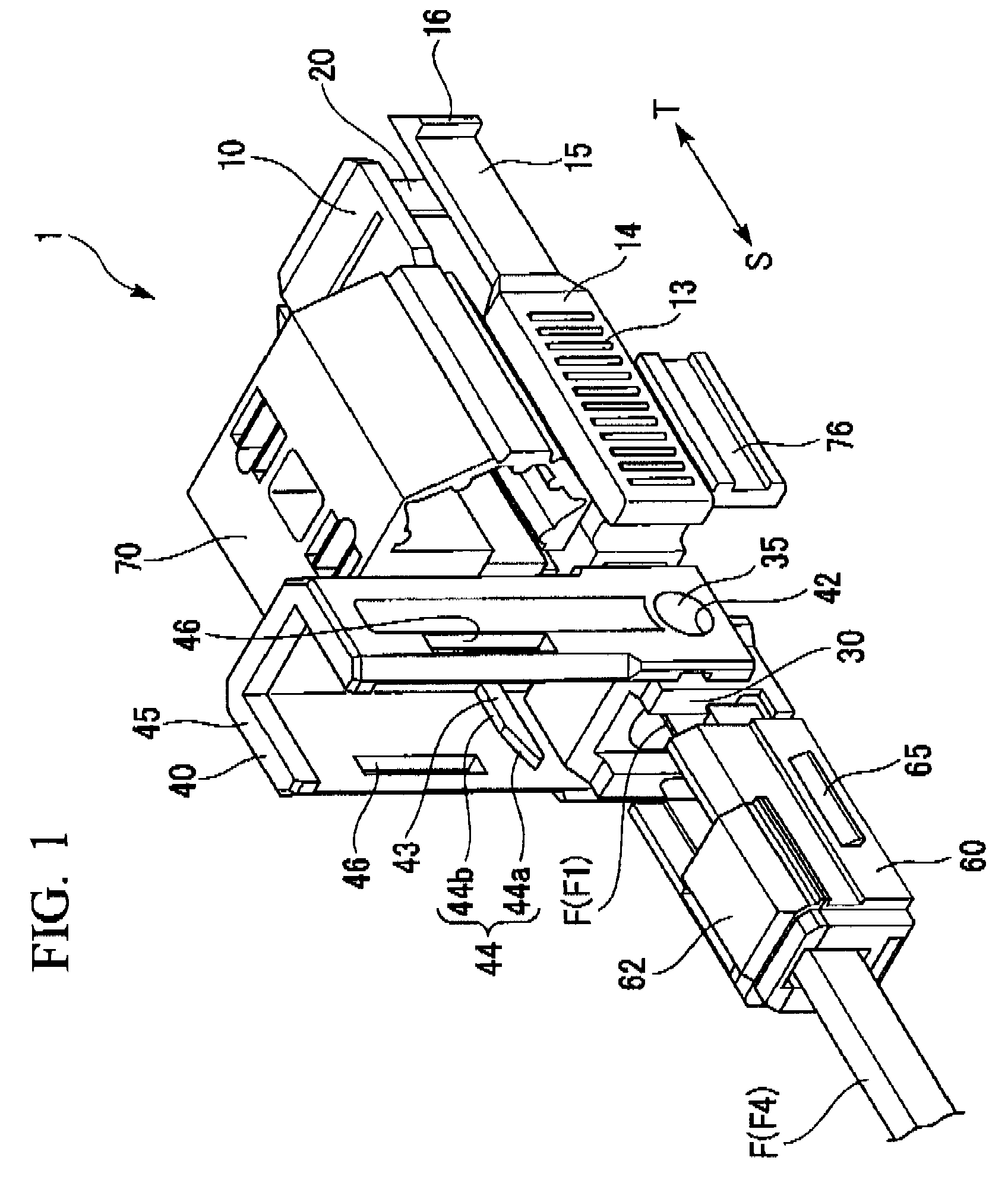

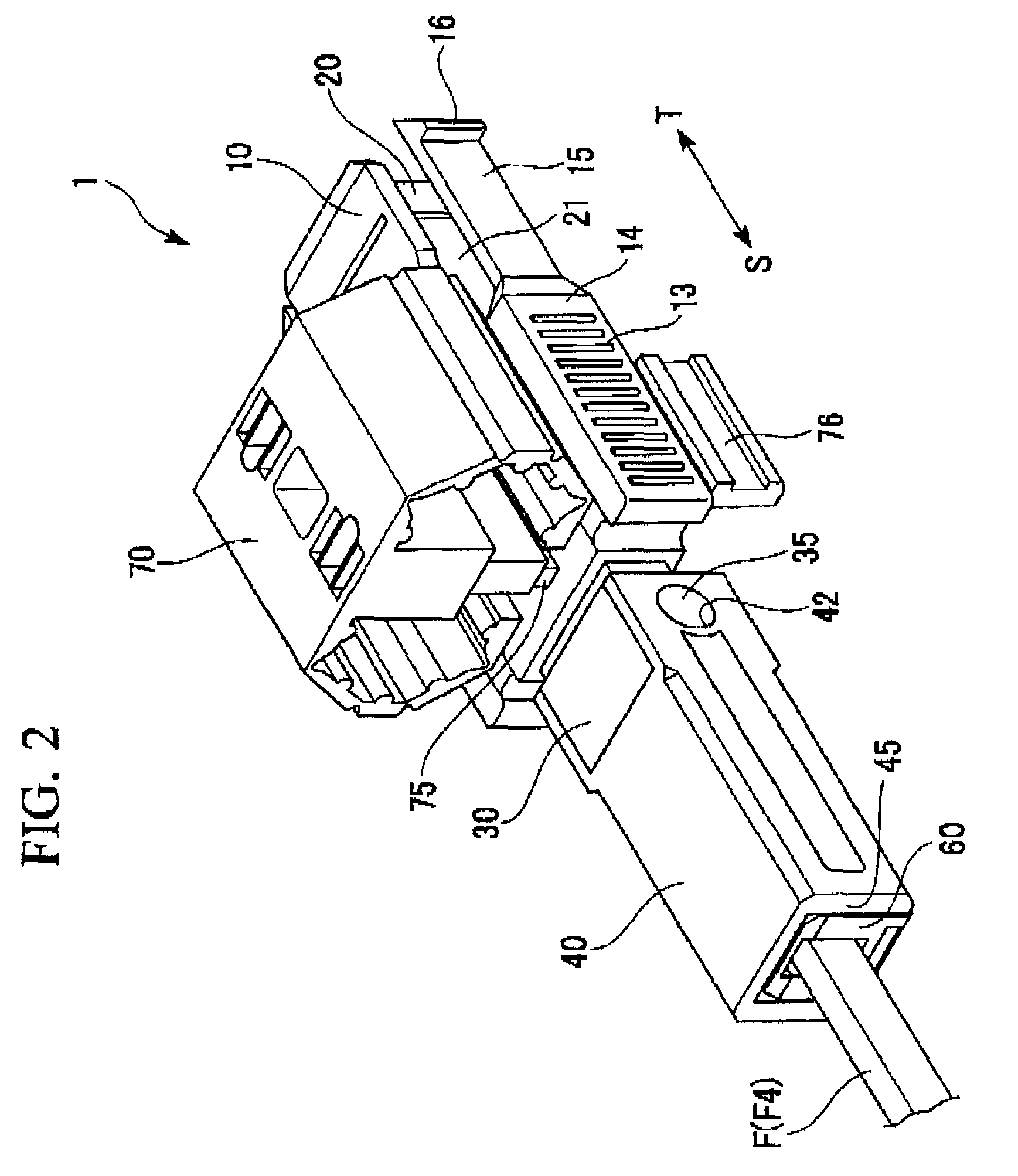

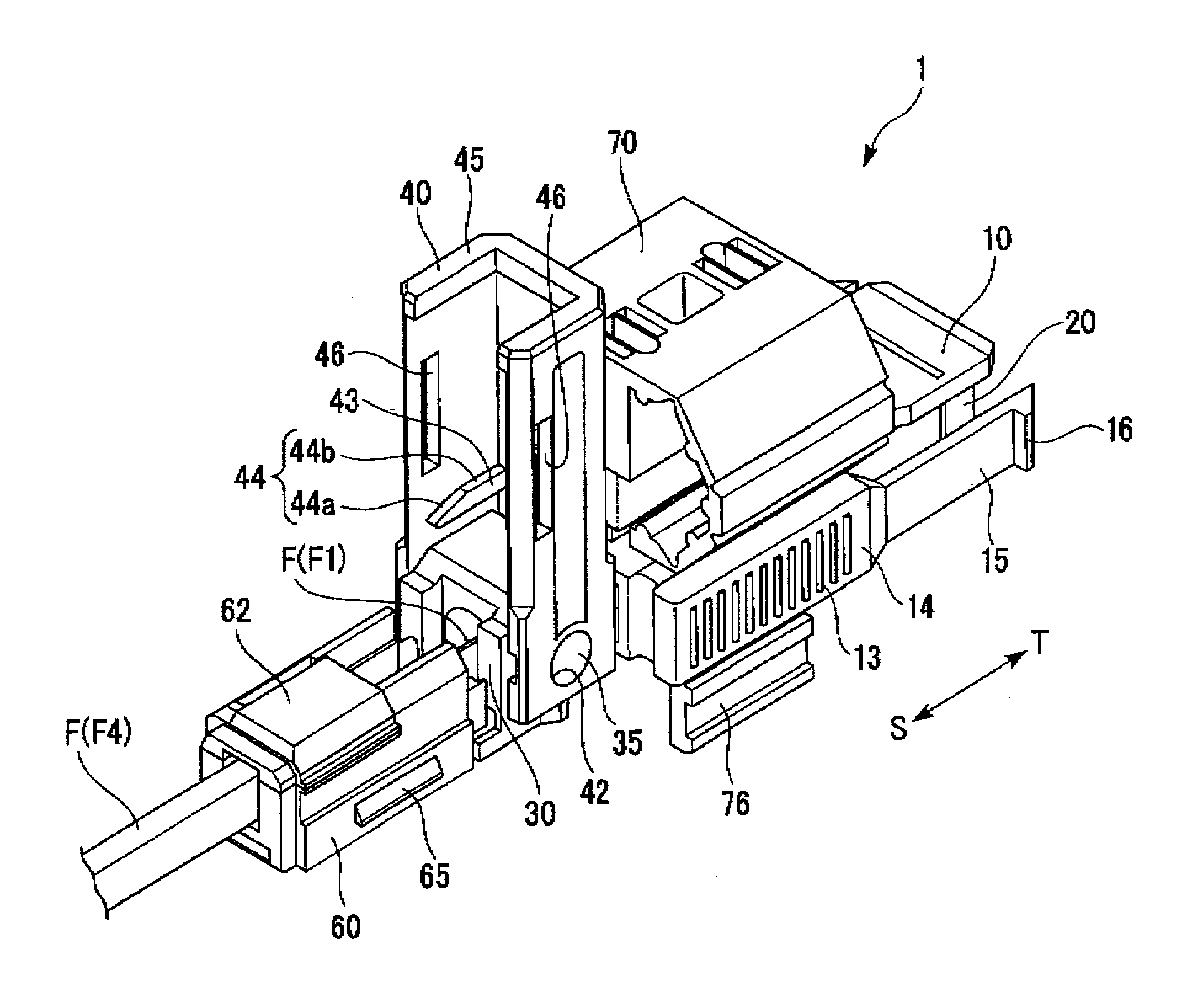

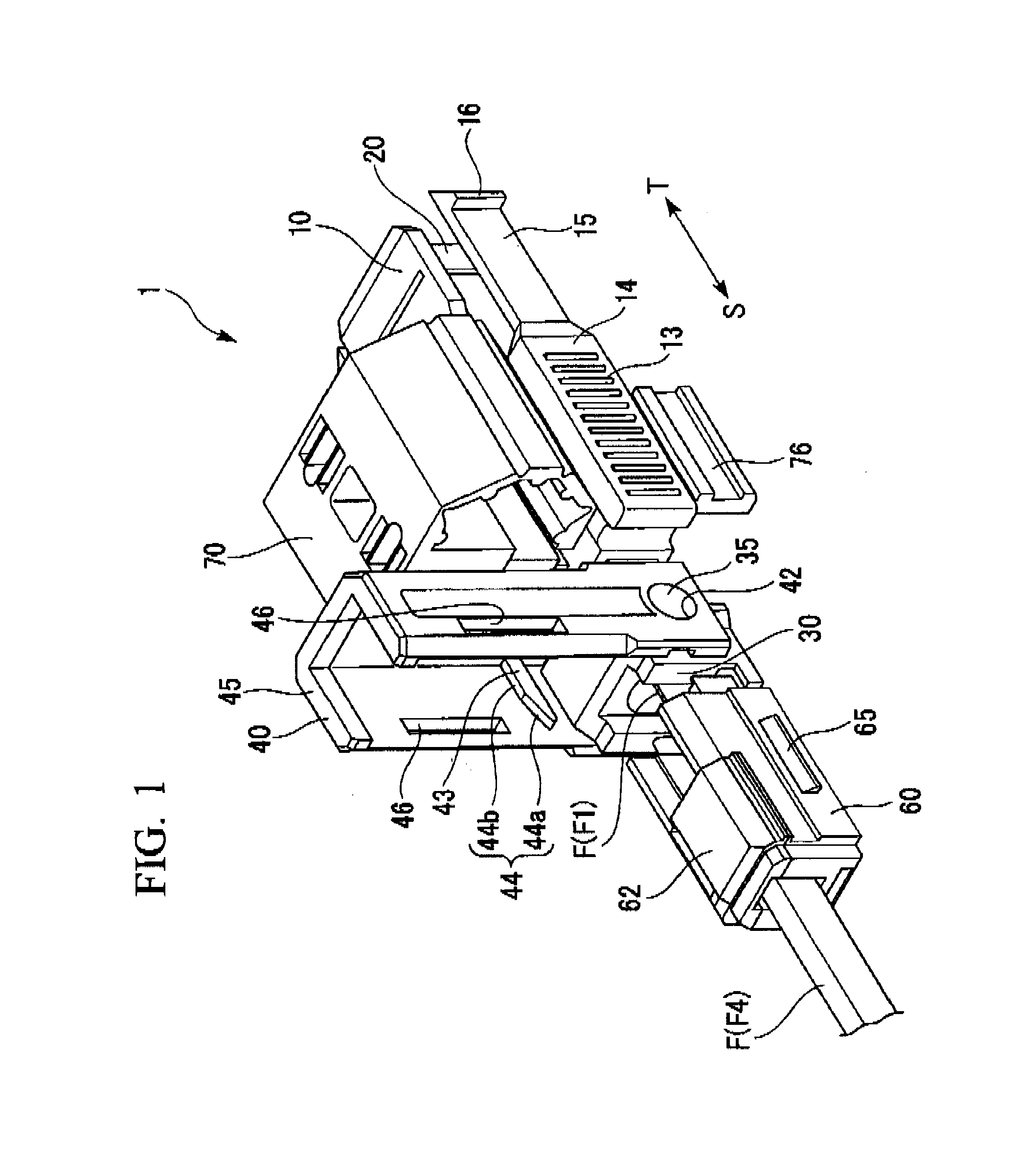

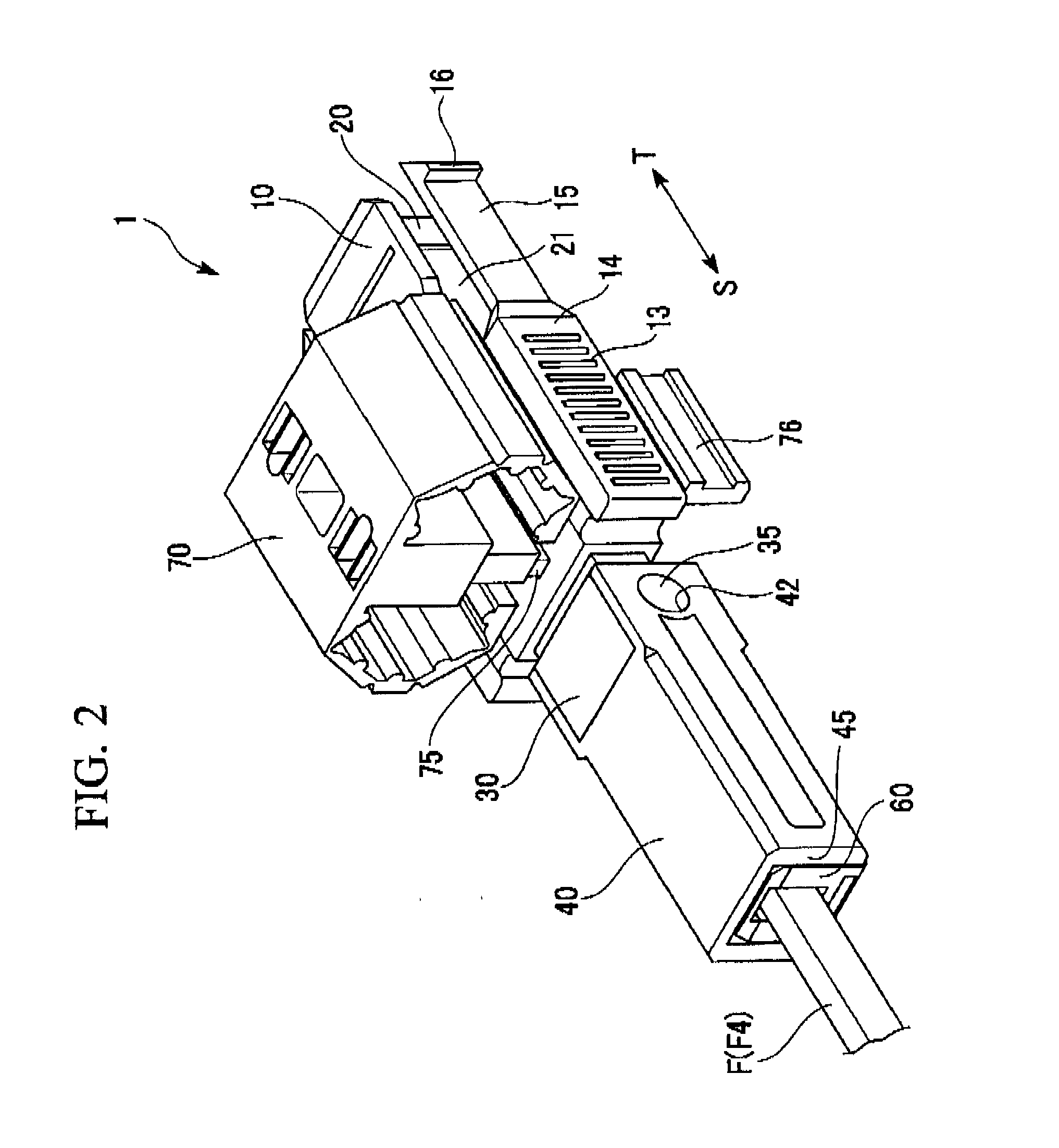

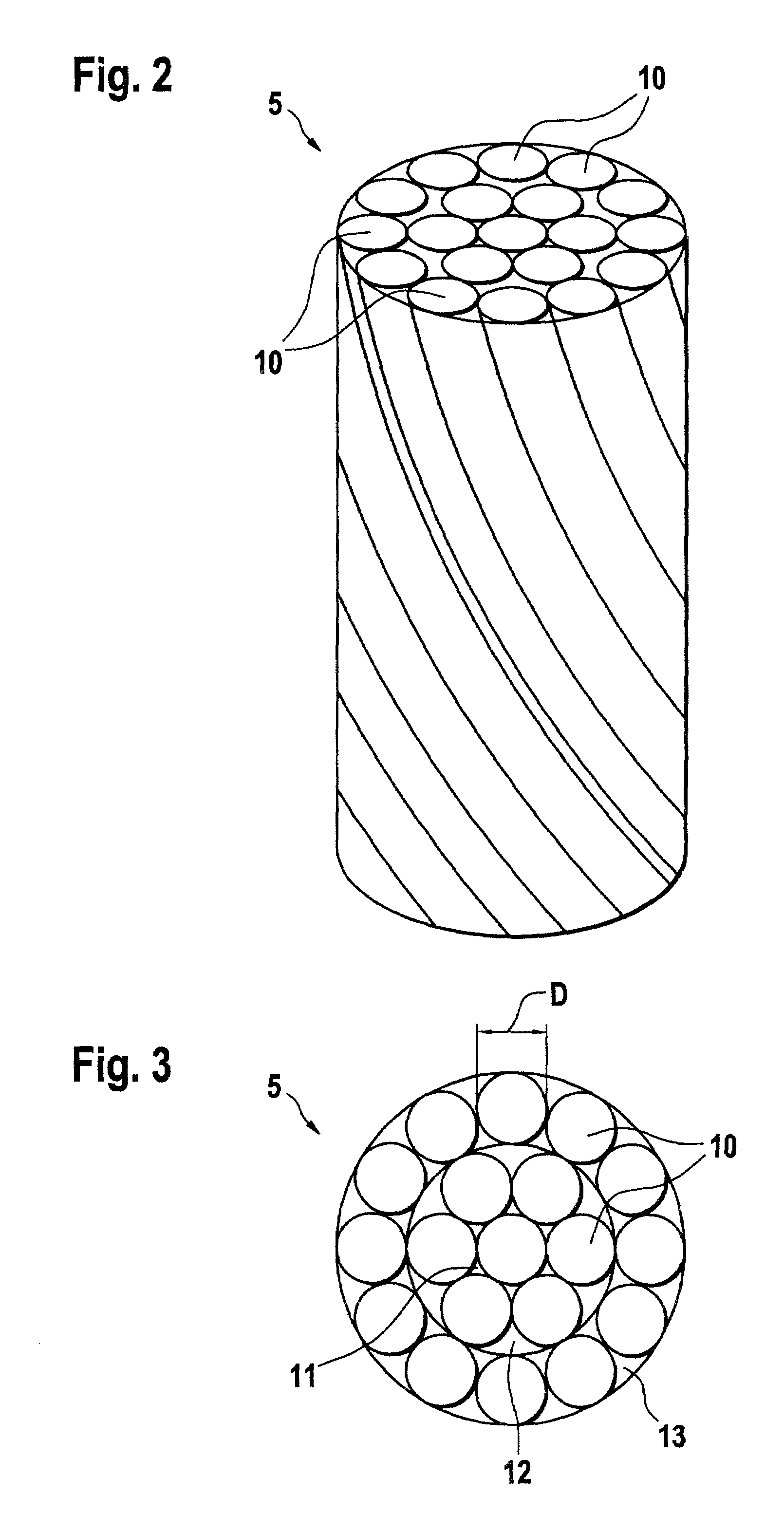

Optical connector

ActiveUS7347627B2Reduce insertionLess bendingCoupling light guidesEngineeringOptical fiber connector

An optical connector includes a connector body that has a first optical fiber housed in advance in a ferrule so as to project from a back end of the ferrule opposite to the connecting end surface and an anchoring fixture that anchors a second optical fiber that is to be optically connected to the first optical fiber, and by pressing the anchoring fixture into the connector body while the second optical fiber is anchored in this anchoring fixture, the anchoring fixture and the connector body are connected to optically connect the first optical fiber and the second optical fiber, and the connecting portion that connects the anchoring fixture and the connector body form a movable connecting portion that is adapted to vary the direction of the anchoring fixture with respect to the connector body.

Owner:FUJIKURA LTD +1

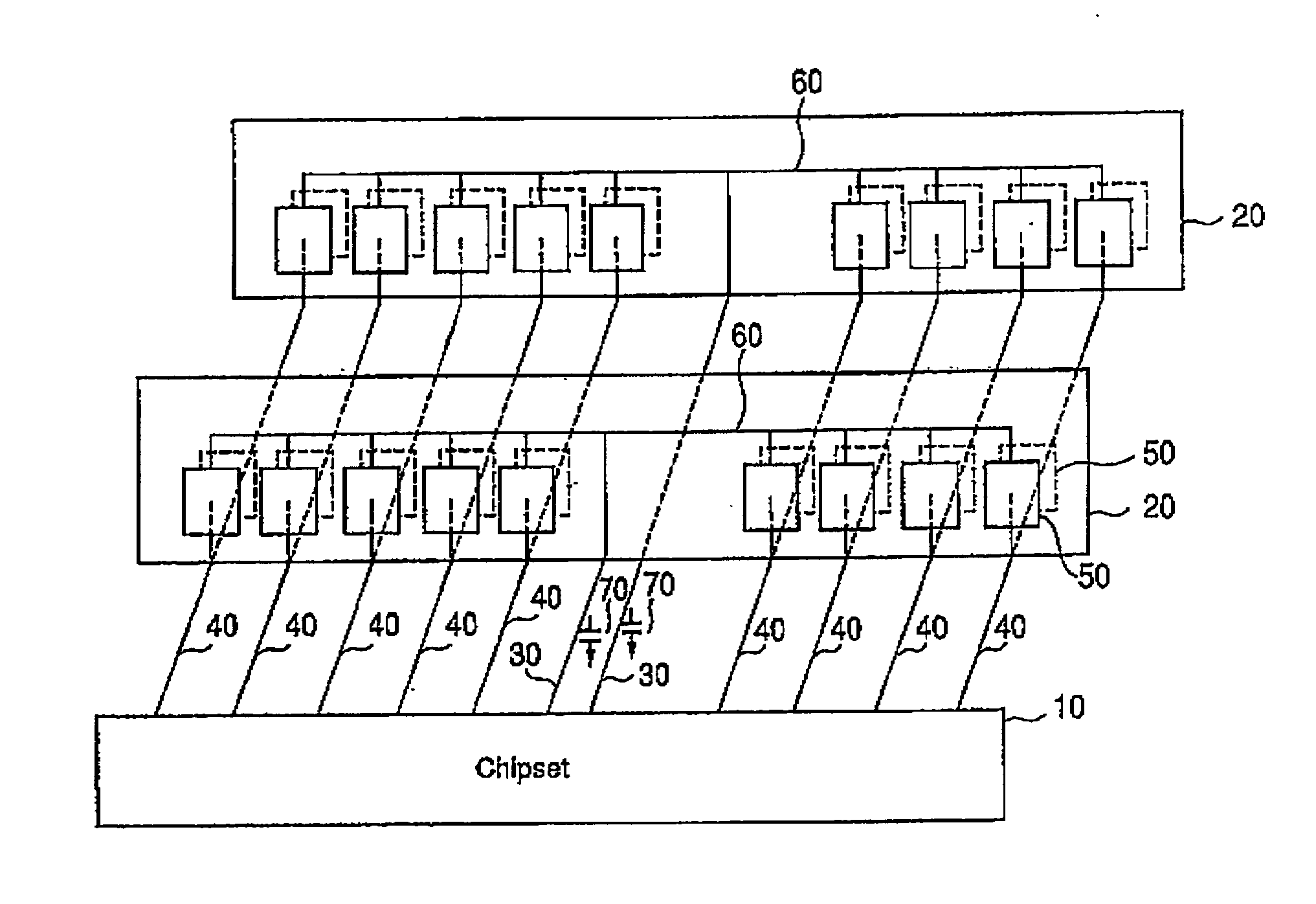

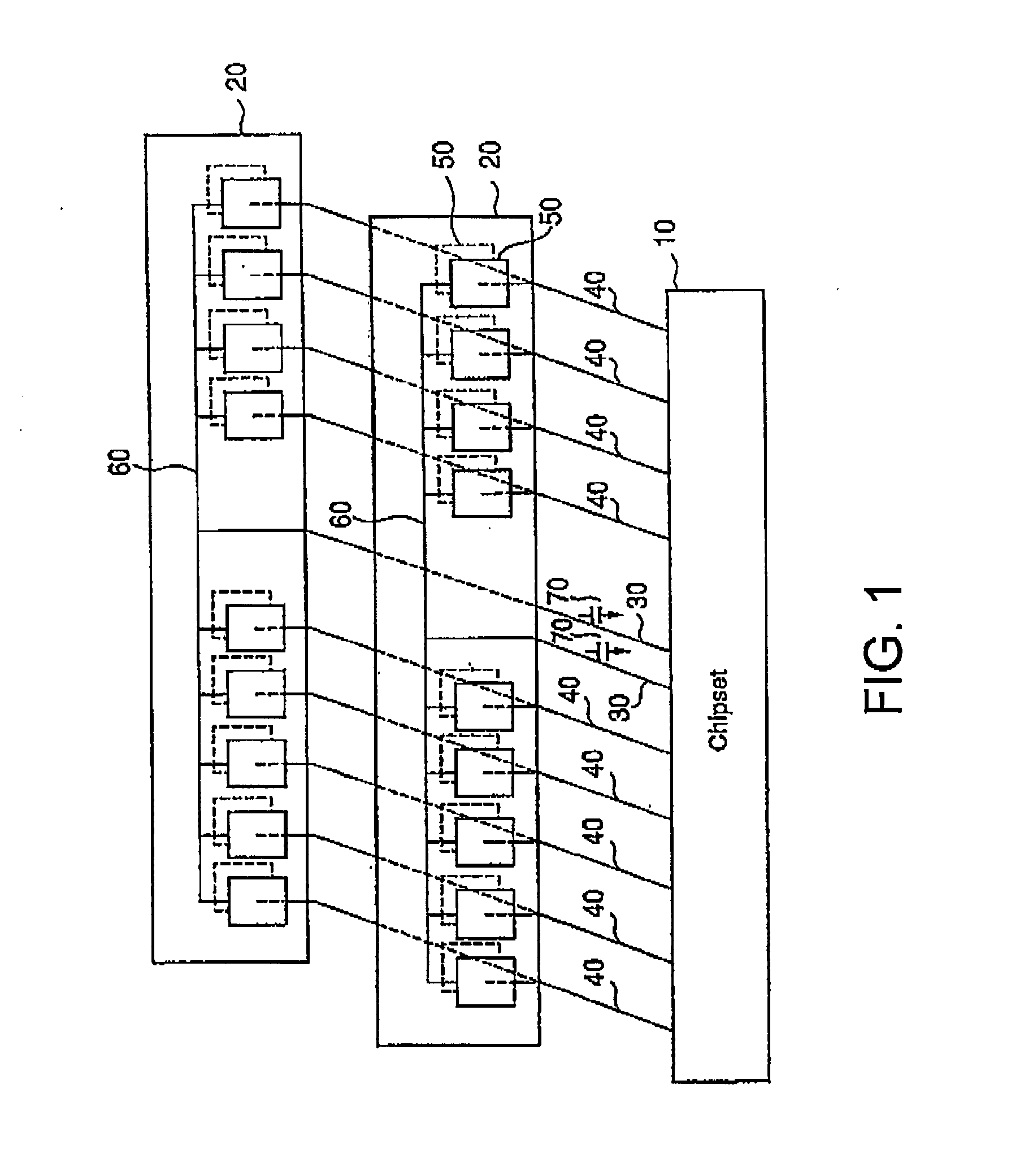

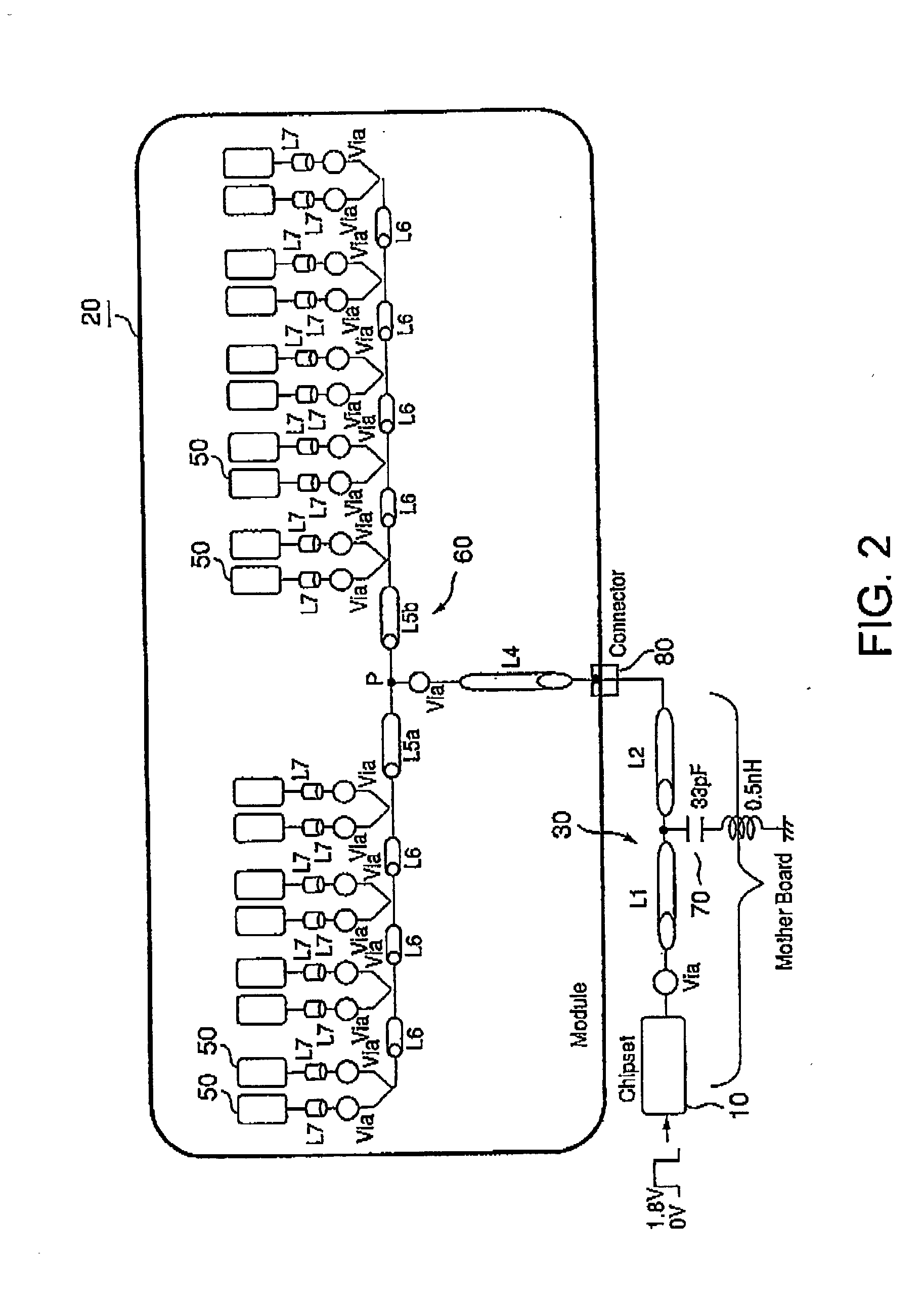

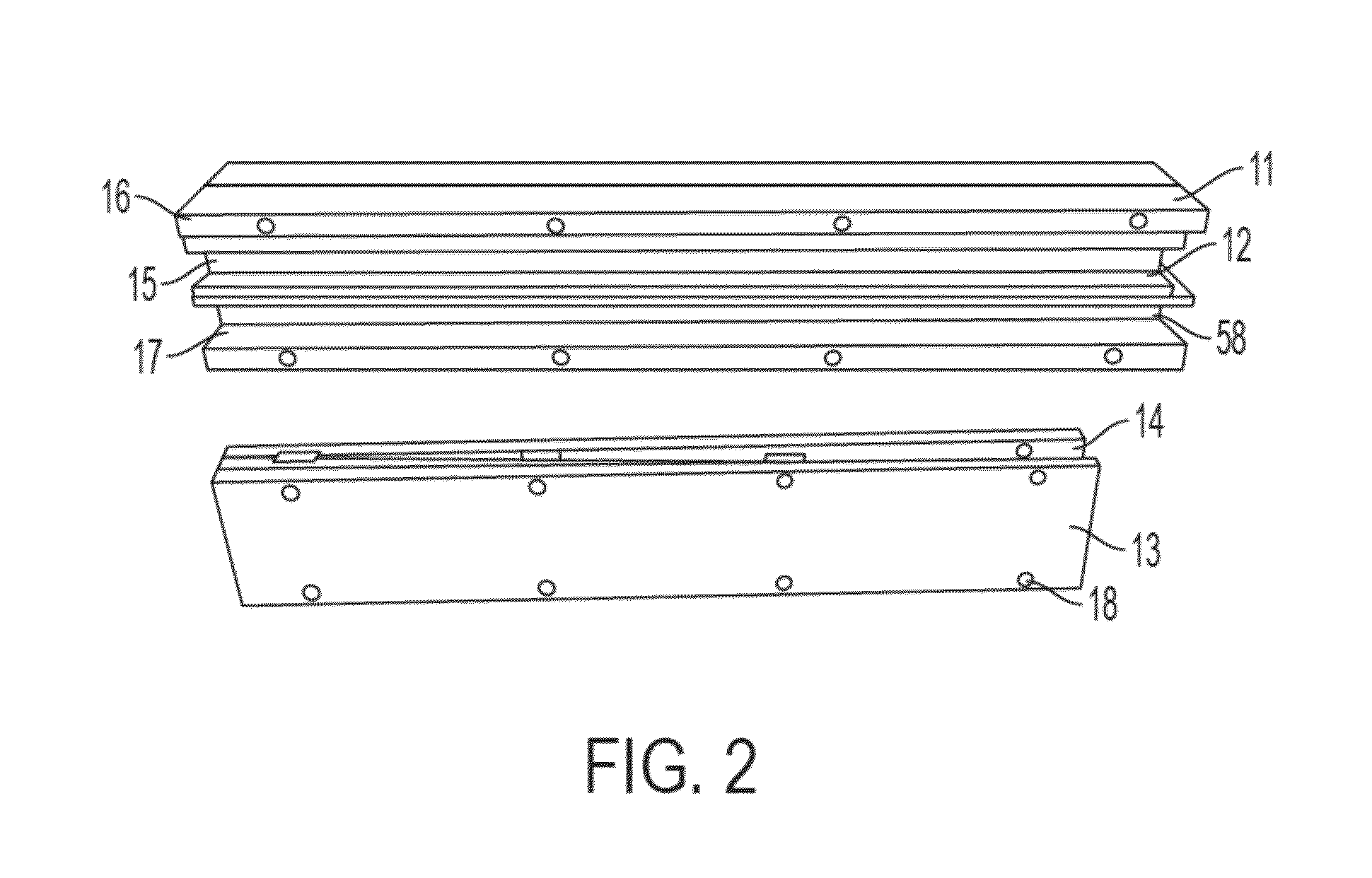

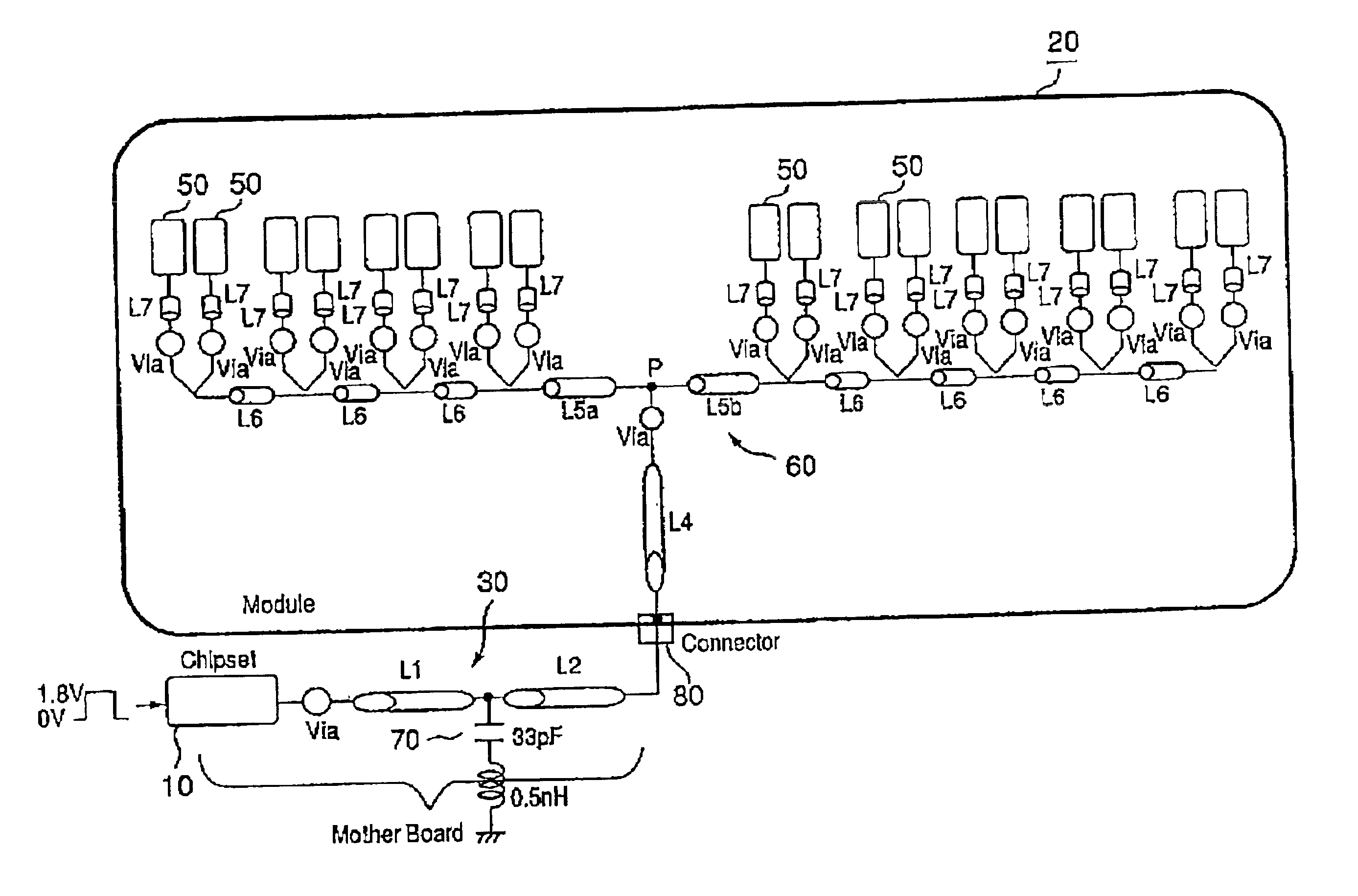

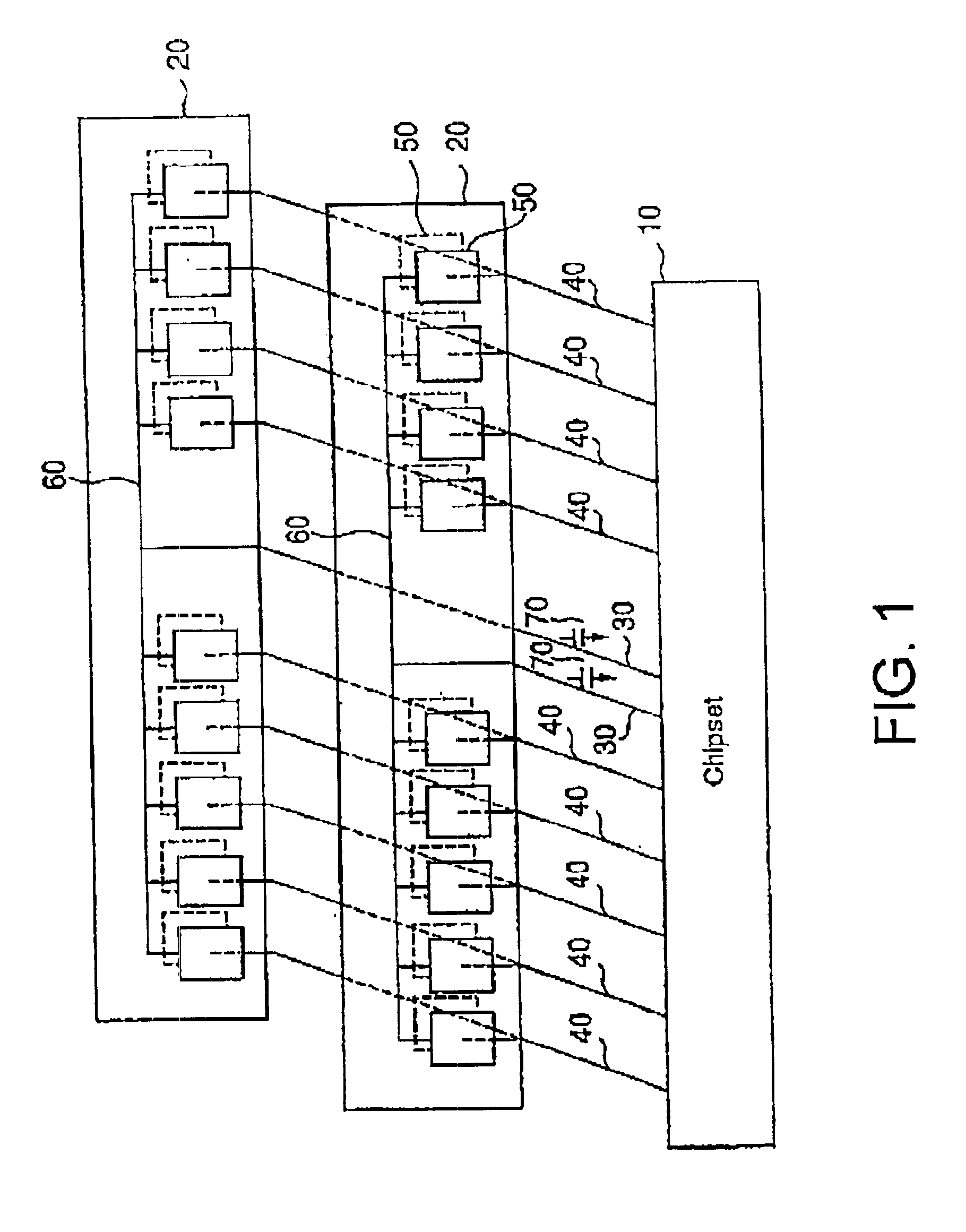

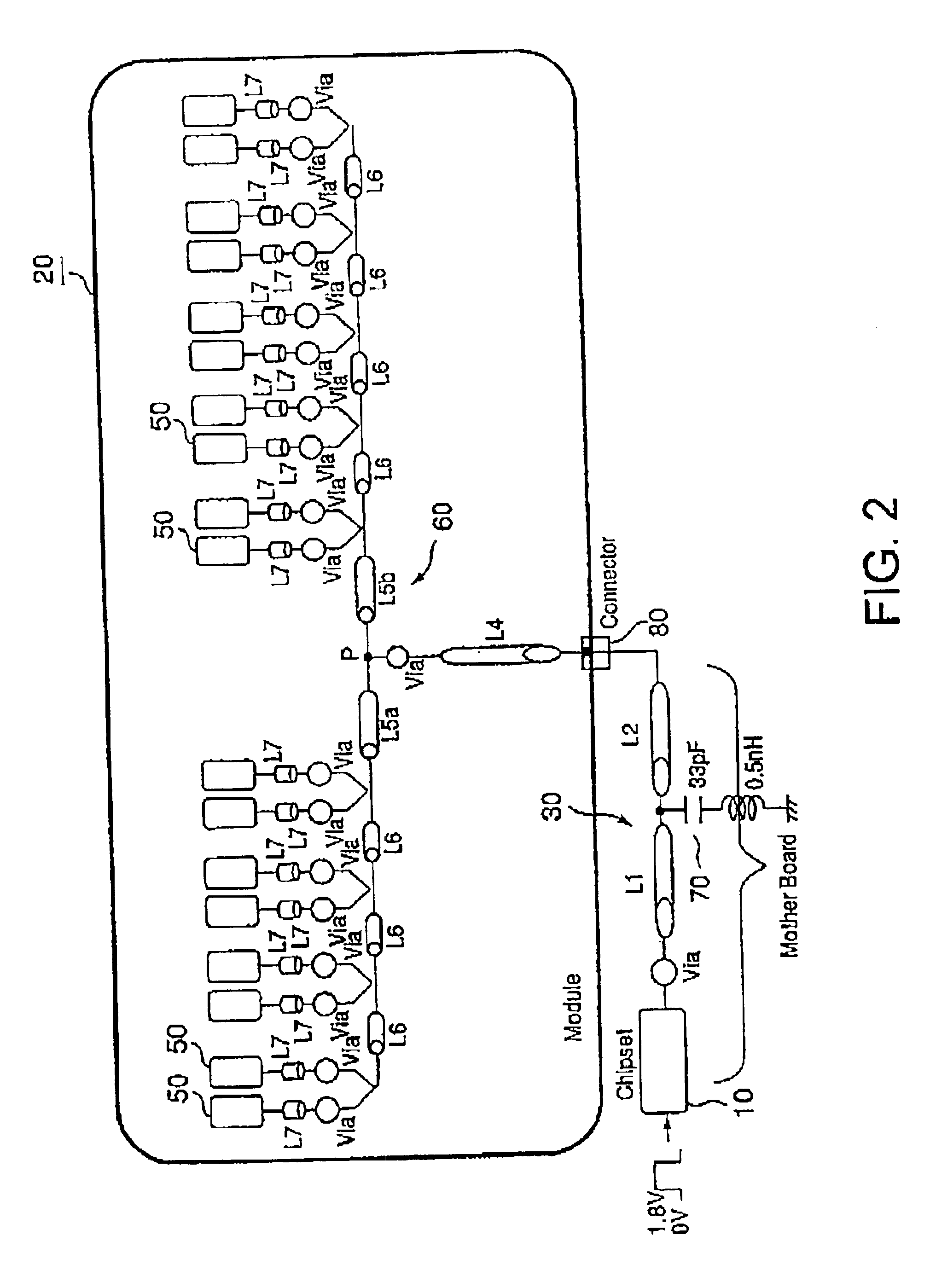

Unbuffered memory system

InactiveUS20030149855A1Good at propagatingSimplified wiring layoutMemory adressing/allocation/relocationDigital storageComputer moduleChipset

A memory module of the unbuffered type with ECC function is employed. Configuration of an internal C / A bus is set to a single T-branch topology. An output impedance of a chipset is maintained substantially constant. A capacitor for cutting high-frequency components of a C / A signal is added on a C / A bus.

Owner:LONGITUDE LICENSING LTD

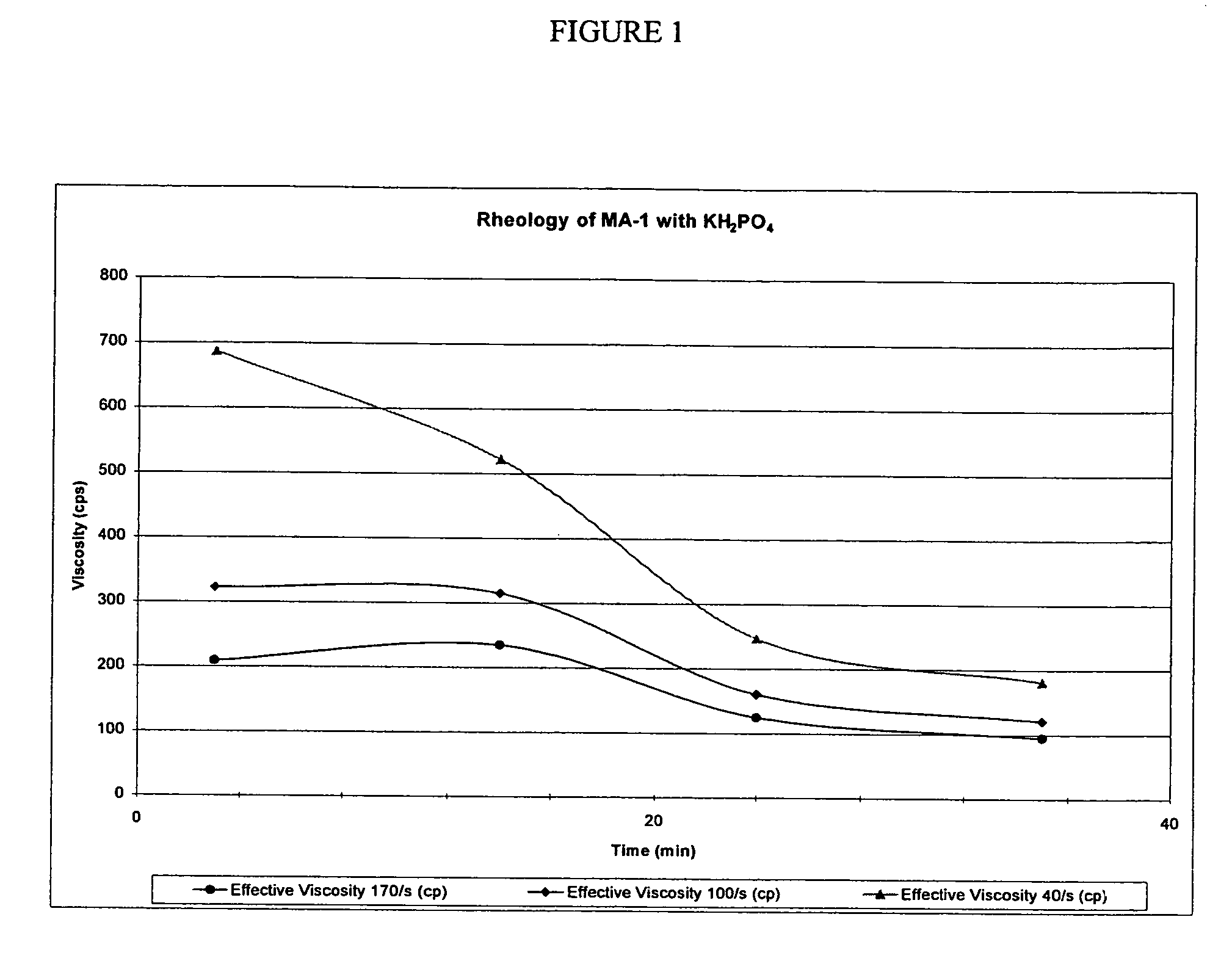

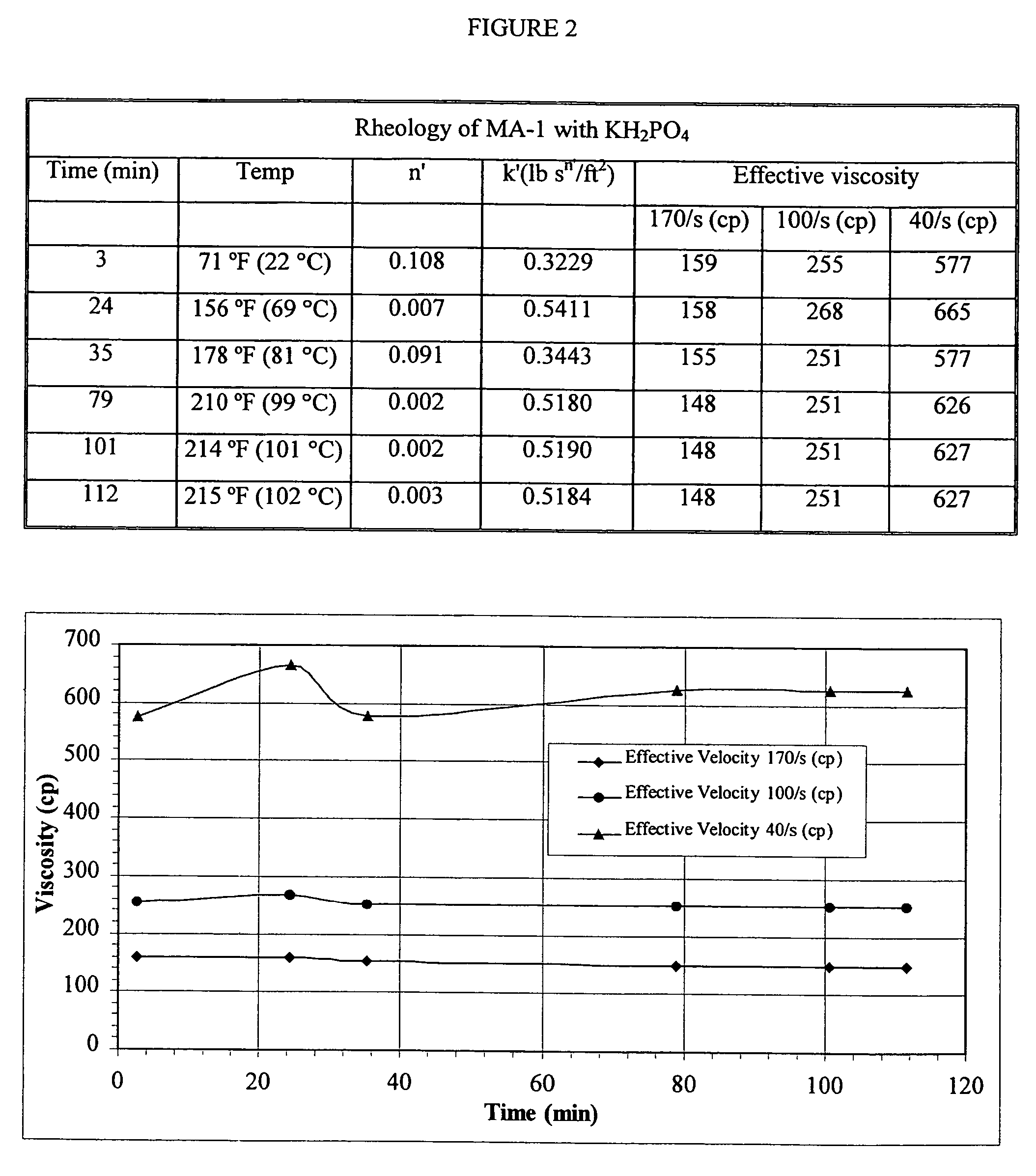

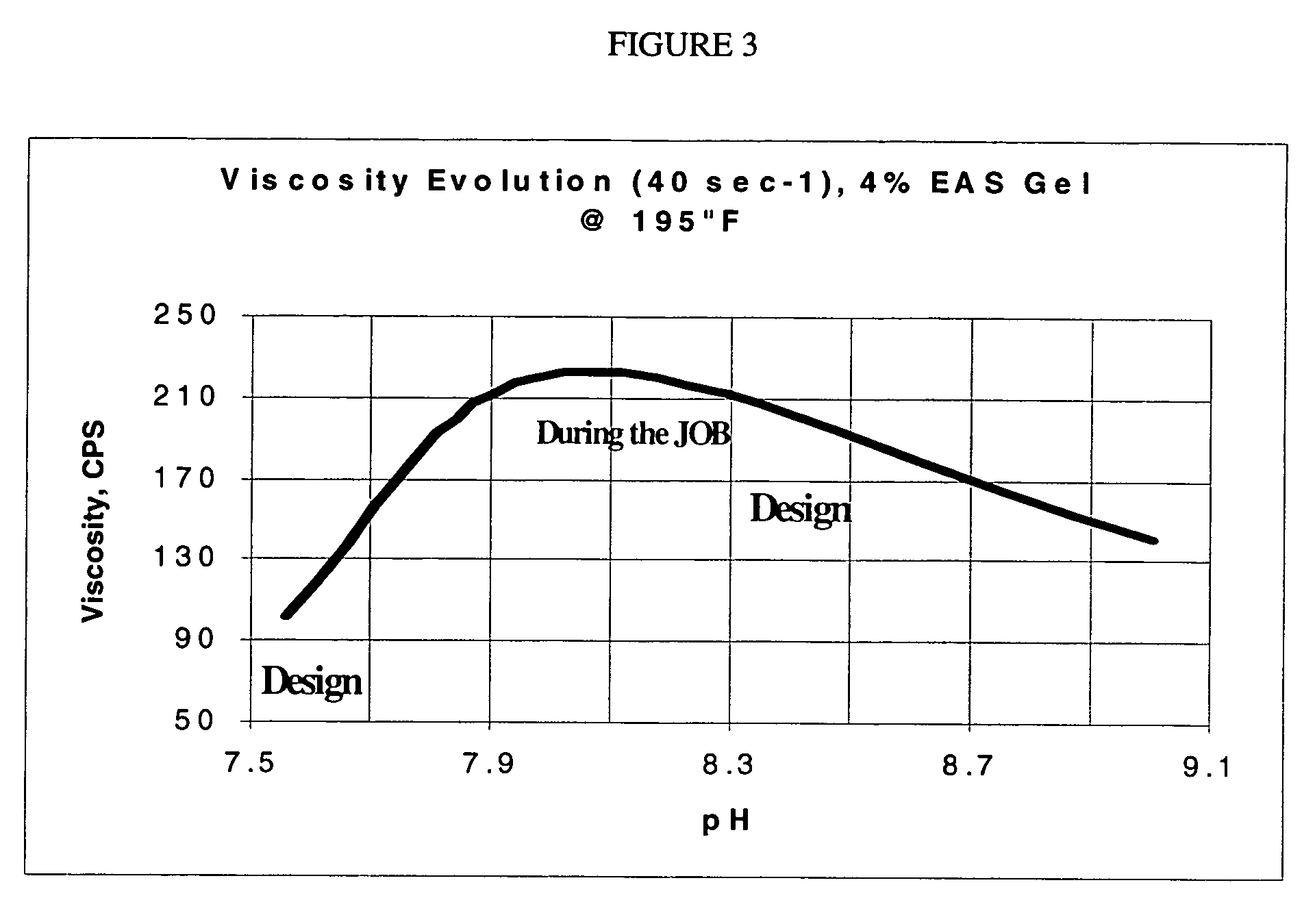

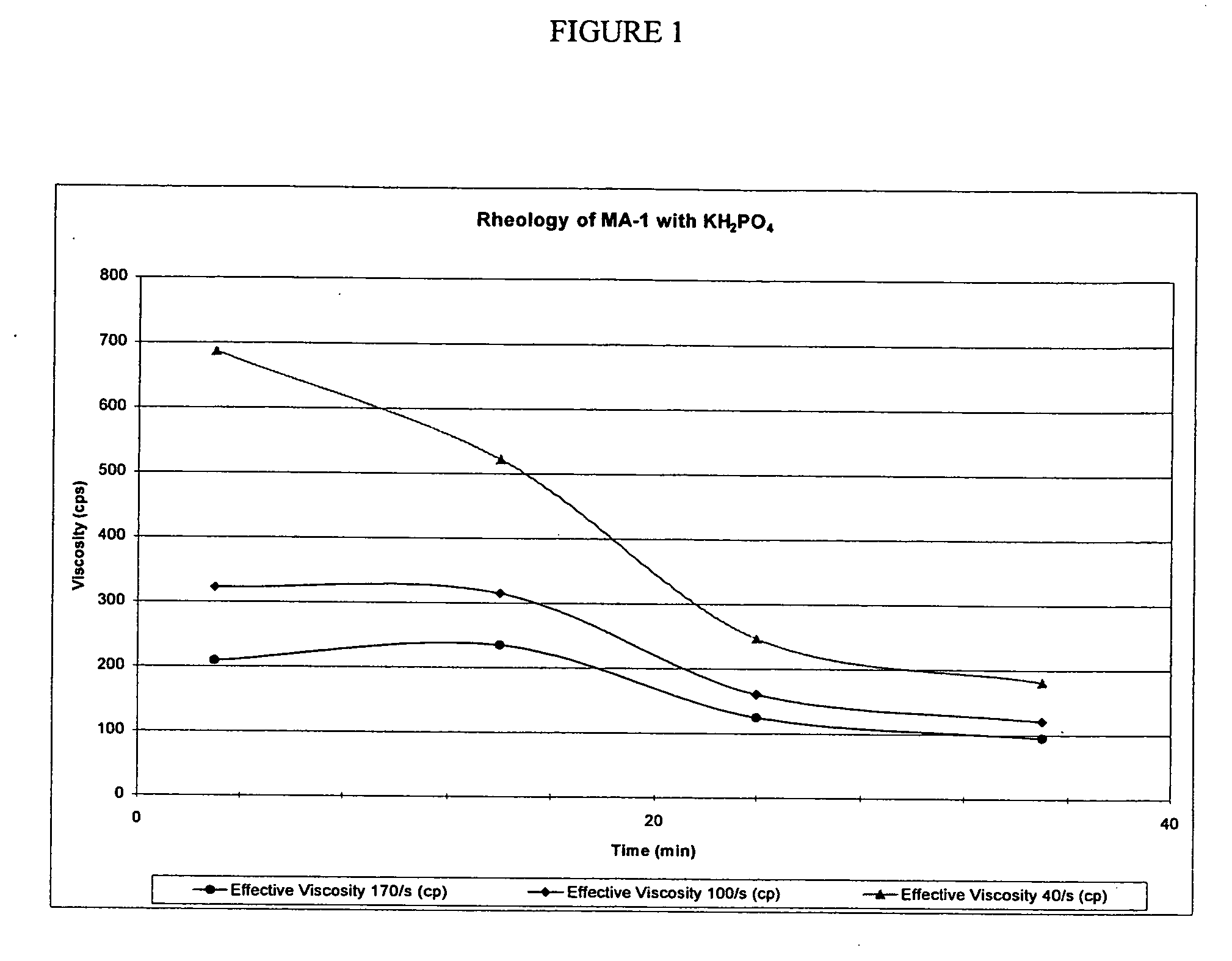

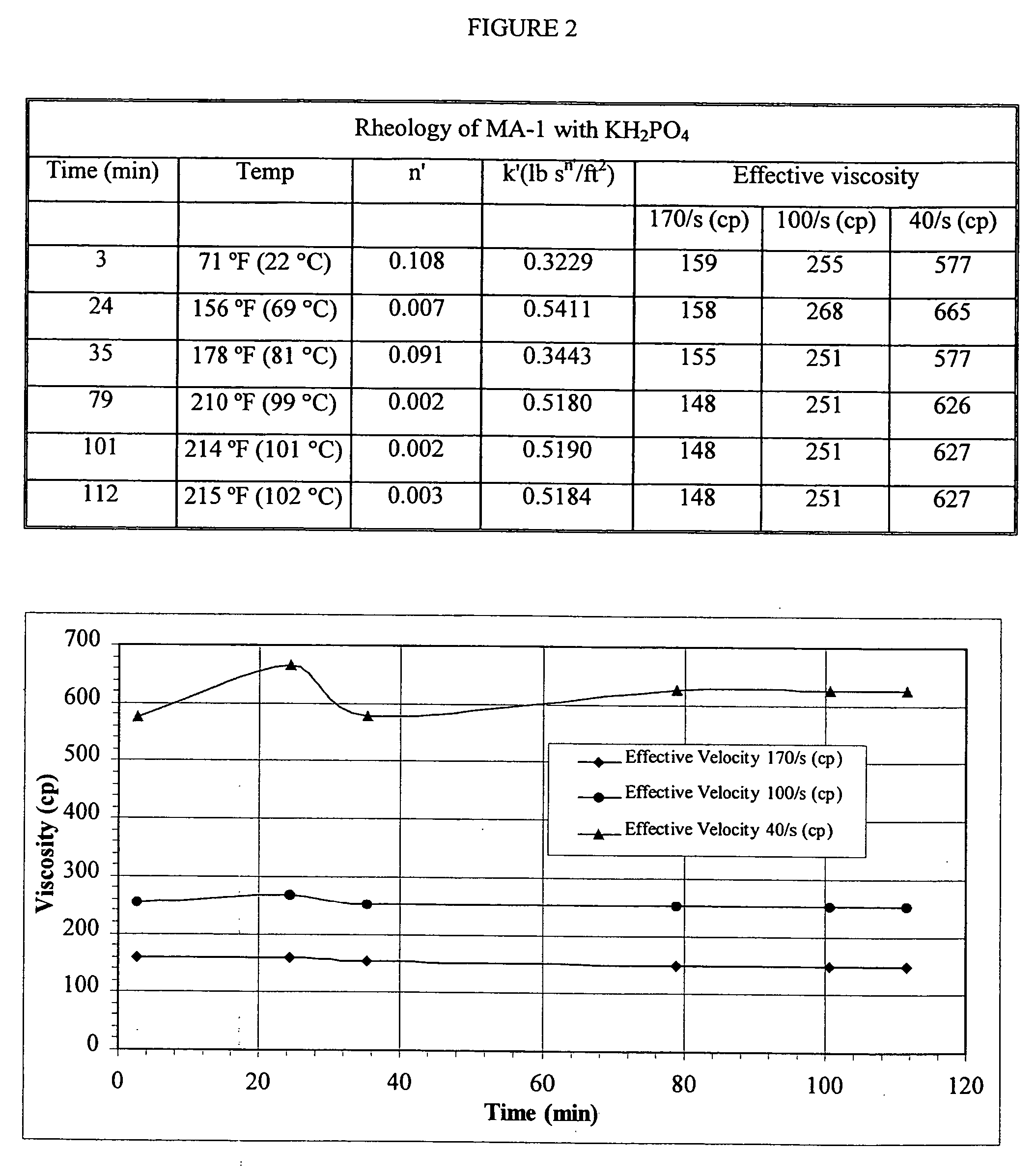

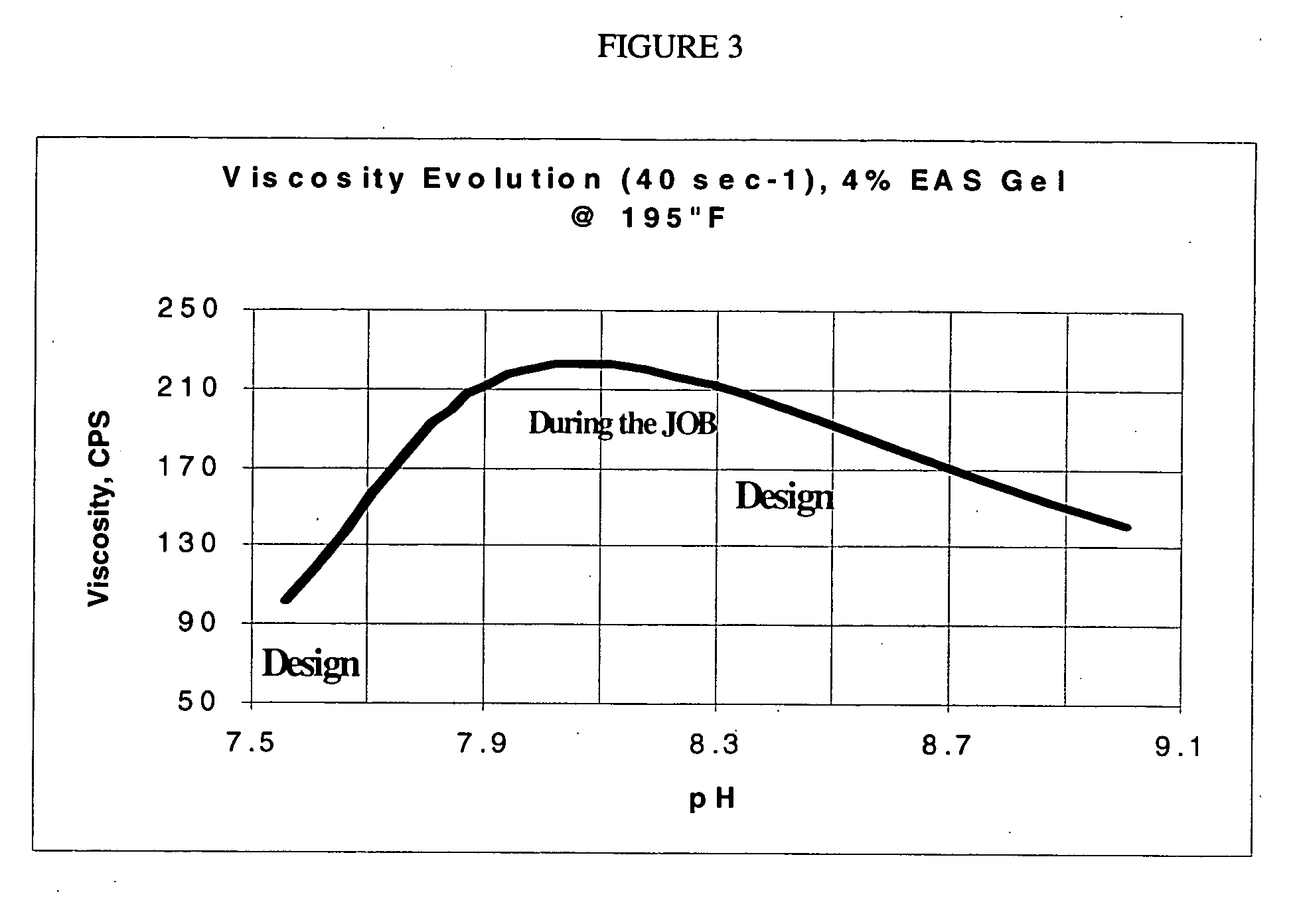

Well service fluid and method of making and using the same

InactiveUS7326670B2Improving leak-off propertyEasy to anchorFlushingDrilling compositionWater productionFracturing fluid

A well service fluid comprising one or more anionic viscoelastic surfactants and one or more polymers is described. The fluids can contain an aqueous or non-aqueous fluid and / or a buffer for adjusting the pH of the fracturing fluid. The well service fluid can be used as a fracturing fluid in order to control water production from a well, while simultaneously increasing the oil production from the well.

Owner:BJ SERVICES CO

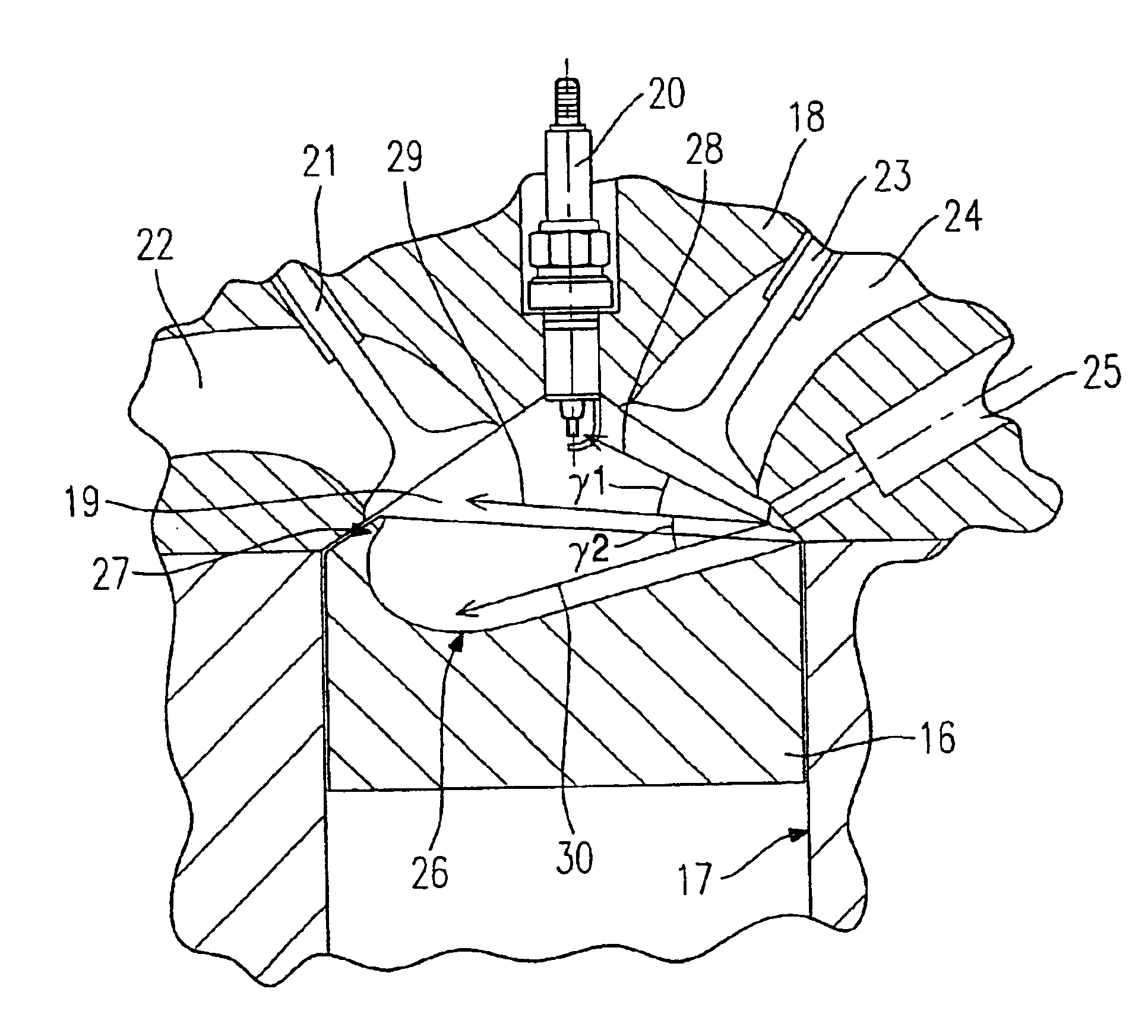

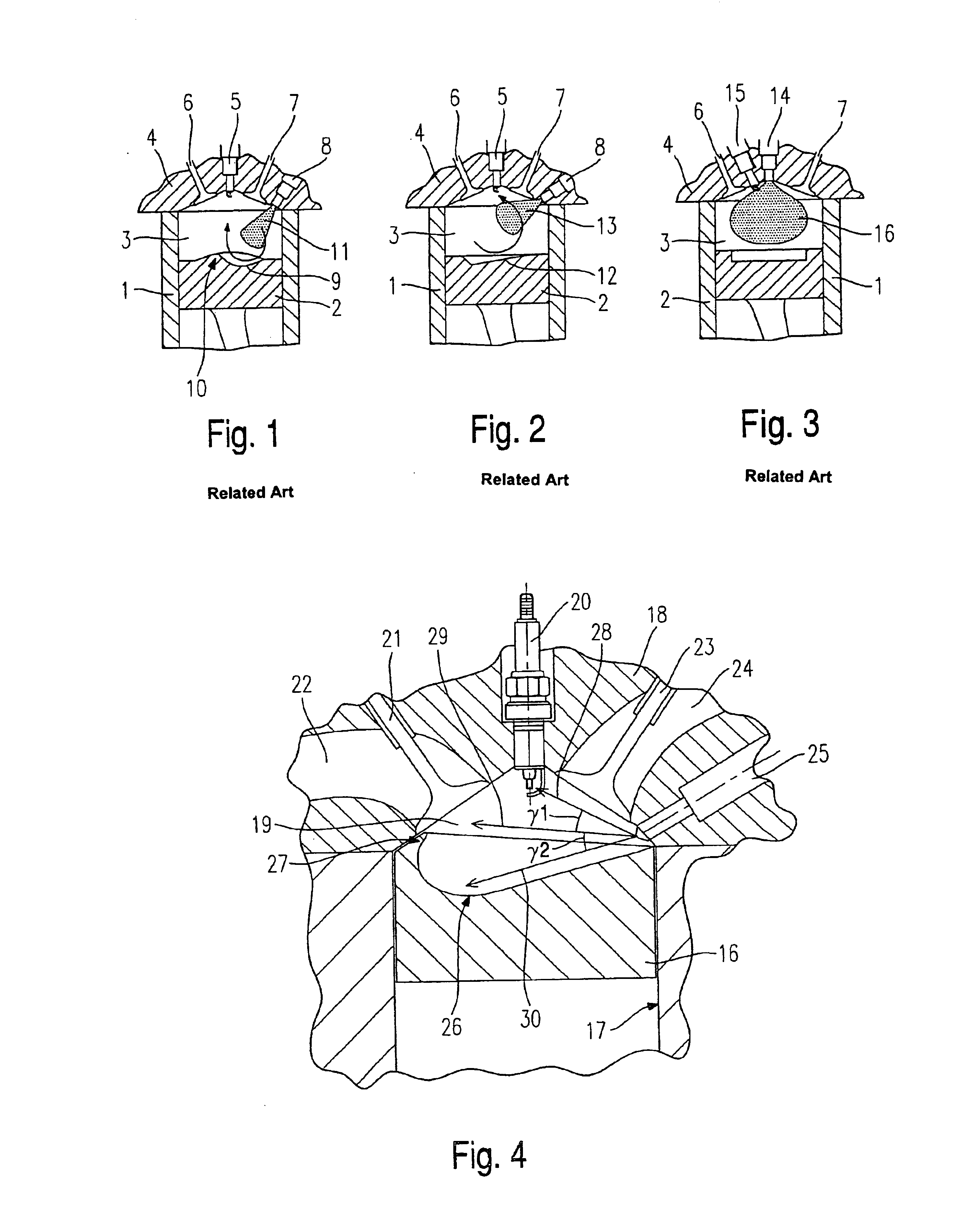

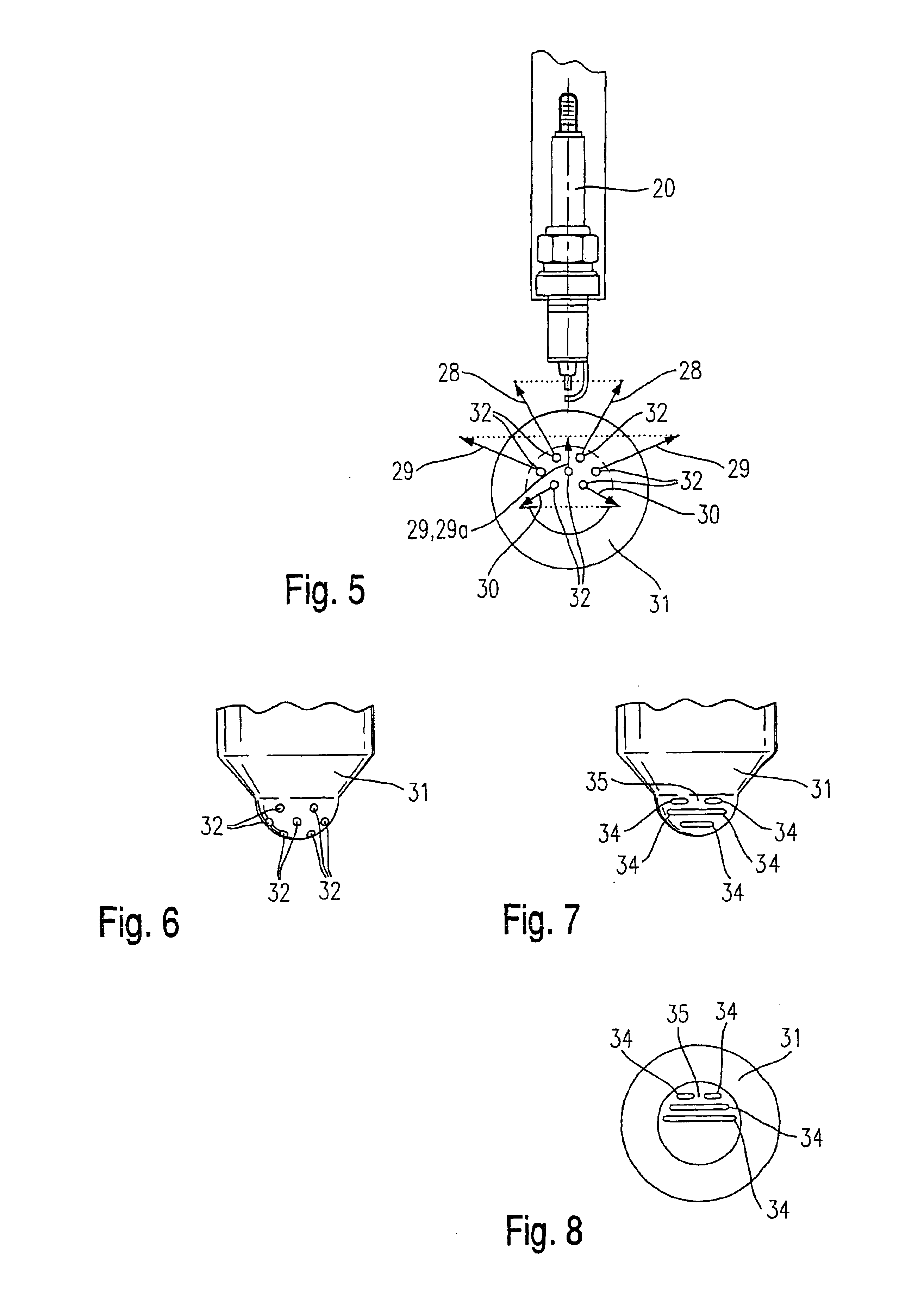

Fuel injection system

InactiveUS6883491B2Avoid disadvantagesSolve the lack of precisionInternal combustion piston enginesCylinder headsExternal combustion engineInlet valve

A fuel-injection system for internal combustion engines has at least one fuel injector injecting fuel into a combustion chamber, which is delimited by a cylinder wall in which a piston is guided. A spark plug projects into the combustion chamber, and the fuel injector is located in the combustion chamber in the region of a gas-intake valve toward the cylinder wall. The fuel injector produces a plurality of fuel jets at least one of these fuel jets being tangentially oriented to the region of the spark plug.

Owner:ROBERT BOSCH GMBH

Optical connector

ActiveUS20070211997A1Reduce insertionLess bendingCoupling light guidesEngineeringOptical fiber connector

An optical connector includes a connector body that has a first optical fiber housed in advance in a ferrule so as to project from a back end of the ferrule opposite to the connecting end surface and an anchoring fixture that anchors a second optical fiber that is to be optically connected to the first optical fiber, and by pressing the anchoring fixture into the connector body while the second optical fiber is anchored in this anchoring fixture, the anchoring fixture and the connector body are connected to optically connect the first optical fiber and the second optical fiber, and the connecting portion that connects the anchoring fixture and the connector body form a movable connecting portion that is adapted to vary the direction of the anchoring fixture with respect to the connector body.

Owner:THE FUJIKURA CABLE WORKS LTD +1

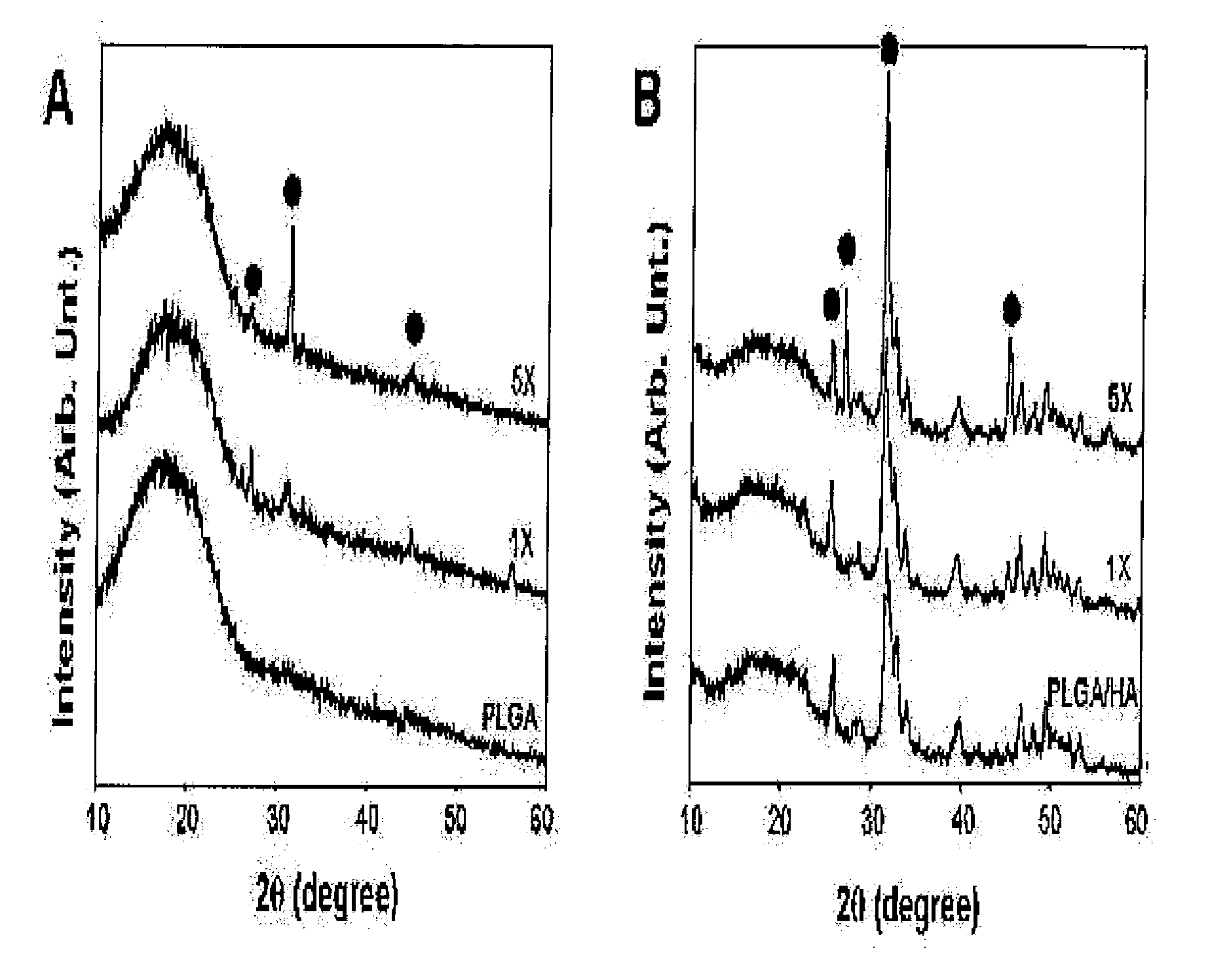

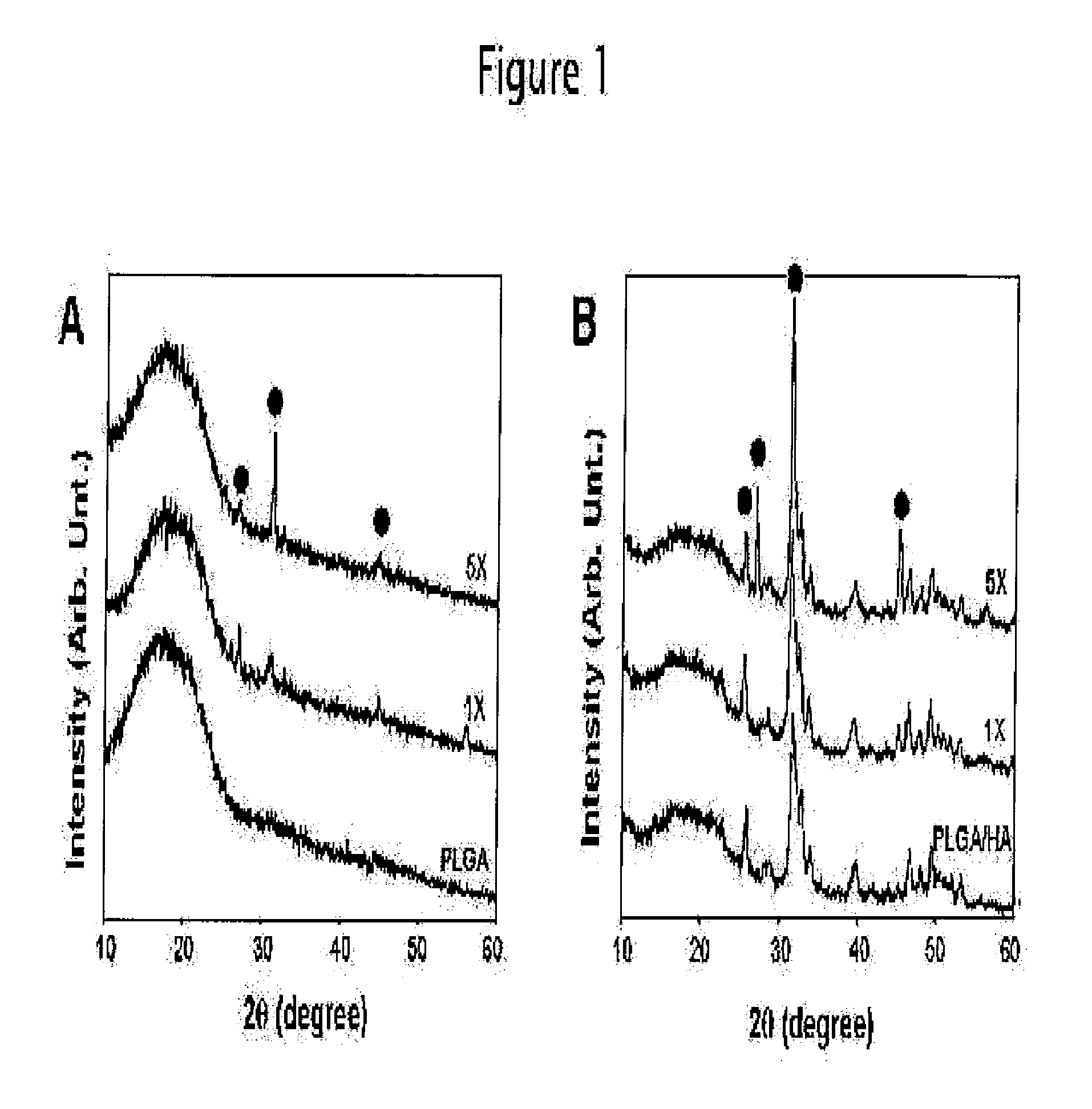

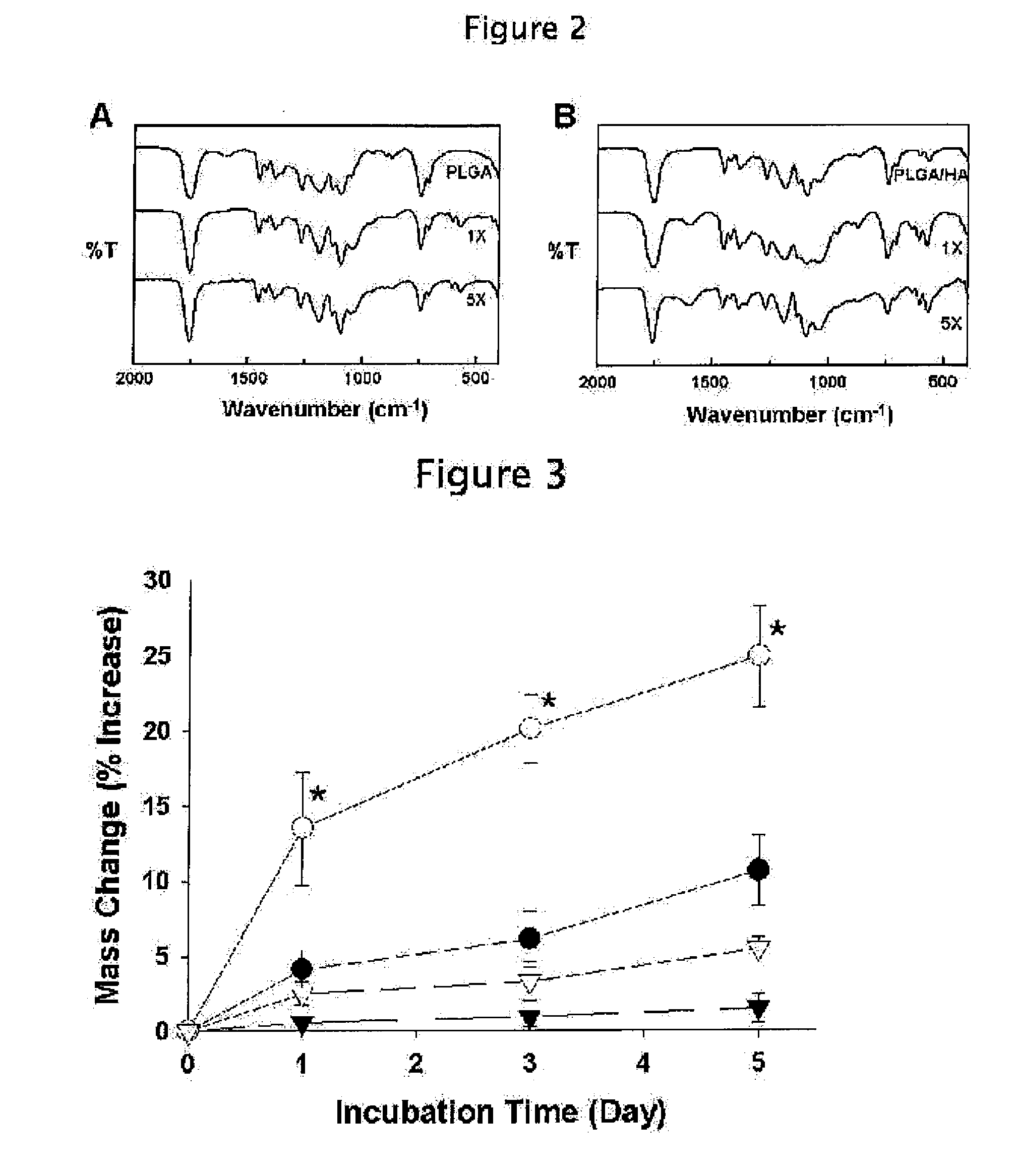

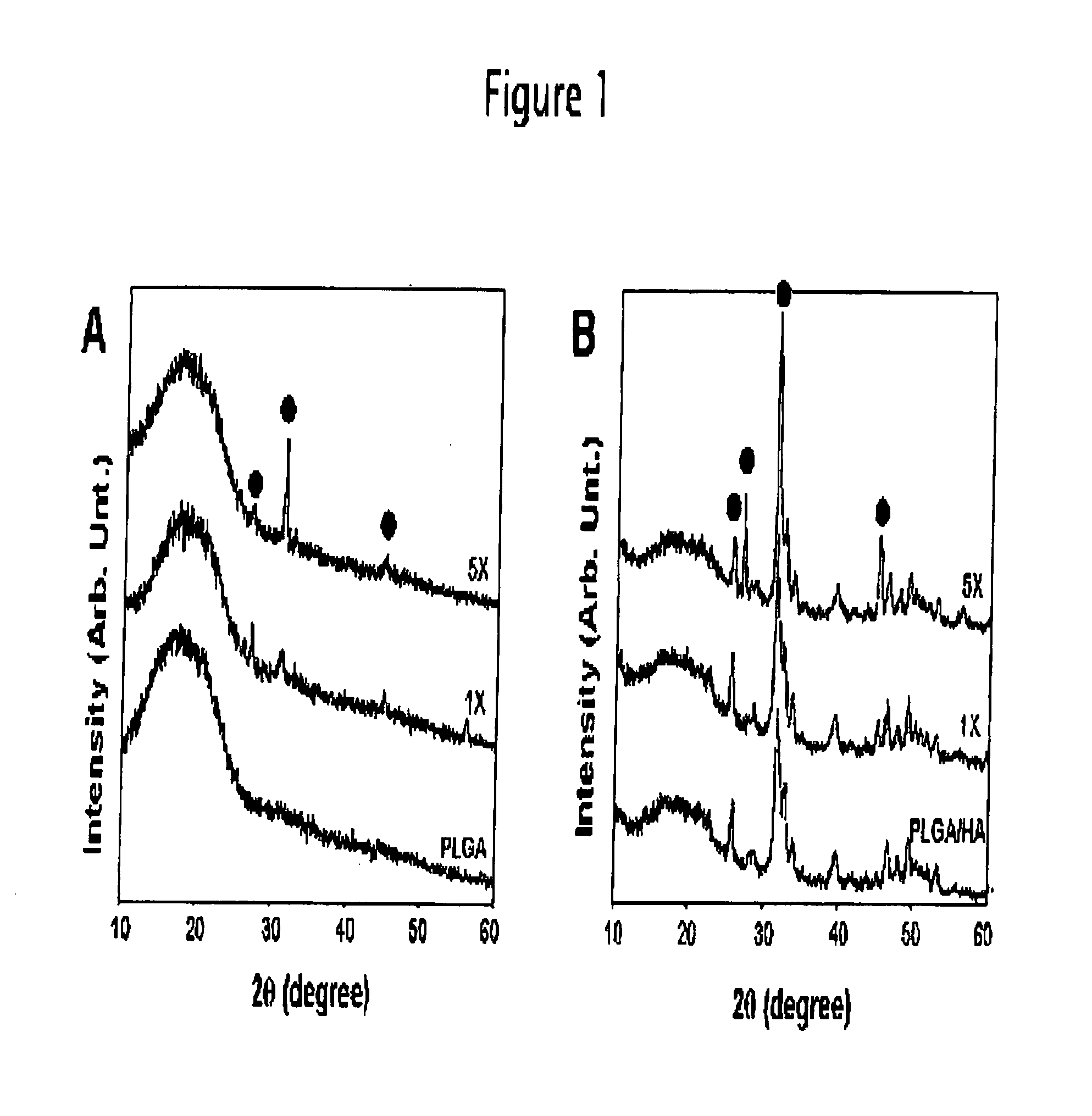

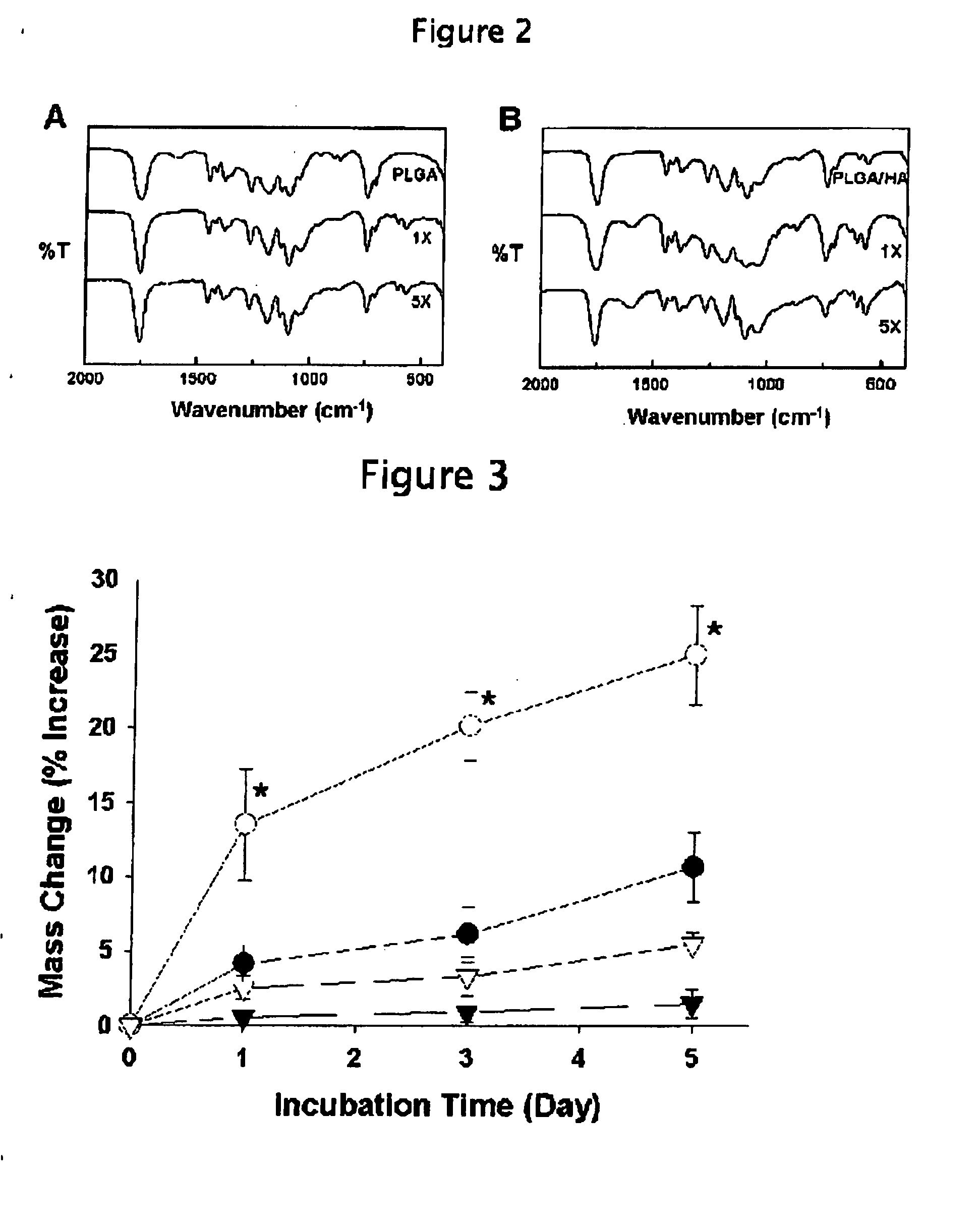

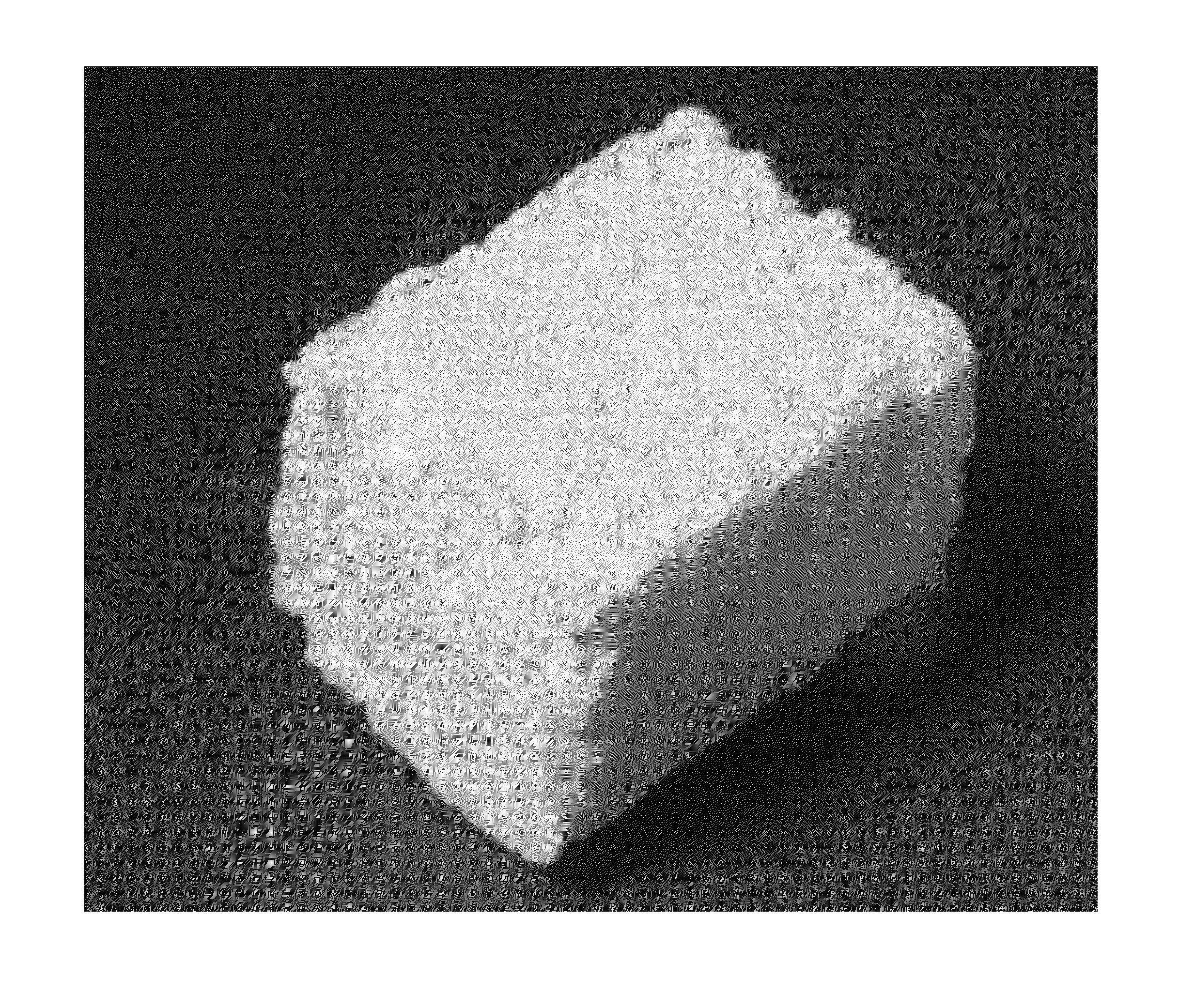

PLGA/Hydroxyapatite Composite Biomaterial and Method of Making the Same

InactiveUS20090048358A1Fastly and highly and uniformly coatedGood at propagatingCosmetic preparationsImpression capsDiseaseApatite

Tissue engineering is a growing field where new materials are being developed for implantation into the body. One important area involves bone graft materials to replace areas of bone lost to trauma or disease. Traditionally, graft material may be harvested from the bone of the individual receiving the graft material. However, this requires an additional surgery and additional recovery. Bone also may be taken from others, or even cadavers, but this introduces biocompatibility problems as well as the risk of disease transfer. Ideally, a biocompatible material is sought that will act as a filler with appropriate mechanical strength, encourage bone healing, and degrade to allow new bone ingrowth without the risk of disease transfer. The present invention is a new composite bone graft material made from biocompatible poly(D,L-lactic-co-glycolic acid) (PLGA) and nano-sized hydroxyapatite particles exposed on its surface using a gas foaming particle leaching (GF / PL) method. A further embodiment of this invention involves coating this PLGA / hydroxyapatite biomaterial with an adherent, fast, uniform coating of a mineral such as apatite. The PLGA polymer portion of the composite provides sufficient mechanical strength to replace bone and is degradable over time to allow new bone tissue ingrowth. The incorporated hydroxyapatite particles increase the composite material's osteogenic properties by providing sites for tissue attachment and propagation. Finally, a uniform coating of mineral apatite on the surface of this novel biomaterial composite further enhances its osteogenic qualities.

Owner:NANO ORTHOPEDICS

PLGA/hydroxyapatite composite biomaterial and method of making the same

InactiveUS20080065228A1Fastly and highly and uniformly coatedGood at propagatingCosmetic preparationsBone implantApatiteBiocompatibility Testing

Tissue engineering is a growing field where new materials are being developed for implantation into the body. One important area involves bone graft materials to replace areas of bone lost to trauma or disease. Traditionally, graft material may be harvested from the bone of the individual receiving the graft material. However, this requires an additional surgery and additional recovery. Bone also may be taken from others, or even cadavers, but this introduces biocompatibility problems as well as the risk of disease transfer. Ideally, a biocompatible material is sought that will act as a filler with appropriate mechanical strength, encourage bone healing, and degrade to allow new bone ingrowth without the risk of disease transfer. The present invention is a new composite bone graft material made from biocompatible poly(D,L-lactic-co-glycolic acid) (PLGA) and nano-sized hydroxyapatite particles exposed on its surface using a gas foaming particle leaching (GF / PL) method. A further embodiment of this invention involves coating this PLGA / hydroxyapatite biomaterial with an adherent, fast, uniform coating of a mineral such as apatite. The PLGA polymer portion of the composite provides sufficient mechanical strength to replace bone and is degradable over time to allow new bone tissue ingrowth. The incorporated hydroxyapatite particles increase the composite material's osteogenic properties by providing sites for tissue attachment and propagation. Finally, a uniform coating of mineral apatite on the surface of this novel biomaterial composite further enhances its osteogenic qualities.

Owner:NANO ORTHOPEDICS

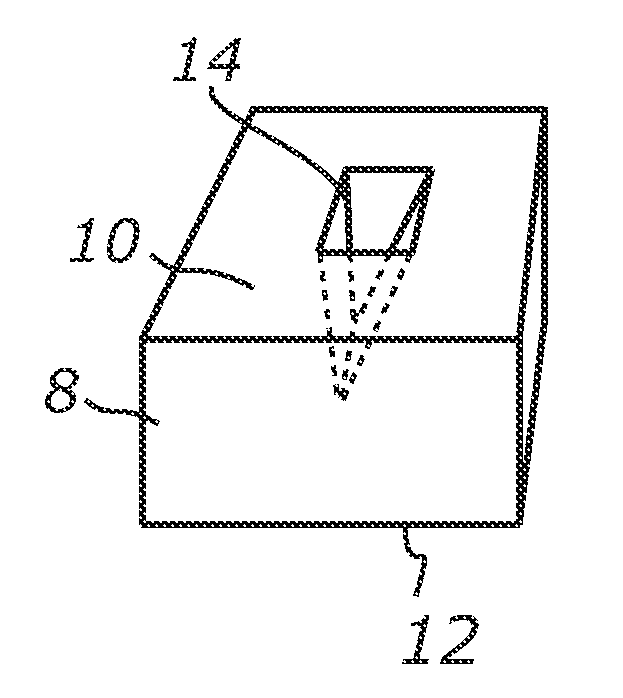

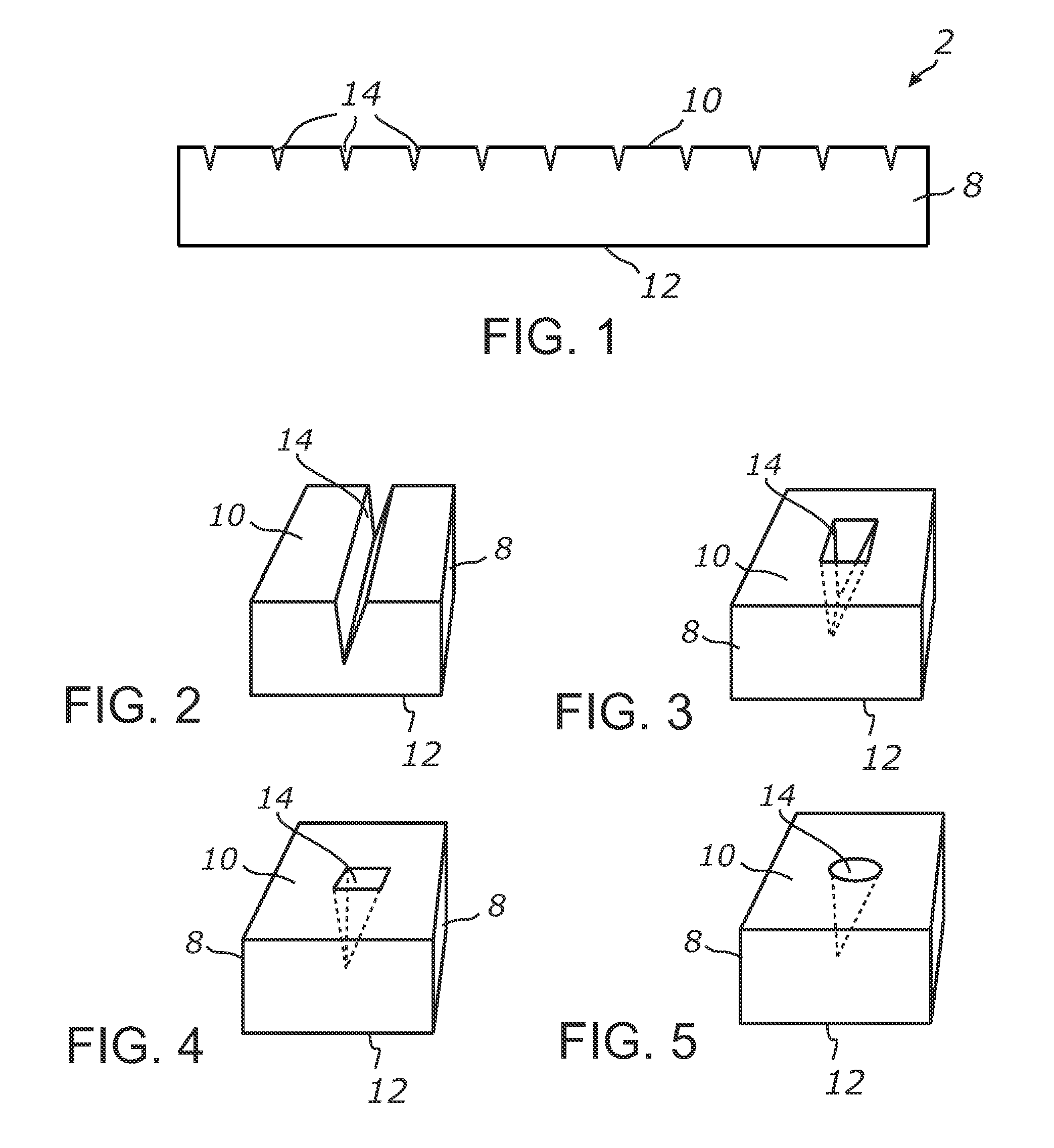

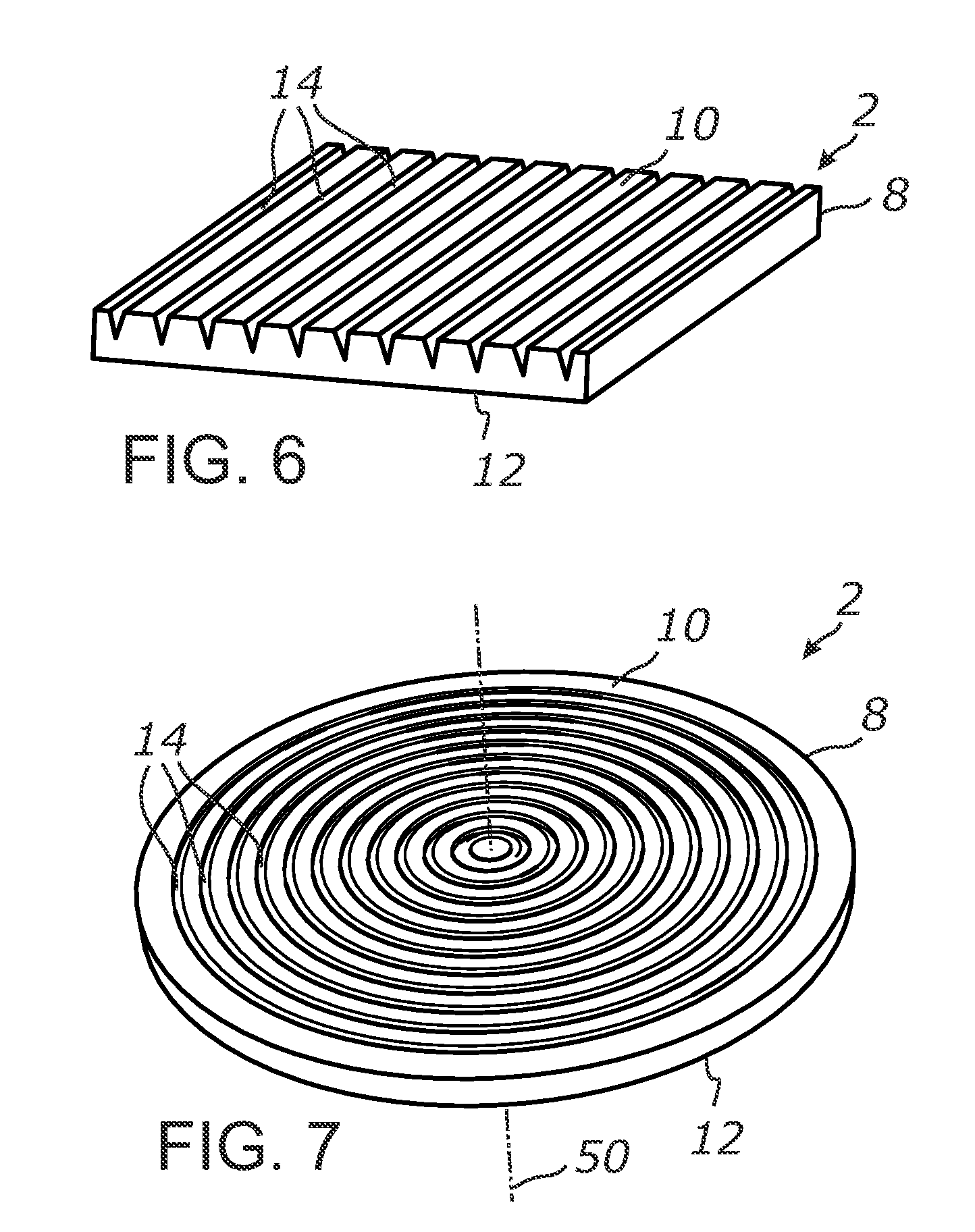

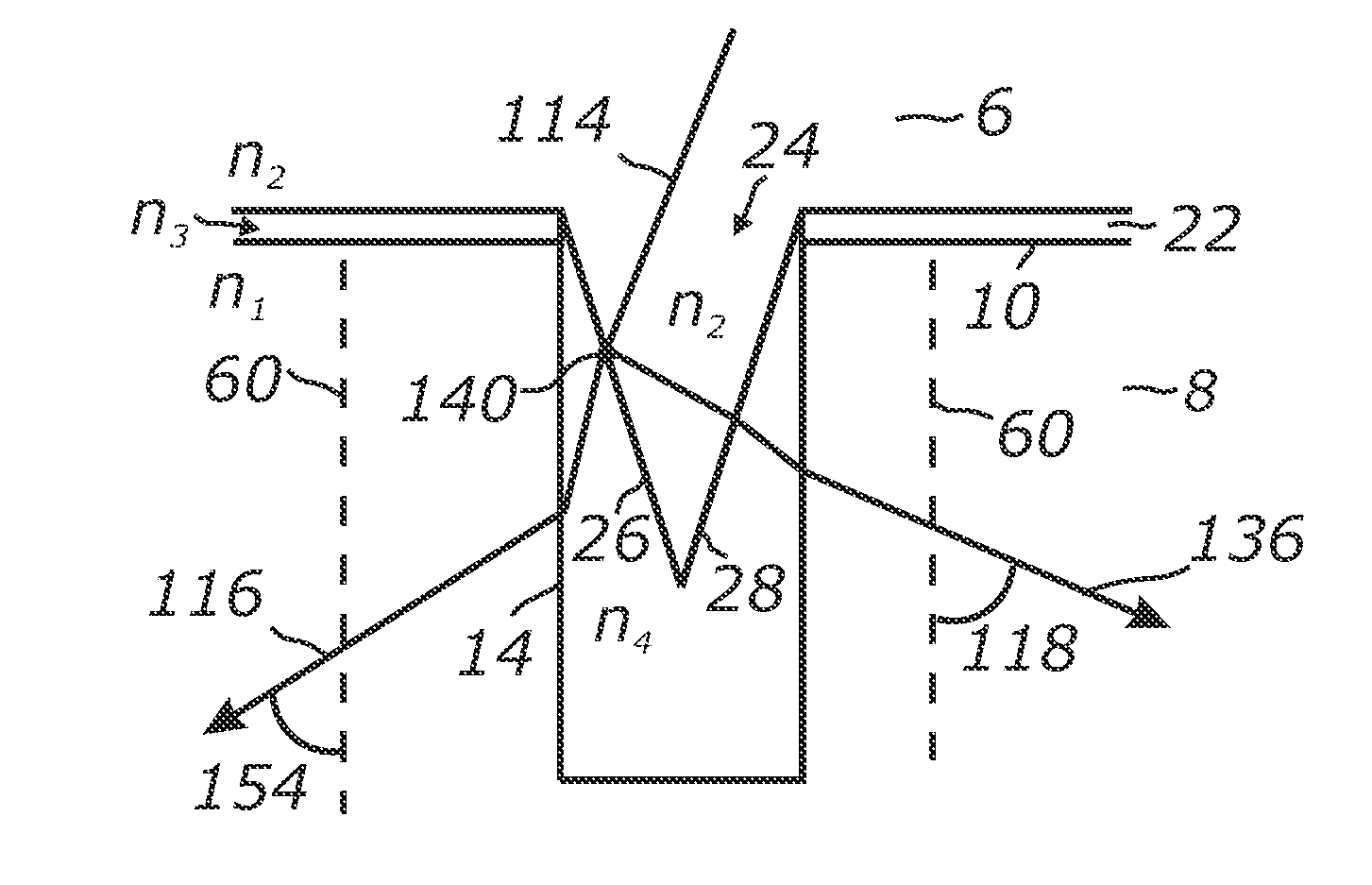

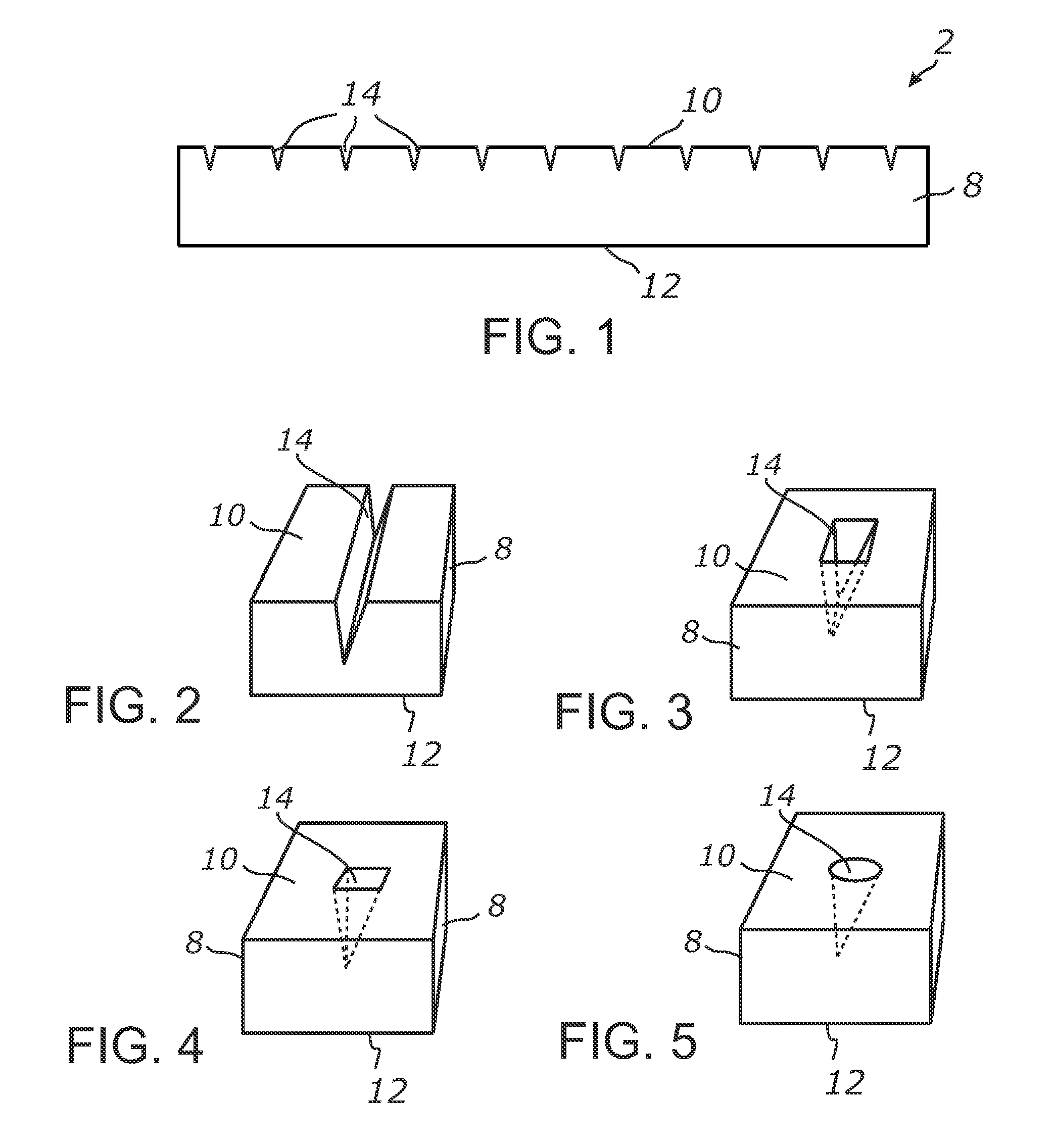

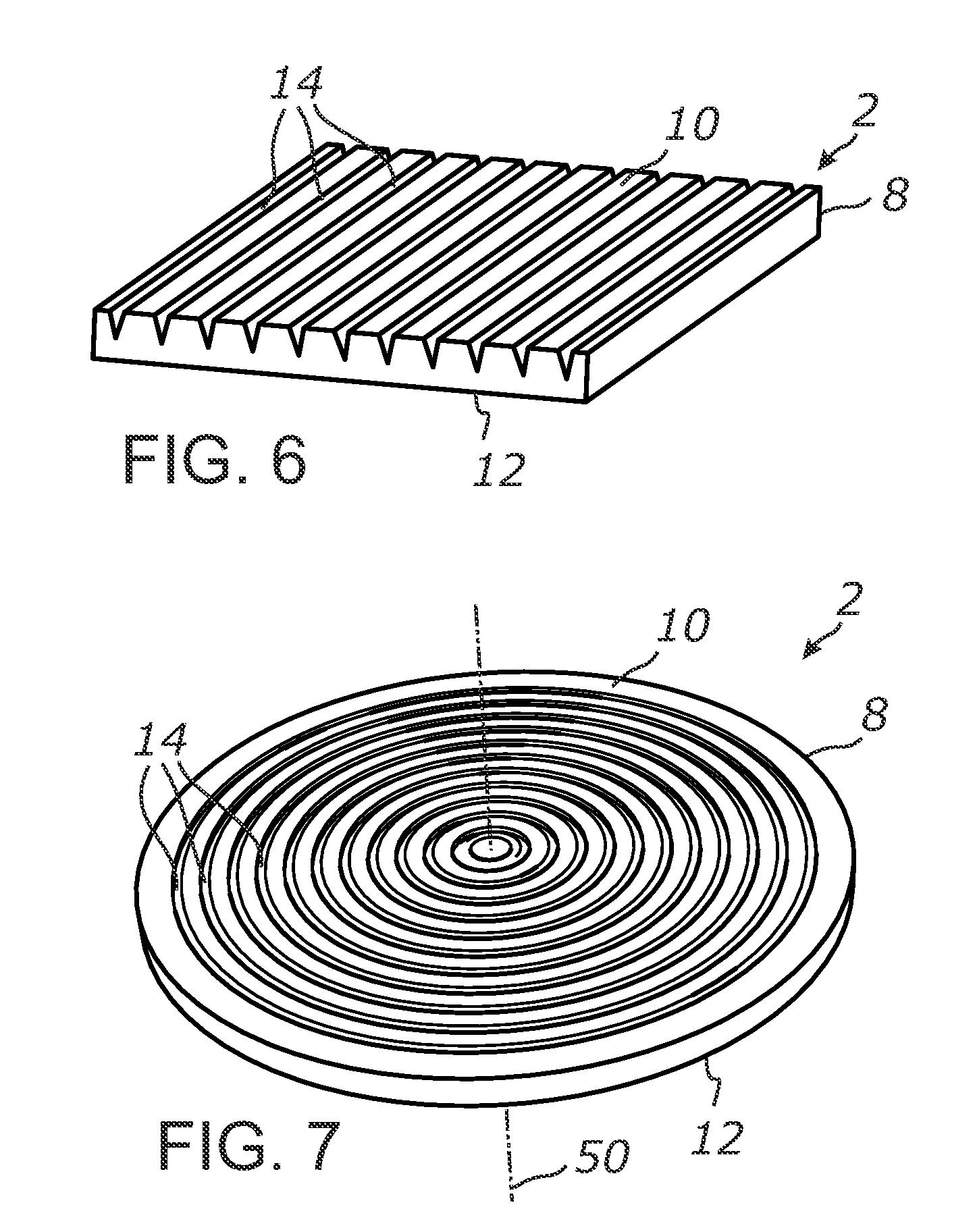

Light trapping optical cover

ActiveUS20120135512A1Enhance useful light absorptionIncrease the optical path lengthBioreactor/fermenter combinationsBiological substance pretreatmentsLight propagation

A light trapping optical cover employing an optically transparent layer with a plurality of light deflecting elements. The transparent layer is configured for an unimpeded light passage through its body and has a broad light input surface and an opposing broad light output surface. The light deflecting elements deflect light incident into the transparent layer at a sufficiently high bend angle with respect to a surface normal and direct the deflected light toward a light harvesting device adjacent to the light output surface. The deflected light is retained by means of at least TIR in the system formed by the optical cover and the light harvesting device which allows for longer light propagation paths through the photoabsorptive layer of the device and for an improved light absorption. The optical cover may further employ a focusing array of light collectors being pairwise associated with the respective light deflecting elements.

Owner:S V V TECH INNOVATIONS

Light trapping optical cover

ActiveUS8290318B2Enhance useful light absorptionIncrease the optical path lengthBioreactor/fermenter combinationsBiological substance pretreatmentsLight propagation

A light trapping optical cover employing an optically transparent layer with a plurality of light deflecting elements. The transparent layer is configured for an unimpeded light passage through its body and has a broad light input surface and an opposing broad light output surface. The light deflecting elements deflect light incident into the transparent layer at a sufficiently high bend angle with respect to a surface normal and direct the deflected light toward a light harvesting device adjacent to the light output surface. The deflected light is retained by means of at least TIR in the system formed by the optical cover and the light harvesting device which allows for longer light propagation paths through the photoabsorptive layer of the device and for an improved light absorption. The optical cover may further employ a focusing array of light collectors being pairwise associated with the respective light deflecting elements.

Owner:S V V TECH INNOVATIONS

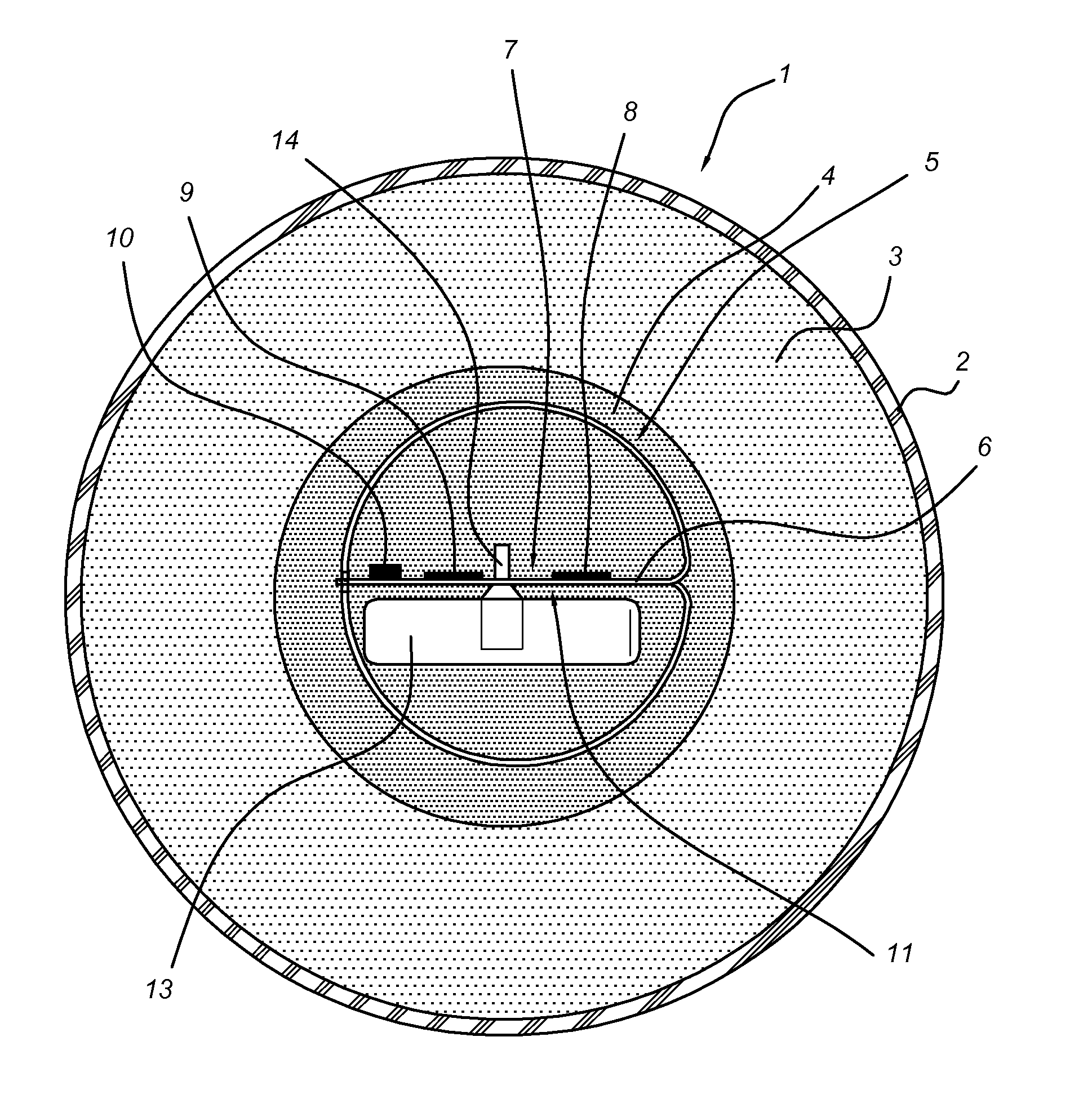

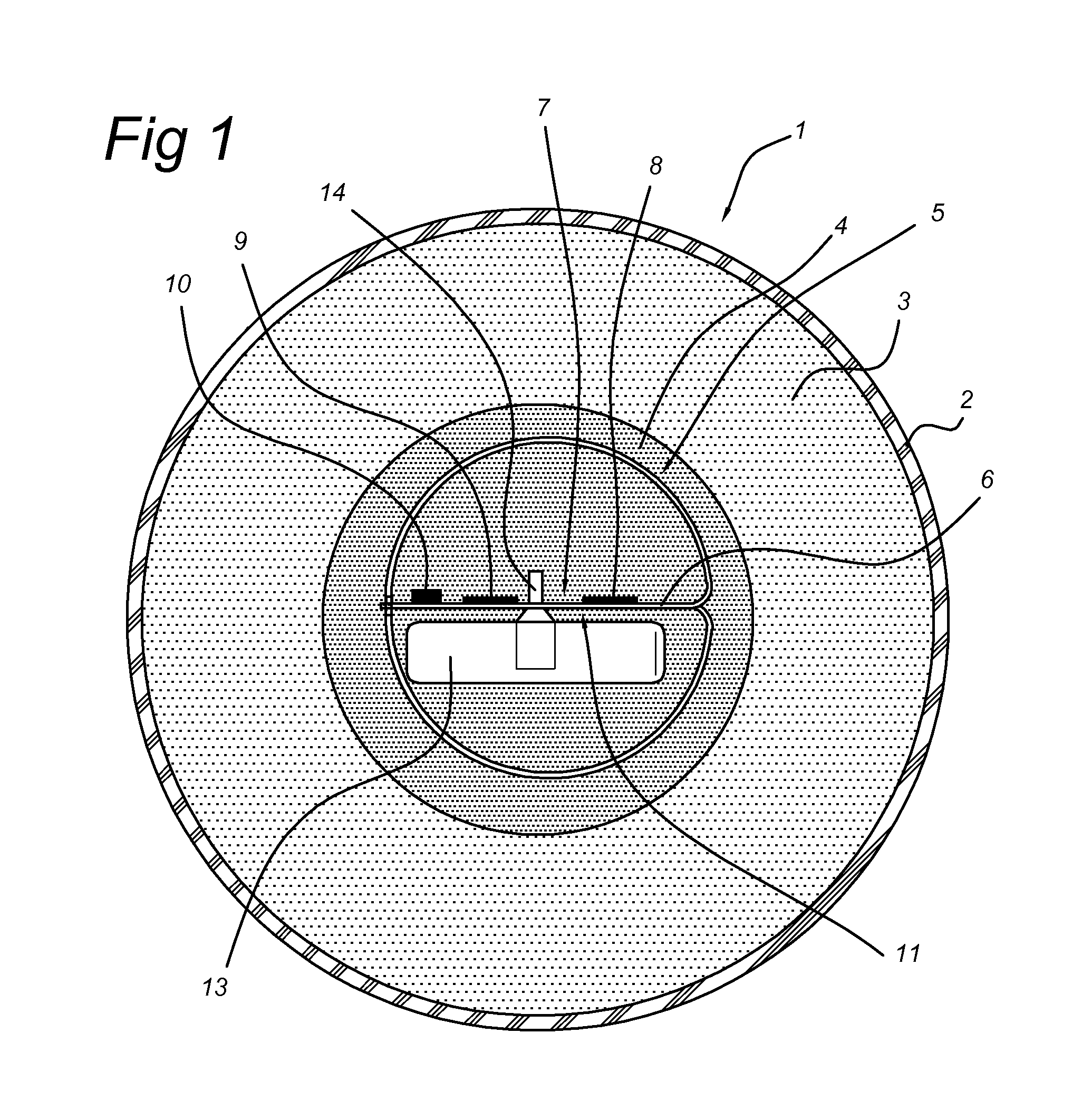

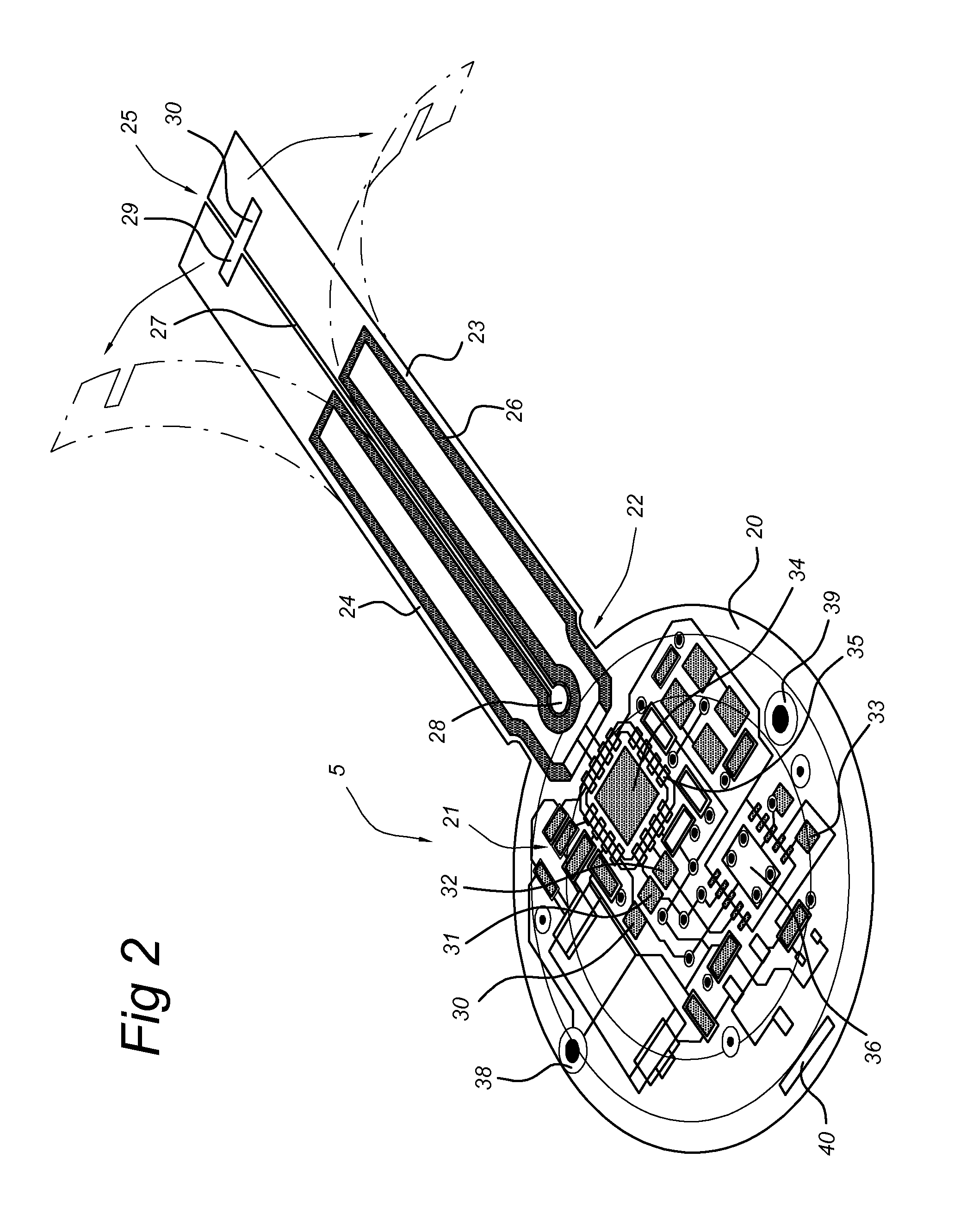

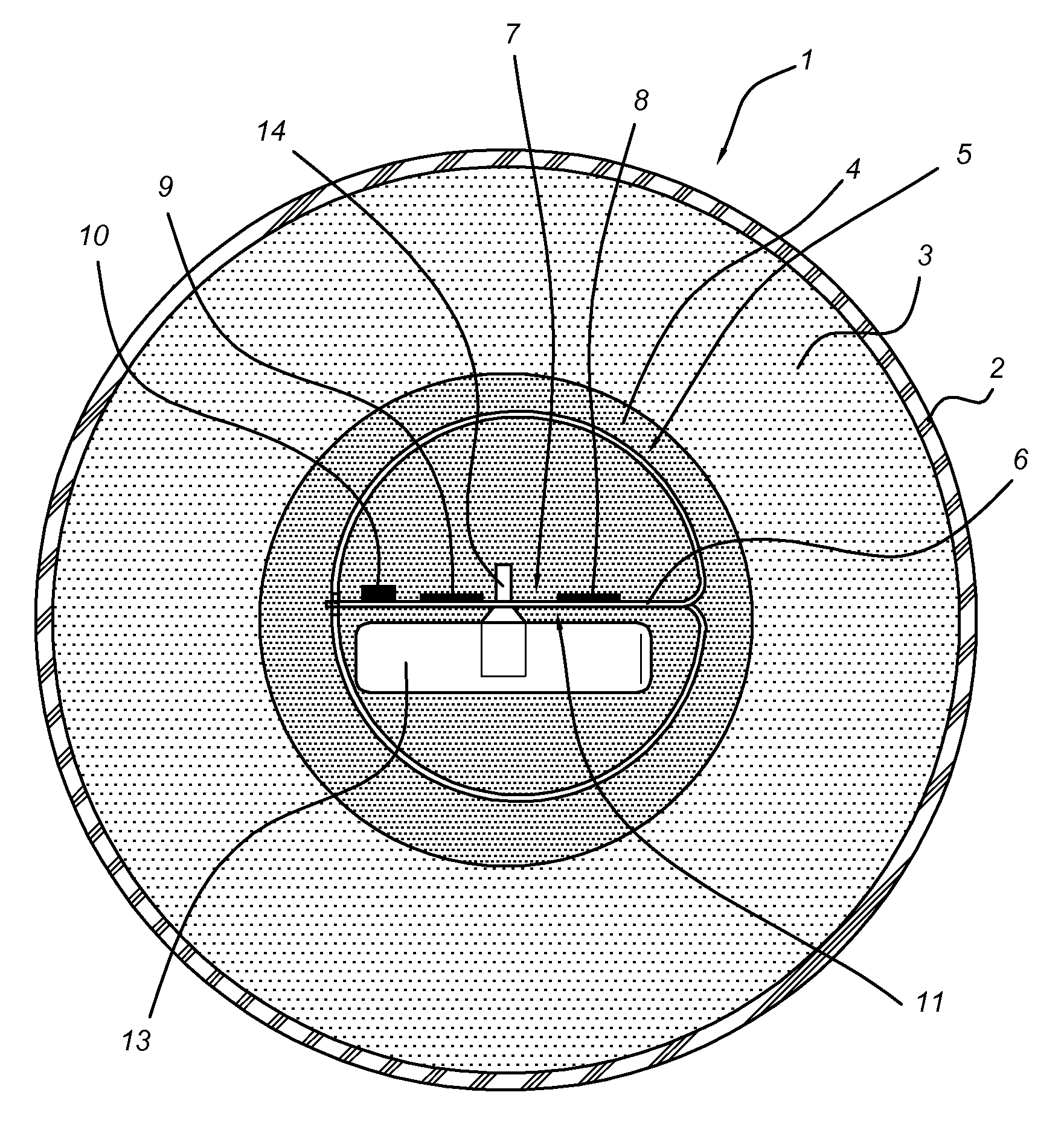

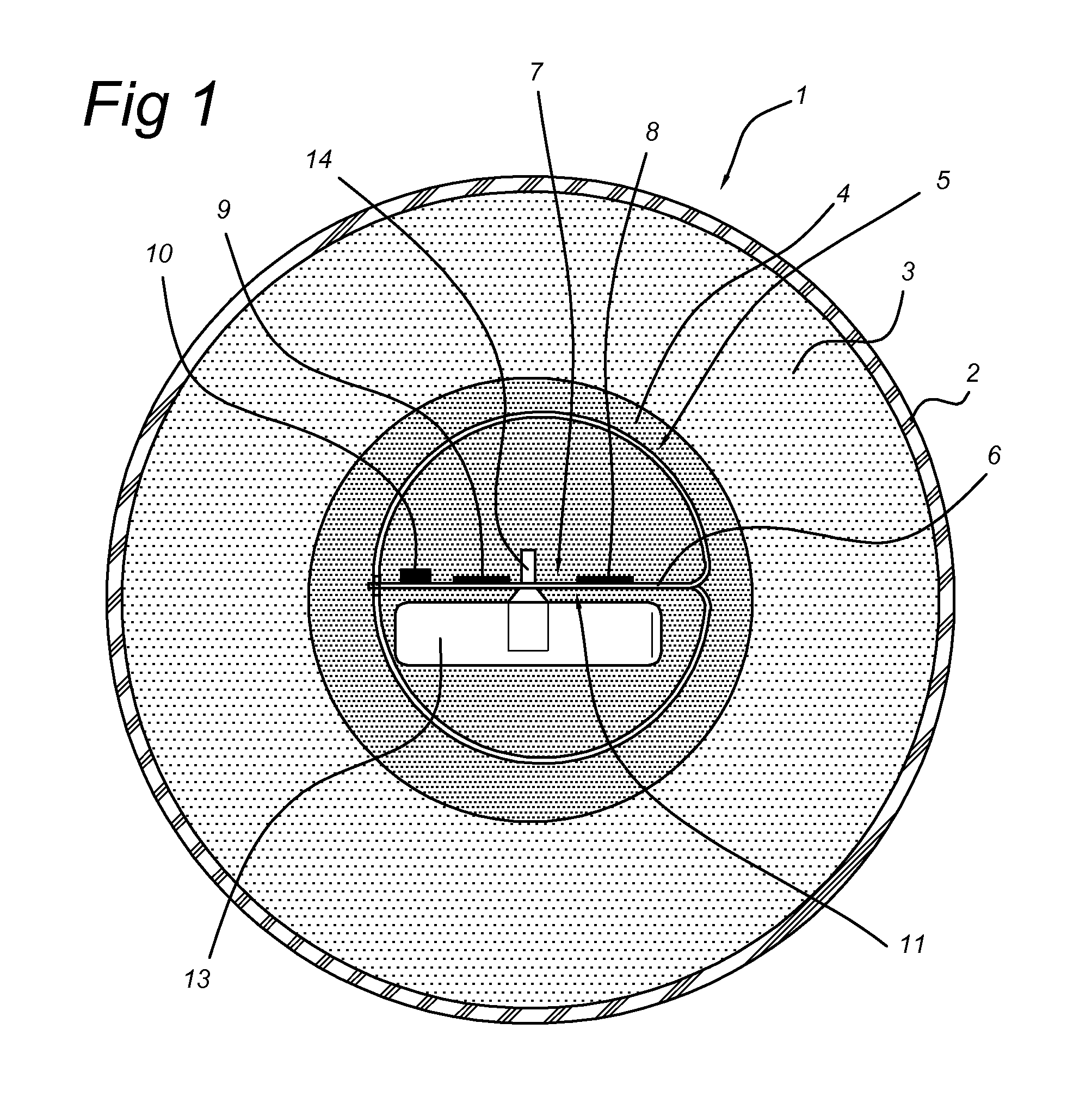

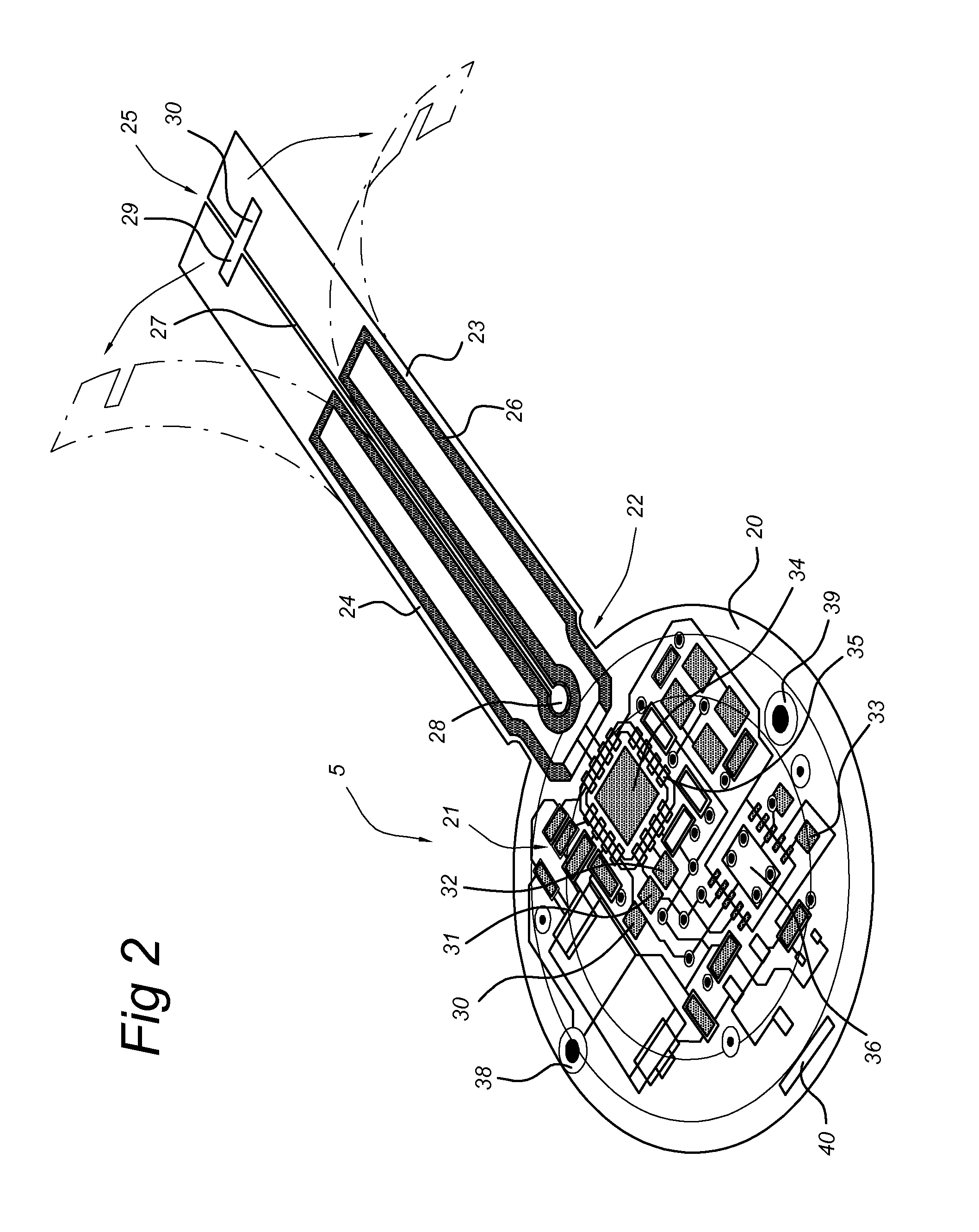

Ball with positioning system

InactiveUS20110215977A1Prevent subsequent tearingFor signal receptionAntenna supports/mountingsGymnastic exercisingEngineeringDipole antenna

A ball (1) for use in a sporting activity can comprise a body having an electrical circuit (21) on a flexible substrate (20) received therein. The electrical circuit (21) comprises a dipole antenna (26) integrally formed with the electrical circuit (21) on the flexible substrate (20). The dipole antenna can comprise two arms (23, 24) each folded in a semi-circular shape.

Owner:PRAZZA

Well service fluid and method of making and using the same

InactiveUS20050003969A1Property is limitedImproving leak-off propertyFlushingDrilling compositionFracturing fluidWater production

A well fracturing fluid comprising one or more anionic viscoelastic surfactants and one or more polymers is described. The fluids can contain an aqueous or non-aqueous fluid and / or a buffer for adjusting the pH of the fracturing fluid. The well service fluid can be used as a fracturing fluid in order to control water production from a well, while simultaneously increasing the oil production from the well.

Owner:BJ SERVICES CO

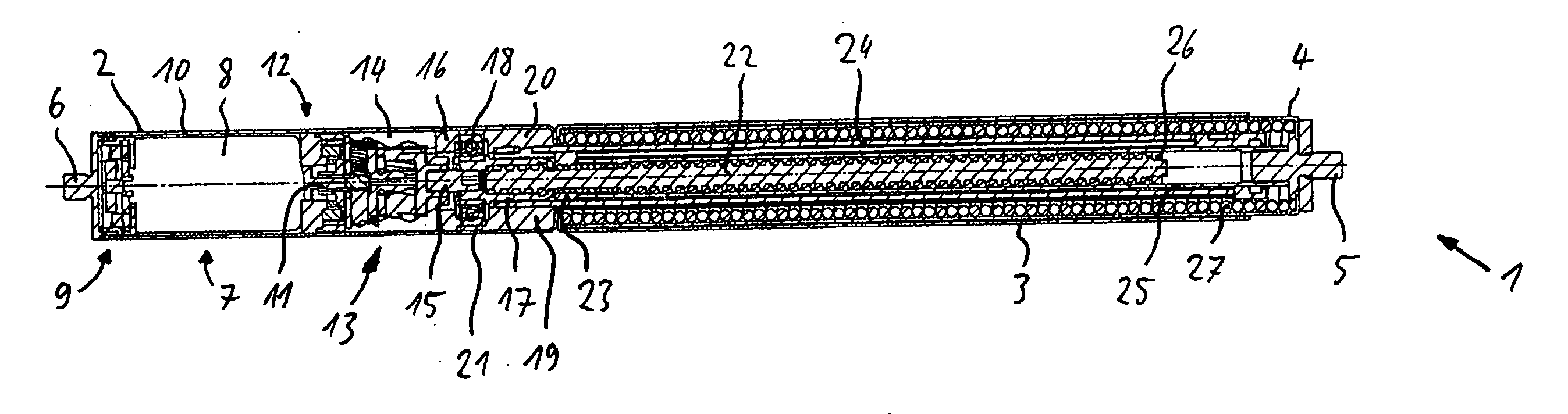

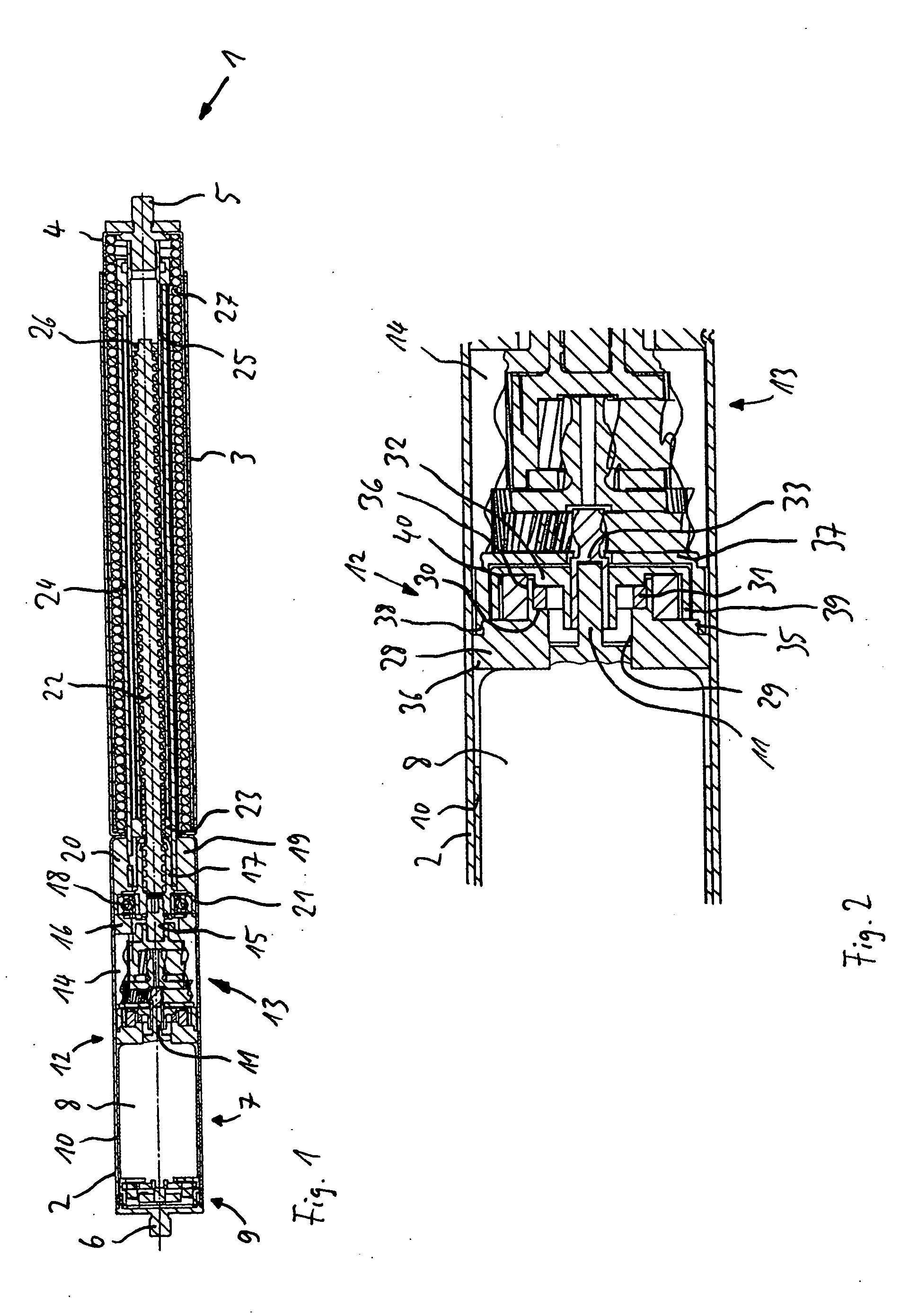

Drive Device

ActiveUS20090000201A1Simple designGuaranteed uptimePower-operated mechanismEngineeringCentrifugal force

A drive device for a hatch of a vehicle, wherein the device includes a first housing part which can be connected to a stationary component or to a movable component, a second housing part, a third housing part which is telescopically guided in the second housing part with an axial freedom of movement and which can be connected to the other of the movable component or the stationary component. A spindle drive comprising a threaded spindle and a spindle nut is mounted on the threaded spindle, by which the third housing part can be driven by a rotary drive and, thus, moved axially with respect to the second housing part. The drive device also includes a brake device, where the brake device comprises a centrifugal force brake.

Owner:STABILUS

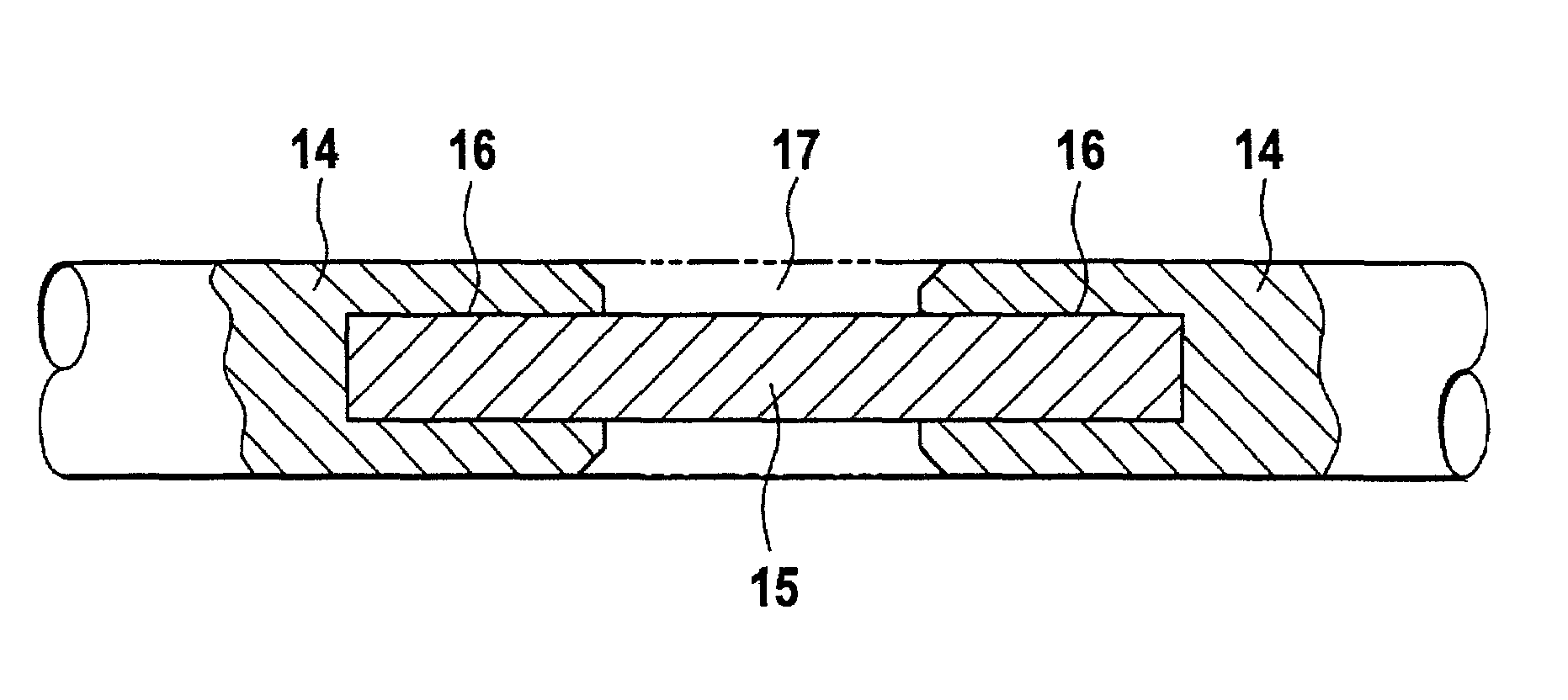

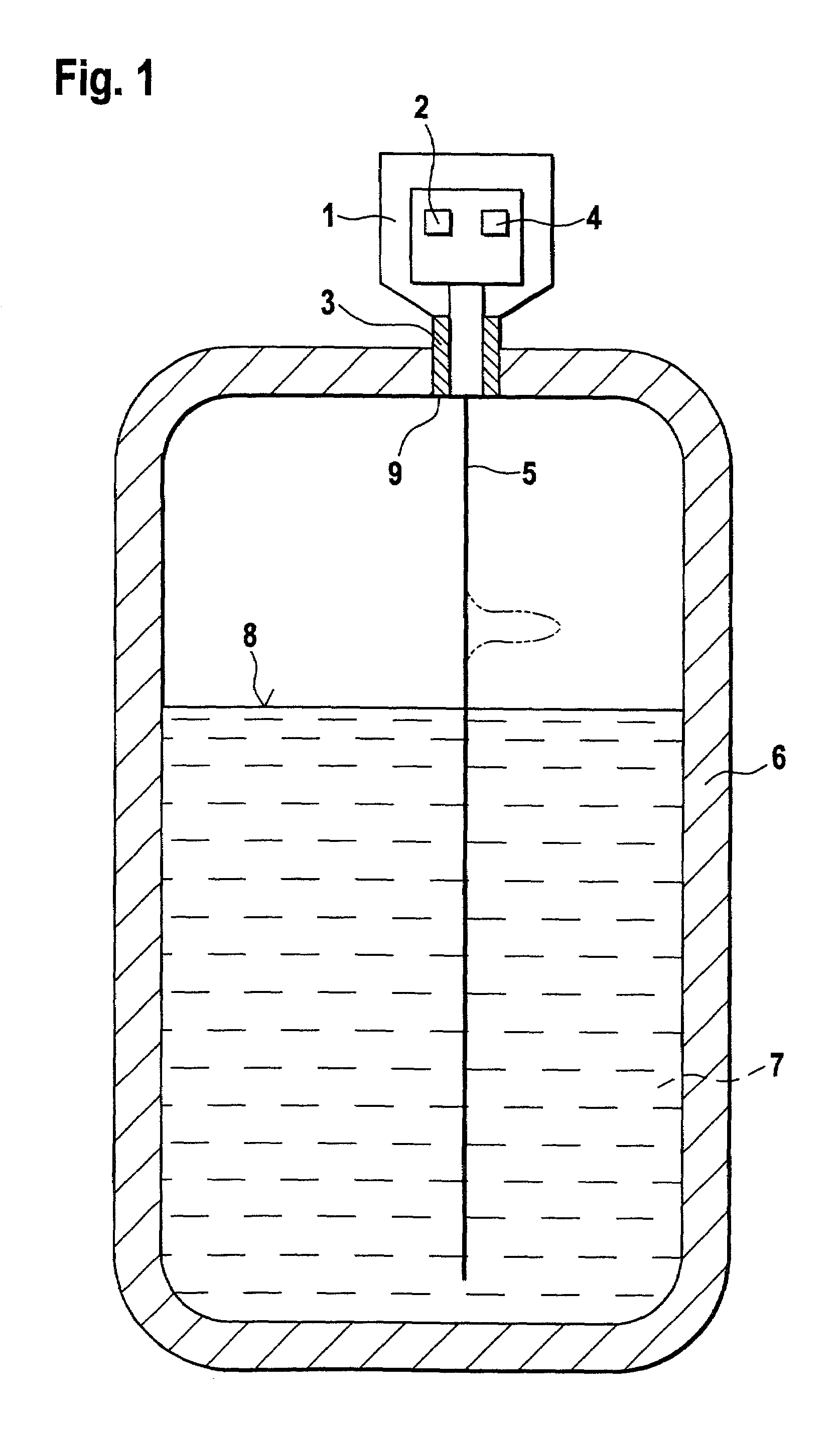

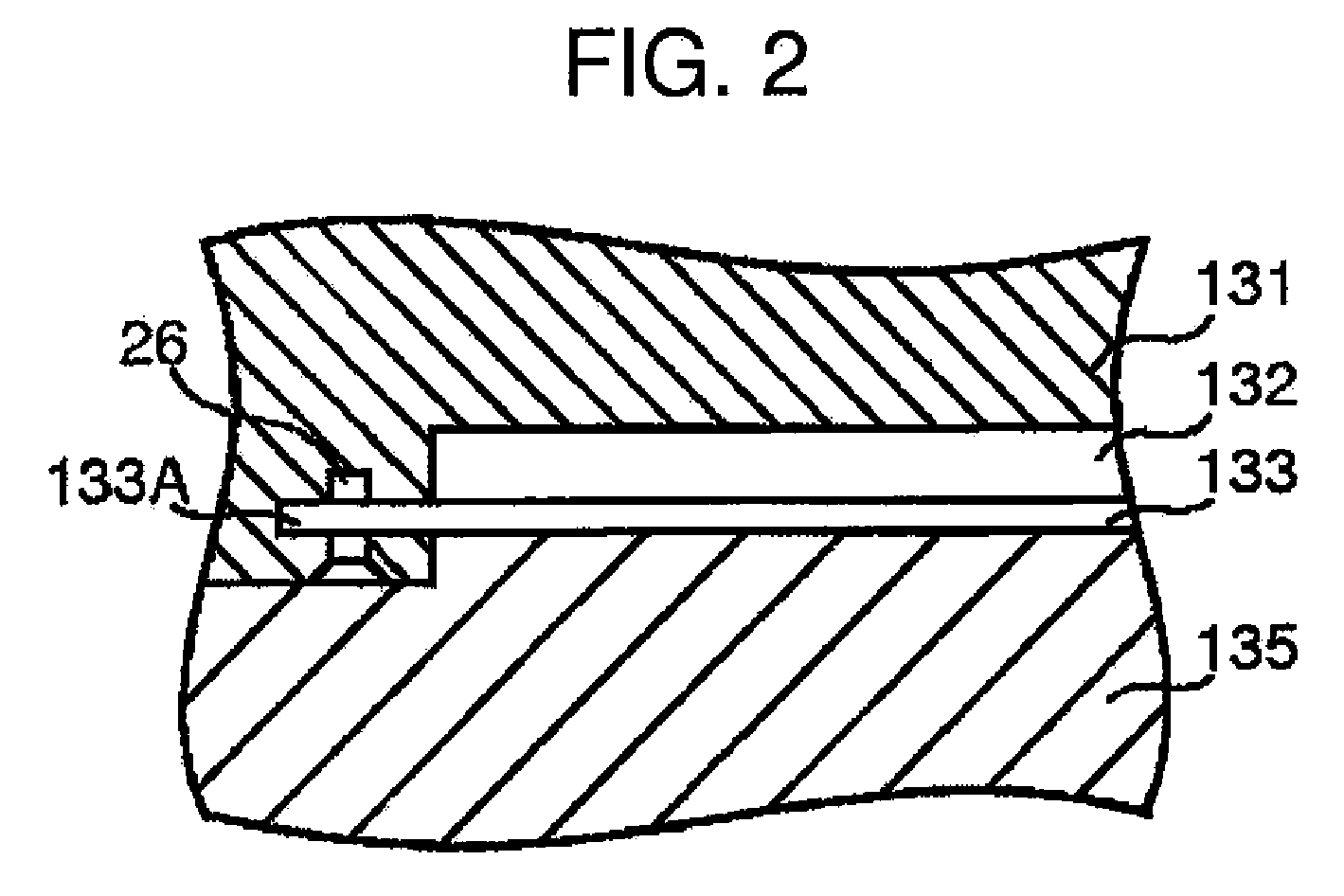

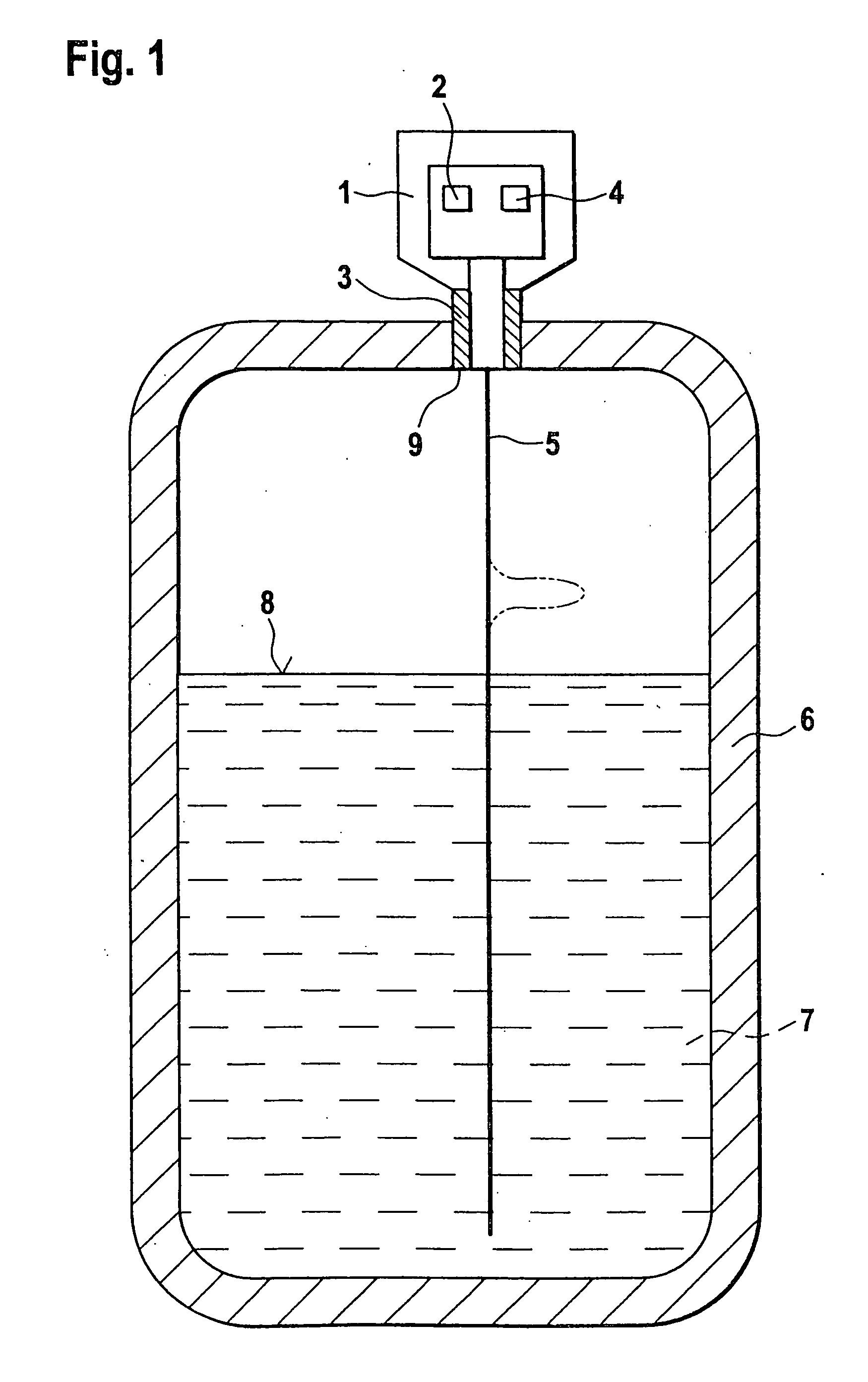

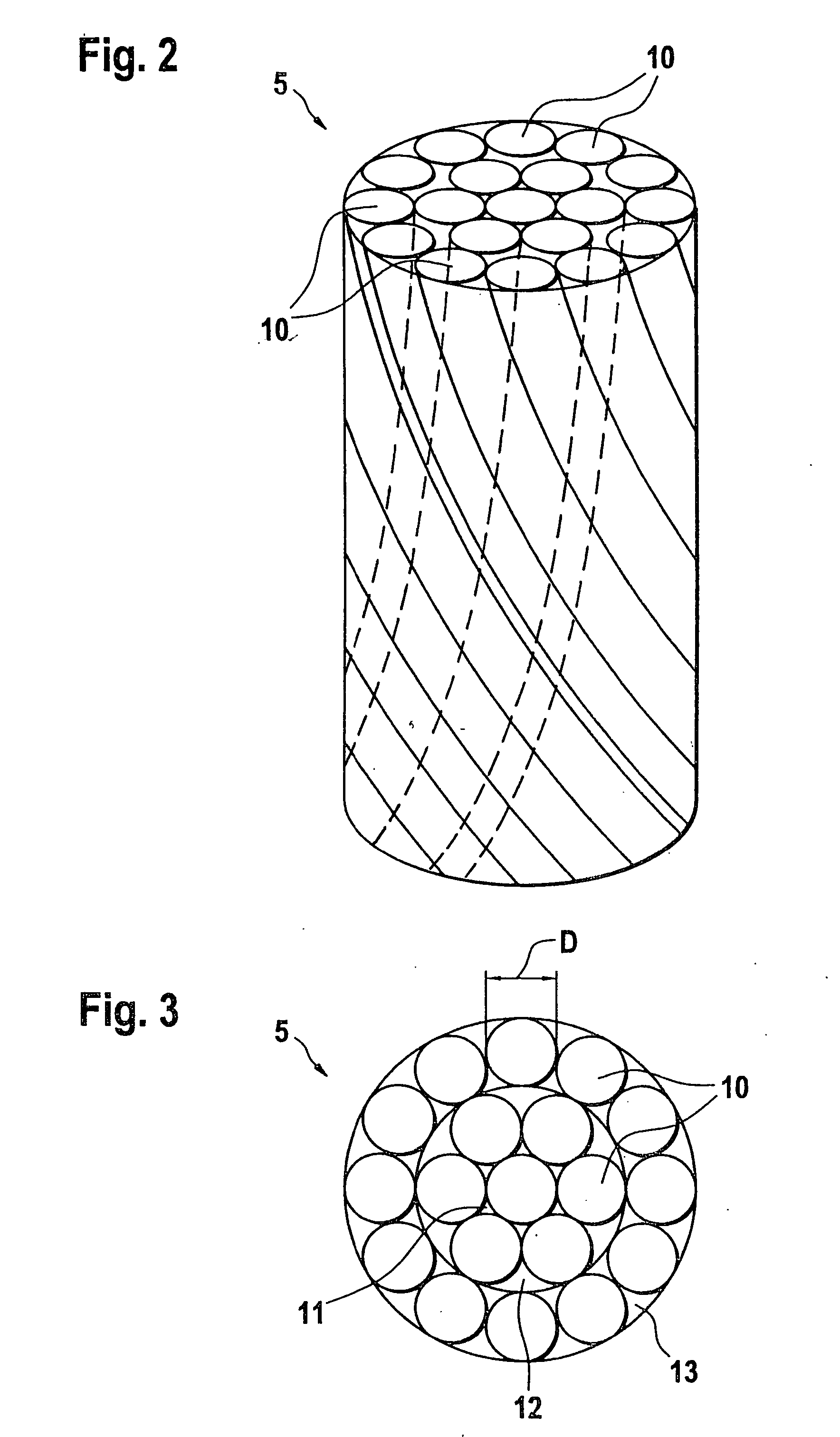

Apparatus for determining and/or monitoring the filling level of a product in a container

ActiveUS7159458B2Increase flexibilityEasy to installSurface/boundary effectMachines/enginesMeasurement deviceHigh frequency

A measuring device for determining the filling level of a product or the position of the interface between two media or phases in a container by means of high-frequency measuring signals which are guided along a waveguide. The waveguide comprises a wire cable with a plurality of individual wires of a predetermined diameter which are twisted together.

Owner:EHNDRESS KHAUZER GMBKH KO KG

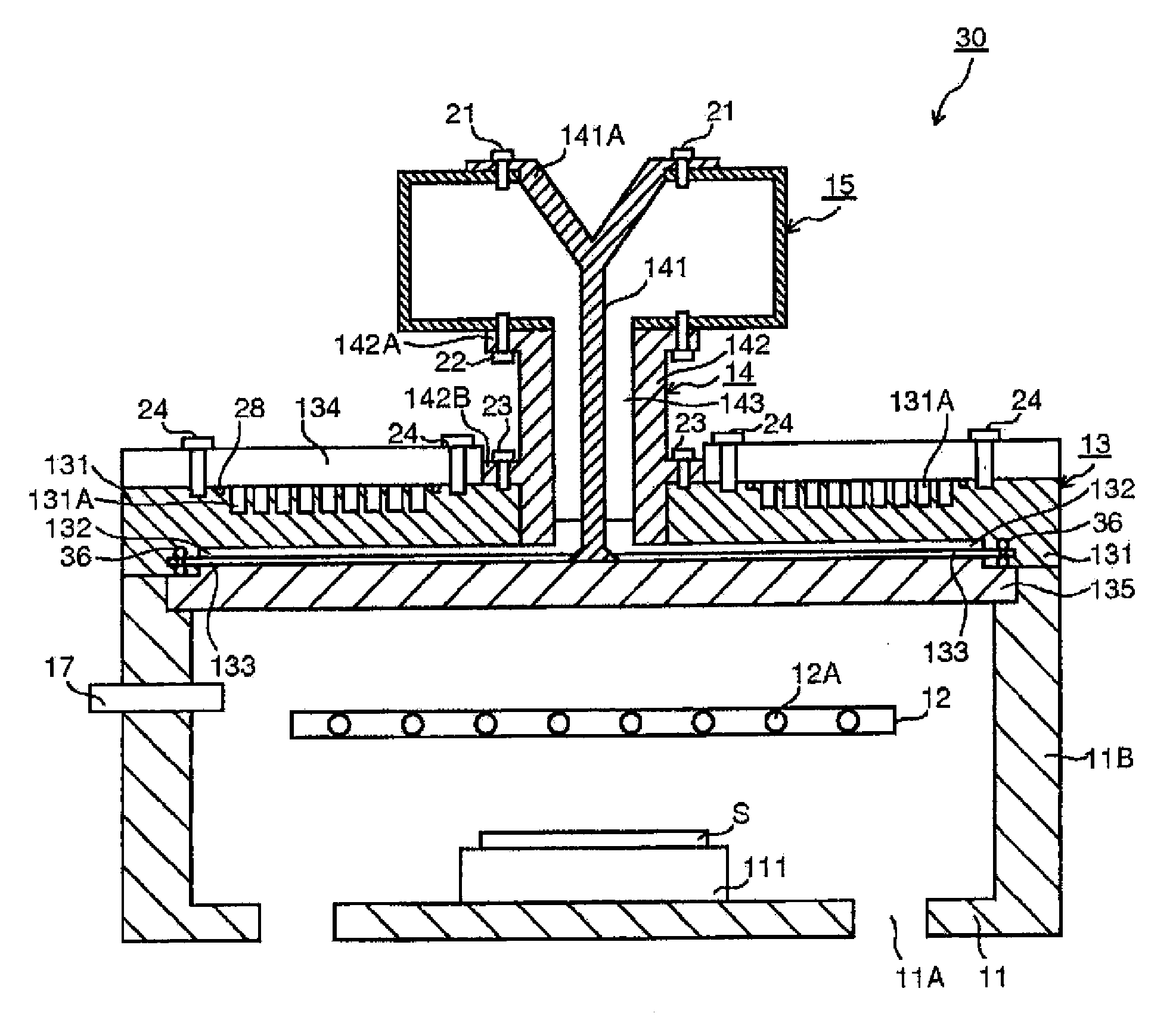

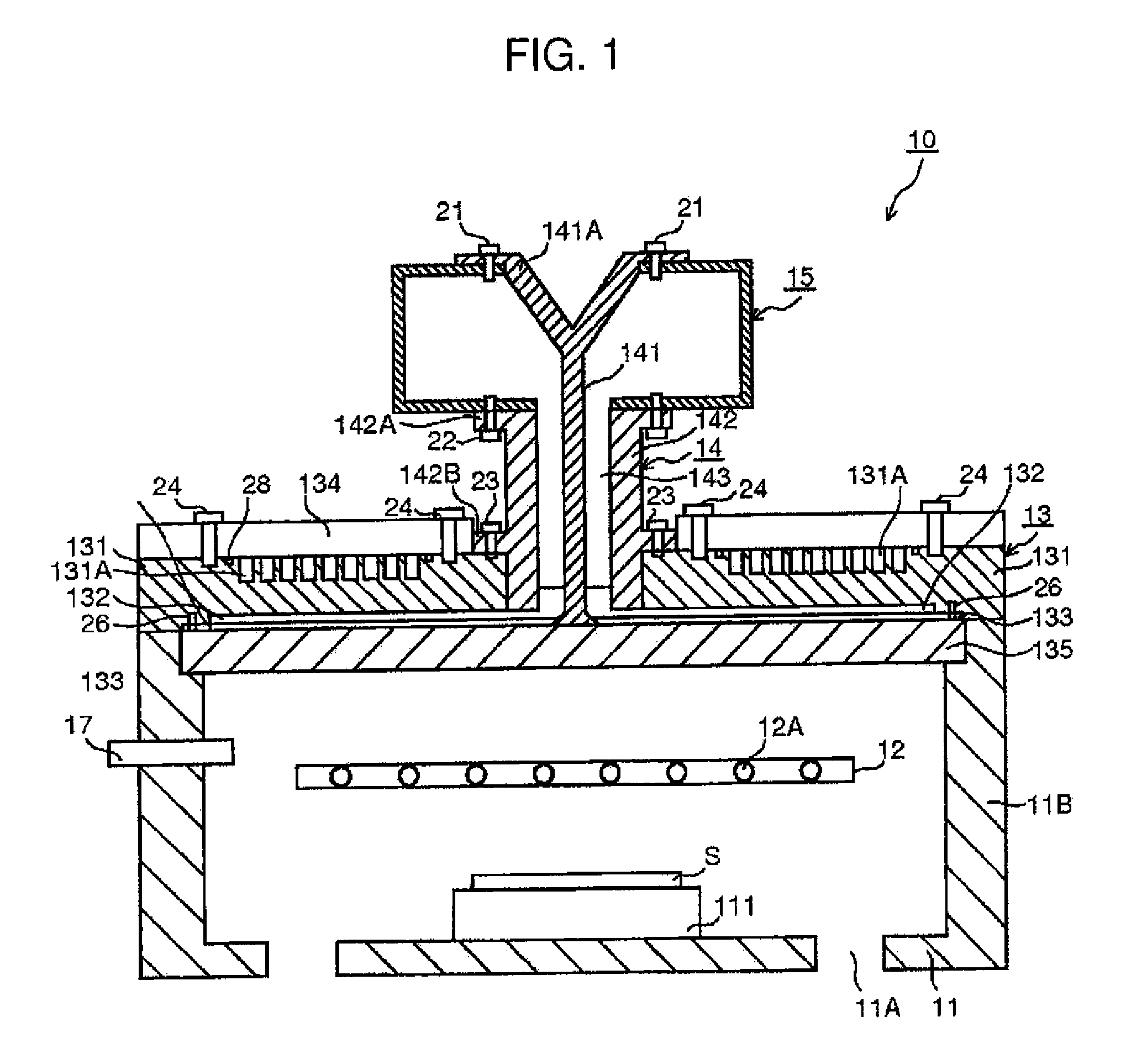

Microwave plasma processing apparatus

InactiveUS20090301656A1Increase contact areaIncrease elasticityElectric discharge tubesSemiconductor/solid-state device manufacturingMicrowaveEngineering

An end of the slot plate of the microwave antenna, which constitutes a microwave plasma processing apparatus, is held and fixed by being held between a pair of metal bodies.

Owner:TOKYO ELECTRON LTD

Apparatus for determining and/or monitoring the filling level of a product in a container

InactiveUS20070034002A1Increase flexibilityEasy to installResistance/reactance/impedenceMachines/enginesMeasurement deviceWaveguide

The invention relates to a measuring device which determines the filling level by means of high-frequency measuring signals which are guided along a waveguide. The invention is based on the object of optimizing the waveguide. According to a preferred embodiment of the apparatus according to the invention, the waveguide is a wire cable which comprises a plurality of individual wires of a predetermined diameter which are twisted together.

Owner:EHNDRESS KHAUZER GMBKH KO KG

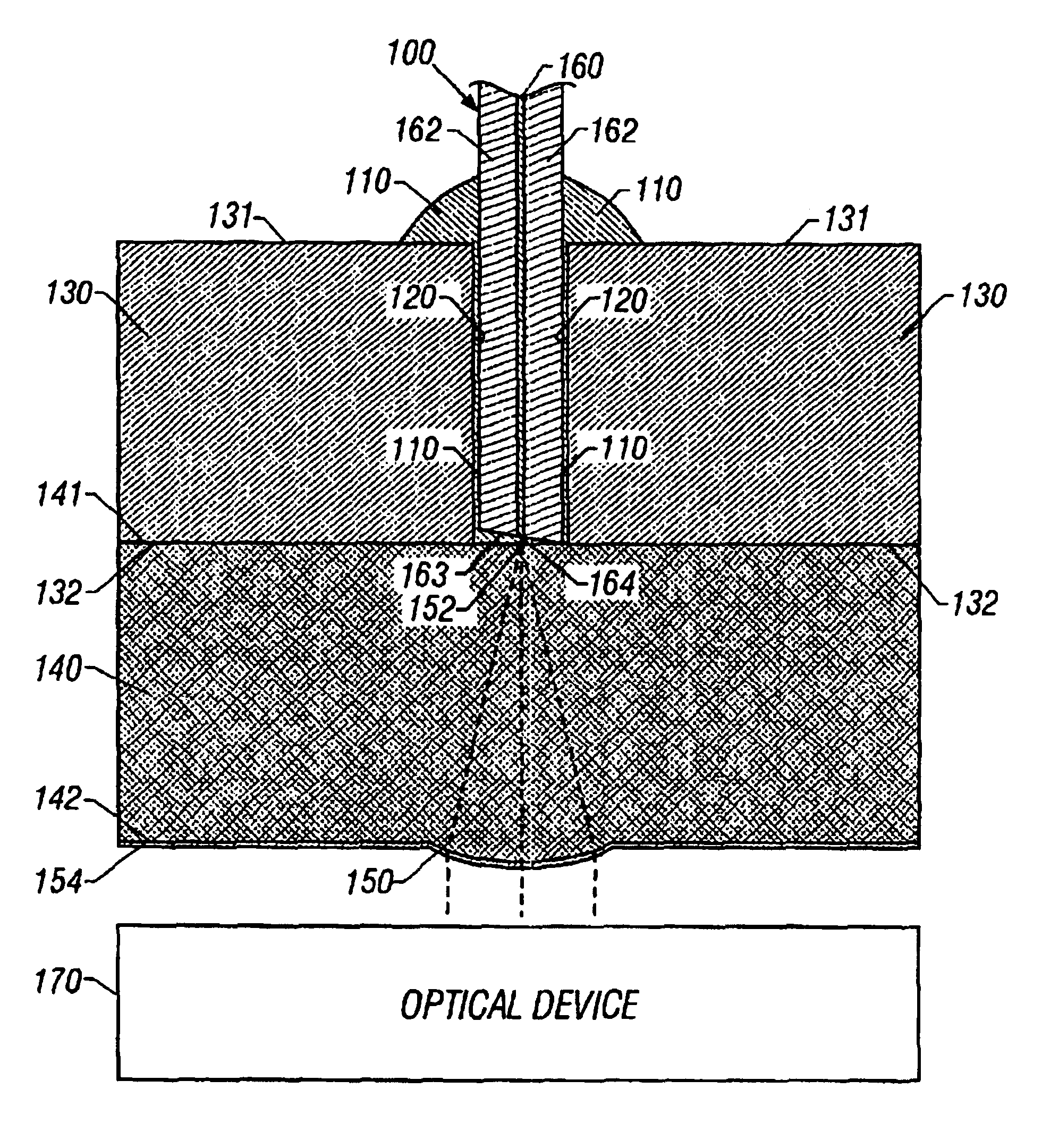

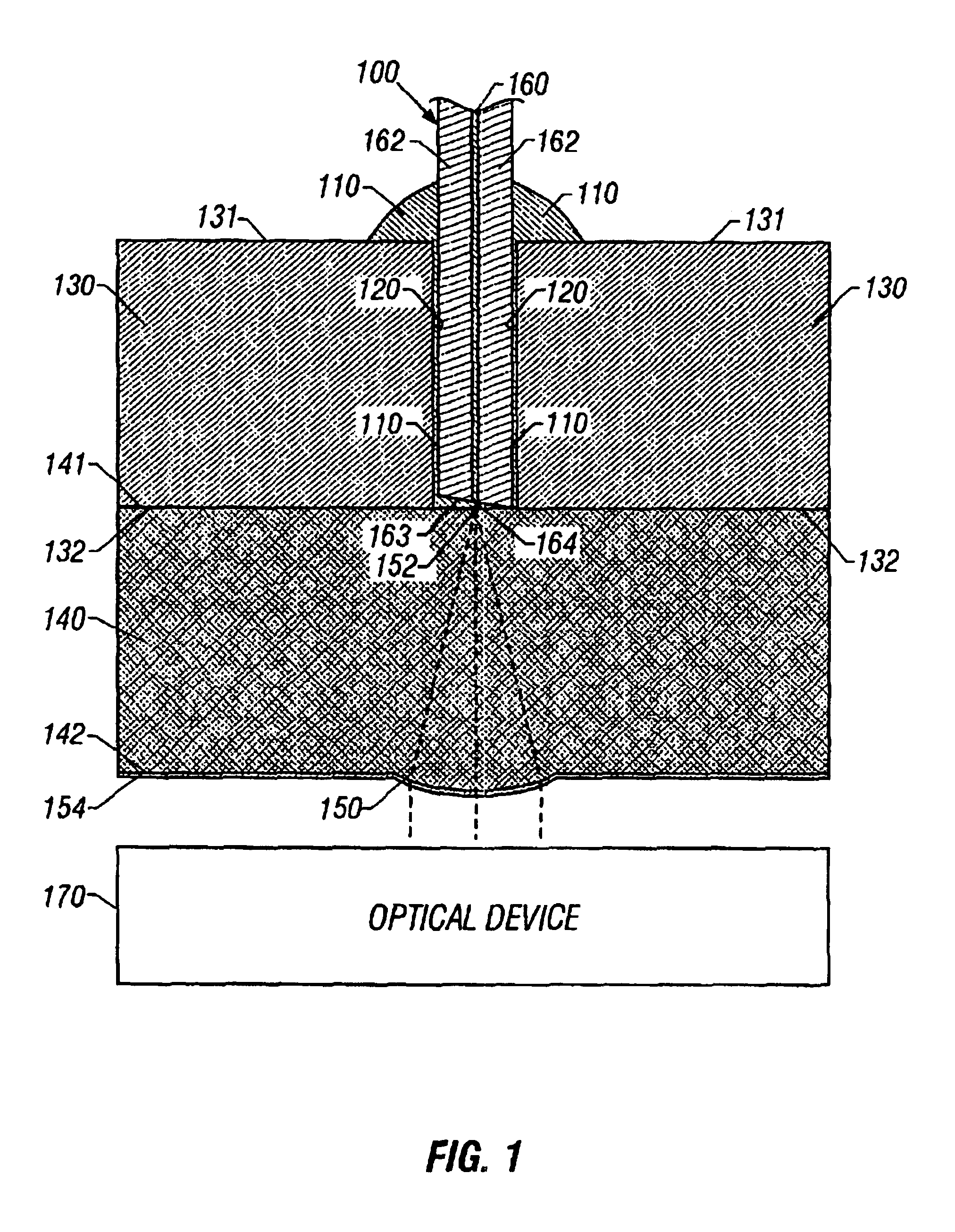

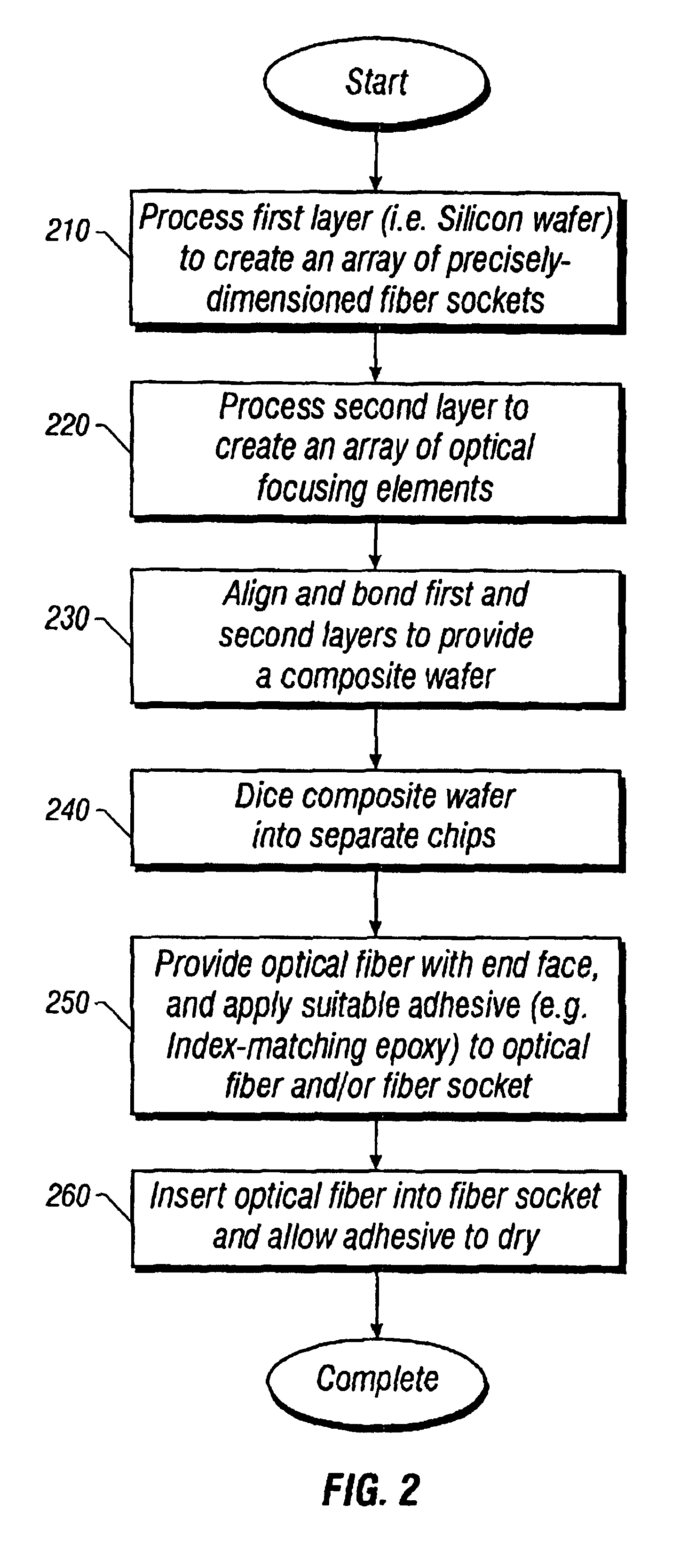

Multilayer optical fiber coupler

InactiveUSRE40416E1Precise optical alignmentAccurately alignCoupling light guidesSecondary layerOpto electronic

A multilayer optical fiber coupler for coupling optical radiation between an optical device and an optical fiber, including a first layer that has a fiber socket formed by photolithographic masking and etching to extend through said first layer, and a second layer bonded to the first layer. The first layer may comprise substantially single-crystal silicon. An optical fiber is inserted into the fiber socket to align the optical fiber precisely within the fiber socket. In one embodiment the optical fiber is a single mode fiber, and an optical focusing element formed on the second layer is aligned with the core of the single mode fiber. The second layer may comprise glass having an index of refraction that approximately matches the index of the optical fiber, and an optical epoxy is used to affix the optical fiber into the fiber socket and fill the gaps between the end face of the fiber and the second layer. Embodiments are disclosed in which an optical device such as a VCSEL or photodetector is bonded to the second layer. Alternative embodiments are disclosed in which the optical device is incorporated into the second layer. Advantages include reduced cost due to batch fabrication techniques, and passive alignment of the optical fiber.

Owner:JIAN BENJAMIN

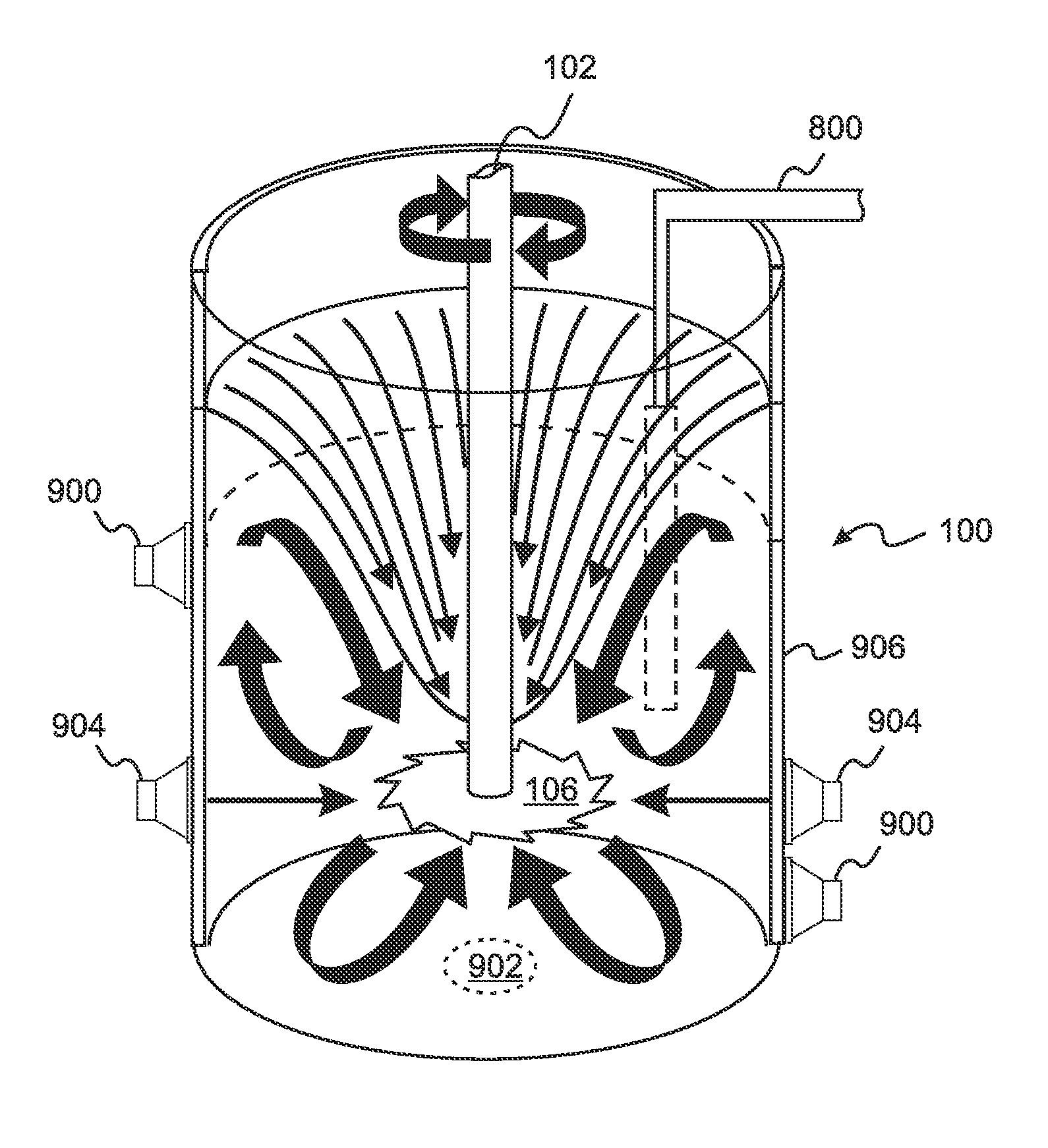

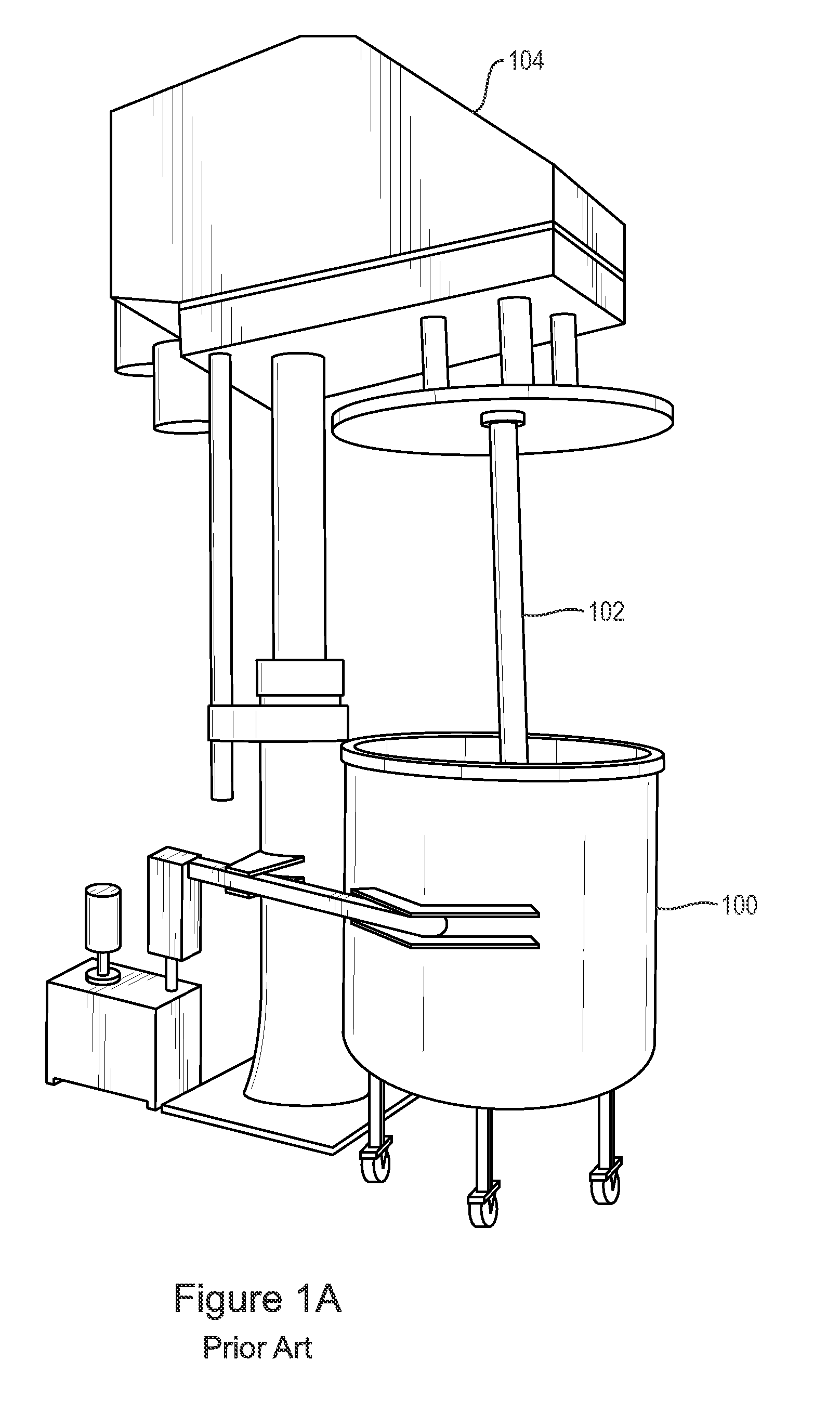

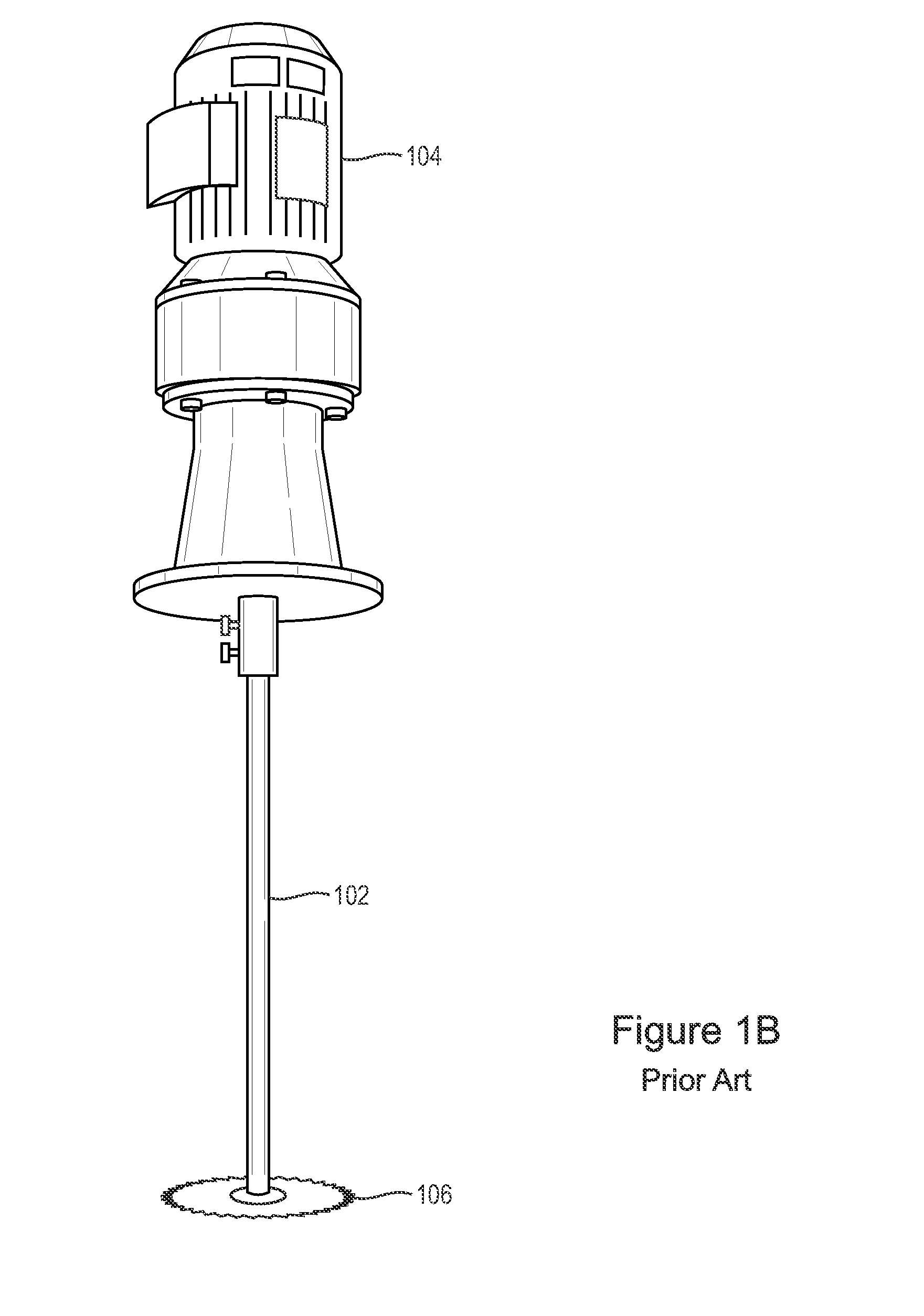

Vibration-assisted apparatus for mixing immiscible liquids and for mixing powders with liquids or with other powders

InactiveUS20150224460A1Effectively and quickly mixedLow viscosityRotating receptacle mixersShaking/oscillating/vibrating mixersImpellerAcoustic energy

A batch or continuous mixer for mixing powders, immiscible liquids, or a powder with a liquid includes one or more vibrational energy applicators which propagate vibrational energy into the mixture, causing powders to flow like liquids and breaking up liquid droplets and powder clumps. In embodiments, the vibration frequency and amplitude are selected according to properties of the mixture components. Vibrations can be propagated through container walls, impellers, or other structures within the mixing container. Vibrated structures can be flexibly supported for enhanced propagation of the vibrations. Vibrational energy can be uniform throughout the container, or focused in a desired region. Ultrasonic energy can be simultaneously applied with acoustic energy.

Owner:BANUS CHRISTOPHER T

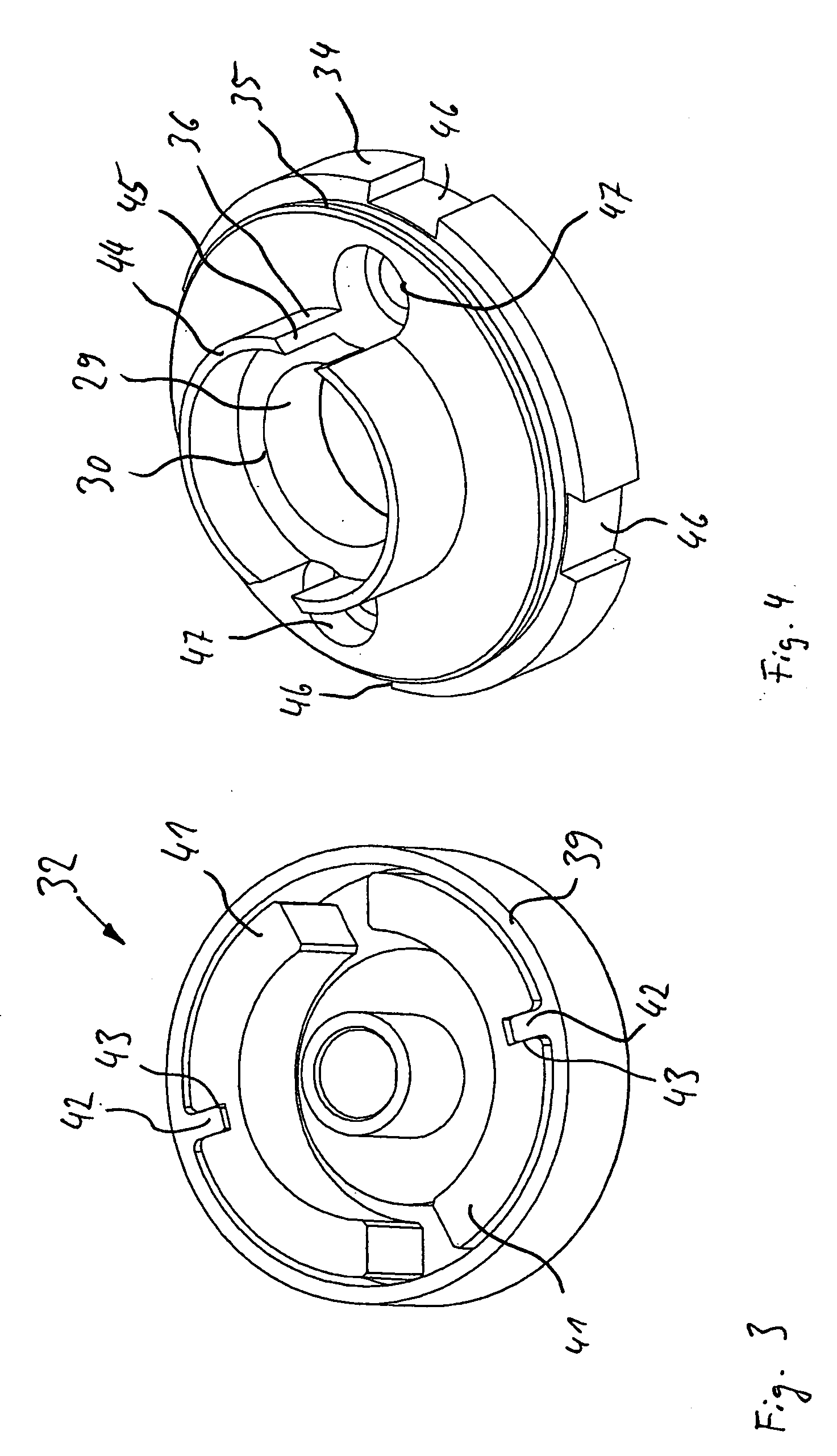

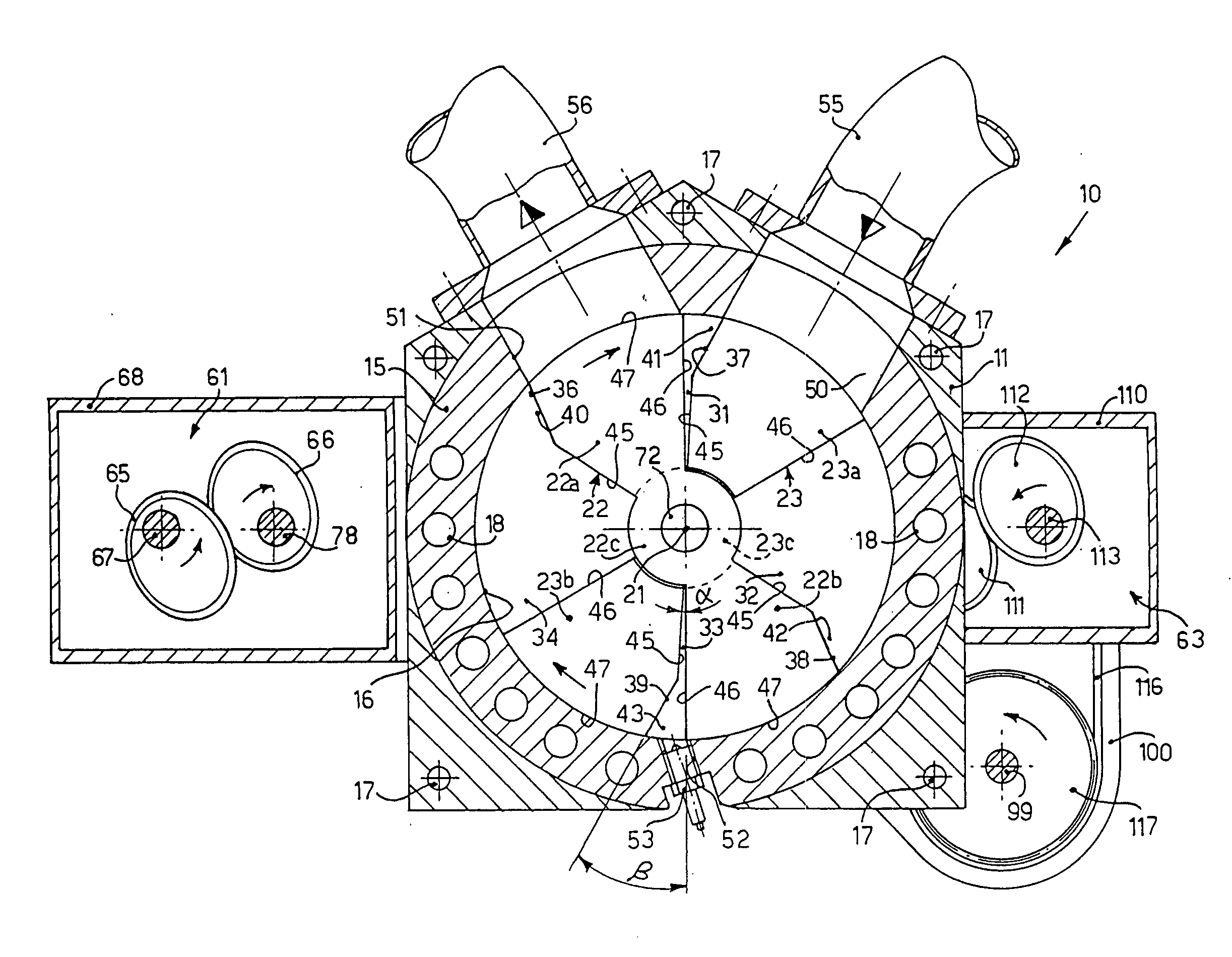

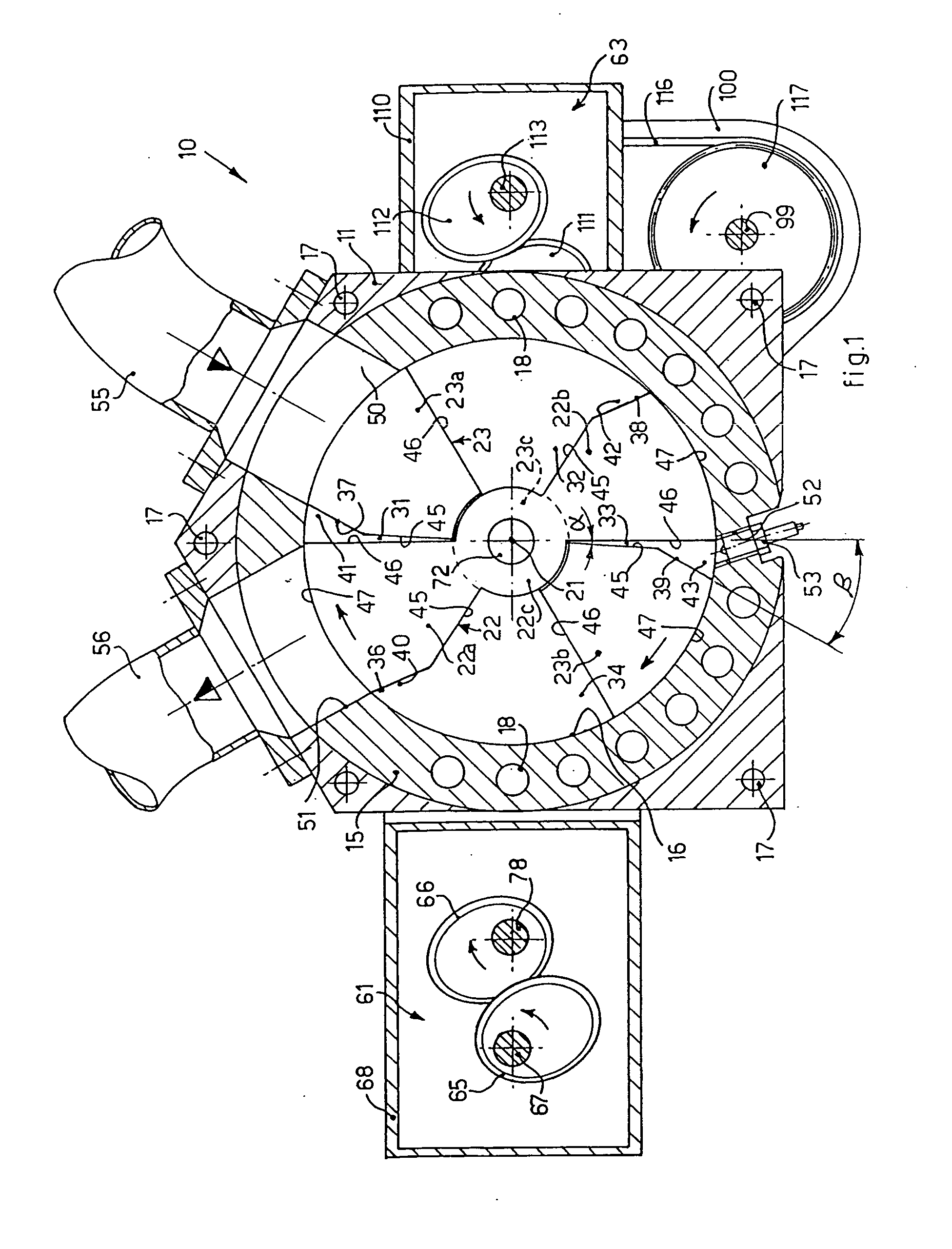

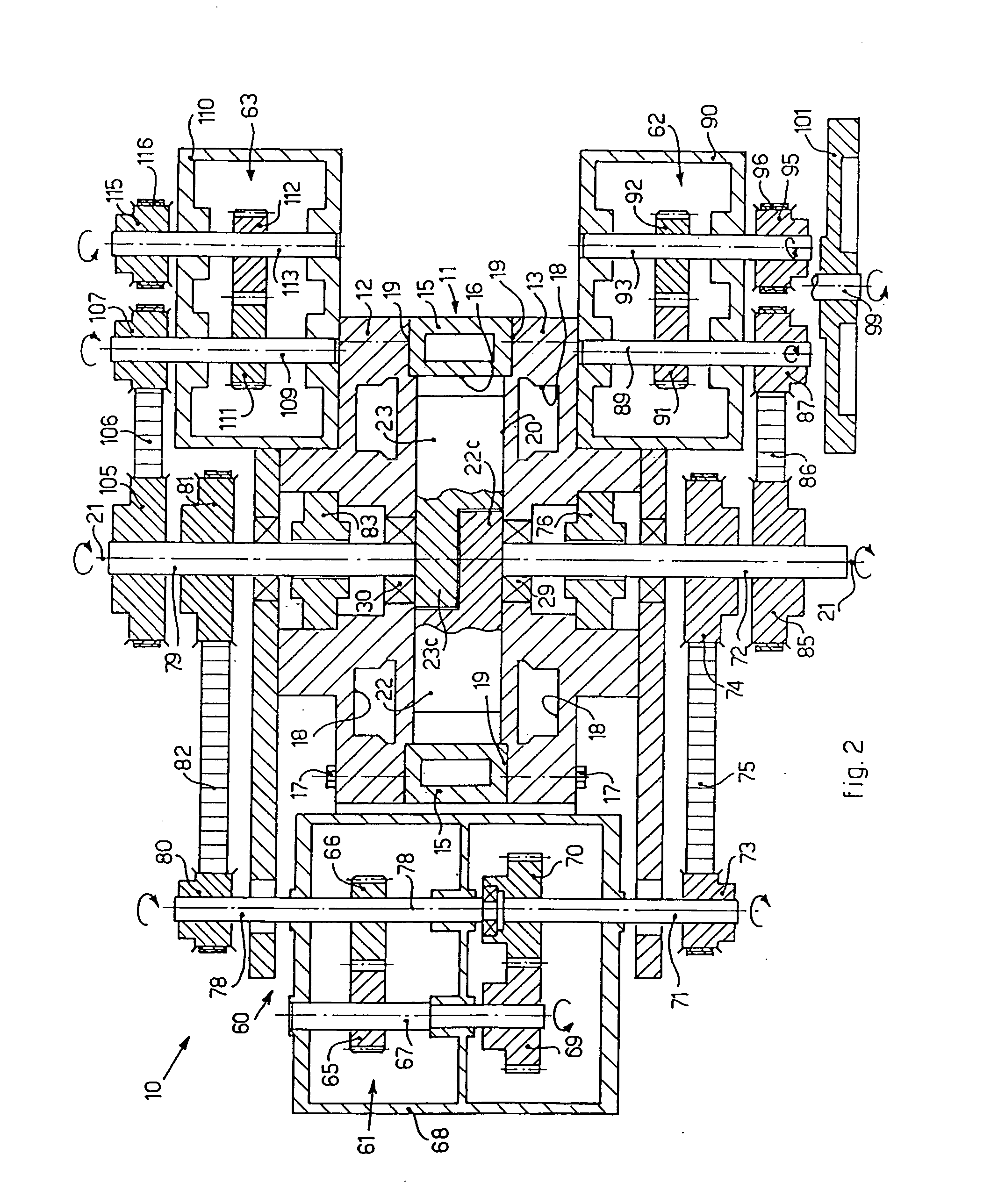

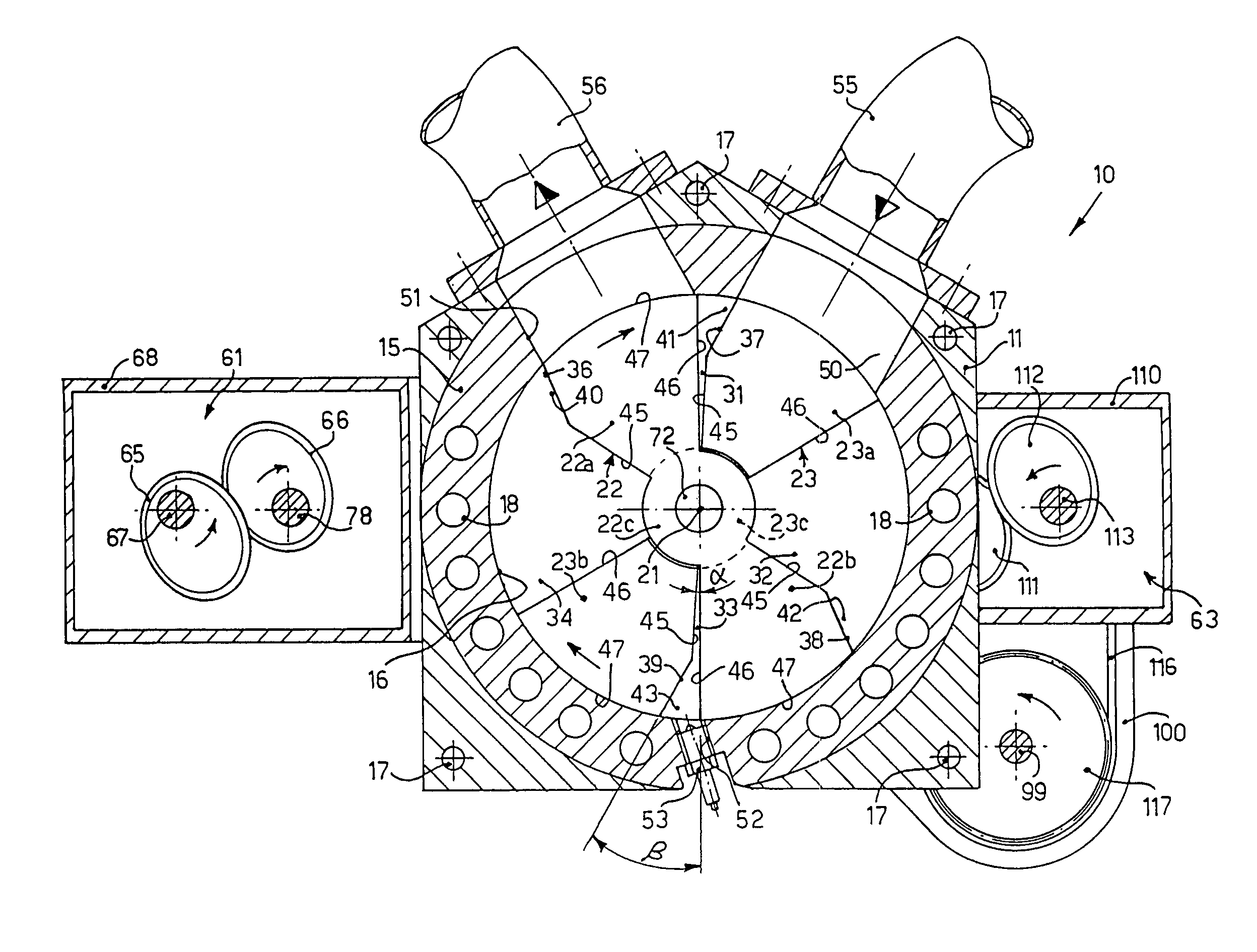

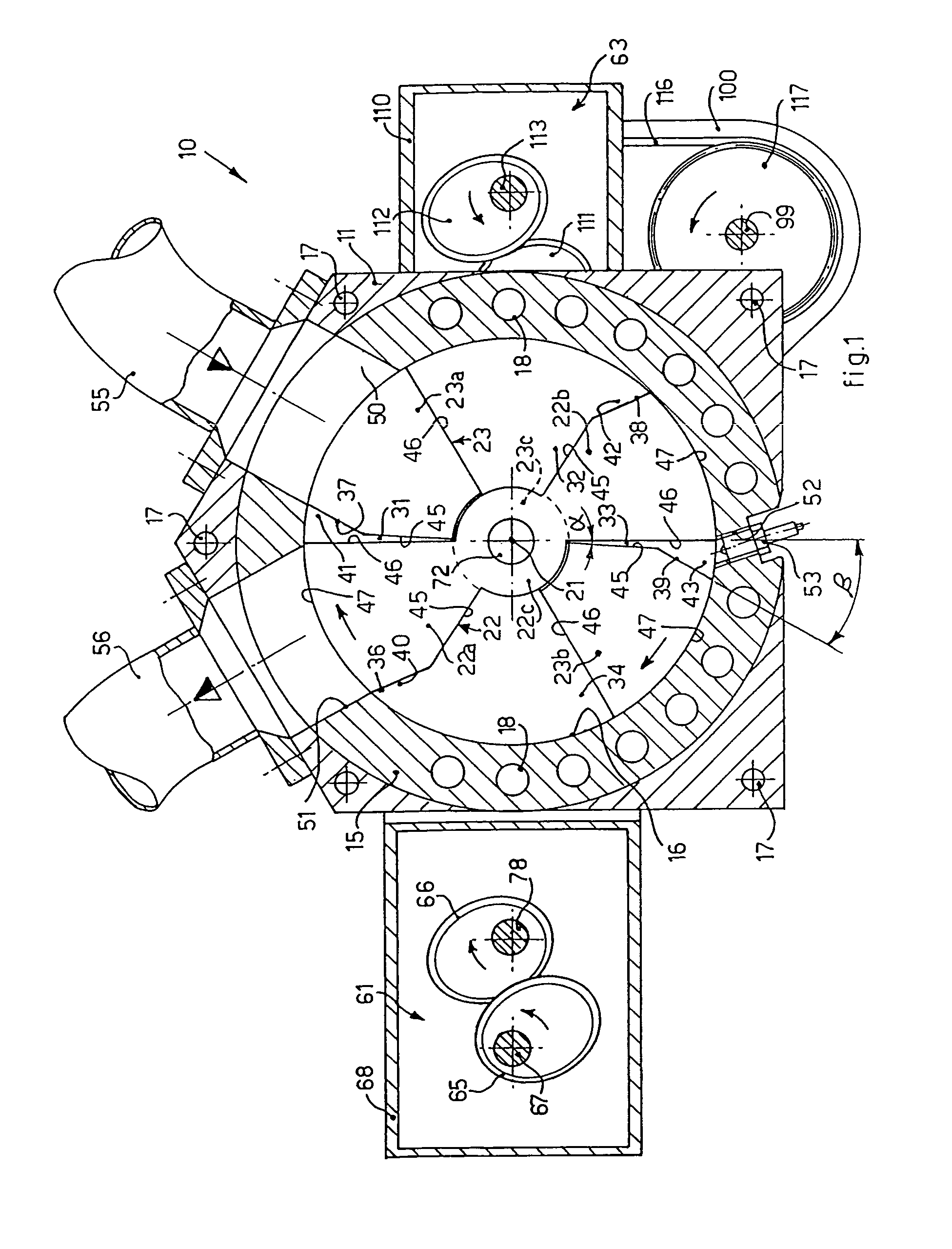

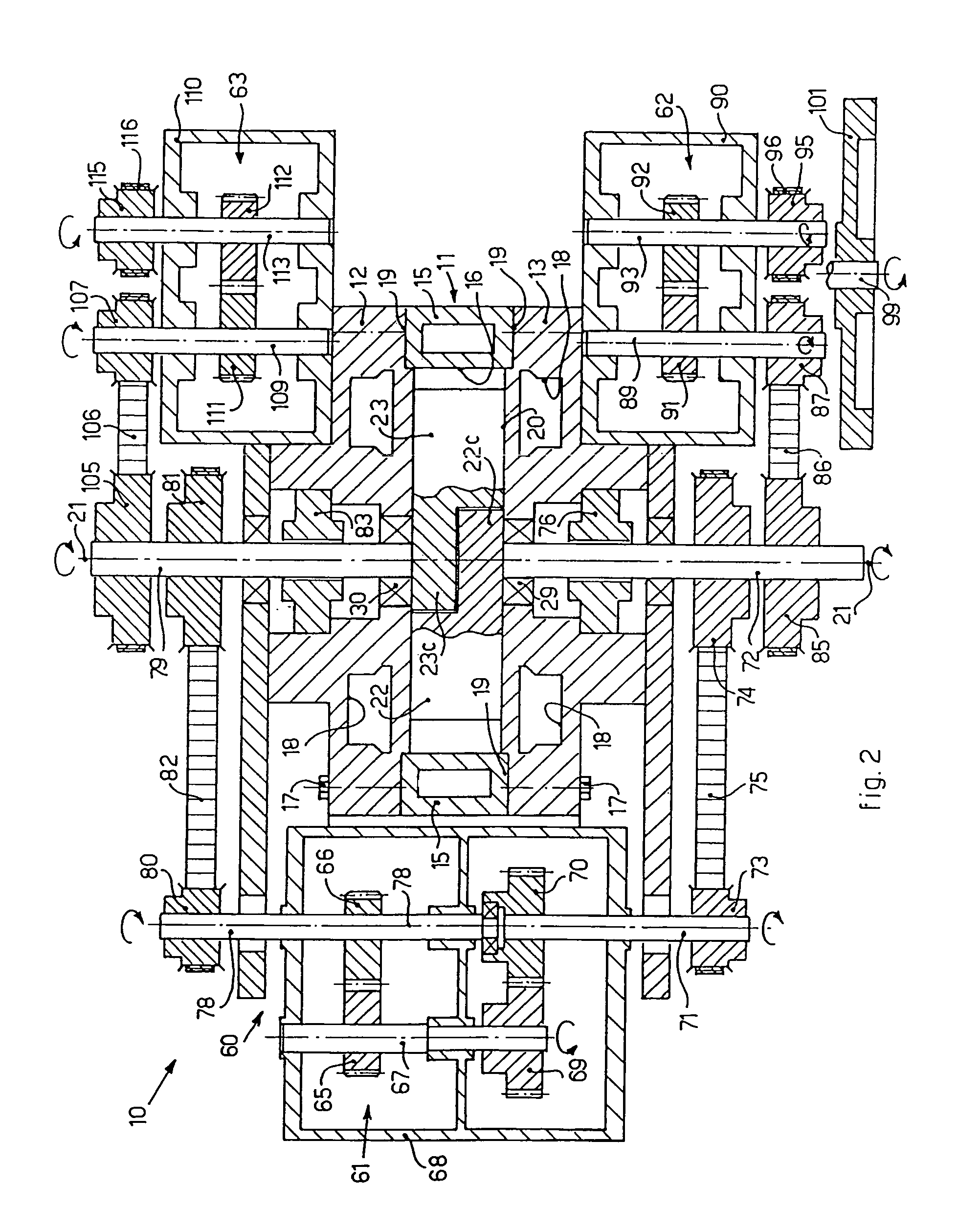

Rotary piston combustion engine

ActiveUS20100139612A1Promote formationMove preciselyInternal combustion piston enginesOscillating piston enginesCombustion chamberAngular velocity

Combustion engine (10) comprising a stator (11) provided with a compartment (16), inside which a rotor (20) is mounted rotatable, which comprises two parts (22, 23) each comprising a peripheral surface (47) and articulated one with respect to the other and both mounted rotatable, around the same axis of rotation (21) substantially coaxial with the compartment (16). The combustion engine (10) comprises kinematisms (60) to coordinate cyclically the rotations of the two parts (22, 23) around the axis of rotation (21), so that each of the parts (22, 23) accelerates or decelerates synchronously with respect to the other, while still both rotating in the same direction and at the same average angular velocity. Each part (22, 23) comprises a first radial arm (22a, 23a, 22b, 23b) provided with a first lateral surface (45) orthogonal to the plane of rotation, to cooperate cyclically with a corresponding second lateral surface (46), also substantially orthogonal to the plane of rotation, a second adjacent radial arm (22a, 23a, 22b, 23b) to define a combustion chamber (31, 32, 33, 34). The first lateral surface (45) comprises a bevel (36, 37, 38, 39) oriented in the direction of the rotation, to define, with the second lateral surface (46) of the adjacent radial arm (22a, 23a, 22b, 23b), a combustion pre-chamber (40, 41, 42, 43) continuous with the combustion chamber (31, 32, 33, 34).

Owner:VALMAX

PLGA/HA hydroxyapatite composite bone grafts and method of making

InactiveUS9005286B2Fastly and highly and uniformly coatedGood at propagatingImpression capsBone implantGlycolic acidBioceramic

The present invention involves tissue engineering constructs made from a new composite bone graft material made from biocompatible poly(D,L-lactic-co-glycolic acid) (PLGA) and bioceramic particles exposed on its surface using a gas foaming particle leaching (GF / PL) method and infused with collagen. Methods and apparatus for of forming scaffolds are also disclosed.

Owner:THIERRY GIORNO

Unbuffered memory system

InactiveUS6873533B2Good at propagatingSimplified wiring layoutMemory adressing/allocation/relocationDigital storageComputer moduleChipset

A memory module of the unbuffered type with ECC function is employed. Configuration of an internal C / A bus is set to a single T-branch topology. An output impedance of a chipset is maintained substantially constant. A capacitor for cutting high-frequency components of a C / A signal is added on a C / A bus.

Owner:LONGITUDE LICENSING LTD

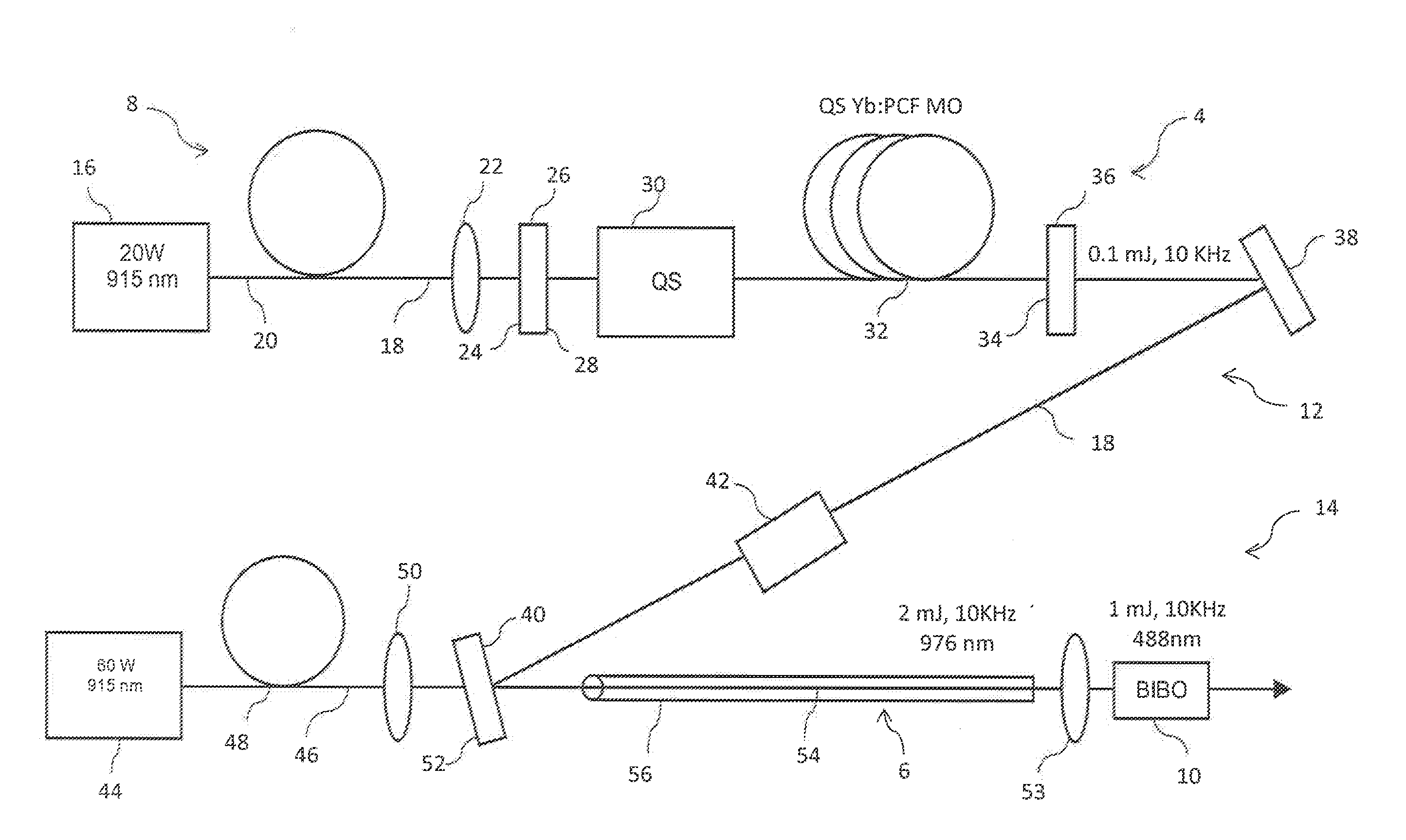

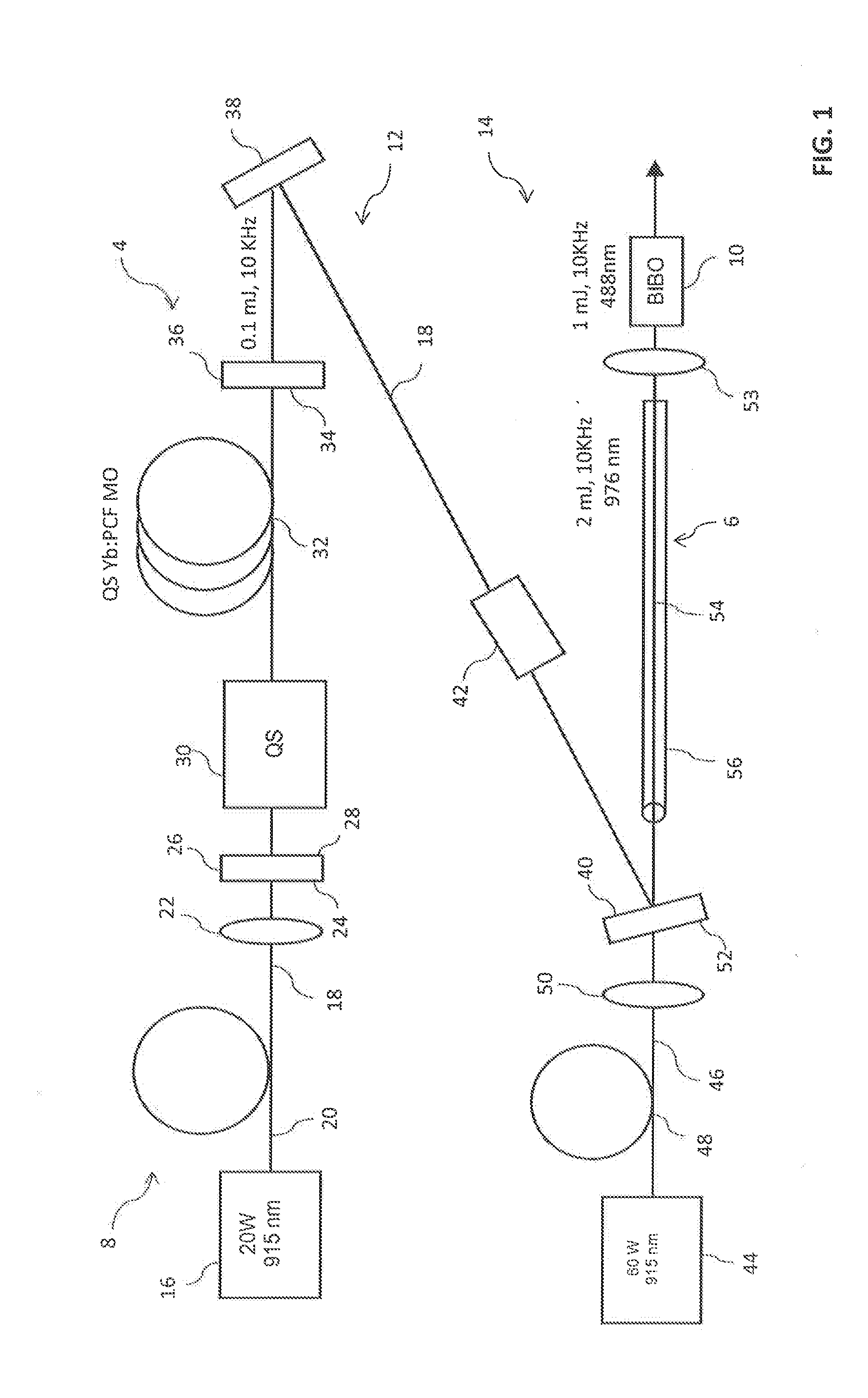

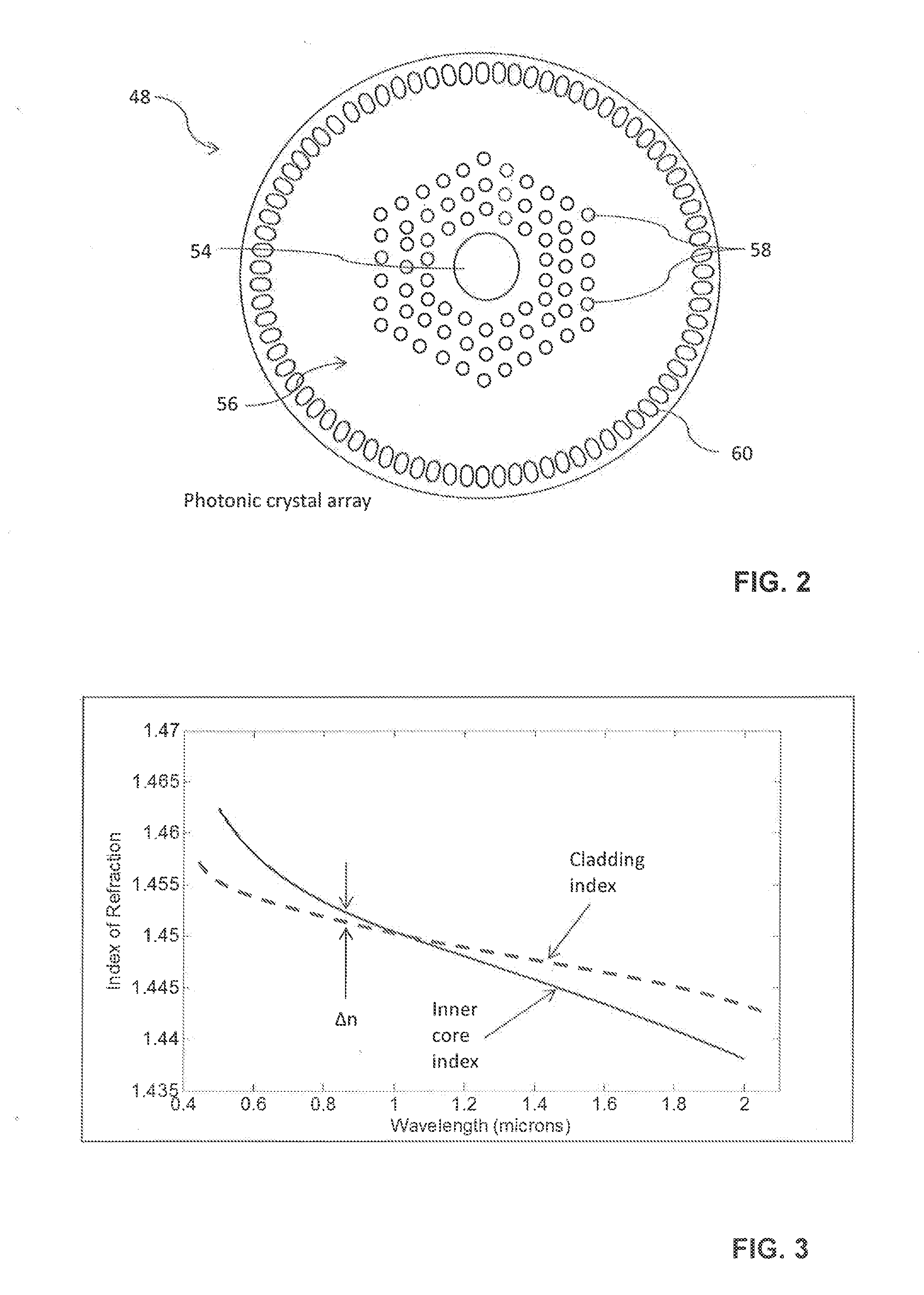

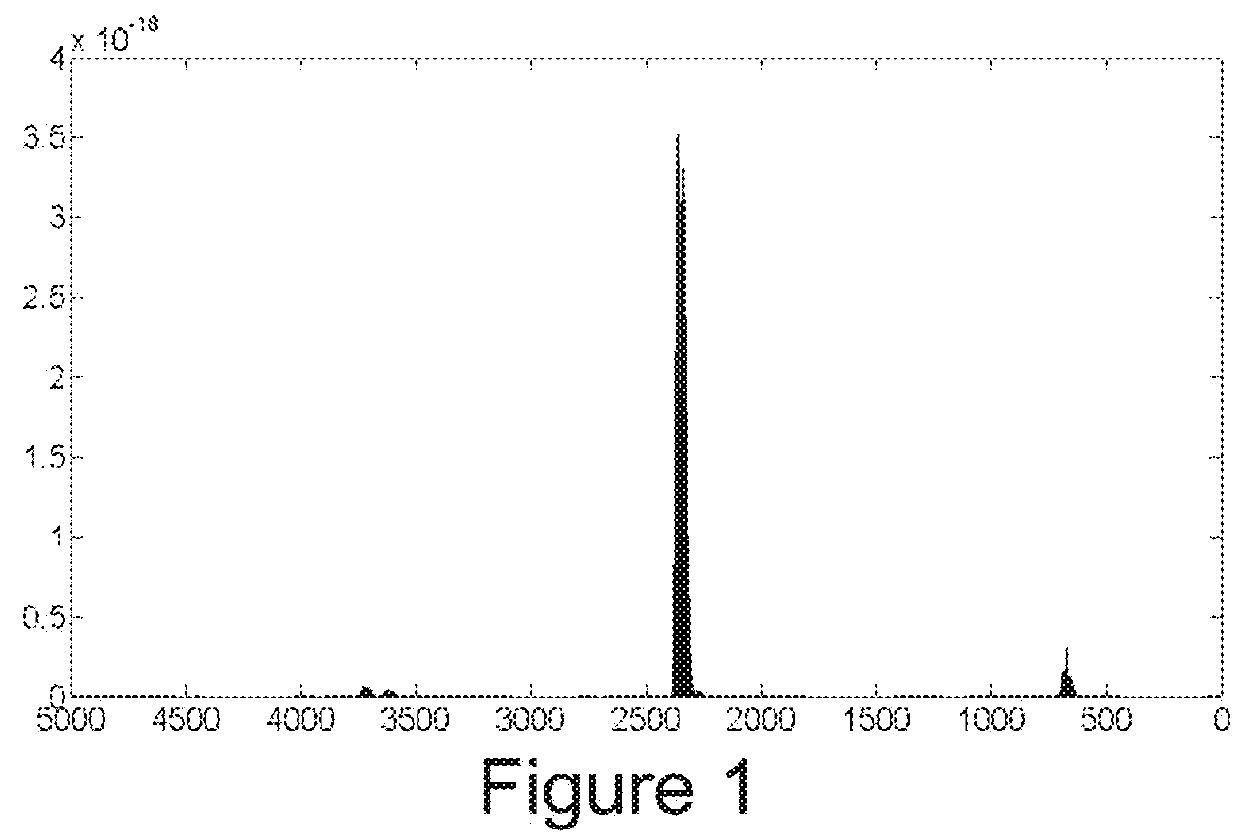

Phosphate photonic crystal fiber and converter for efficient blue generation

ActiveUS20160099539A1Favorable gain propertyImprove featuresActive medium shape and constructionLight demodulationOptoelectronicsPhosphate glass

In the method for generating blue laser light with high optical and electrical efficiency, wherein the improvement comprises the step of using a phosphate glass photonic crystal fiber rod as a gain medium.

Owner:BAE SYST INFORMATION & ELECTRONICS SYST INTERGRATION INC

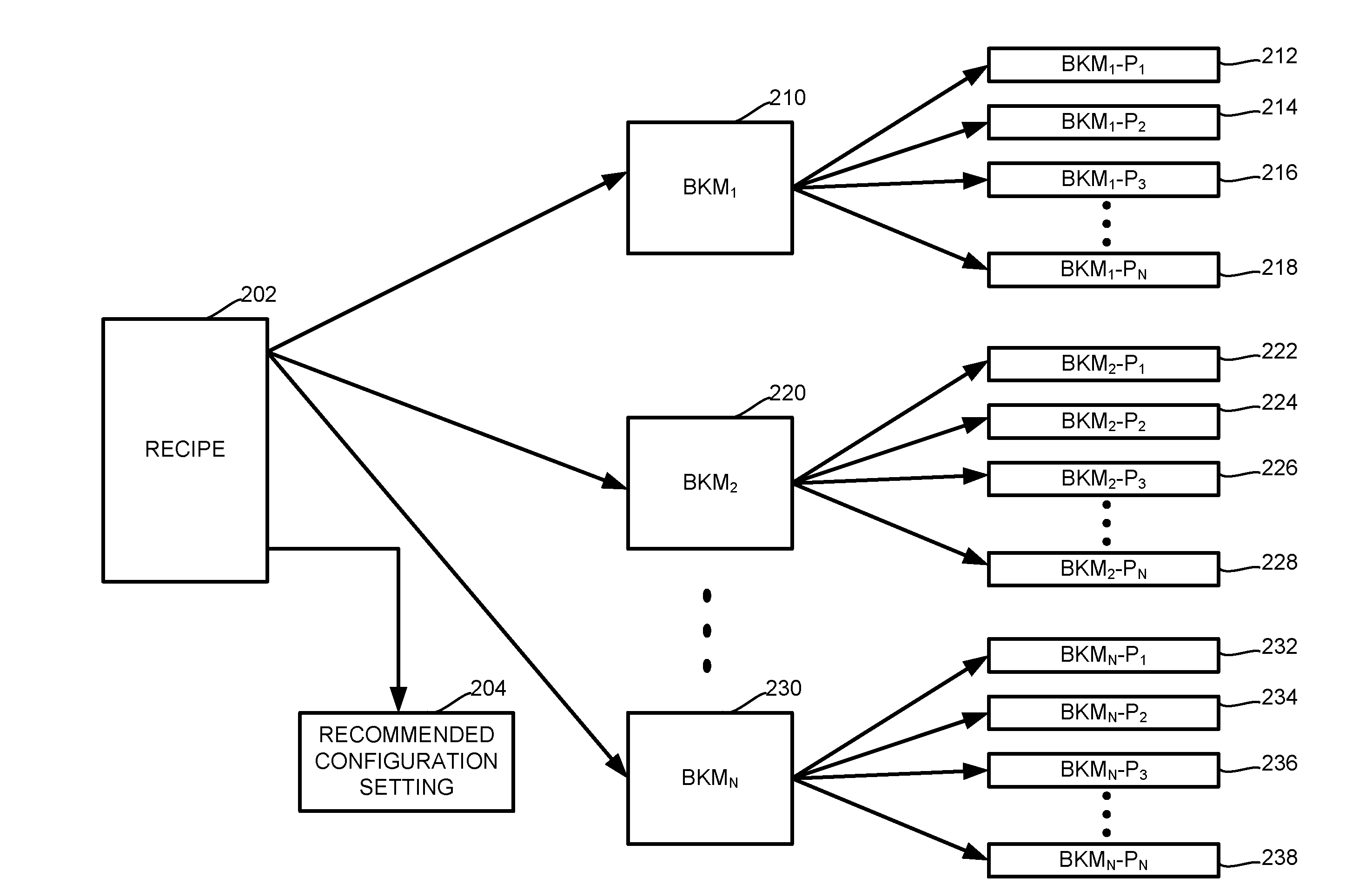

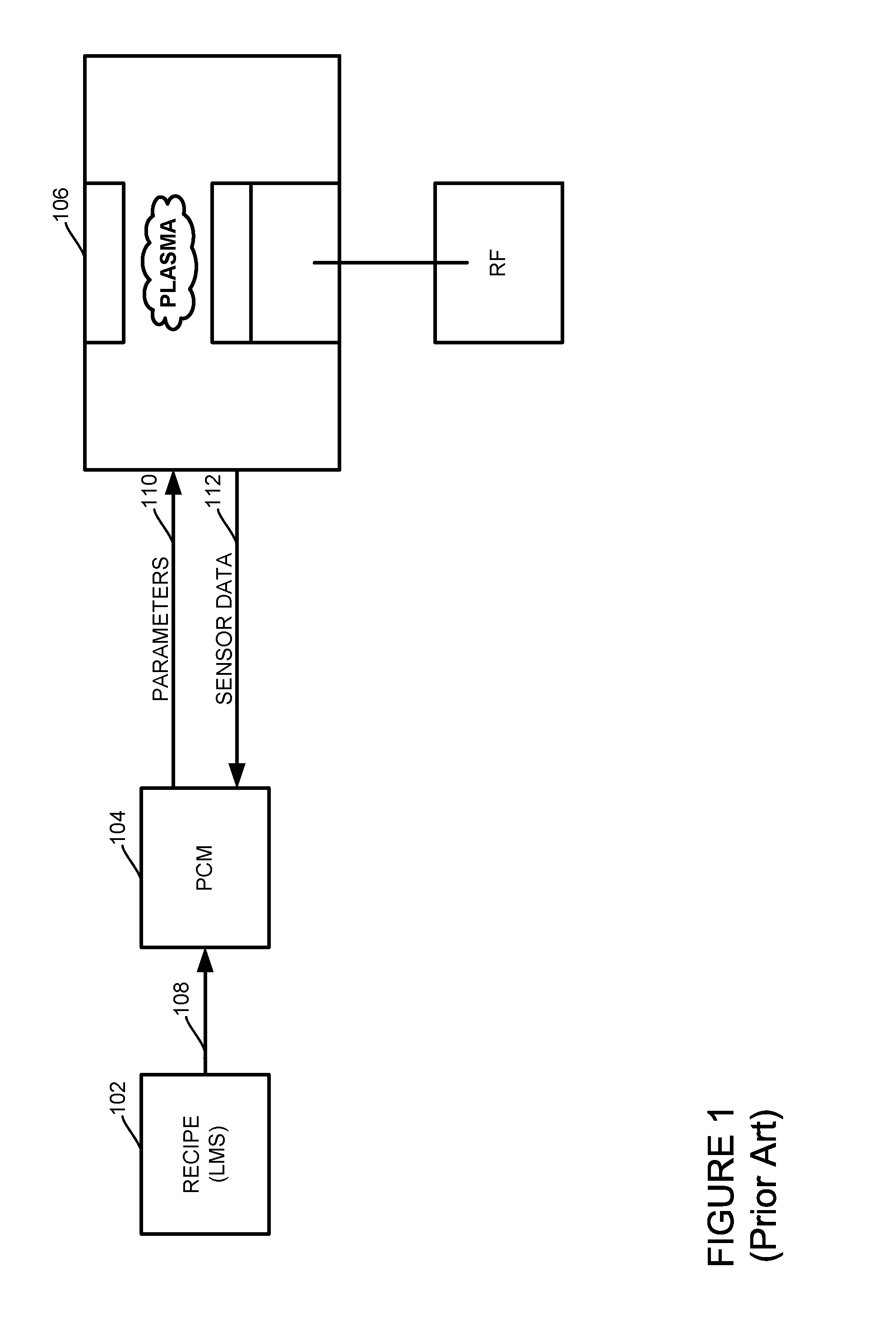

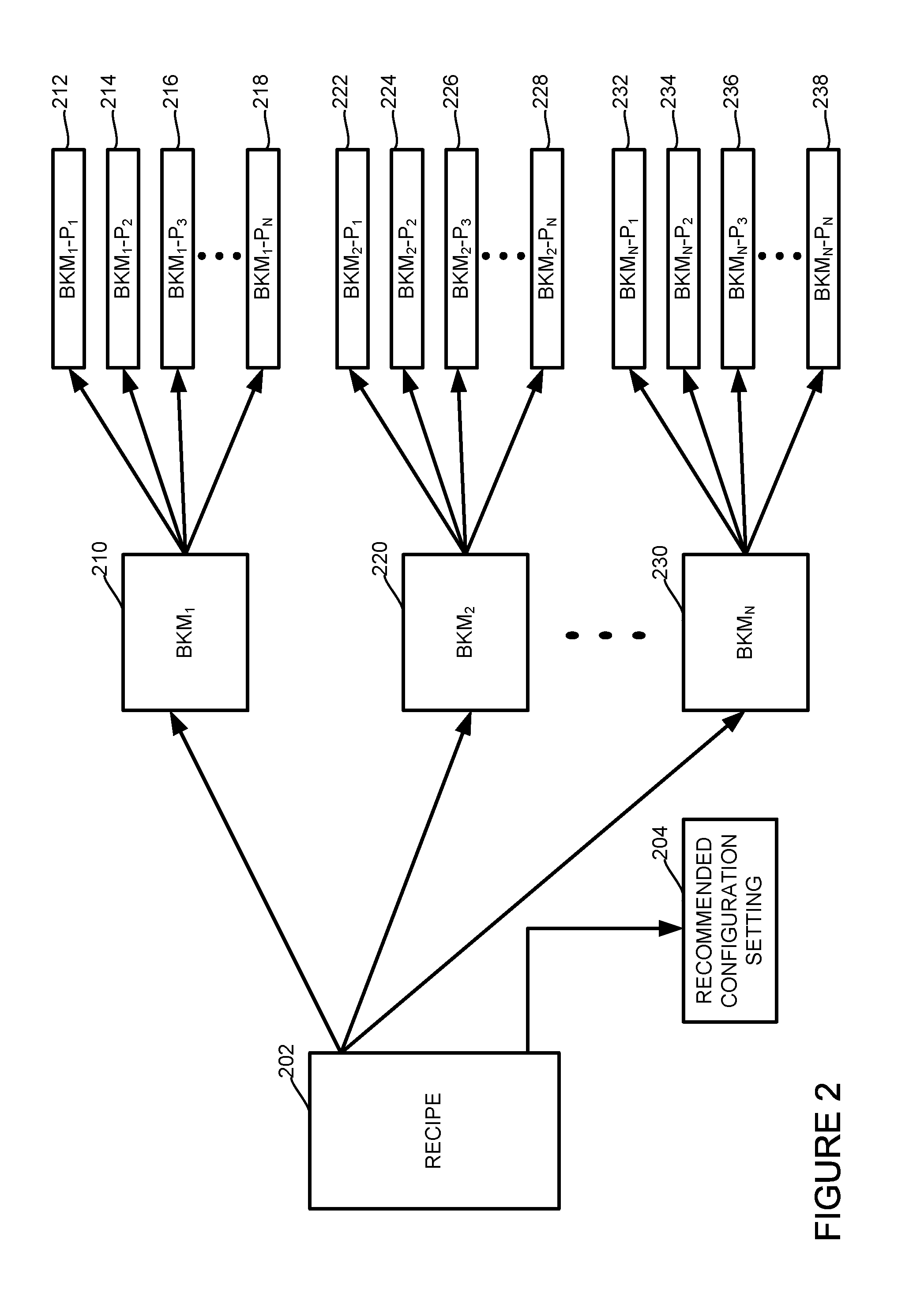

Methods and Arrangement for Creating Recipes Using Best-Known Methods

ActiveUS20080188970A1Good at propagatingProgramme controlSemiconductor/solid-state device manufacturingGuidelineGood practice

A method for affecting a creation of a recipe for processing a substrate in a processing system is provided. The method includes providing a best-know method driven recipe editor. The best-known method driven recipe editor incorporates best-known methods (BKMs), which are best practice specifications for the recipe. The method also includes creating a plurality of BKM modules based on the BKMs for the recipe. The method further includes defining rules for parameters in the plurality of BKM modules. The rules are propagated by the BKMs. The methods moreover includes creating a BKM driven recipe by employing the best-known method driven recipe editor to enter values for the parameters within the guidelines of BKM rules.

Owner:LAM RES CORP

Ball with positioning system

InactiveUS8876008B2Low costPrevent subsequent tearingGymnastic exercisingGolf ballsEngineeringDipole antenna

A ball (1) for use in a sporting activity can comprise a body having an electrical circuit (21) on a flexible substrate (20) received therein. The electrical circuit (21) comprises a dipole antenna (26) integrally formed with the electrical circuit (21) on the flexible substrate (20). The dipole antenna can comprise two arms (23, 24) each folded in a semi-circular shape.

Owner:PRAZZA

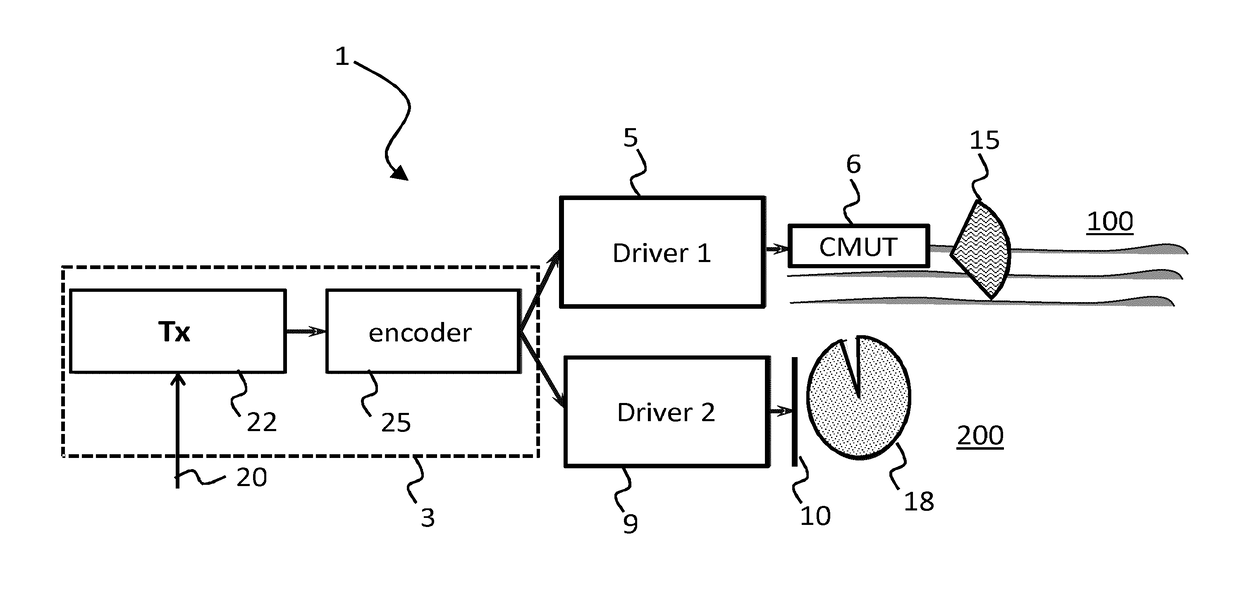

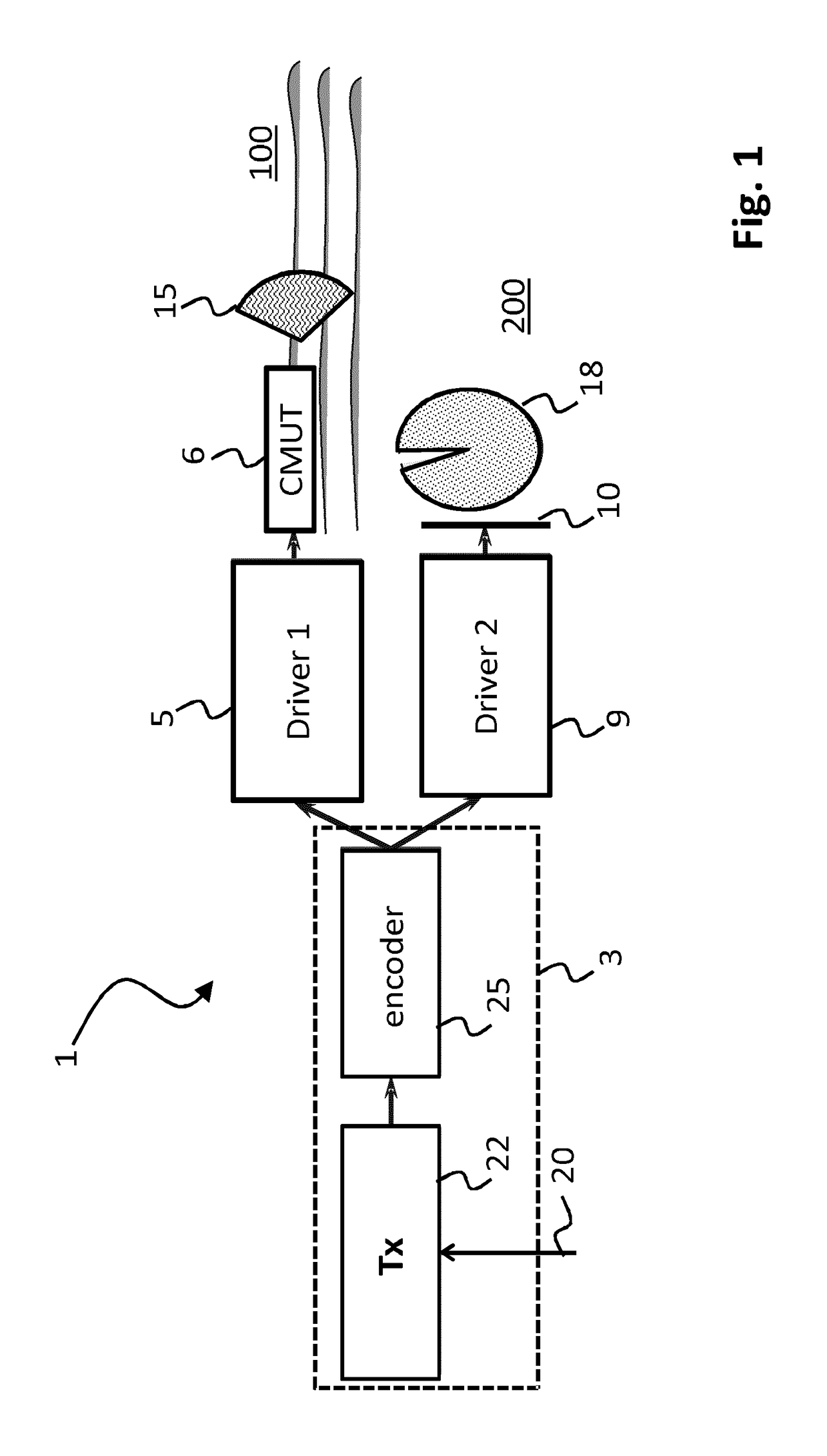

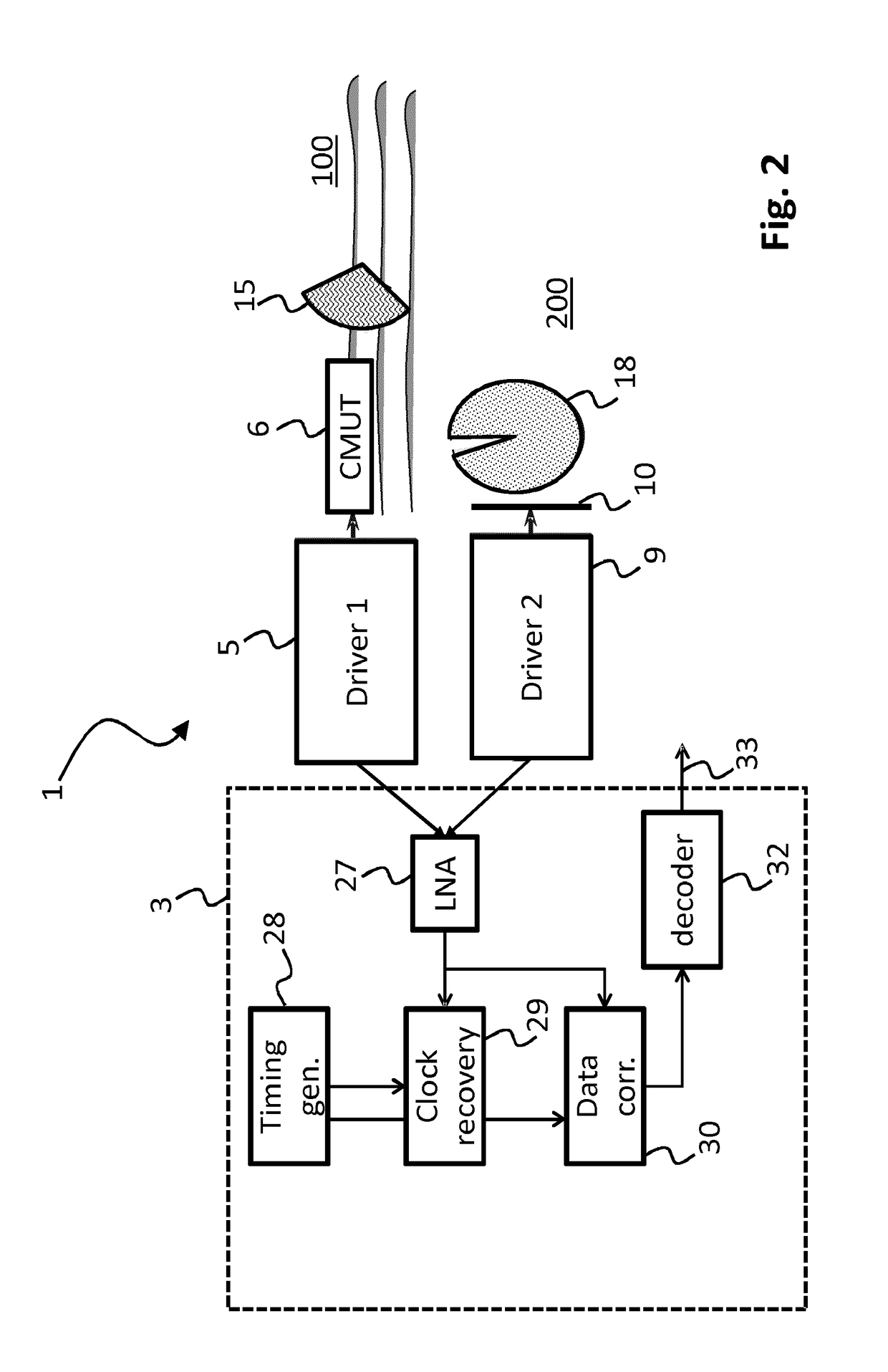

Communication device and system for performing data communication using a human or animal body as transmission medium

InactiveUS20170244495A1Avoid accumulationImprove signal-to-noise ratioPower managementTransmissionTransceiverUser device

The invention is directed at a communication device for performing data communication using a human or animal body as transmission medium. The communication device comprises a transceiver unit comprising at least one of a transmitter and a receiver. The communication device also comprises an electrostatic transducer for enabling data communication via a surface of the body with one or more user devices in touch with or located near (i.e. in close proximity, e.g. within a range of 0-10 mm therefrom) the body. The communication device further comprises an ultrasonic transducer for enabling data communication through the body using ultrasonic waves. Both the electrostatic transducer and the ultrasonic transducer are capacitive type transducers connected to and operated via the transceiver unit.

Owner:KONINKLJIJKE PHILIPS NV

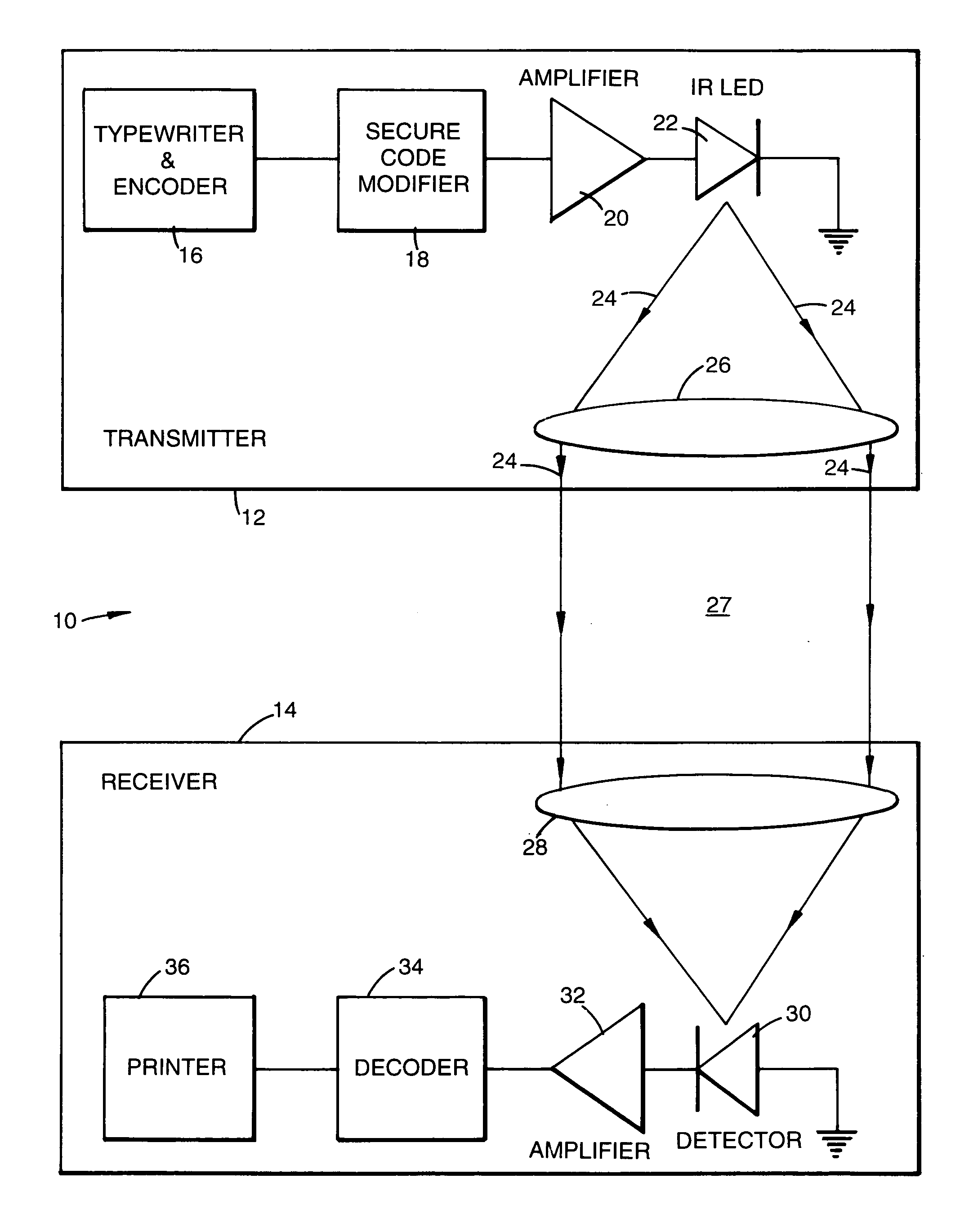

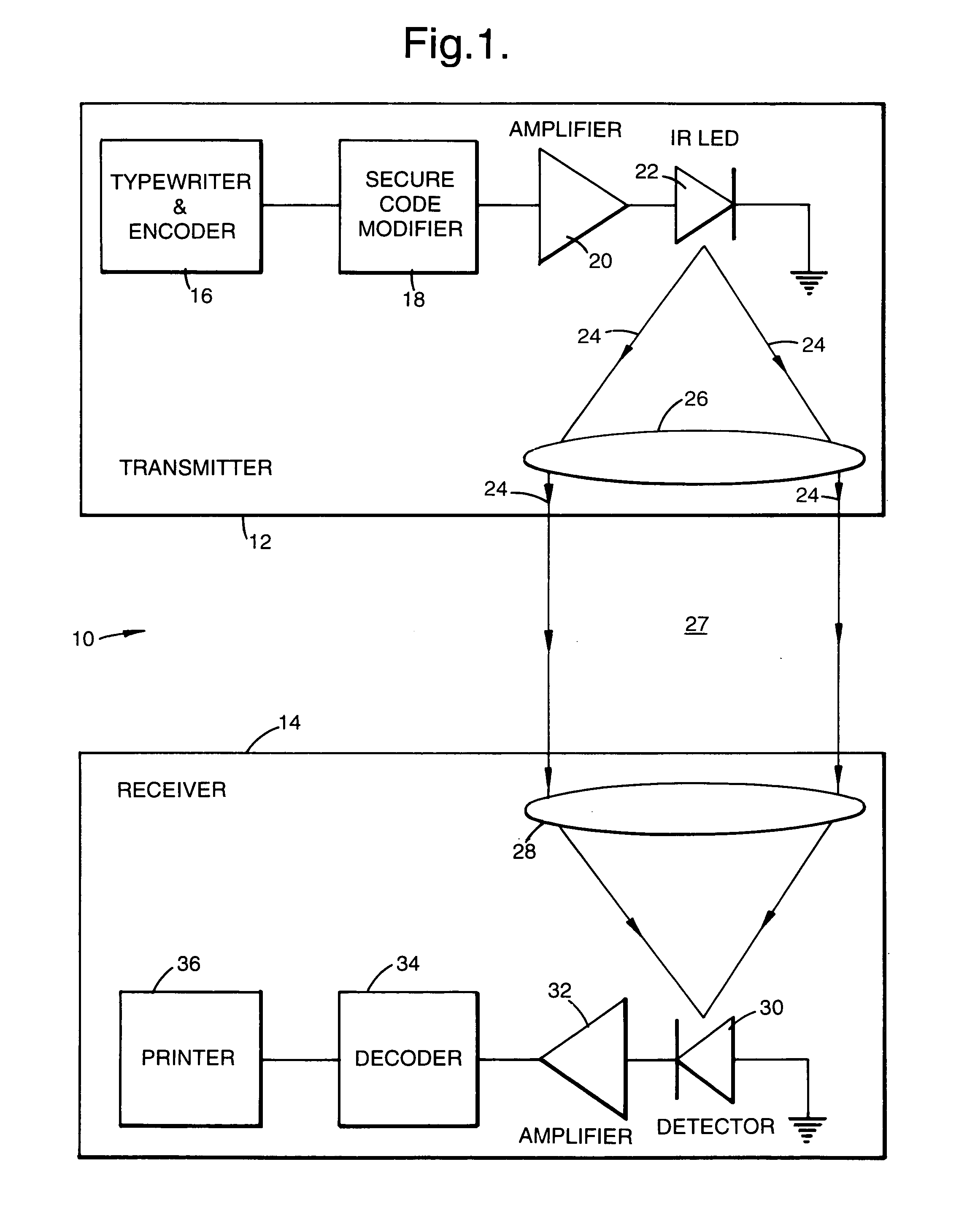

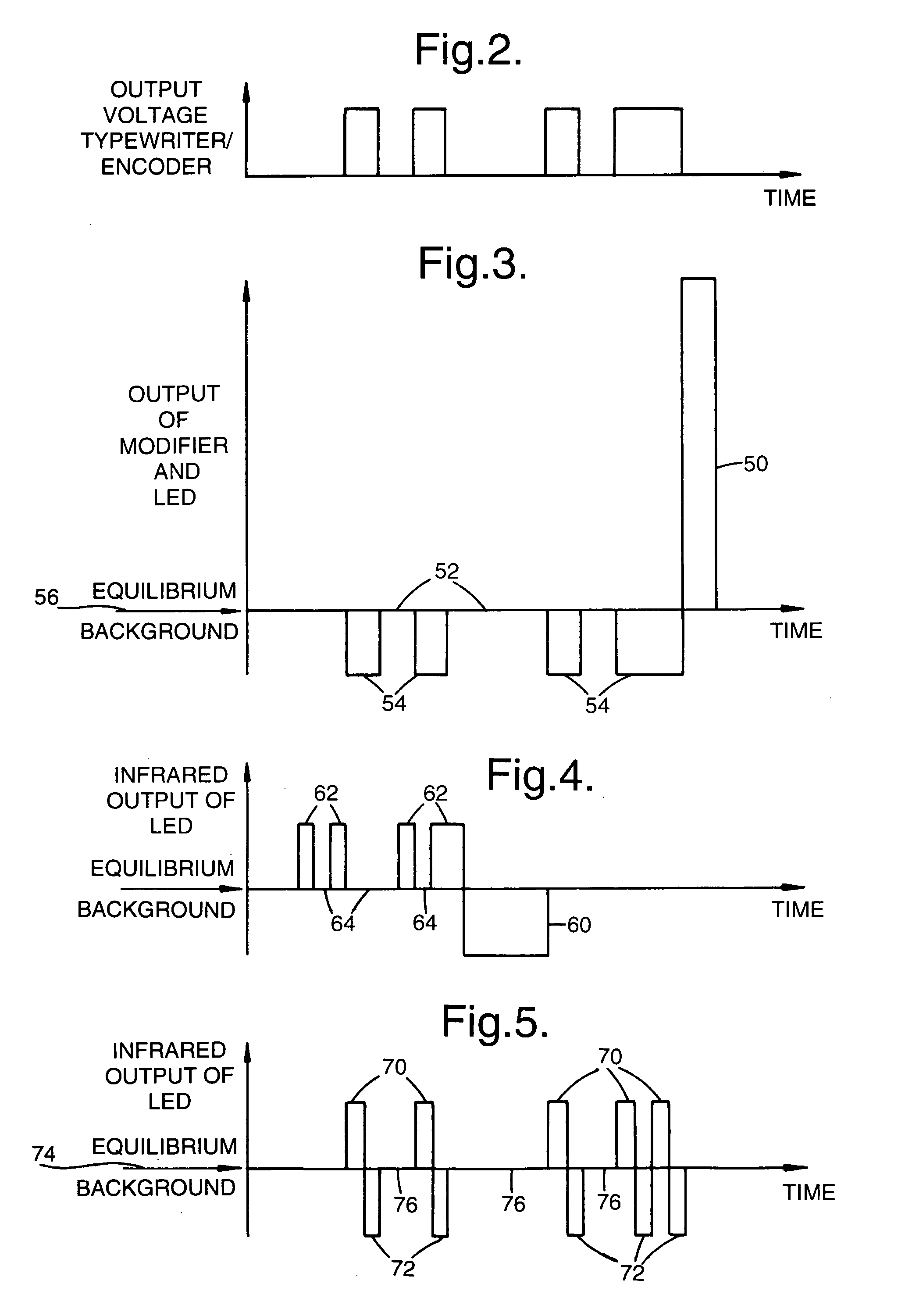

Communications system

InactiveUS7639950B1Keep for a long timeGood at propagatingLine-of-sight transmissionNon-linear opticsCommunications systemAudio power amplifier

A communications system incorporates a transmitter a receiver. The transmitter includes an infrared light emitting diode (LED). The LED output is positive or negative luminescence, i.e. above or below an equilibrium background intensity level respectively, according to the polarity of its bias signal. The receiver contains a lens to focus light from the LED onto a diode detector, from which signals pass to an amplifier, decoder and printer. Output signals from the LED have an average intensity equal to the equilibrium background intensity level and a frequency greater than 100 Hz or byte rate greater than 100 bytes / sec. They are not discernible by conventional thermal infrared imagers with frame rates of 50 Hz or less because integration in such an imager renders them indistinguishable from background.

Owner:QINETIQ LTD

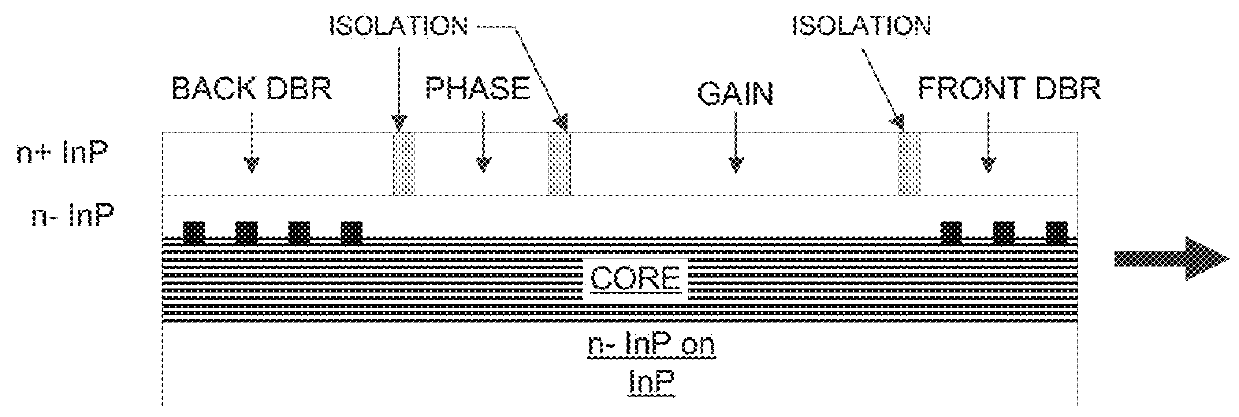

Passive waveguide structure with alternating GaInAs/AlInAs layers for mid-infrared optoelectronic devices

ActiveUS9231368B2Large band gapGood at propagatingOptical wave guidanceLaser detailsSemiconductor materialsButt joint

Disclosed is a semiconductor optical emitter having an optical mode and a gain section, the emitter comprising a low loss waveguide structure made of two alternating layers of semiconductor materials A and B, having refractive indexes of Na and Nb, respectively, with an effective index No of the optical mode in the low loss waveguide between Na and Nb, wherein No is within a 5% error margin of identical to a refractive index of the gain section and wherein the gain section is butt-jointed with the low loss waveguide, and wherein the size and shape of the optical mode(s) in the low loss waveguide and gain section are within a 10% error margin of equal. Desirably, at least one of the semiconductor materials A and B has a sufficiently large band gap that the passive waveguide structure blocks current under a voltage bias of 15 V.

Owner:THORLABS QUANTUM ELECTRONICS

Rotary piston combustion engine

ActiveUS8408179B2Promote formationMove preciselyInternal combustion piston enginesOscillating piston enginesCombustion chamberAngular velocity

Combustion engine (10) comprising a stator (11) provided with a compartment (16), inside which a rotor (20) is mounted rotatable, which comprises two parts (22, 23) each comprising a peripheral surface (47) and articulated one with respect to the other and both mounted rotatable, around the same axis of rotation (21) substantially coaxial with the compartment (16). The combustion engine (10) comprises kinematisms (60) to coordinate cyclically the rotations of the two parts (22, 23) around the axis of rotation (21), so that each of the parts (22, 23) accelerates or decelerates synchronously with respect to the other, while still both rotating in the same direction and at the same average angular velocity. Each part (22, 23) comprises a first radial arm (22a, 23a, 22b, 23b) provided with a first lateral surface (45) orthogonal to the plane of rotation, to cooperate cyclically with a corresponding second lateral surface (46), also substantially orthogonal to the plane of rotation, a second adjacent radial arm (22a, 23a, 22b, 23b) to define a combustion chamber (31, 32, 33, 34). The first lateral surface (45) comprises a bevel (36, 37, 38, 39) oriented in the direction of the rotation, to define, with the second lateral surface (46) of the adjacent radial arm (22a, 23a, 22b, 23b), a combustion pre-chamber (40, 41, 42, 43) continuous with the combustion chamber (31, 32, 33, 34).

Owner:VALMAX

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com