PLGA/Hydroxyapatite Composite Biomaterial and Method of Making the Same

a technology of hydroxyapatite and composite biomaterials, which is applied in the field of hydroxyapatite composite biomaterials and the field of making the same, can solve the problems of leaving voids formerly occupied by sodium chloride particles, and achieve the effects of fast, high, and uniform coating, and promote bone cell propagation and ingrowth better

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

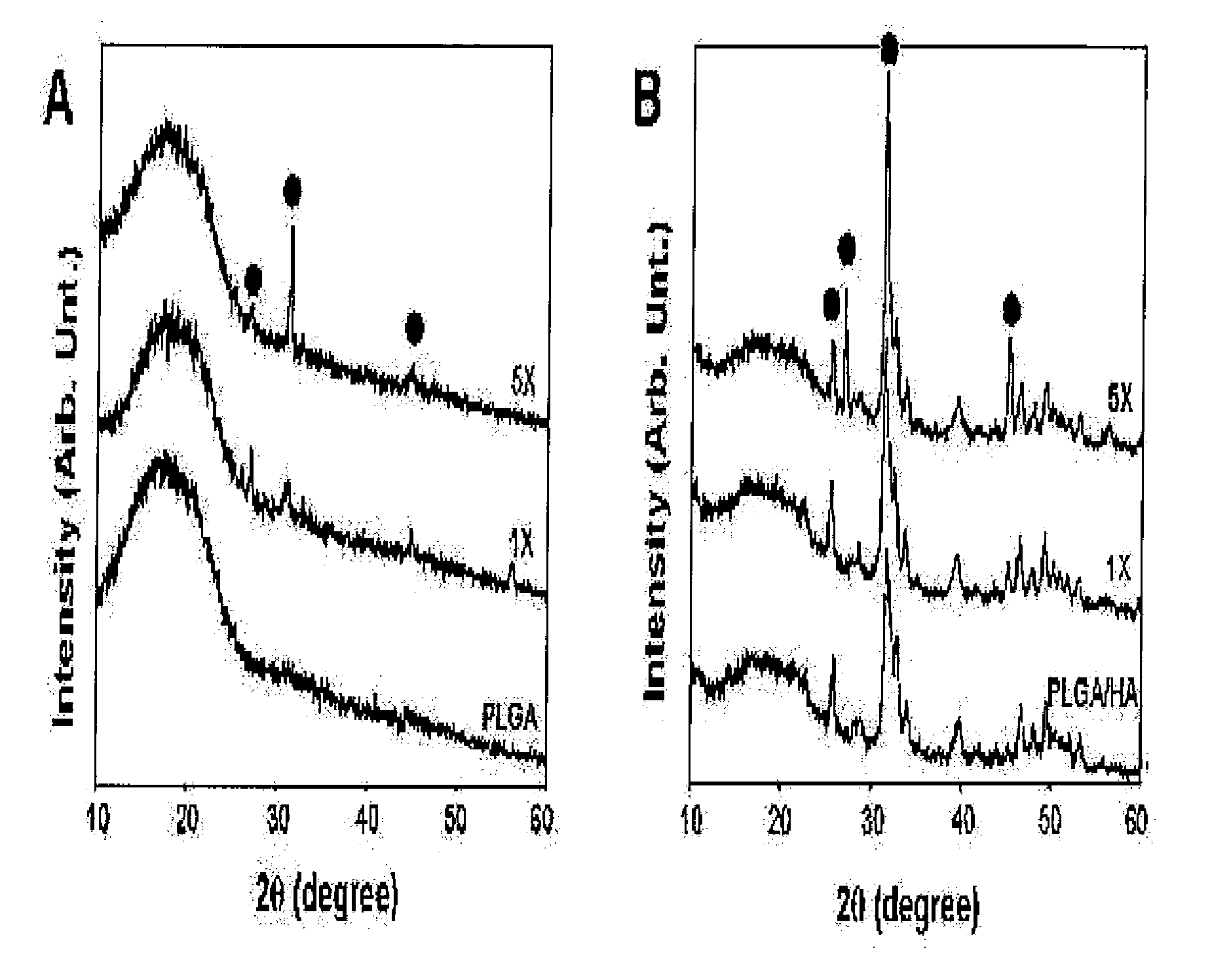

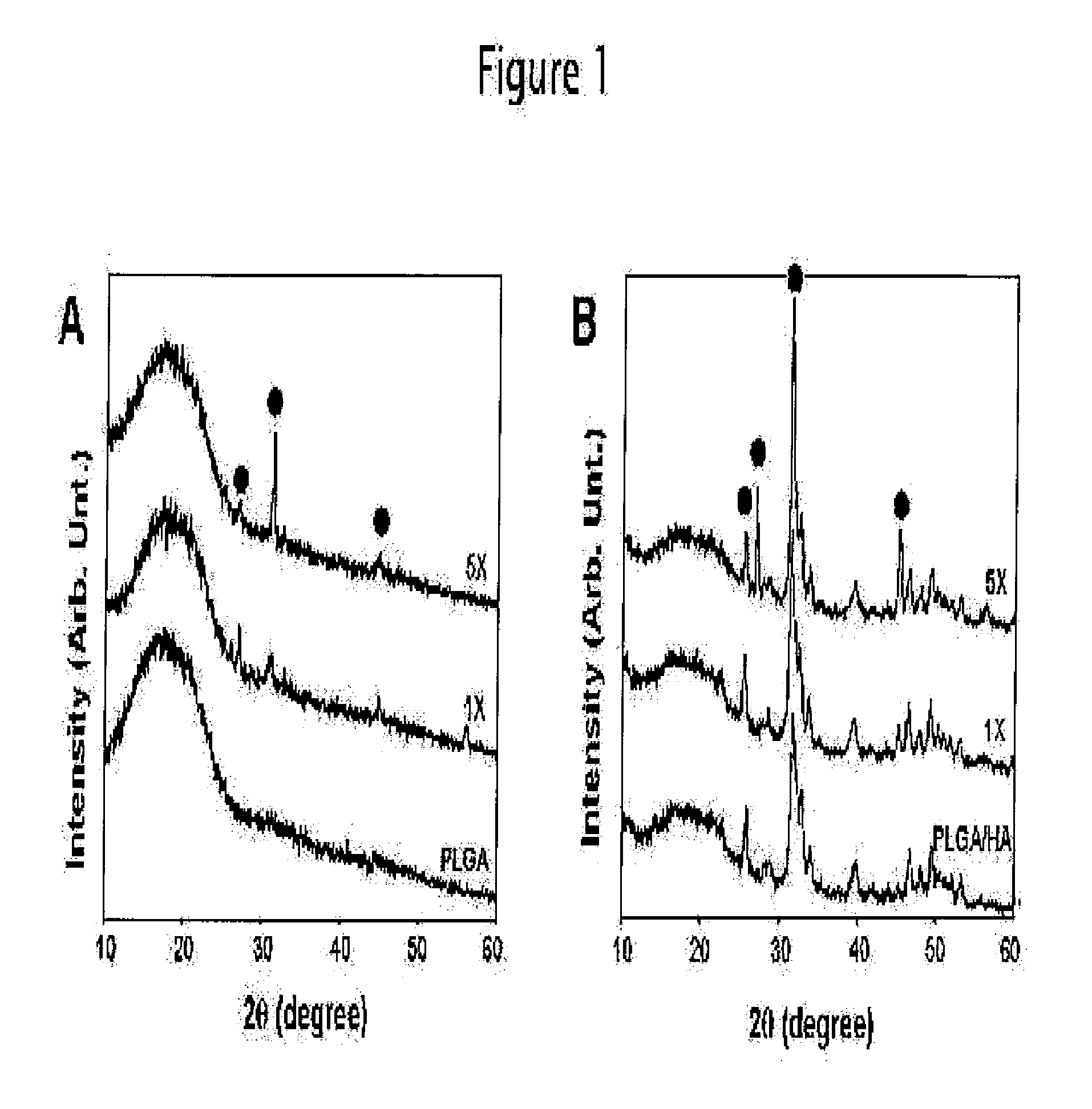

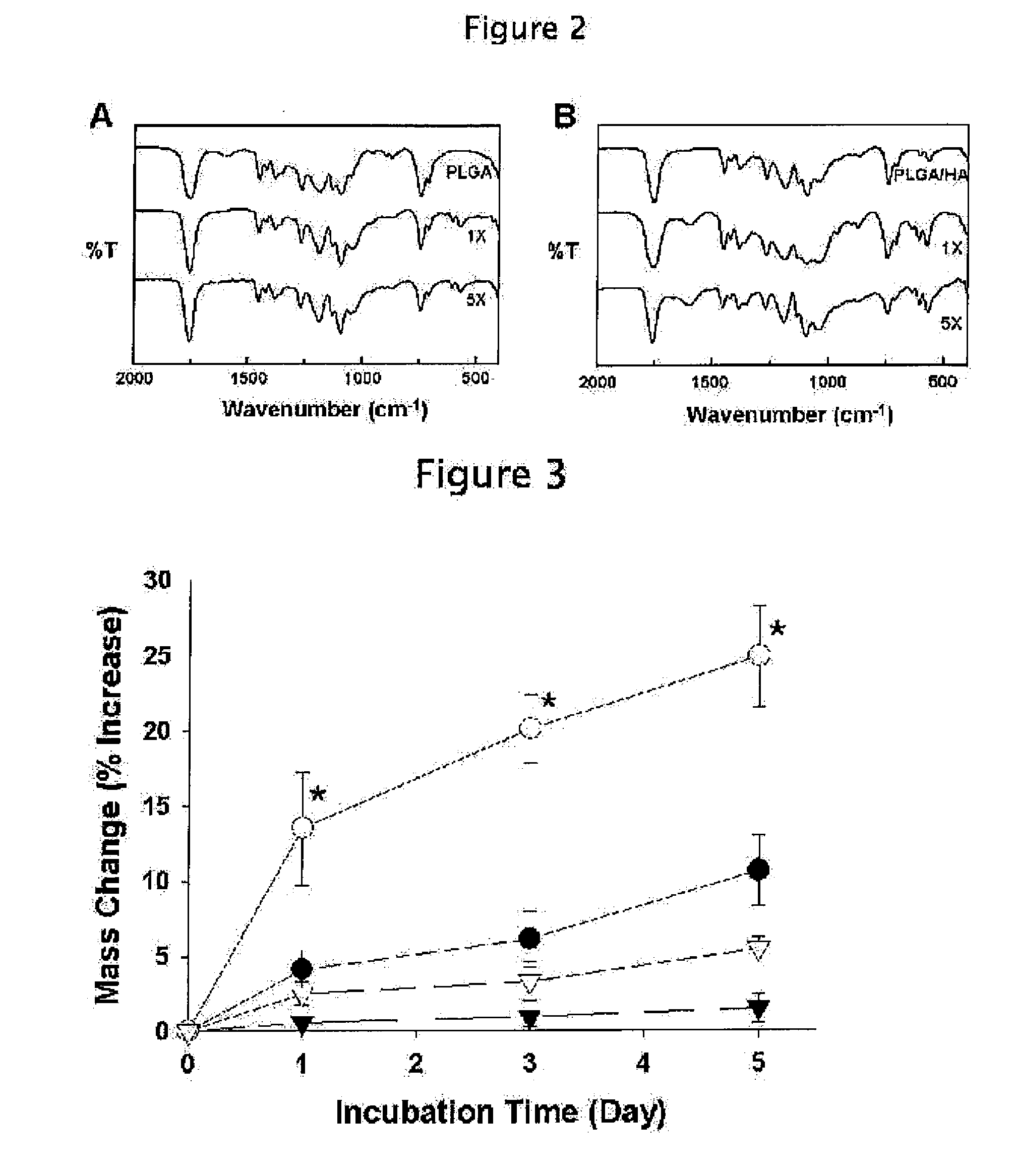

[0064]Porous PLGA / HA composite scaffolds were fabricated by the modification of a previously described GF / PL method of 24. Harris L D, Kim B S, Mooney D J. Open pore biodegradable matrices formed with gas foaming. J Biomed Mater Res 1998; 42: 396-402. PLGA / HA composites were prepared with 75:25 PLGA particles (diameter=100-200 mm, molecular weight=100,000 Da, Birmingham Polymers, Birmingham, Ala.), HA nanoparticles (diameter=approximately 100 nm, Berkeley Advanced Biomaterials Inc., Berkeley, Calif.), and sodium chloride particles (diameter=100-200 mm, Sigma, St. Louis, Mo.). The PLGA pellets were ground using a Tekmar grinder (Bel-Art Products, Pequannock, N.J.) and sieved to obtain particles ranging from 100 to 200 mm. The salt particles were sieved to yield a range of sizes from 100 to 200 mm. The polymer particles were mixed with the HA and NaCl particles. The PLGA / HA / NaCl mass ratio was 1:1:9. The mixture was loaded into a disk mold (diameter=1.35 cm; Aldrich Chemical Co., Milw...

example 2

[0091]Increasing interest has currently been focused on polymer / ceramic composite materials as bone substitutes because these materials have advantages over ceramic scaffolds and polymer scaffolds for bone tissue engineering. Calcium phosphate-based ceramics, such as hydroxyapatite (HA) and tricalcium phosphate, have been used as bone substitutes, but these materials have poor mechanical performance. Most synthetic polymer biomaterials have low surface wettability due to their composition of noncharged elements. Such hydrophobic surfaces are unfavorable to osteogenic cells as they show a lower proliferative and a higher apoptotic rate on hydrophobic surfaces than on hydrophilic surfaces. In addition, these polymeric biomaterials have a bioinert surface that lacks bioactive functions for bone formation, therefore evoking minimal tissue responses. An essential requirement for bone grafts is the ability to create a bond with the living host bone through the formation of a biologically ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com