Automobile door taping machine

A door bag and edge machine technology, which is applied in the directions of forming tools, feeding devices, positioning devices, etc., can solve the problems of difficult installation and debugging, poor quality of workpieces, and difficult installation, so as to reduce the workload of mold repair and the overall structure is reasonable. , the effect of up and down smooth and smooth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described in detail below in conjunction with the accompanying drawings.

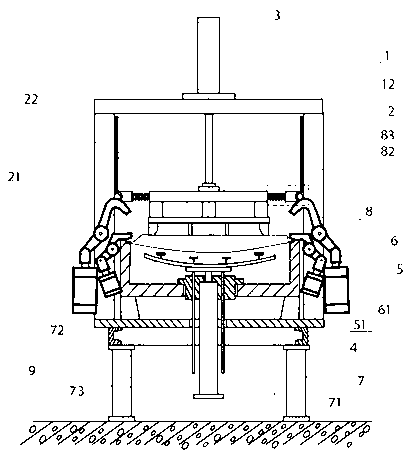

[0018] Such as figure 1 As shown, the automobile door edge binding machine of the present invention has a bottom plate 9 as the machine foundation at the bottom, and a first cylinder 3 for driving the clamping device 2 to move vertically up and down in the portal frame 1 at the top of the portal frame 1. Bottom mold 4 is fixed in gantry 1 on bottom plate 9, and clamping device 2 is above bottom mold 4, and each side of bottom mold 4 is respectively provided with prepackage module 5 and edge wrapping module 6, wherein, prepackage The module 5 is driven by the first hydraulic device 51, and the hemming module 6 is driven by the second hydraulic device 61, wherein the hydraulic device is connected to the hydraulic pump station through a liquid circuit, and the hydraulic pump station has two output circuits, which are composed of the first hydraulic device 51 Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com