Polymeric liquid crystal composition and application thereof

A technology of polymerizable liquid crystal and composition, applied in liquid crystal materials, optics, instruments, etc., can solve the problems of uneven photo-alignment, mismatch of photoresist properties, and uneven alignment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

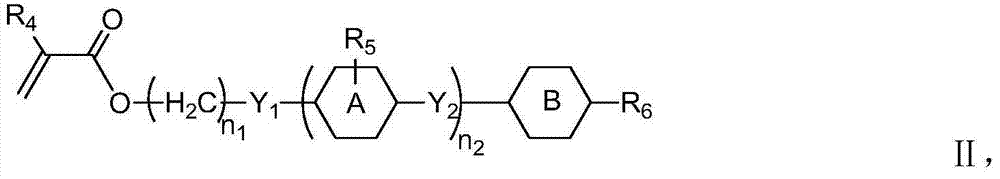

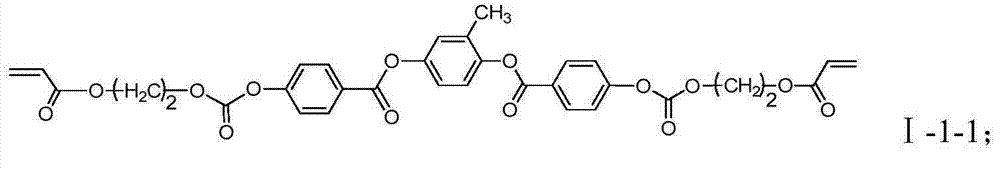

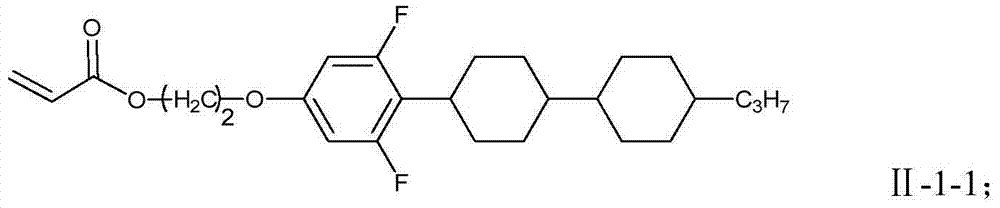

Method used

Image

Examples

Embodiment 1

[0120]

[0121] Performance parameter test results: Mp: 20°C; Cp: 105°C; n o : 1.498; △n: 0.157; supercooling time: 30 days; good alignment.

Embodiment 2

[0123]

[0124] Performance parameter test results:

[0125] Mp: 20°C; Cp: 105°C; n o : 1.497; △n: 0.157; supercooling time: 20 days; good alignment.

Embodiment 3

[0127]

[0128] Performance parameter test results:

[0129] Mp: 20°C; Cp: 105°C; n o : 1.500; △n: 0.146; supercooling time: 10 days; good alignment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com