Preparation method of purple rice sandwich toast bread

A bread and sandwich technology, applied in dough processing, pre-baked dough processing, dough sheeting machine/rolling machine/rolling pin, etc., can solve problems such as troublesome and slow bread production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] A preparation method of purple rice sandwich toast bread, comprising the following steps:

[0047] S1, ingredients: take raw materials according to Table 1;

[0048] S2. Kneading dough: Stir the weighed raw materials evenly to form dough;

[0049] S3. Freezing: Put the dough into the cold storage for 100 minutes, and the temperature of the cold storage is -7~-12°C;

[0050]S4, open crisp: use the automatic crisp open machine to press the frozen dough into a thickness of 3 cm, wrap 0.5 parts of shortening sheets, and open into crisp noodles;

[0051] S5. Forming and proofing: shape the crispy noodles, put them in the proofing room for 2 hours, the temperature of the proofing room is 38°C, and the humidity is 85%;

[0052] S6. Baking: bake the proofed crispy noodles for 30 minutes, and obtain bread after cooling. The baking temperature is 180°C;

[0053] S7. Sliced sandwich: Slice the bread, and sandwich 21.35 parts of purple rice paste through a toast sandwich machi...

Embodiment 2-4

[0055] With reference to Table 1, the difference from Example 1 is the difference in raw material consumption.

[0056]

[0057]

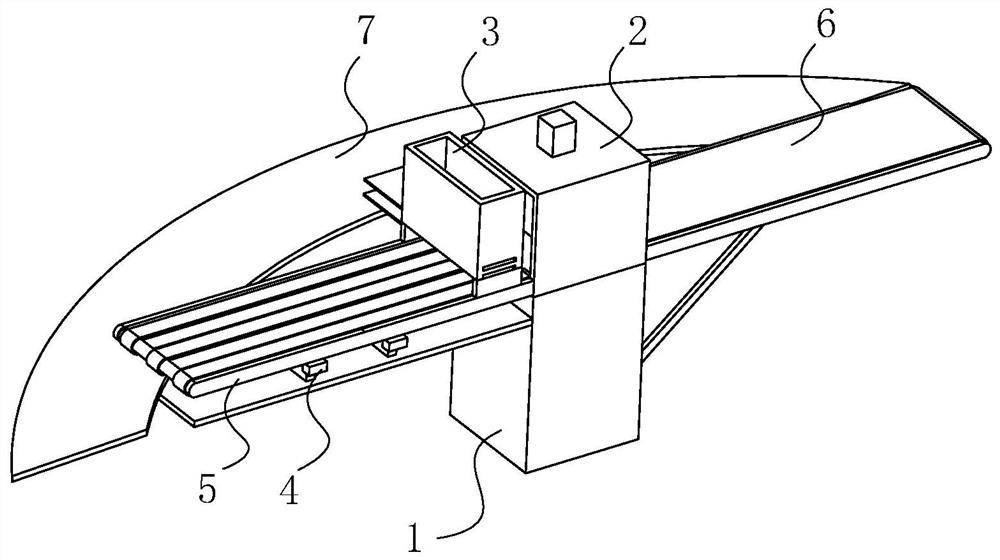

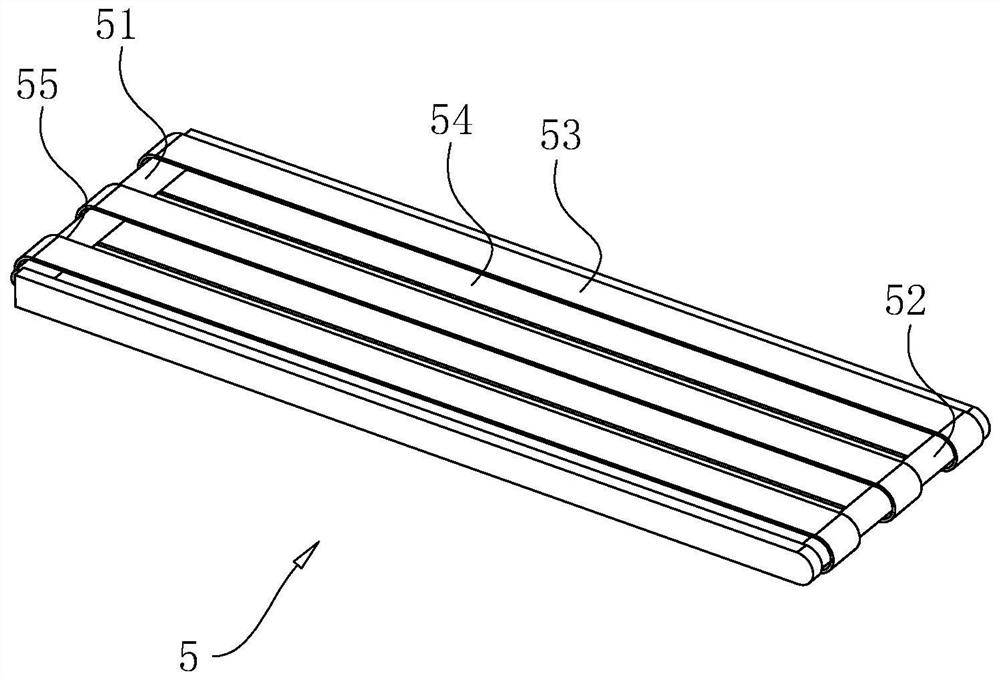

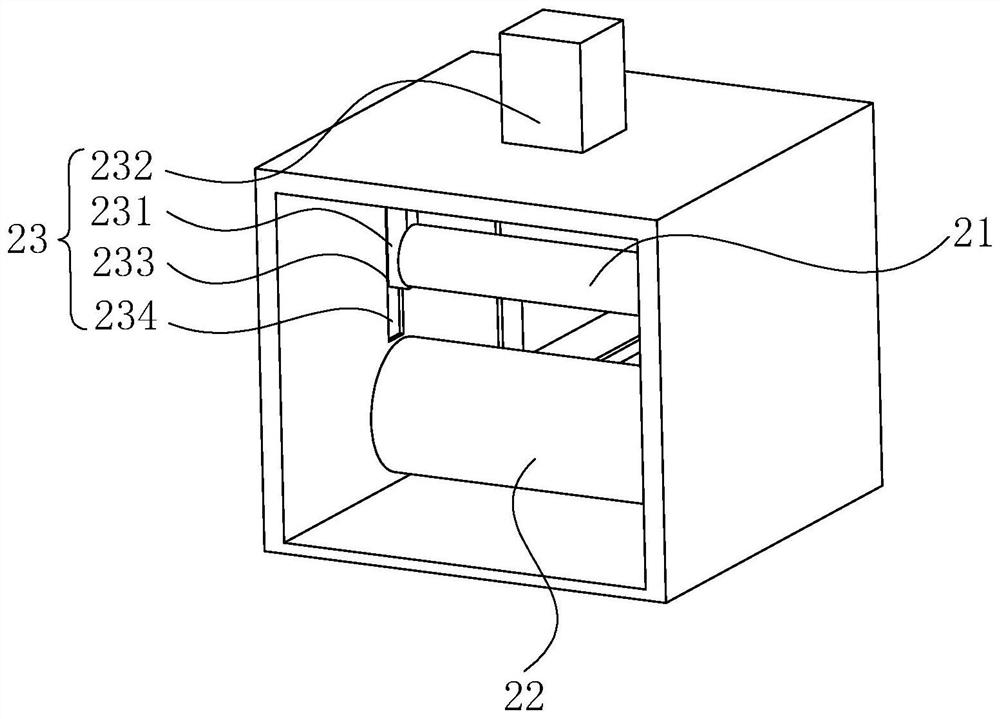

[0058] The automatic open crisper used in the embodiment 1-4, it comprises frame body 1, dough sheet device 2, discharge device 3 and regulating device 4, and dough sheet device 2 is fixed on frame body 1, and on frame The first conveying member 5 and the second conveying member 6 are installed, and the first conveying member 5 and the second conveying member 6 are positioned at both sides of the dough sheet device 2, and the first conveying member 5 and the second conveying member 6 are all connected to the pressing surface. The film device 2 is connected, and the drive source that drives the first transmission belt and the second transmission member 6 to rotate in the same direction is installed on the frame. The end of the first conveying member 5 far away from the dough pressing device 2 is connected with a rotary conveying member 7, and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Radian | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com