High-speed deep groove ball bearing

A deep groove ball bearing, high-speed technology, applied in the direction of ball bearings, bearing components, shafts and bearings, etc., can solve the problems of lack of quantitative research on the internal dimensions of bearings, lack of matching relationship between steel balls and grooves, failure of lubrication of rotating support bearings, etc. , to achieve the effect of overcoming stress concentration, small friction, and eliminating blocking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

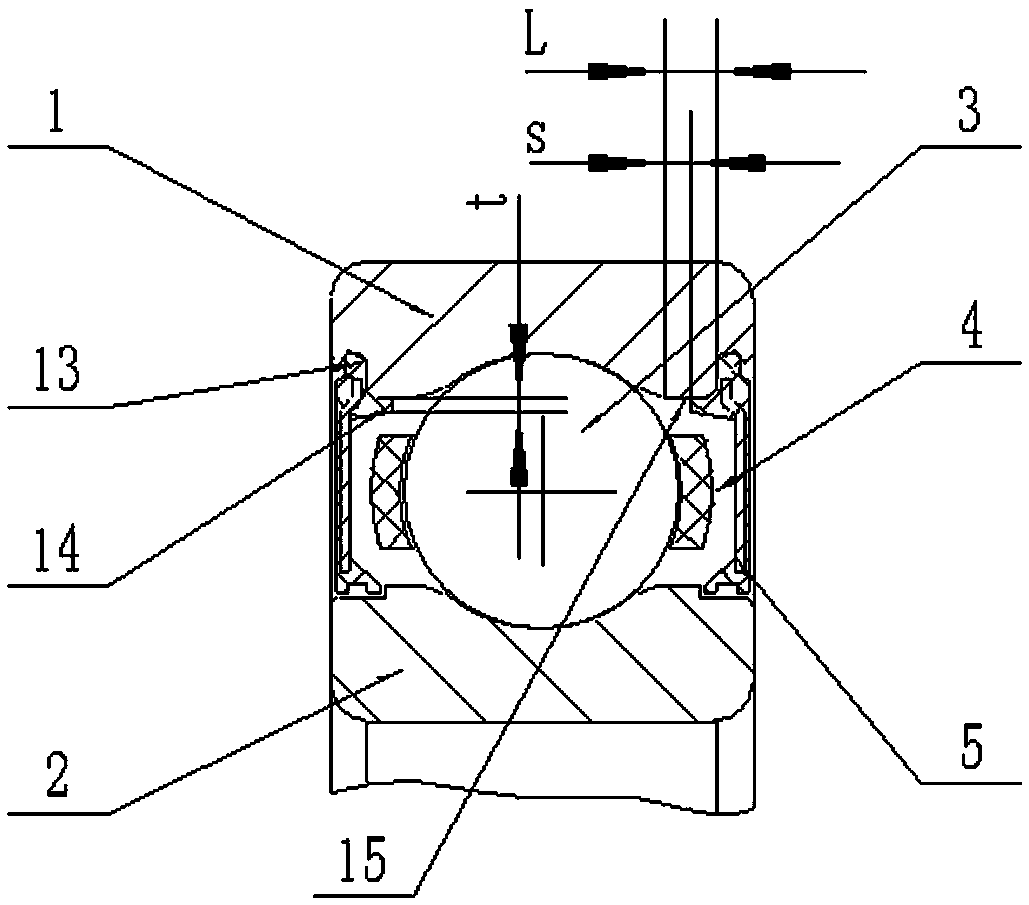

[0021] The figure is a schematic diagram of the structure of the high-speed deep groove ball bearing of the drive motor of the new energy vehicle in the section passing through the bearing axis.

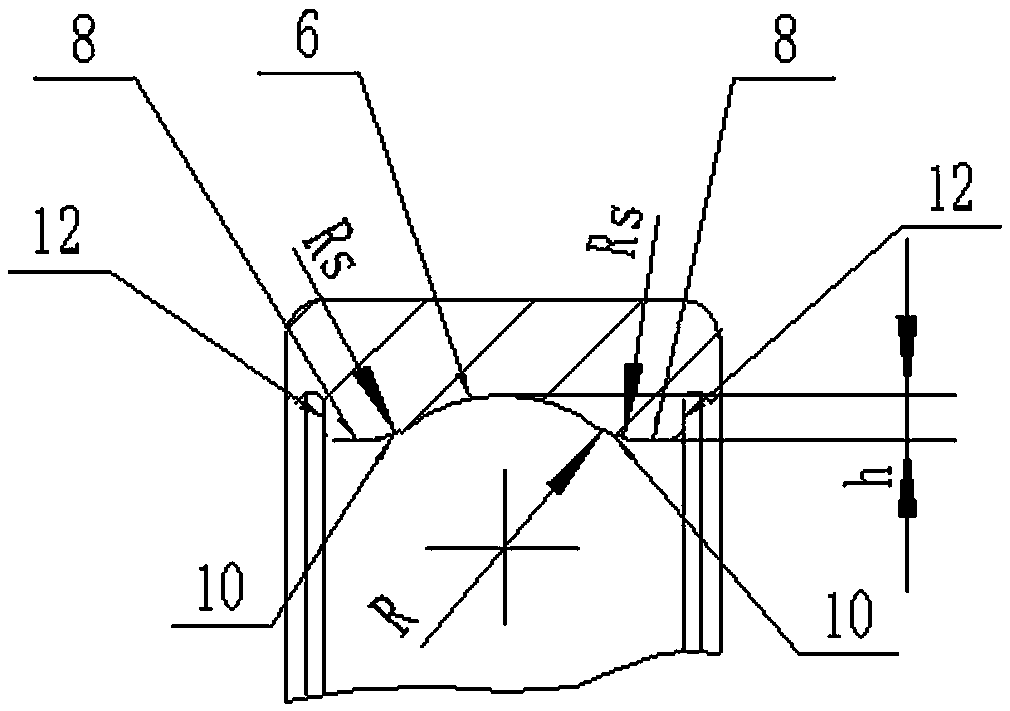

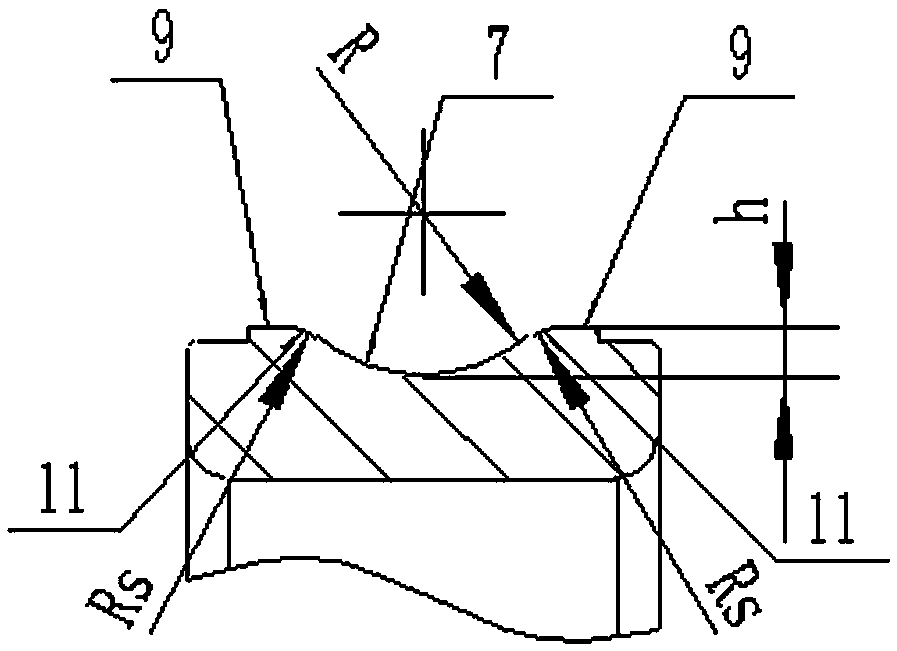

[0022] Description will be made in conjunction with the accompanying drawings. The high-speed deep groove ball bearing in the figure is composed of bearing outer ring 1, bearing inner ring 2, steel ball 3, engineering plastic cage 4, sealing ring 5, and viscous grease distributed in each position (lubricating grease is not shown in the figure). fat). The bearing inner ring 2 is processed with an annular inner groove 7 at the outer diameter portion, and the bearing outer ring 1 is processed with an annular outer groove 6 at the inner diameter portion. The steel ball 3 rolls on the inner channel 7 and the outer channel 6. It not only revolves around the center of the bearing, but also rotates around its own axis. The rolling friction force is much smaller than the sliding friction for...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com