Patents

Literature

176results about How to "Avoid nasty accidents" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

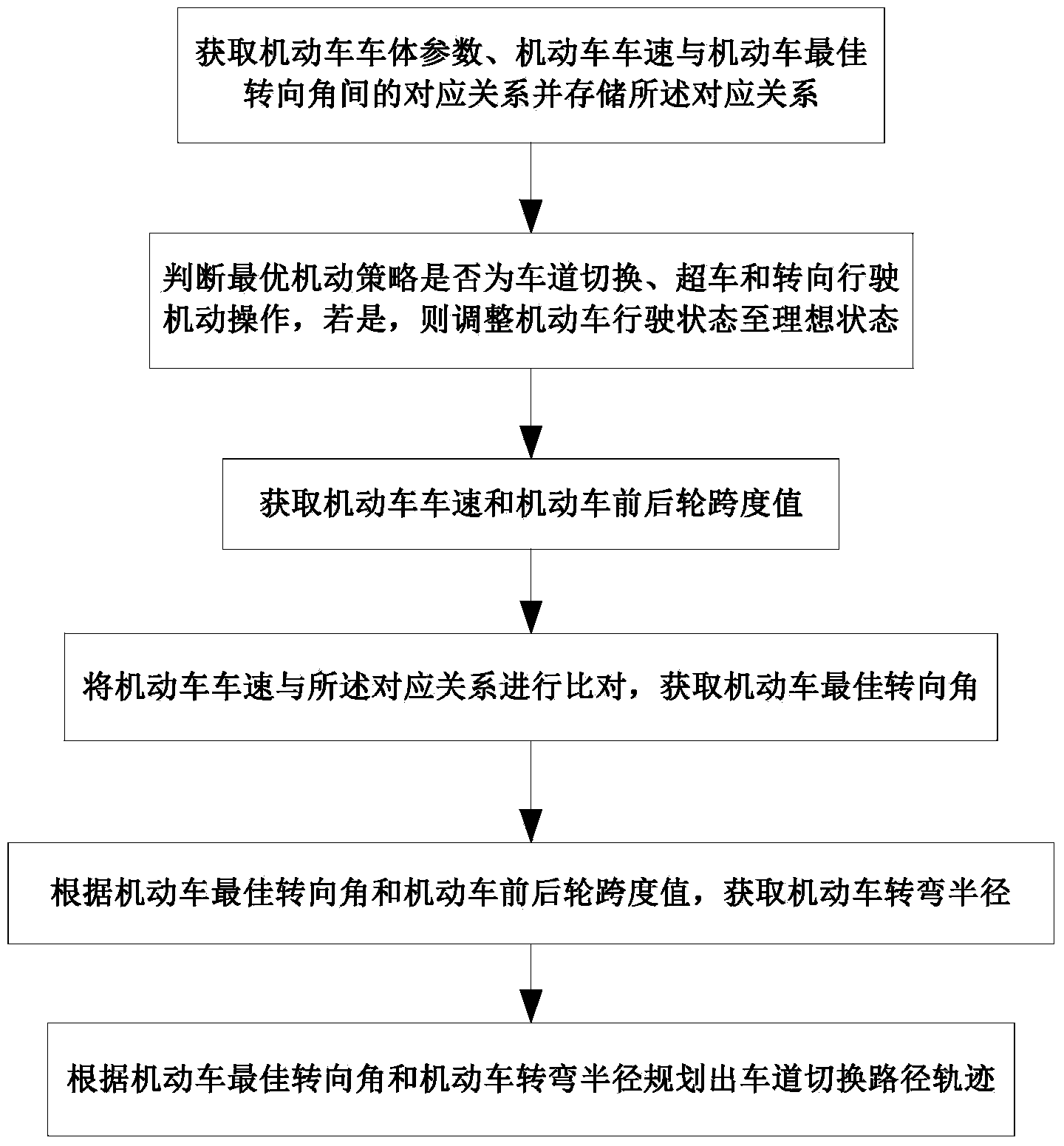

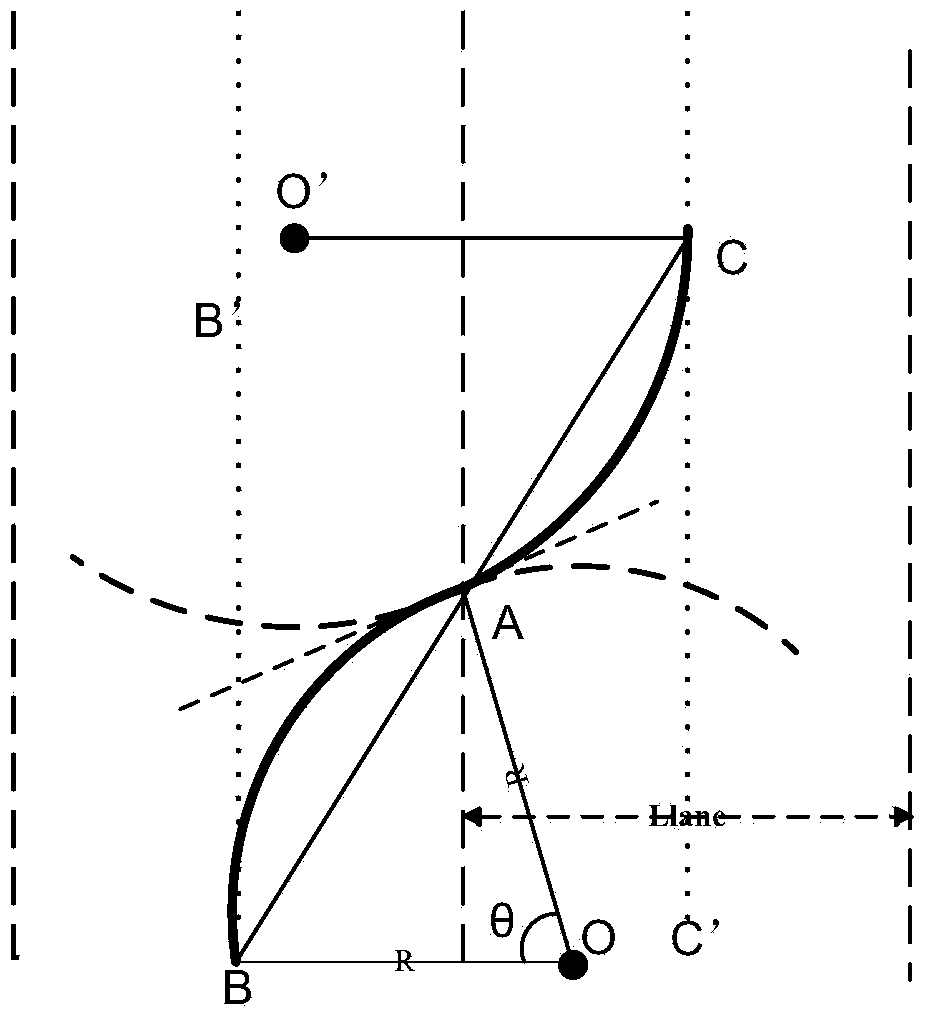

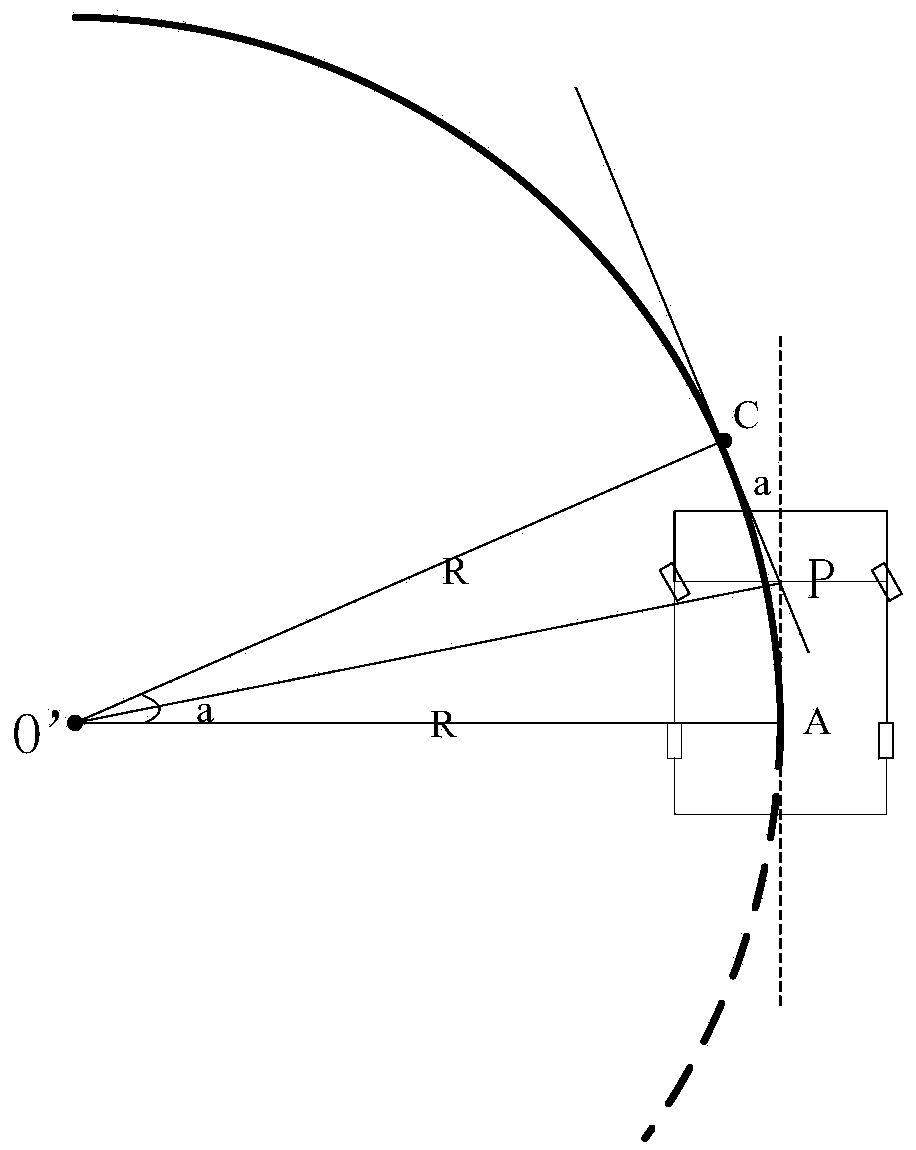

Automatic driving method and automatic driving system

ActiveCN103646298AEnsure driving safetyAvoid accidentsForecastingPosition/course control in two dimensionsAutomotive engineeringAxle track

The invention provides an automatic driving method and an automatic driving system. A corresponding relation among vehicle body parameters of the motor vehicle, a vehicle speed and an optimum turning angle of the motor vehicle are acquired firstly; a driving state of the motor vehicle is adjusted to be an ideal state when optimum maneuvering strategies are lane switching, overtaking and turning driving maneuvering operation; the speed of the motor vehicle and a distance of front and back wheel shafts are acquired; contrast between the speed of the motor vehicle and the corresponding relation is carried out to acquire an optimum turning angle of the motor vehicle; a turning radius of the motor vehicle is acquired according to the optimum turning angle of the motor vehicle and the distance of the front and back wheel shafts; and a lane switching path locus of the motor vehicle can be planned according to the optimum turning angle and the turning radius of the motor vehicle. Through the method and the system, the lane switching path locus of the motor vehicle under an automatic driving state can be planned according to the optimum maneuvering strategies, and most accurate reference basis is provided for automatic driving of the motor vehicle.

Owner:SHANDONG INST OF ADVANCED TECH CHINESE ACAD OF SCI CO LTD

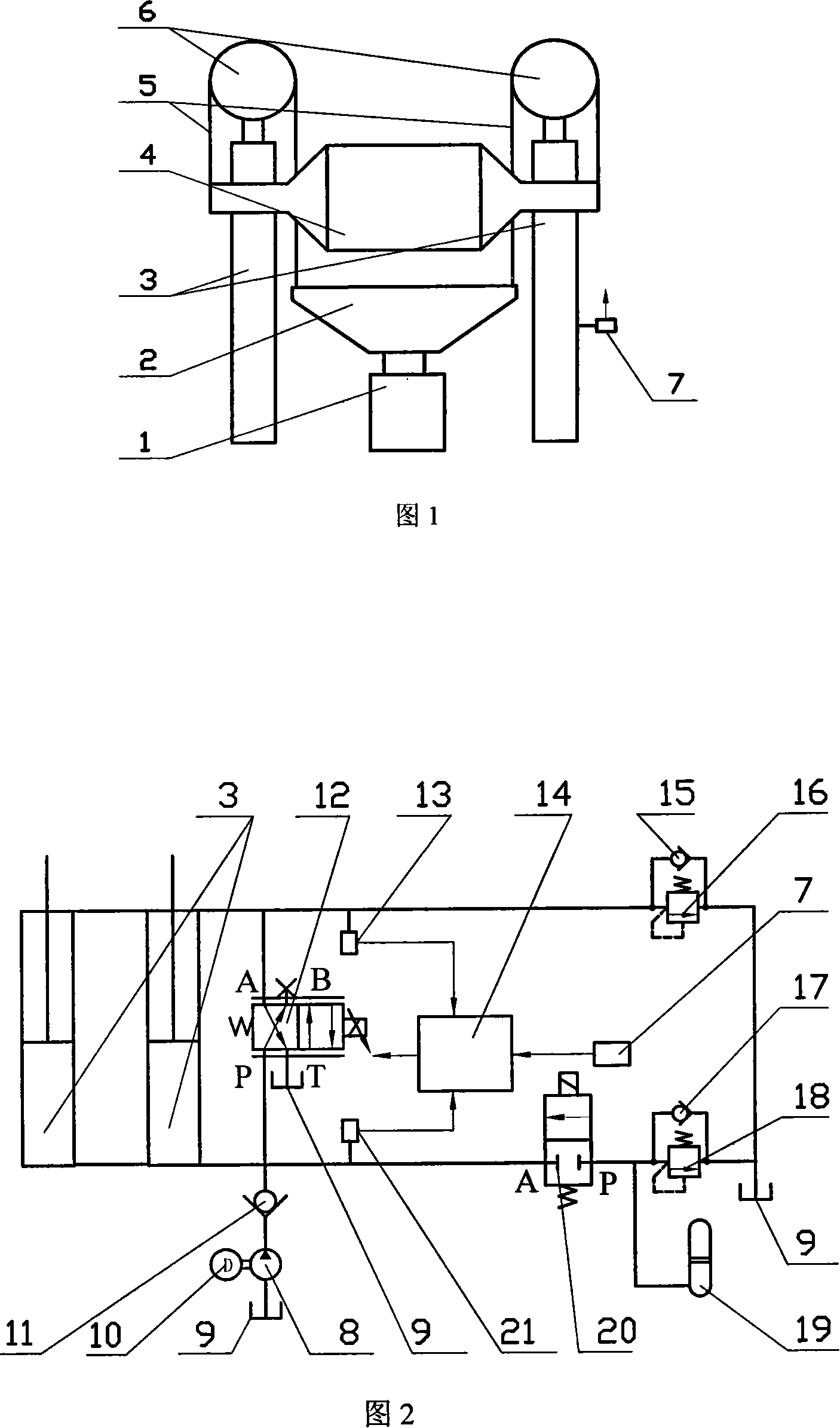

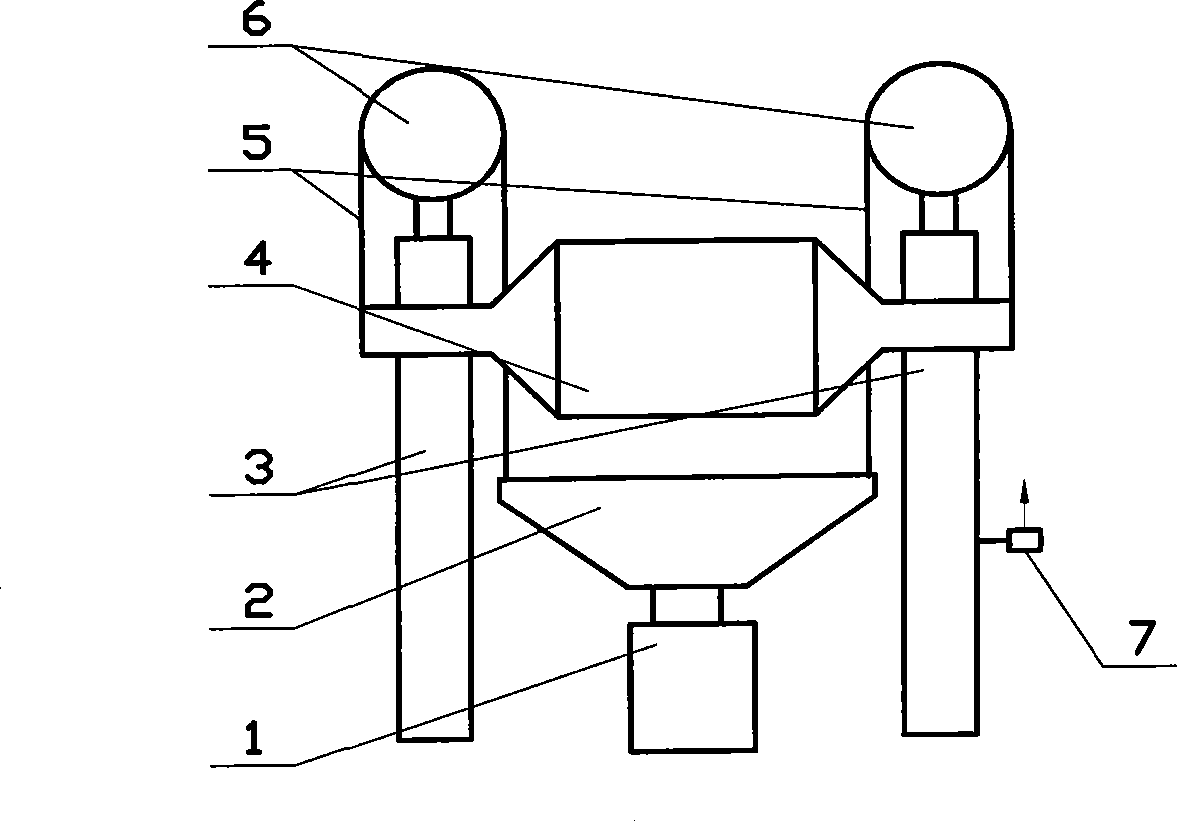

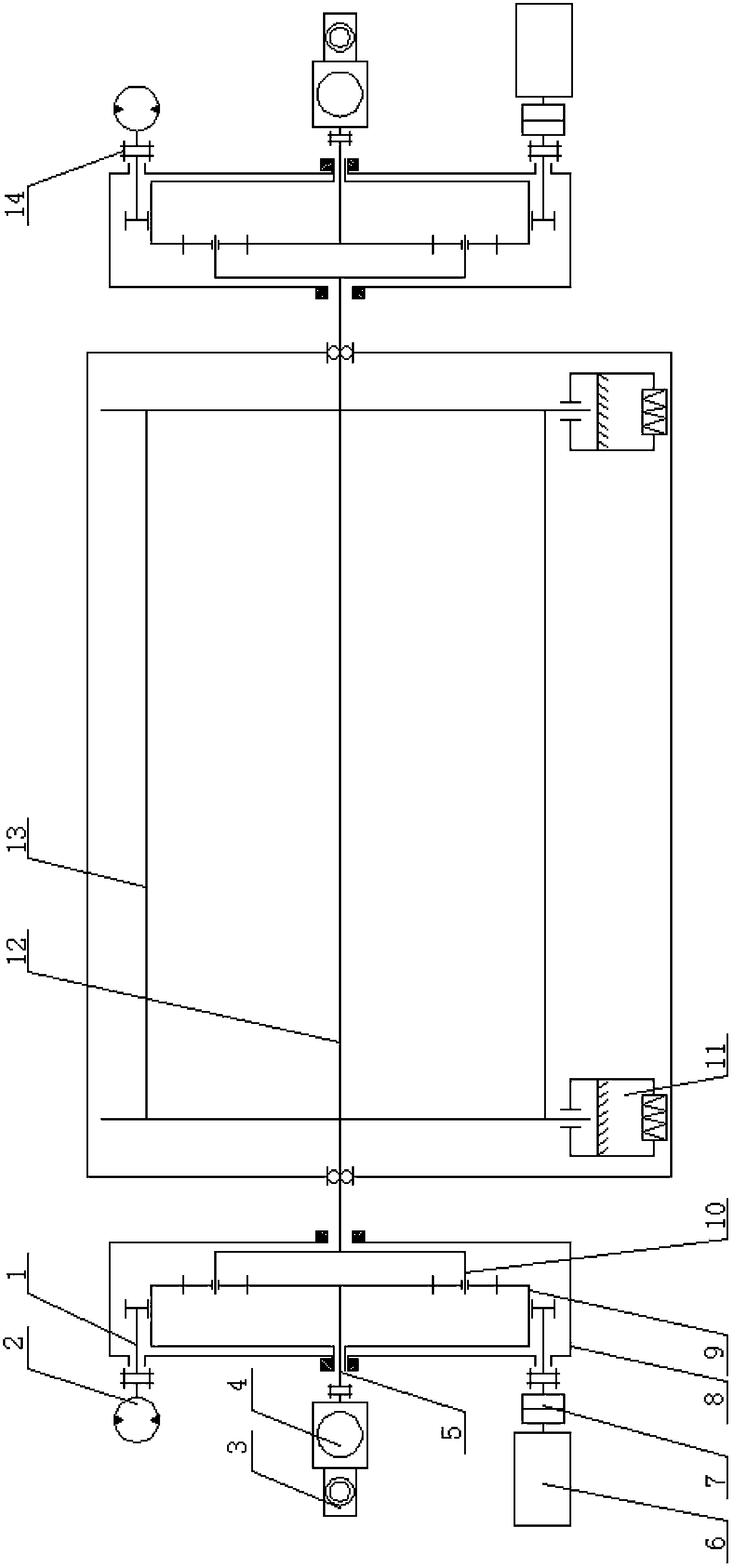

Drilling column heave compensation device of marine floating type drilling platform

InactiveCN101798909ALimit consumptionOvercome dynamic loadDrilling rodsServomotorsHydraulic cylinderCompensation effect

The invention discloses a drilling column heave compensation device of a marine floating type drilling platform. A composite hydraulic cylinder is adopted as a heave compensation hydraulic cylinder in a crown block heave compensation device; the high-pressure hydraulic oil output by a hydraulic pump flows into a rodless cavity of an inner cylinder and a rod cavity of an outer cylinder of the composite compensation hydraulic cylinder by a compensation control valve to provide controllable additional force for a piston rod of the outer cylinder; and the resultant force of the force and the hydraulic force acted by the rodless cavity of the outer cylinder of the compensation hydraulic cylinder provides support force to a crown block. The direction and magnitude of the additional force are controlled according to the platform heave motion, and the compensation effect of a heave compensation system is improved. A control unit transmits a control command to the hydraulic system according to the motion speed of the platform in the vertical direction, wherein the motion speed is obtained by detection, drives a piston of the compensation hydraulic cylinder to push the crown block to move and compensates the heave motion of the platform so that the crown block, a traveling block and a large hook are in a static state in the vertical direction relative to the well bottom in the allowable range.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

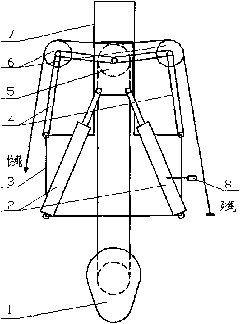

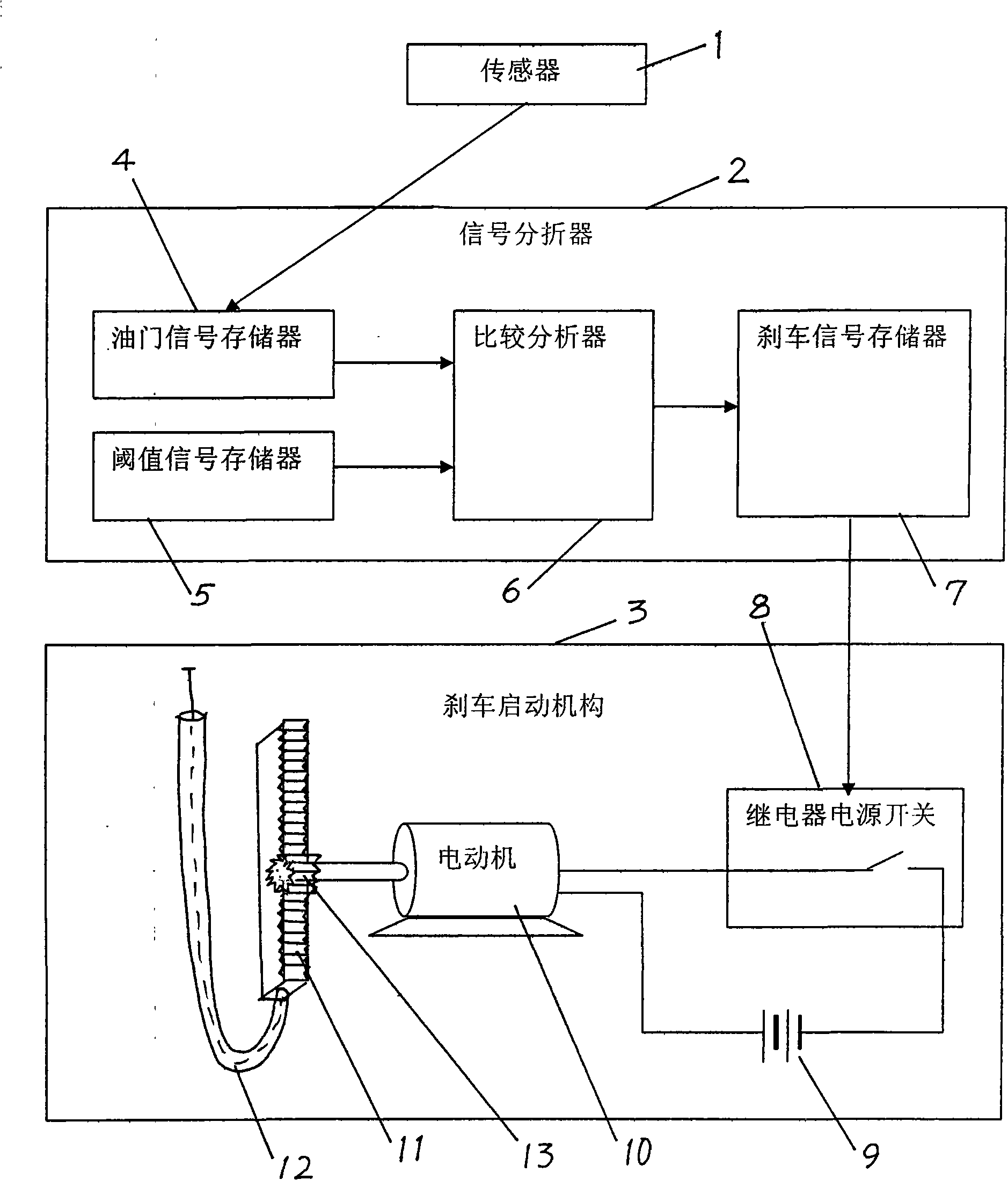

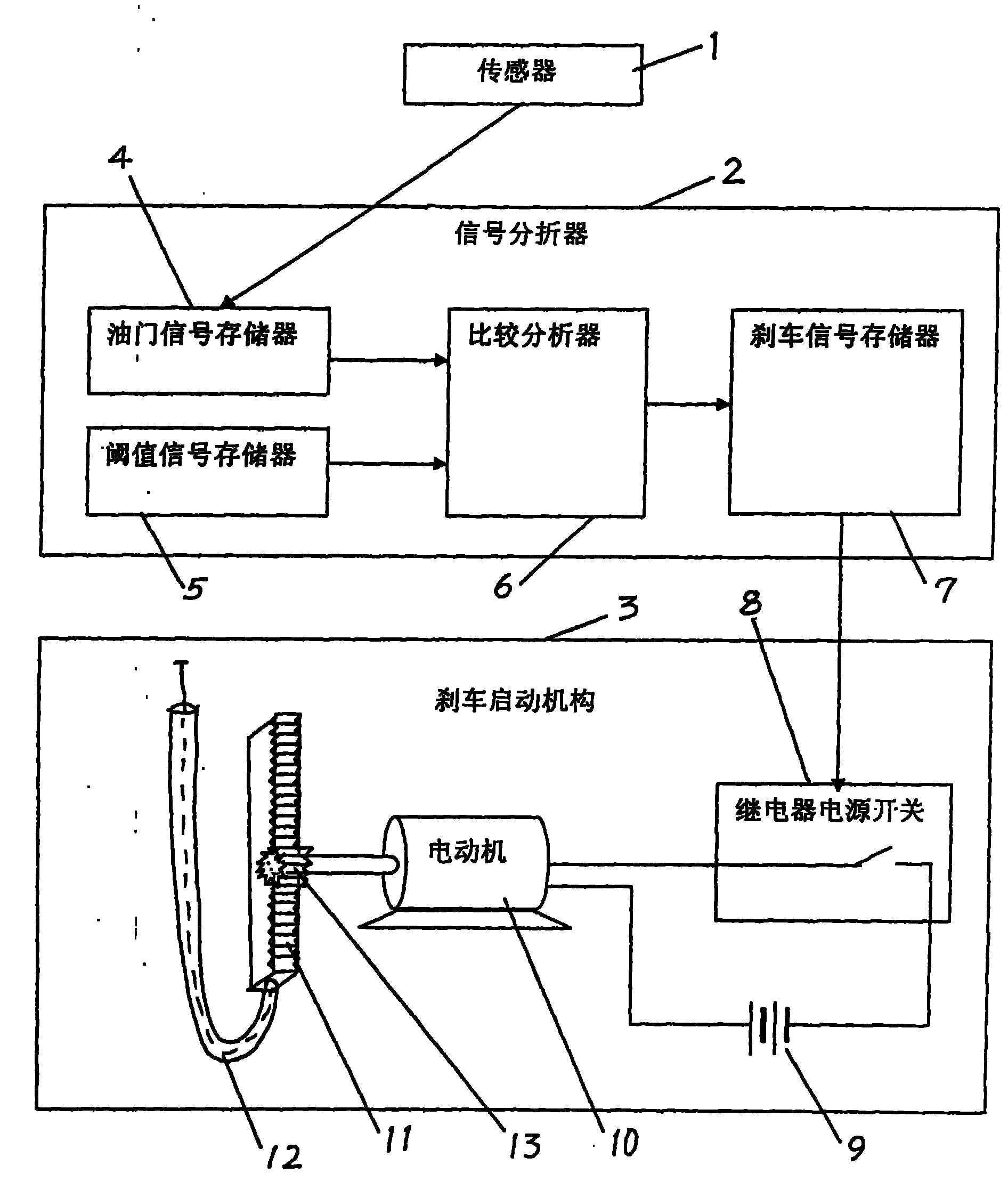

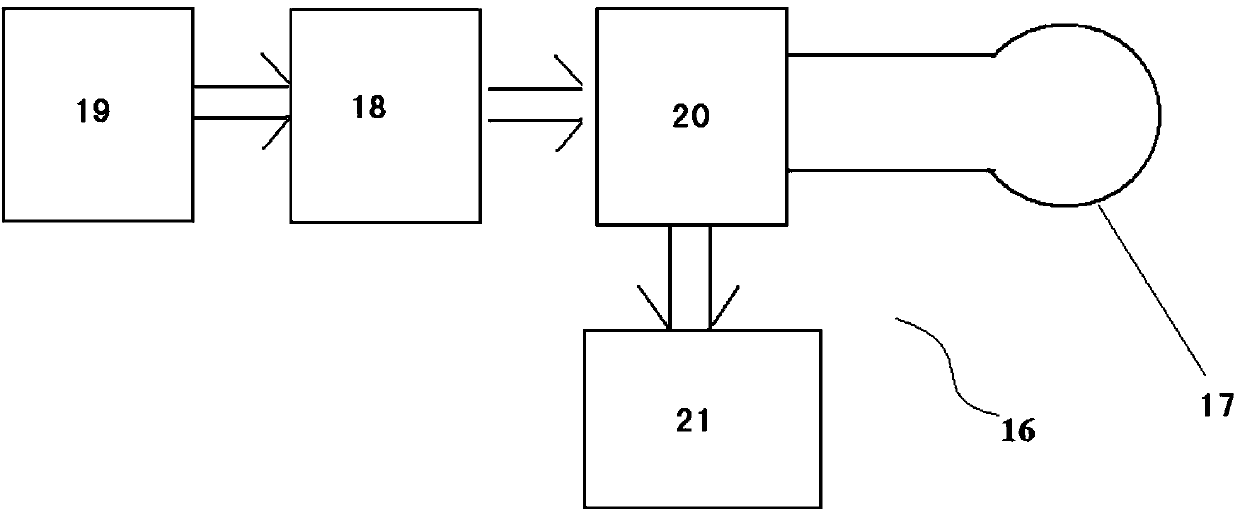

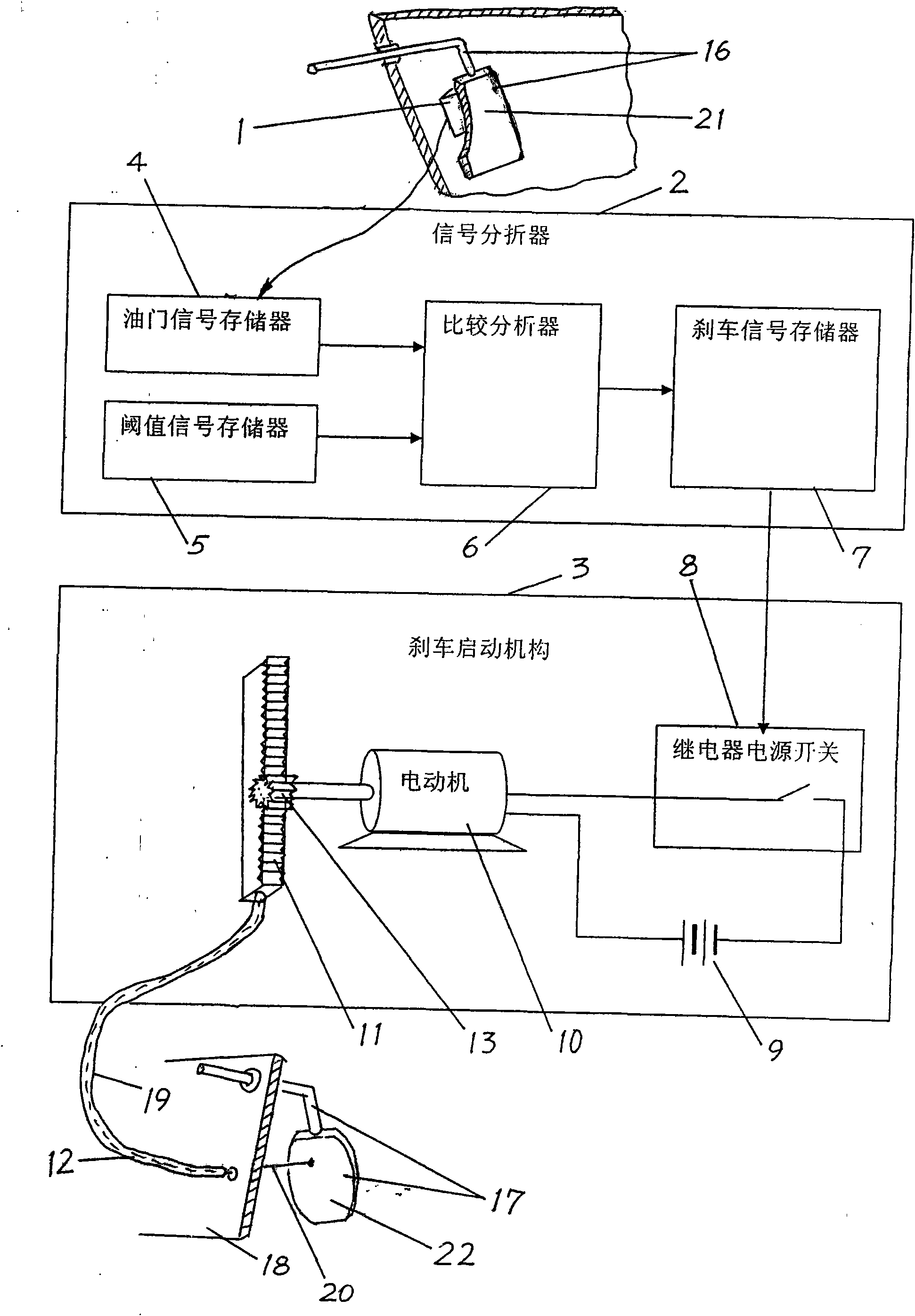

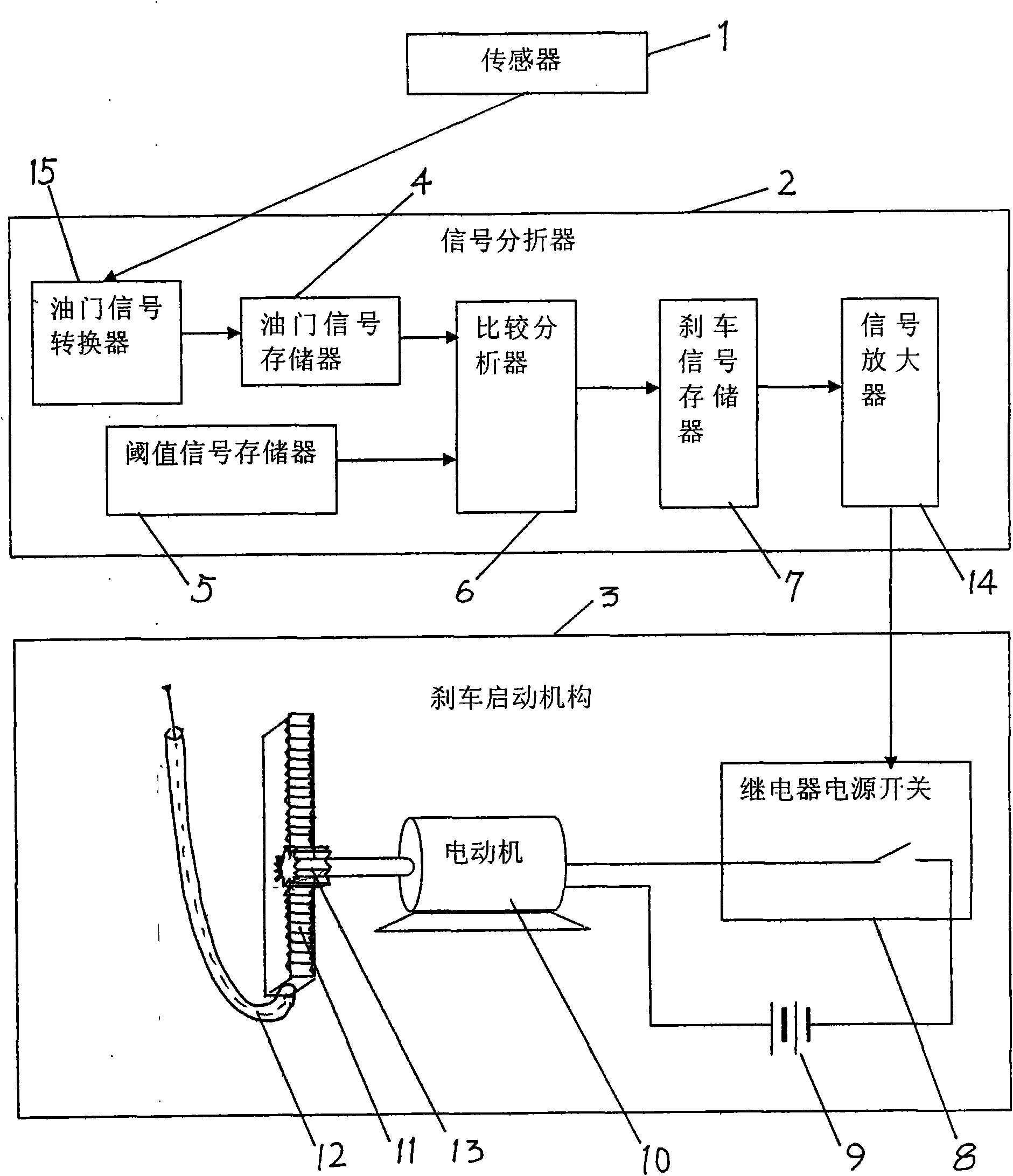

Device for automatically correcting accelerator pedal misoperation to braking operation by electrical and mechanical combination

InactiveCN102114776AAvoid nasty accidentsAvoid Vicious Traffic AccidentsFoot actuated initiationsPropulsion unit arrangementsElectricitySignal analyzer

The invention relates to a device for automatically correcting an accelerator pedal misoperation to a braking operation by electrical and mechanical combination, which belongs to a device capable of obtaining a mechanical operation for driving a brake device by means of electrical signal conversion of a mechanical operation of stepping on an accelerator pedal by mistake. The device comprises a sensor and is characterized in that the device further comprises a signal analyzer and a brake starting mechanism, wherein the sensor is connected with the signal analyzer to transmit an accelerator signal from the sensor to the signal analyzer, the signal analyzer is connected with the brake starting mechanism and transmits a brake start-up signal to the brake starting mechanism. The invention has the advantages that the mechanical operation of stepping on the accelerator pedal by mistake is converted into an accelerator electrical signal through the sensor, an electrical signal of serious accelerator pedal misoperation is analyzed, then the electrical signal of serious accelerator pedal misoperation is converted into an electrical signal for starting the brake device, and the brake starting mechanism generates a braking mechanical operation, as a result, the mechanical operation of stepping on the accelerator pedal by mistake is automatically converted into the braking operation of thevehicle, which prevents the occurrence of serious vehicle accidents caused by the misoperation of the accelerator pedal.

Owner:ZHEJIANG XIANAN AUTOMOBILE BREAKING SYST

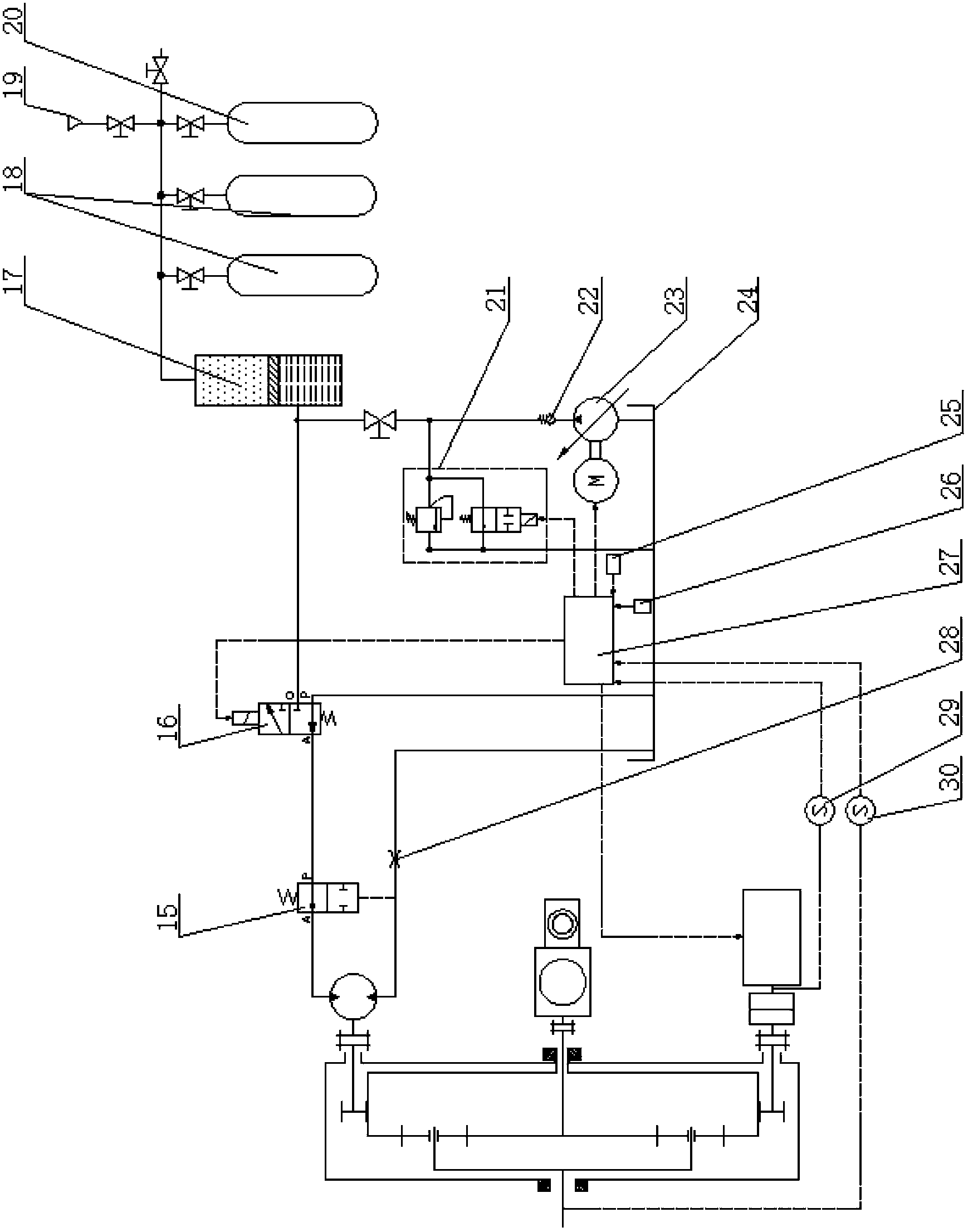

Drilling column heave compensator for floating drill platform in the sea

InactiveCN101130949ALimit consumptionImprove the compensation effectArtificial islandsUnderwater structuresCompensation effectEngineering

The present invention discloses one kind of heave compensation system for drill stem of marine floating drilling platform. High pressure hydraulic oil is led from the energy accumulator through a compensation control valve to the compensating hydraulic cylinder, so as to provide one additional force controlled based on the heave motion of the platform for raised compensation effect. The control unit detects the vertical motion of the platform to control the hydraulic system for compensating the heave motion of the platform by means of the steel cable or chain to make the crossbeam and rotary hook in vertically quiescent state relative to the well bottom. The present invention is superior to traditional passive heave compensation system, and has high reaction speed, high compensation precision, low power consumption and low operation cost.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

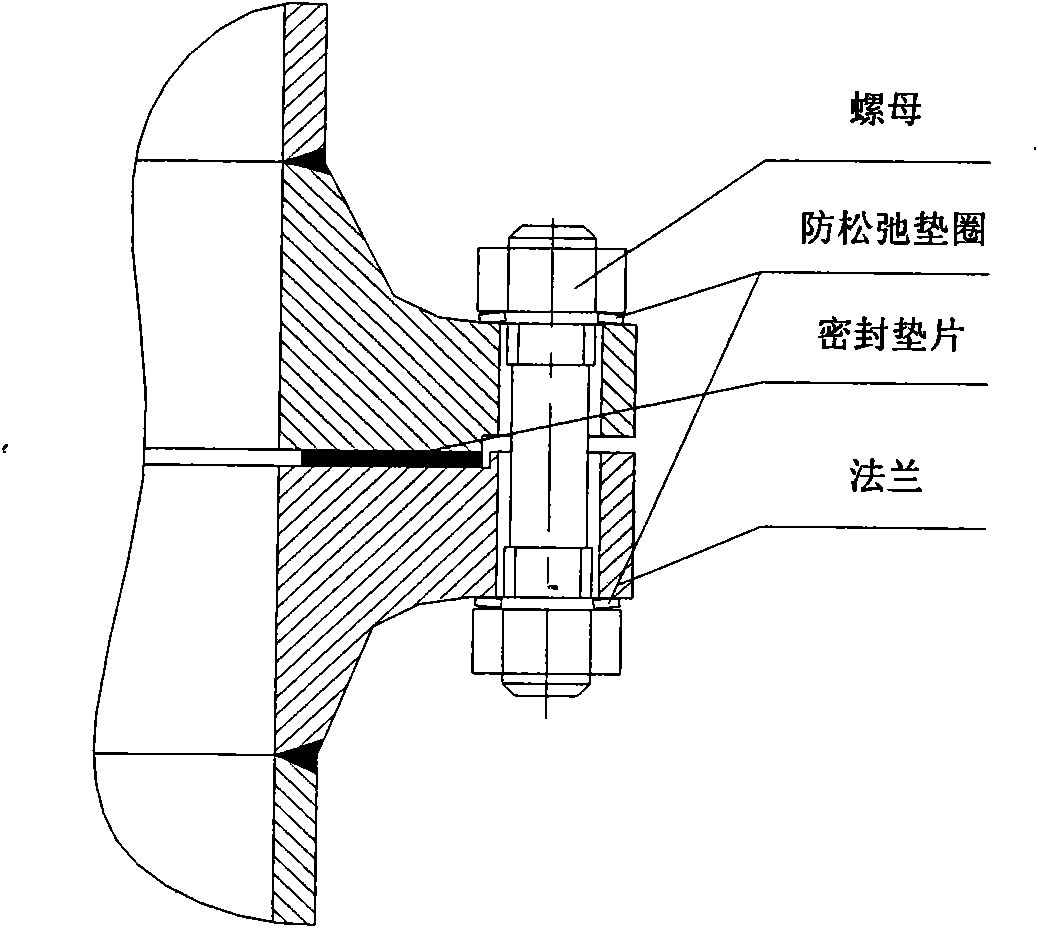

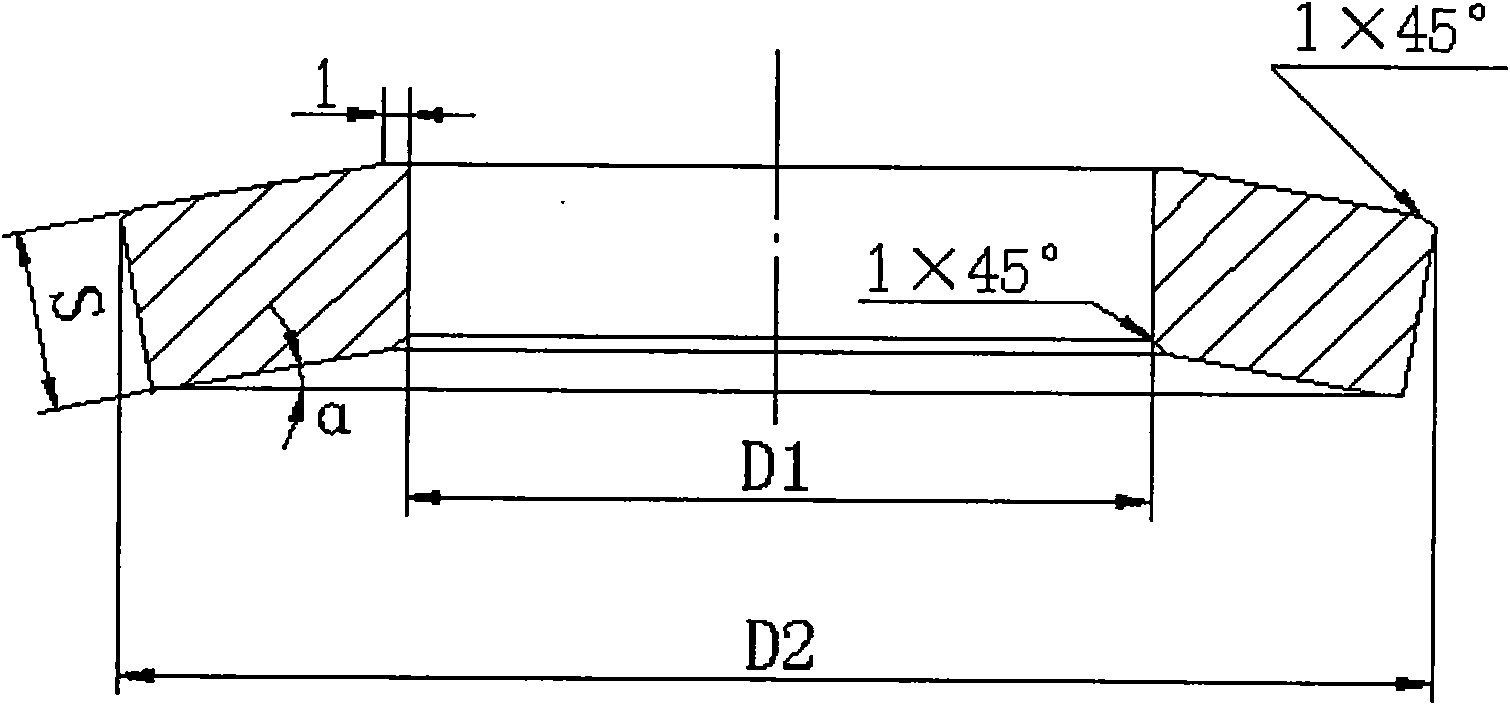

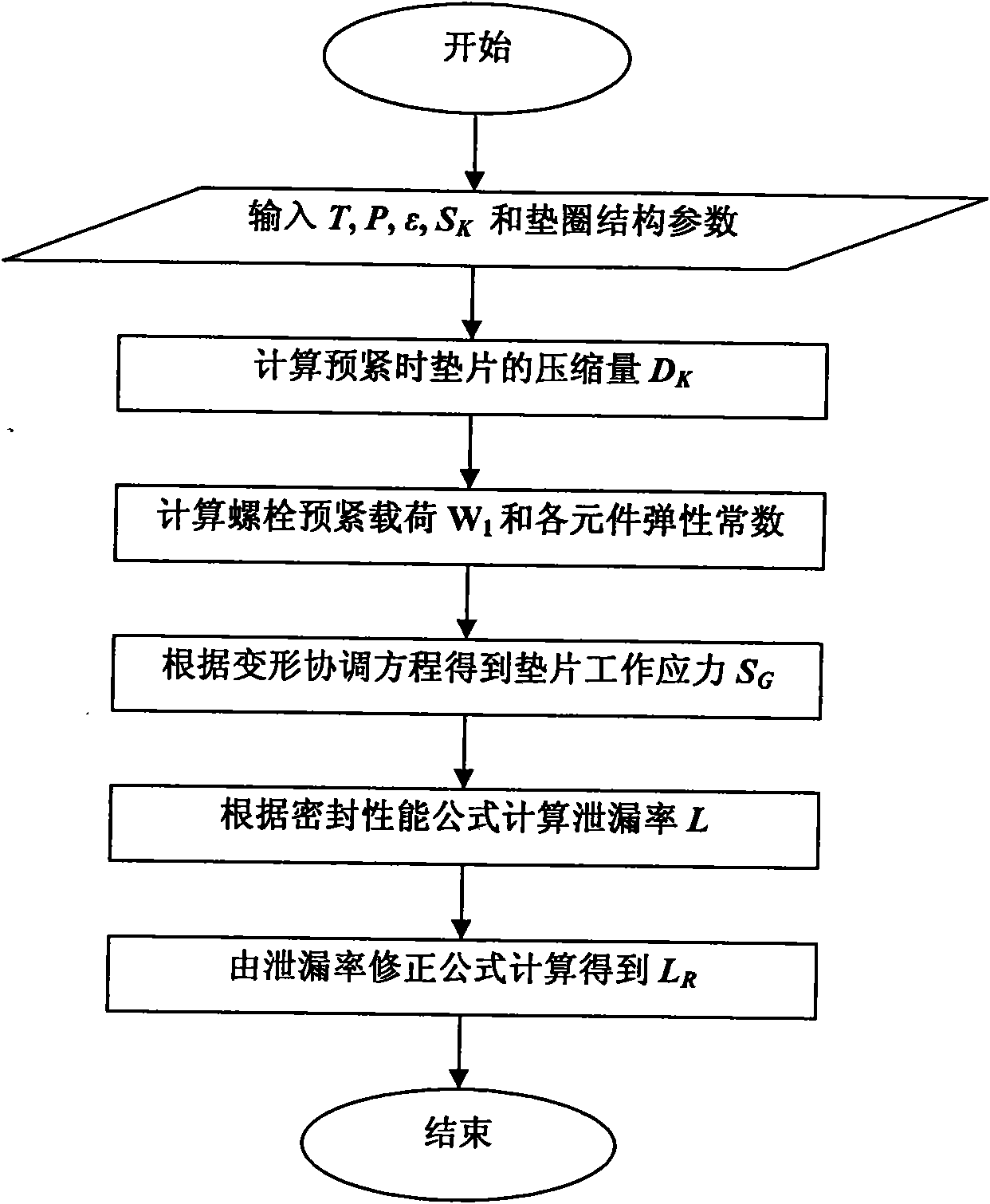

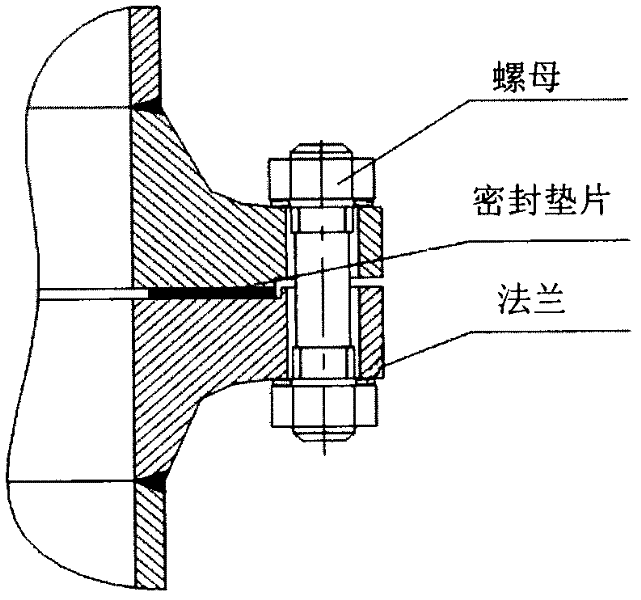

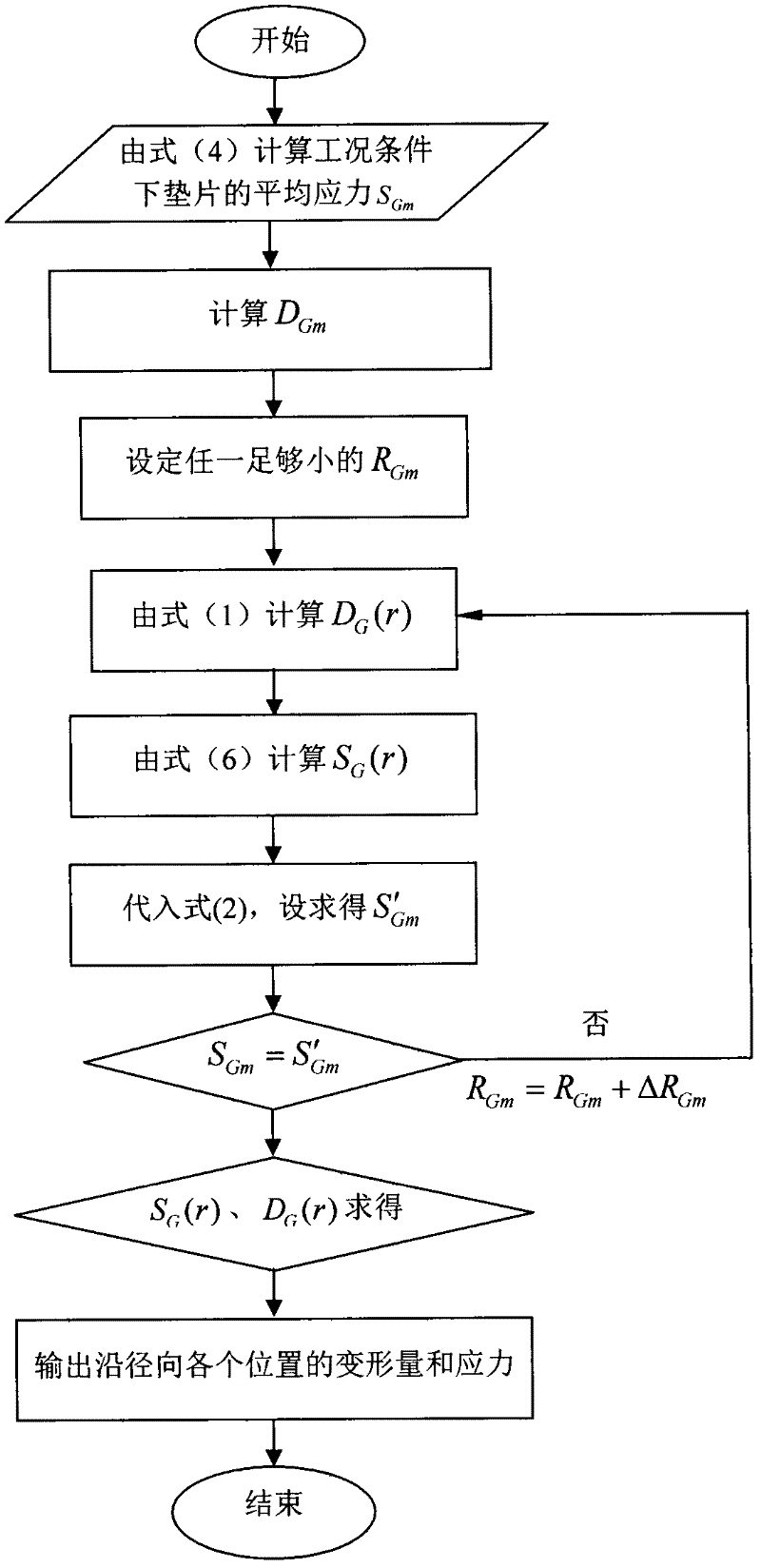

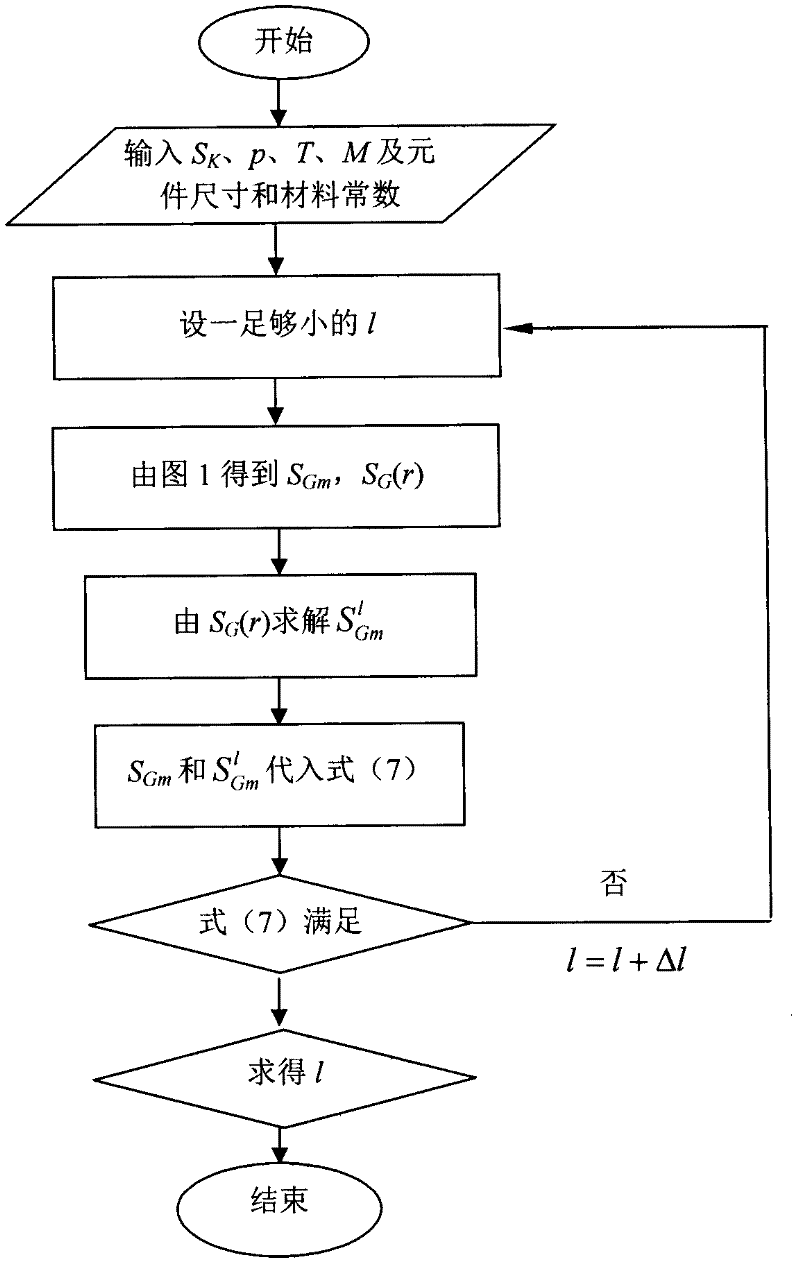

Predicting method of leakage rate of bolted flange connection structure with anti-loosing washer

InactiveCN101667229AAccurate predictionThe calculation principle is simpleFluid-tightness measurementSpecial data processing applicationsEngineeringHigh pressure

The invention relates to a predicting method of the leakage rate of a bolted flange connection structure with an anti-loosing washer. Aiming at the defect that the leakage rate of the prior bolted flange connection structure with the anti-loosing washer can not be predicted, by establishing the deformation compatibility equation of the bolted flange connection with the anti-loosing washer and calculating the pretightening force and the working stress of a gasket, and according to the tightness principle, the predicting method of the leakage rate of the bolted flange connection structure with the anti-loosing washer is established, so that the prediction of the leakage rate of the connection structure is realized. The predicting method of the invention has simple calculation principle and method and accurate prediction result, and can be widely applied to the prediction and calculation of the leakage rate of the connection structure in the circumstance of high temperature and high pressure and larger fluctuation of temperature and pressure.

Owner:NANJING UNIV OF TECH

Ocean floating drill platform string heave compensation device

InactiveCN101382042ALimit energy consumptionImprove the compensation effectDerricks/mastsUnderwater drillingSprocketType system

The invention discloses a novel drill stem heave compensation device for an ocean floating type drilling platform. A combined type hydraulic cylinder is adopted as a heave compensation hydraulic cylinder. The high-pressure hydraulic oil outputted from a hydraulic pump is led into a non-rod cavity of the inner casing of the combined type hydraulic cylinder through a compensation control valve, and therefore a controllable subsidiary force is provided for an outer casing piston rod. The controllable subsidiary force and the pressure of an accumulator acted by a non-rod cavity of the outer casing of the compensation hydraulic cylinder jointly form a support force for a hook load. The subsidiary force is controlled according to the heave movement of the platform, thereby improving the heave compensation effect of a conventional driven type system. According to the detected movement speed of the platform in the vertical direction, a control unit gives a control command to the hydraulic system so as to drive a piston of the compensation hydraulic cylinder to drive a sprocket to move, thereby compensating the heave movement of the platform under a chain or the chain action, and consequently enabling a cross beam and the hook to be in a static status relative to a hole bottom in the vertical direction within an allowable range. The drill stem heave compensation device can effectively control the consumption of the energy, reduce the operating cost of the system, and improve the compensation precision.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

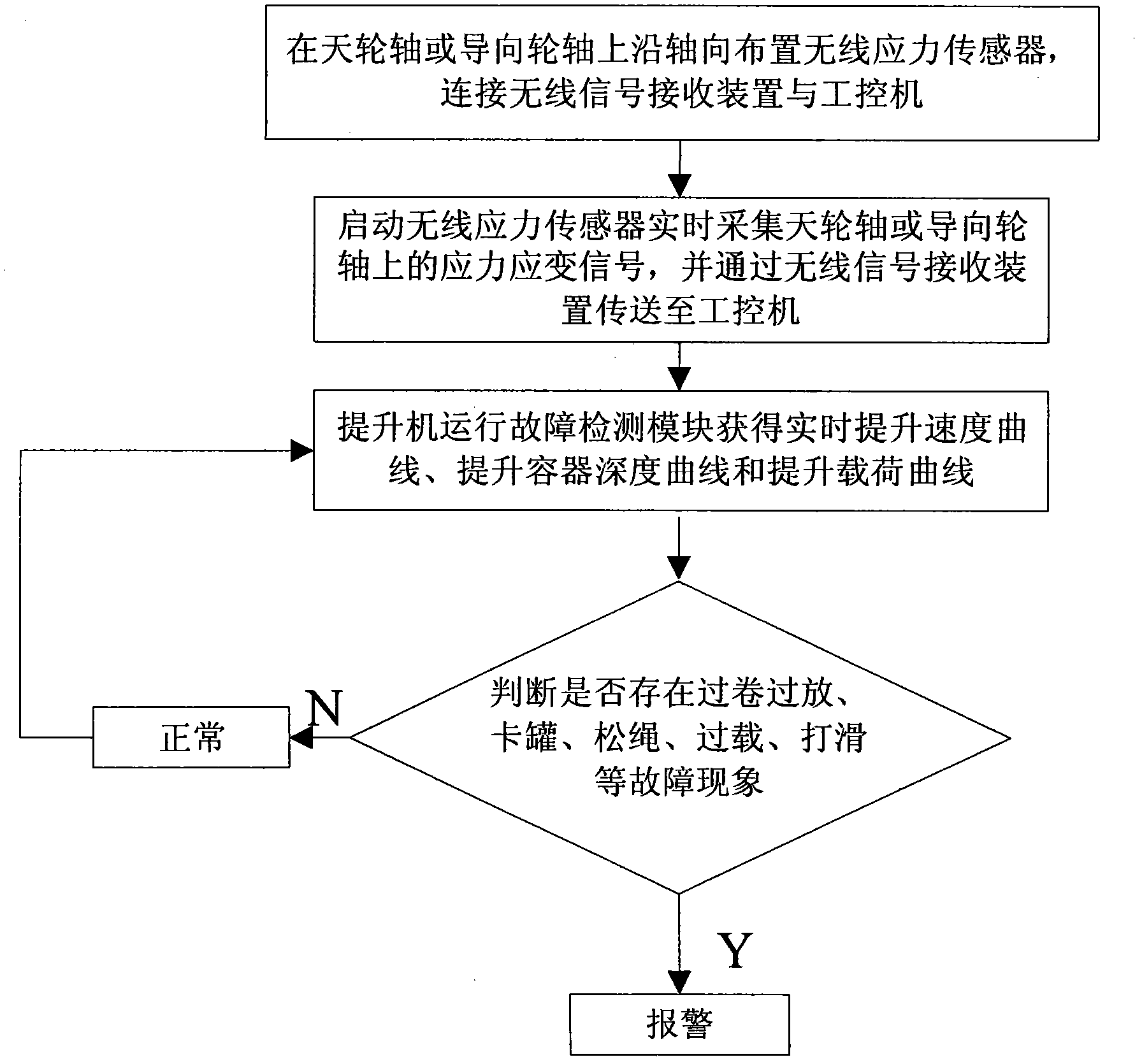

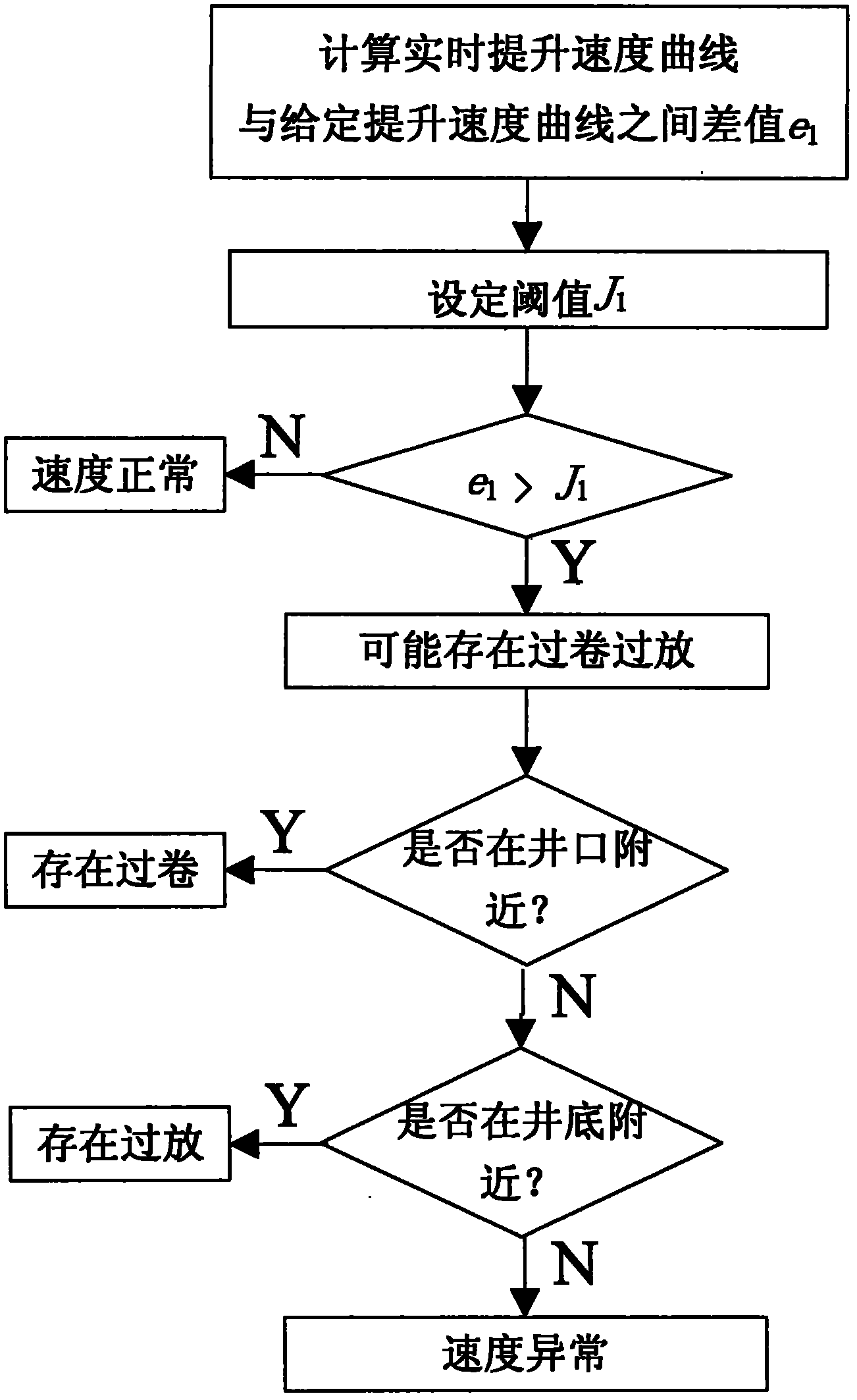

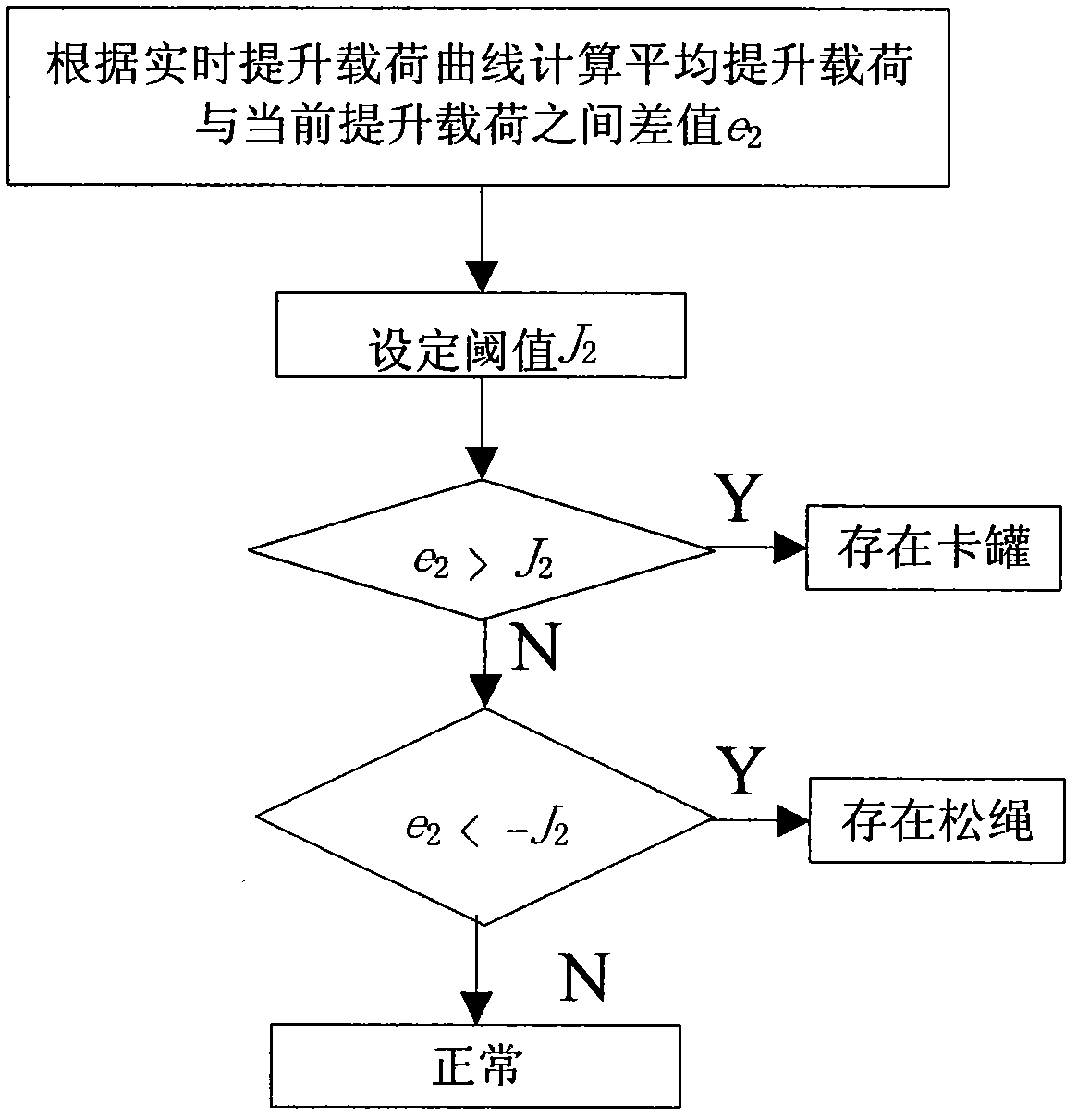

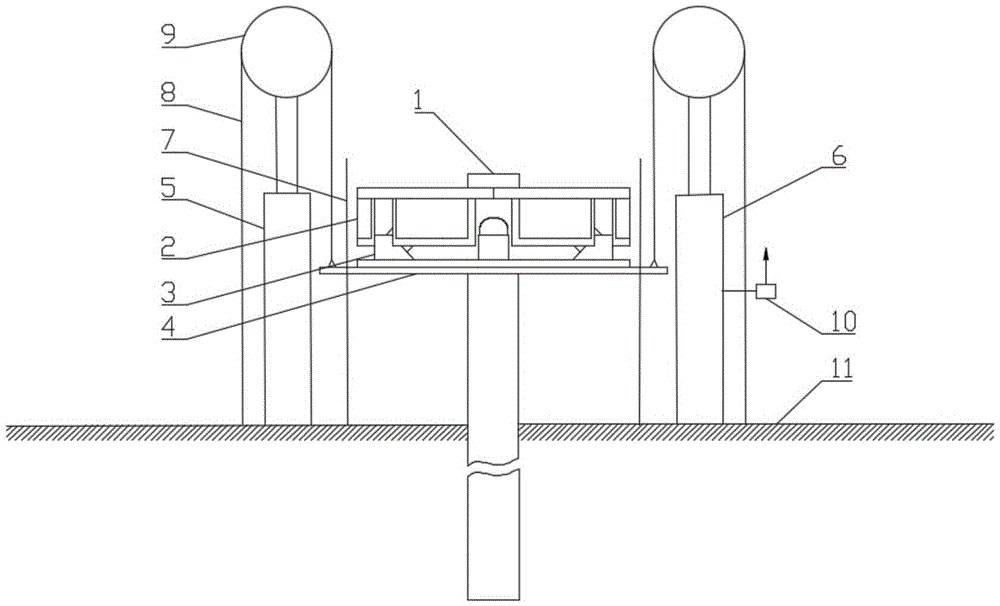

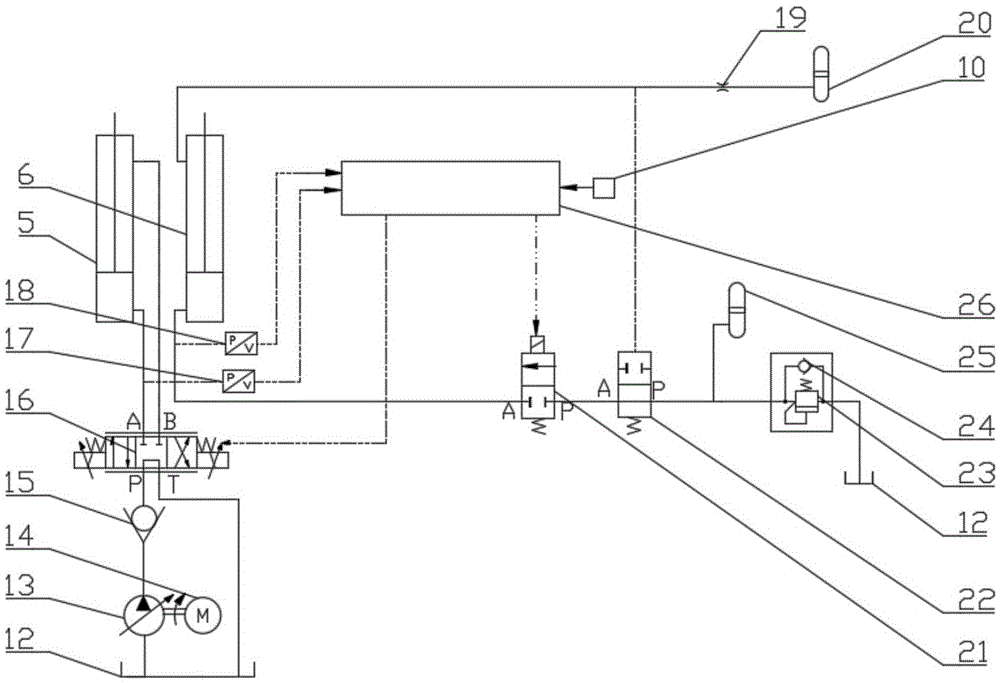

Method for detecting operation troubles of mine hoist

The invention relates to a method for detecting operation troubles of a mine hoist. The method comprises the following steps of: axially arranging a wireless stress sensor on a hoisting sheave shaft or a guide wheel shaft, wherein the wireless stress sensor is used for acquiring a stress-strain signal on the shaft and transmitting the stress-strain signal to an industrial personal computer through a wireless signal receiving device; identifying peaks and troughs of the stress-strain signal to acquire a real-time hoisting speed curve and a hoisting container depth curve by a mine hoist operation trouble detection module in the industrial personal computer, simultaneously converting the stress-strain signal according to a corresponding relationship between the stress-strain signal and a hoisting load to acquire a real-time hoisting load curve; and judging whether phenomena such as over-winding, over-unwinding, slipping, cage clamping, rope releasing, overloading and the like exist or not by combining the hoisting speed curve given by the hoist, rated load and the reading of a depth indicating meter on the basis of the acquired three real-time curves. The method has the advantages ofsimple required hardware equipment, high reliability, high anti-interference performance, high real time property and capacity of detecting various troubles simultaneously.

Owner:CHINA UNIV OF MINING & TECH

Marine floating type drilling riser flexible hanger

ActiveCN105649560ASimplify the suspension operation stepsShorten suspension operation timeDrilling rodsWell/borehole valve arrangementsHydraulic cylinderUniversal joint

The invention discloses a marine floating type drilling riser flexible hander which mainly comprises a chuck-universal joint assembly, a motion compensation device, a guide mechanism and a hydraulic power unit. The chuck-universal joint assembly is combined by adopting an embedded structure, suspension and up-down of a water string can be achieved, and it is ensured that the chuck swings by a certain angle along with a riser; a distance-increasing type motion compensation hydraulic cylinder is adopted on the motion compensation device to drive the chuck-universal joint assembly to do compensation motion. The guide mechanism ensures that the chuck-universal joint assembly does rectilinear motion along a guide rail through sliding fit of a sliding block installed on the chuck-universal joint assembly and the guide rail, and the radial load of the riser is borne. The hydraulic power unit provides power and control for the whole device. On the basis of achieving the conventional suspension and up-down operation function, the system structure height is lowered, the riser suspension operation step is simplified, suspension time is shortened, the variation amplitude of the load in the riser is lowered, and the suspension performance and reliability of the riser are improved.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

Ferroalloy

An iron alloy comprises (wt%): C 0.01-0.22, Si 0.08-1.00, Mn 4.5-12.00, P 0.02-0.2, S 0.025-0.06, Ni 3.50-22.00, Cr 15.00-24.00, Mo 0.05-6.00, and balanced with Fe. It is of explsion-proof and no sparks so as to be used to make containers for dangerous or chemical materials or the other explosion-proofing tools or apparatus.

Owner:金雹峰

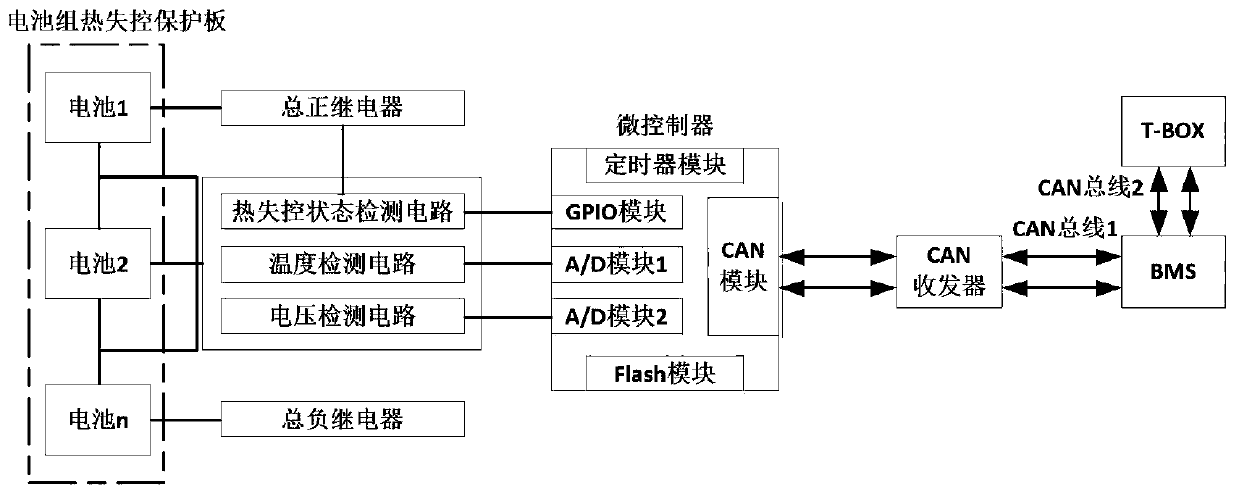

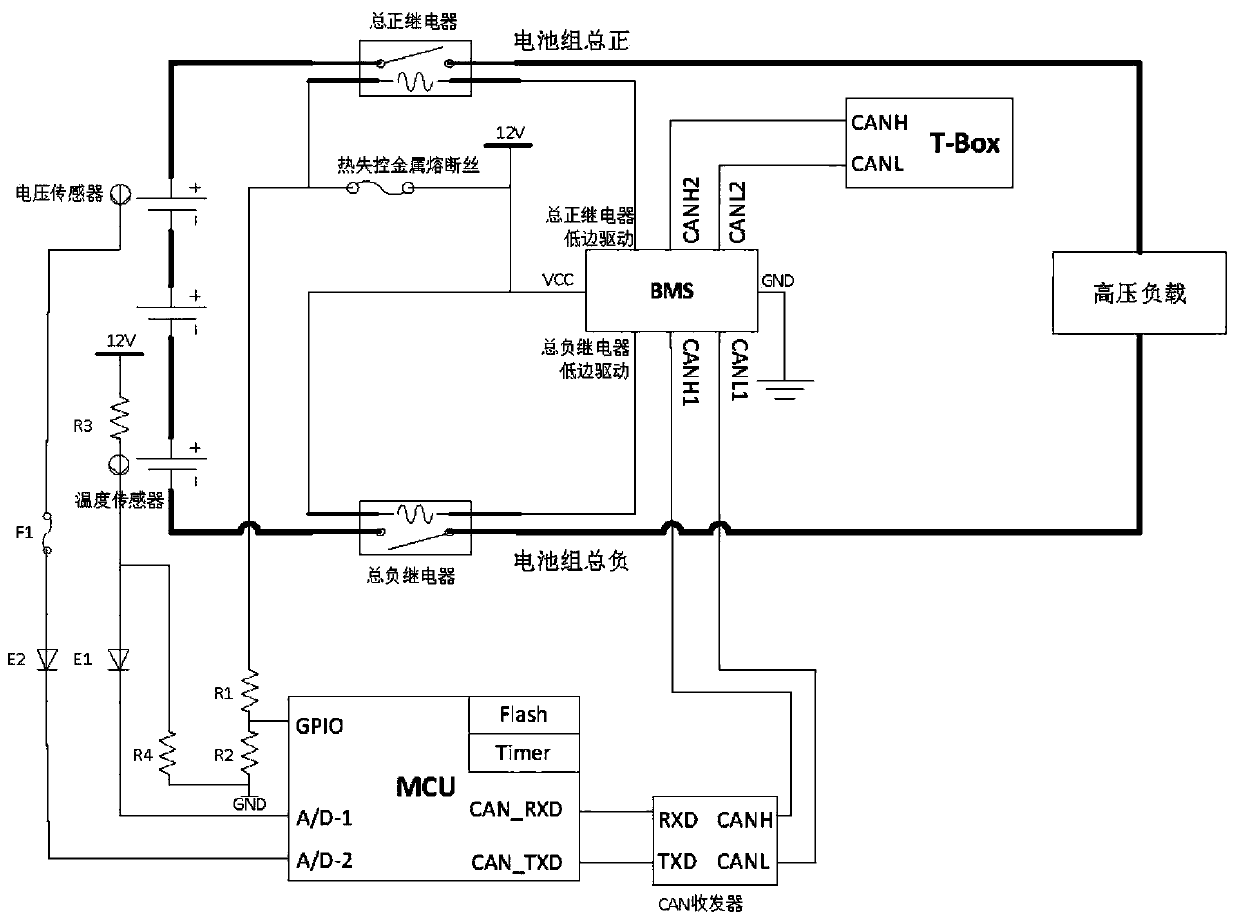

Thermorunaway detection and protection device and method of power battery pack of electric automobile

PendingCN110525219AReal-time detection of temperatureReal-time detectionElectric devicesSecondary cells testingMicrocontrollerData terminal

The invention discloses a thermorunaway detection and protection device and method of a power battery pack of an electric automobile, and relates to the field of failure detection and safety protection of electric automobiles. The device mainly comprises a microcontroller, a temperature detection circuit, a voltage detection circuit, a thermorunaway protection circuit, a local area network transceiver and a thermorunaway protection plate. Through cooperation with a battery management system, a main positive relay, a main negative relay and a vehicle-mounted data terminal of the electric automobile, by means of the special control method and protection measures, when the thermorunaway risk exists in the power battery pack, an alarm is given immediately, after the thermorunaway phenomenon happens, protection measures can be taken for the battery pack in time, and therefore the accident risk is reduced, and equipment consumption is reduced.

Owner:JIANGLING MOTORS

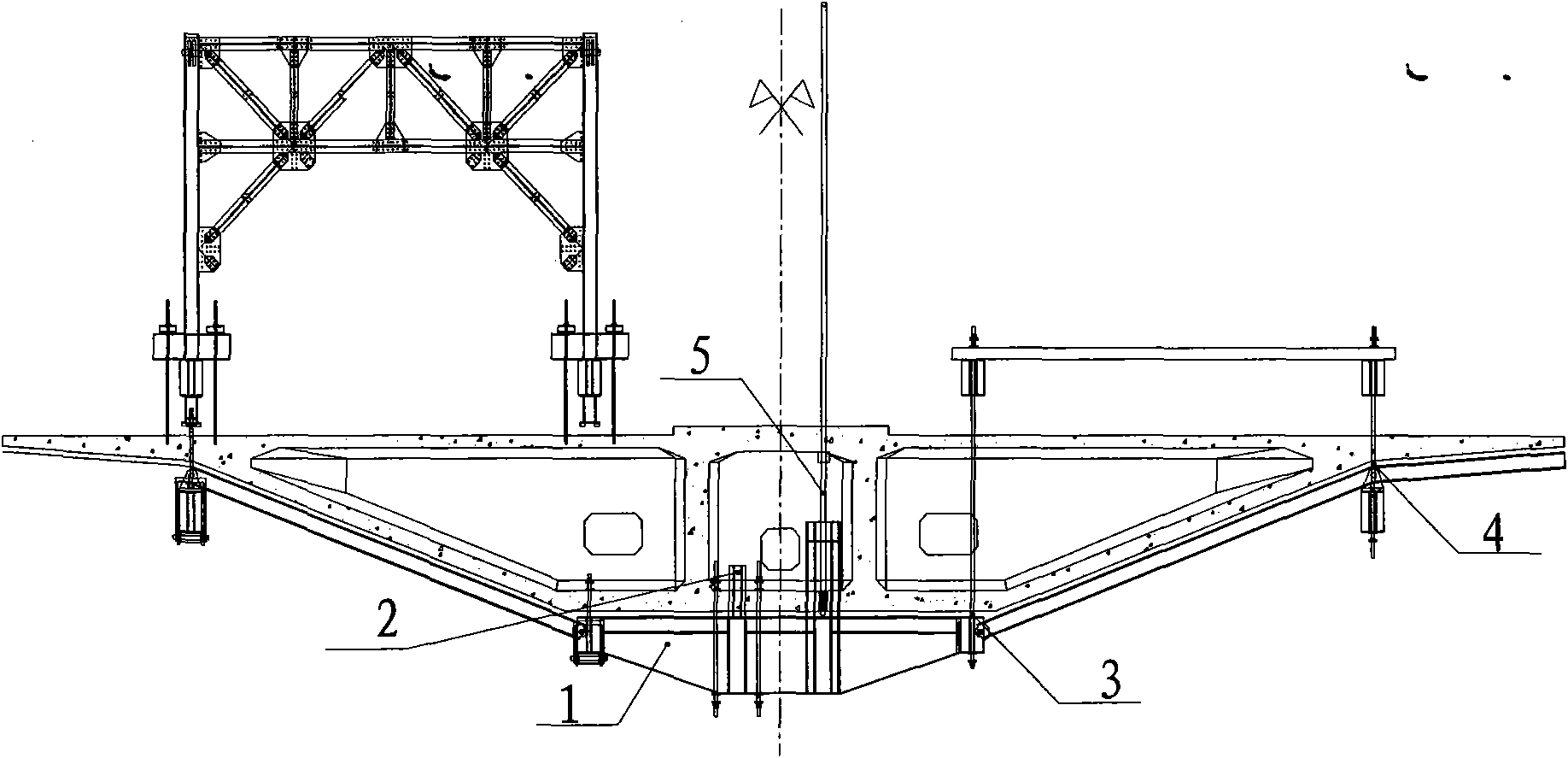

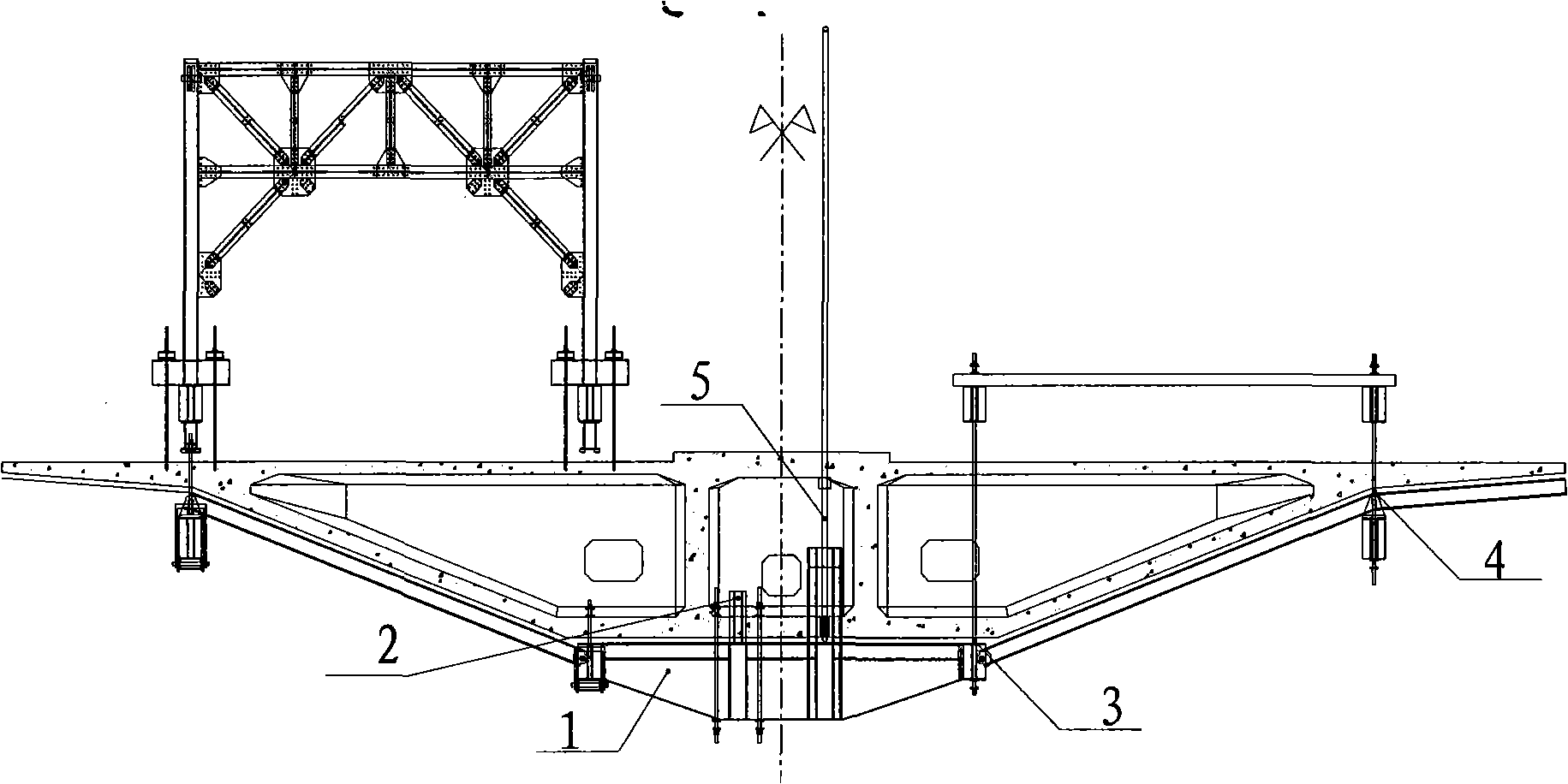

Cradle stress and deformation early warning system

InactiveCN101881001AAvoid nasty accidentsGuarantee quality and safetyBridge erection/assemblyElectricityEarly warning system

The invention discloses a cradle stress and deformation early warning system. The early warning system is characterized in that: the early warning system comprises sensors mounted on all the parts and a control cabinet, the sensors are electrically connected with the control cabinet, the control cabinet is provided with a preset program and a warning device, the stress value and the deformation value of each controlled part transmitted by the sensors are compared with preset values, and when the stress value or the deformation value exceeds the preset value, the warning device is started to give the alarm. The adopted technical scheme can timely monitor the stress and deformation of a cradle structure in order to prevent the occurrence of severe accidents and ensure the construction quality.

Owner:CHONGQING URBAN CONSTR HLDG GRP

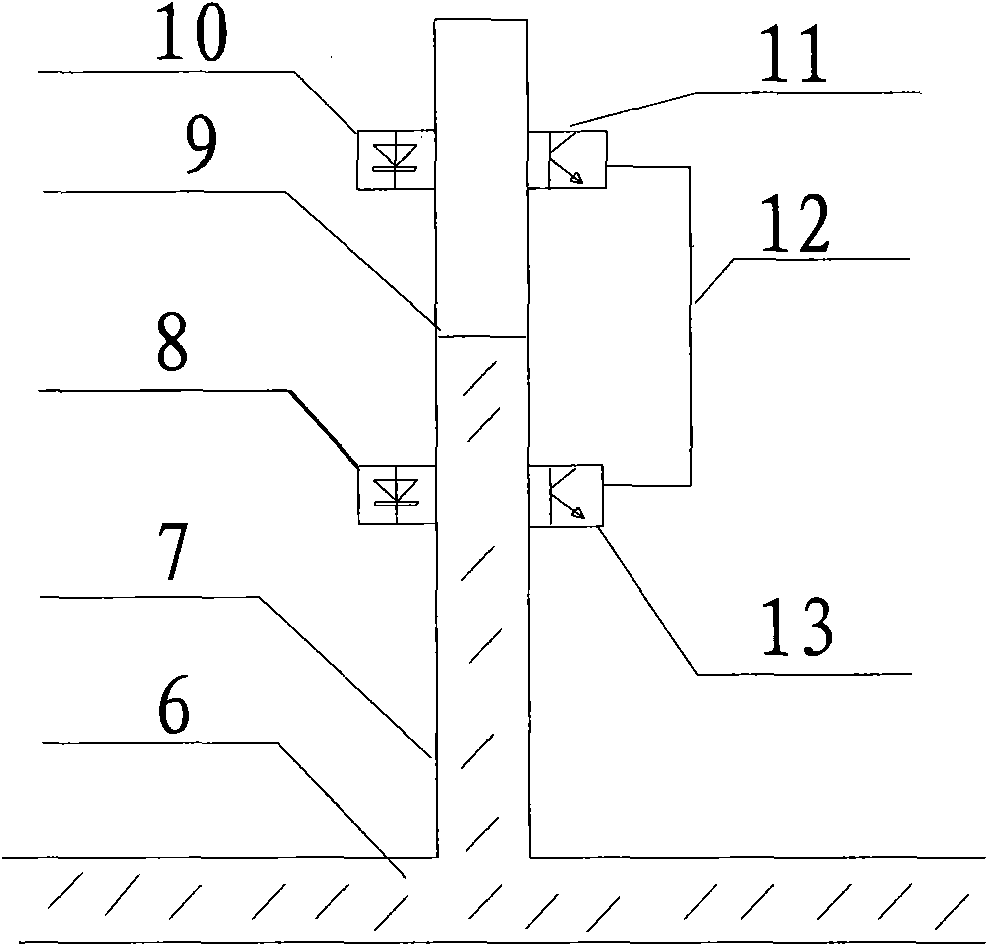

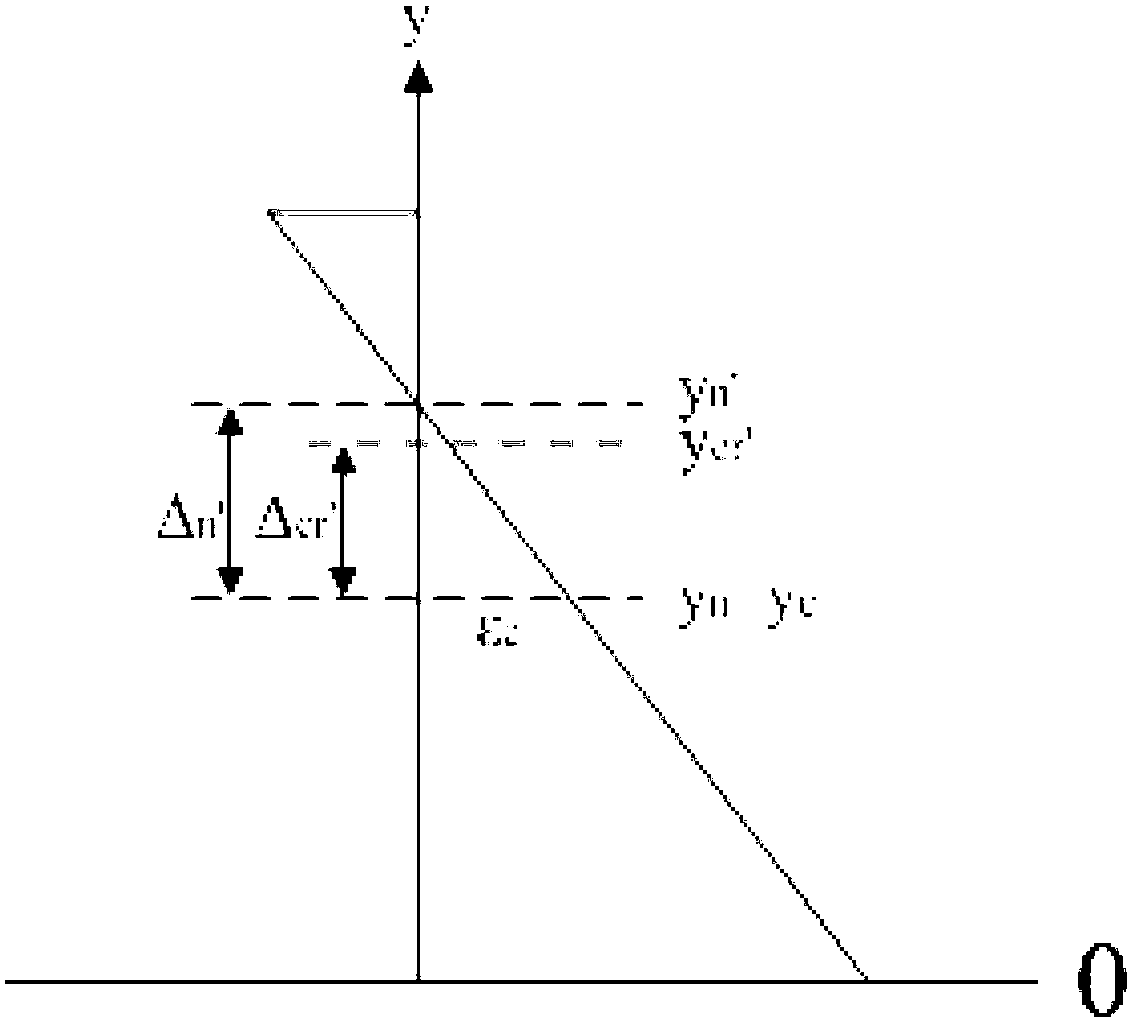

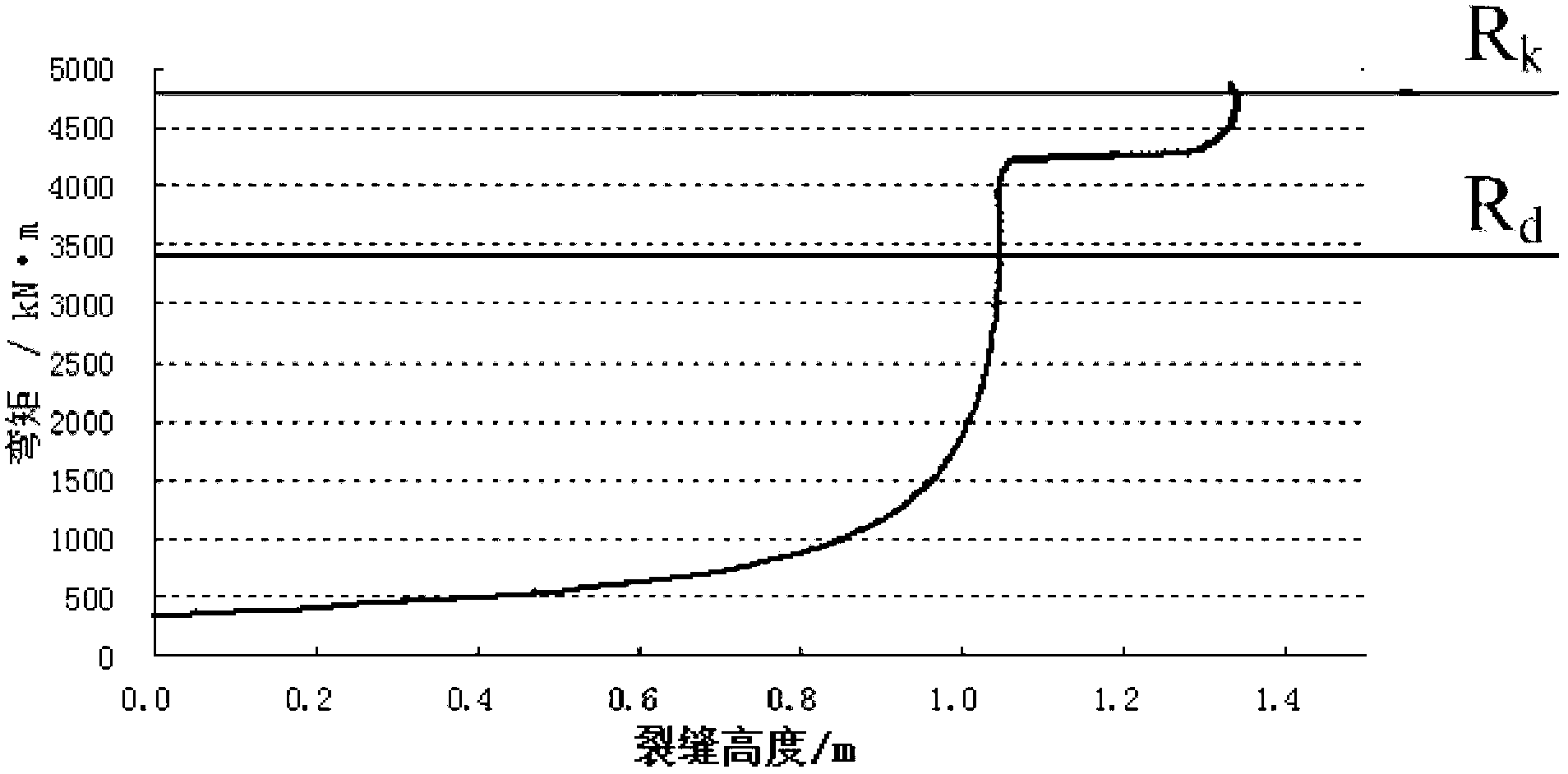

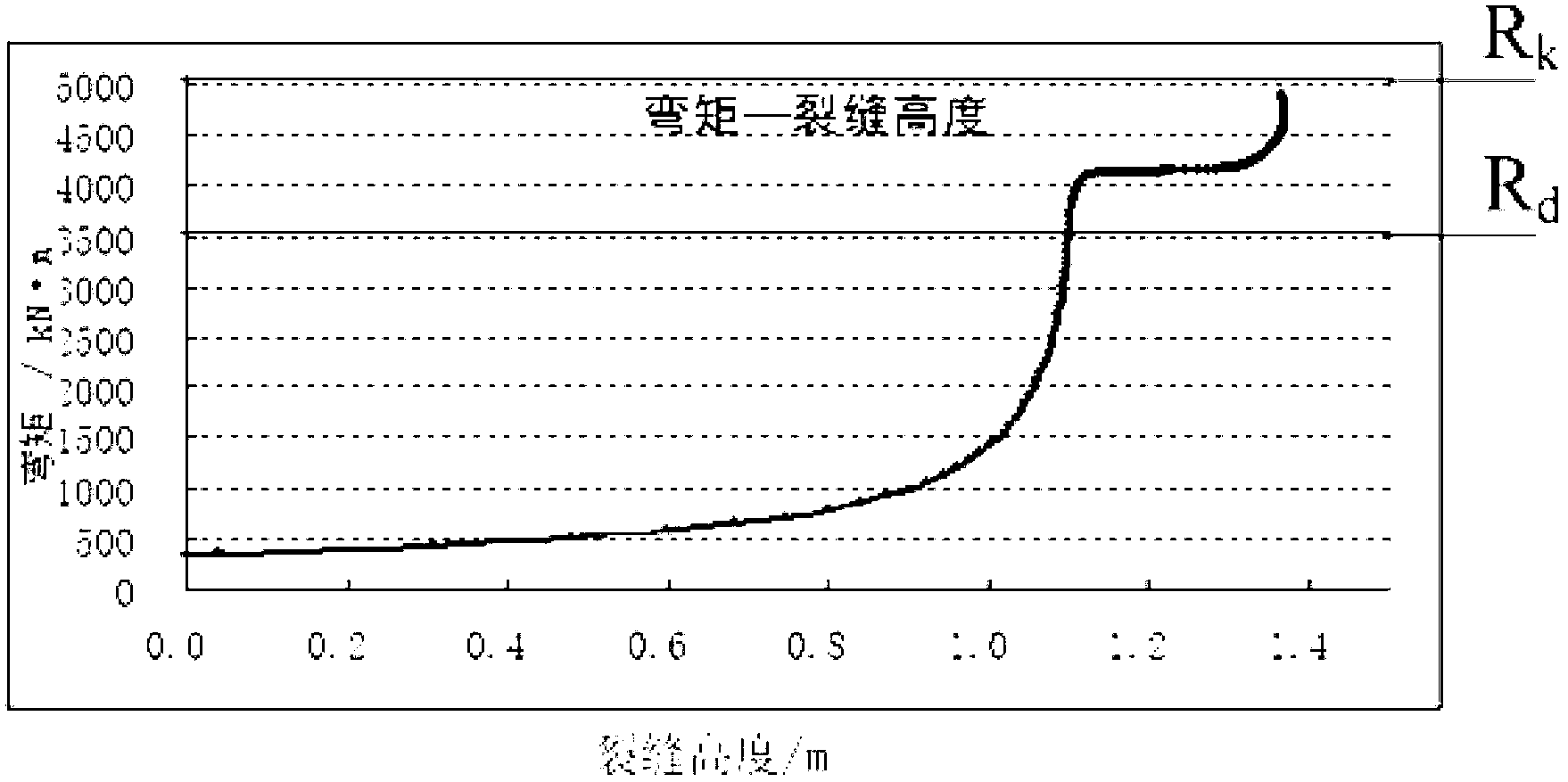

Beam bridge damage assessment early-warning method and early-warning system based on crack development height

InactiveCN103226084ATimely detection of damageMonitoring content is intuitiveMaterial strength using steady bending forcesEarly warning systemConductive coating

The invention relates to a beam bridge damage assessment early-warning method and an early-warning system based on a crack development height. According to the early-warning method, early warning is carried out when a crack in a main beam of the beam bridge requiring monitoring develops to a dangerous crack height range of a main beam mid-span cross section. The main beam mid-span cross section dangerous crack height range is provided according to a main beam resistance designed value and a main beam resistance standard value, and is determined according to a bending moment-crack height diagram of the main beam mid-span cross section. The bending moment-crack height diagram is obtained according to a cross section non-linear whole process analysis upon the bridge cross section. The early-warning system comprises conductive coatings coated on dangerous crack height ranges of various main beam mid-span cross sections of the beam bridge, and a data processing and early-warning device. The data processing and early-warning device comprises a data acquisition device, a microprocessor, and a GMS short message module. When a crack on the monitored beam bridge main beam develops to a dangerous crack height range, the system carries out early warning with a form of short messages.

Owner:CHANGAN UNIV

Prediction method of leakage rate of bolted flange connection structure

InactiveCN102519674AReduce wasteAvoid casualtiesFluid-tightness measurementTemperature stressTemperature and pressure

The invention relates to a prediction method of a leakage rate of a bolted flange connection structure, and belongs to the technical field of sealing. A gasket is an important sealing element in bolted flange connection, and the tightness width of the gasket is a key factor which determines the sealing performance of the connection structure. In order to solving the defects that the leakage rate of the connection structure can not be predicted in the traditional bolted flange standard design method, and under the conditions that the connection structure bears an external load, and high temperature and pressure and temperature and pressure have greater fluctuation, and the like, the predication is inaccurate in the traditional predication method of the leakage rate, so the prediction method of the leakage rate of the bolted flange connection structure is provided according to the relationship among the calculated tightness width of the gasket and the material of the gasket, the connection form of the connection structure, the load, working conditions and the like, and a numerical example and experimental verification are provided. The predication method has the characteristics of simple calculation method and high accuracy, and the leakage rate of the bolted flange connection structure can be accurately predicated under different working conditions according to the calculation method, and thus the security, stability and long-period operation of process equipment are ensured.

Owner:CHANGZHOU UNIV

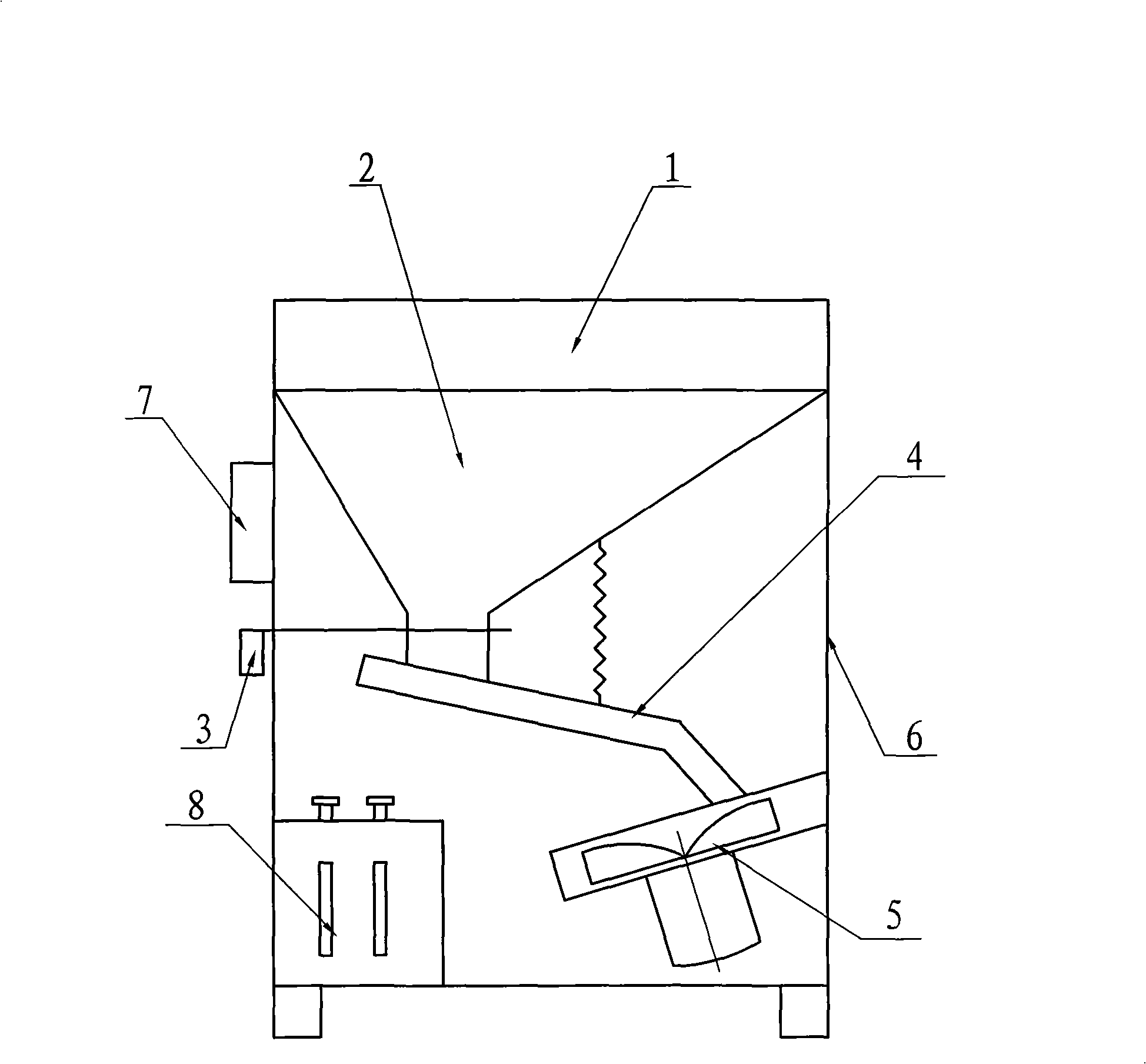

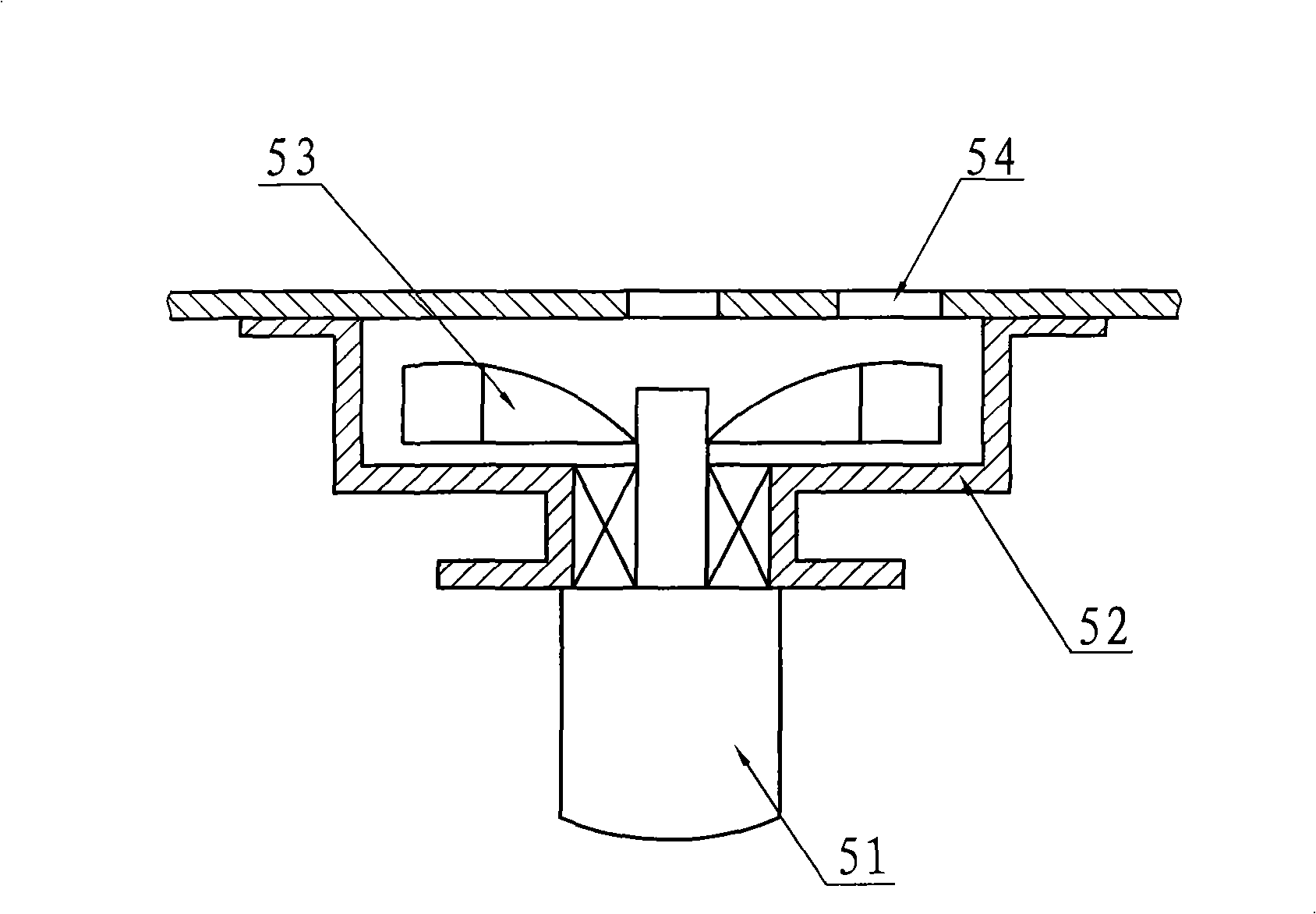

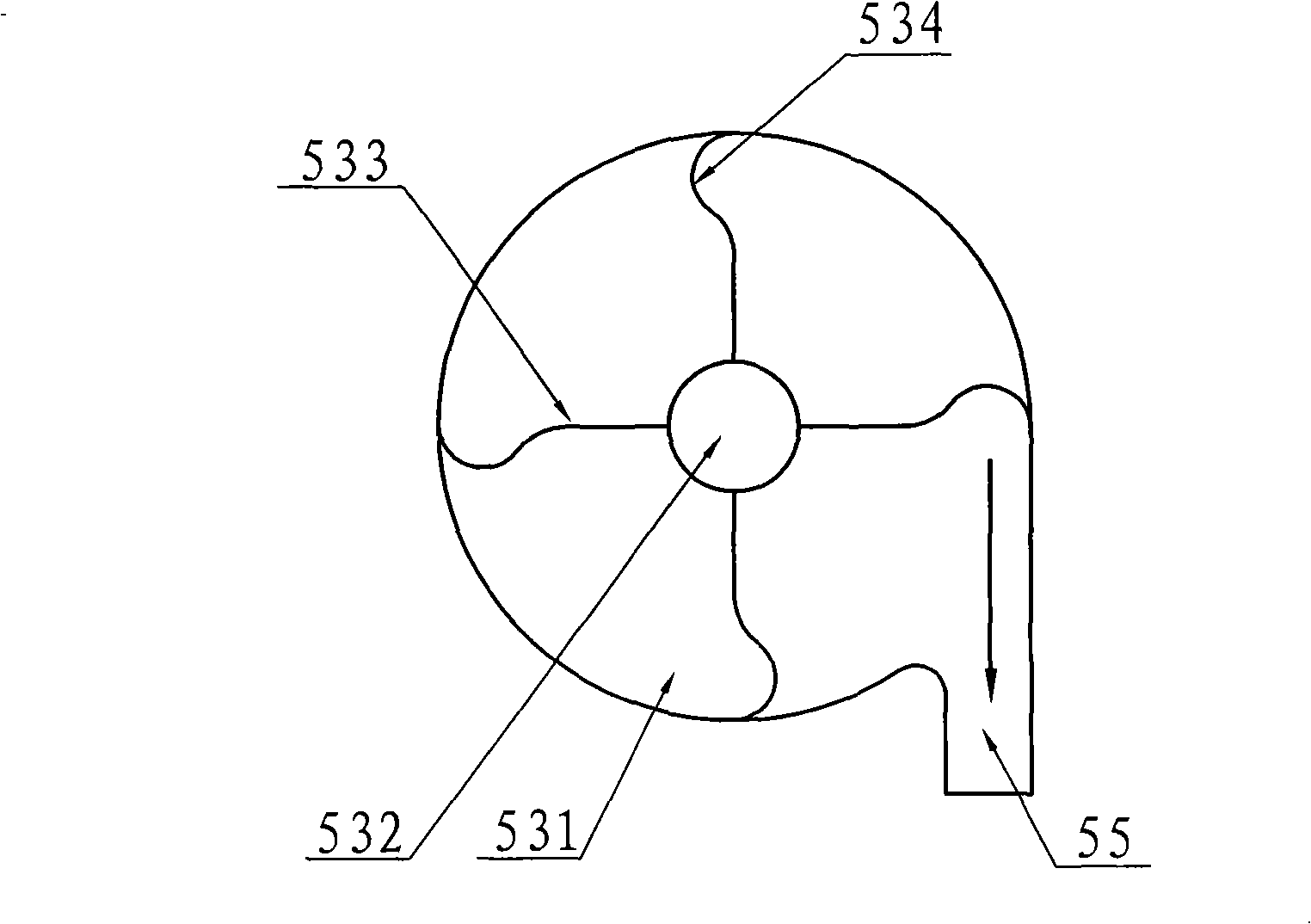

Marine blow-throwing bait feeder for pound

InactiveCN101536680AAvoid nasty accidentsSimple structurePisciculture and aquariaImpellerDynamic balance

A marine blow-throwing bait feeder for a pound comprises a direct current controlling and setting box and a battery jar, wherein the direct current controlling and setting box, the battery jar and a direct current motor are electrically connected with one another; a bait casting disc consists of a direct current motor, a shell, a throw-blowing impeller, a material falling port and a material outlet; the throw-blowing impeller consists of a soleplate, an impeller base and a plurality of profiled vanes, wherein the profiled vanes are uniformly distributed on the soleplate; the external end of each profiled vane is provided with a slot; and the whole throw-blowing impeller meets the dynamic balance requirement. The battery jar is used as the power supply of the bait feeder so that the bait feeder can be directly arranged on a boat and carry out uniform bait-throwing operation in any distance on the water surface together with the boat, thus leading the bait feeding in the pound to be more reasonable and scientific. As the external end of the impeller is additionally provided with the slot, when the granulated feeds are fallen into the material casting disc, both complete granulated feeds and fine granulations can be cast or blown into the pound under the high-speed rotation of the impeller; more importantly, the bait feeder thoroughly avoids the serous accidents generated due to guy creepage of alternating current.

Owner:常州金坛希望科研仪器有限公司

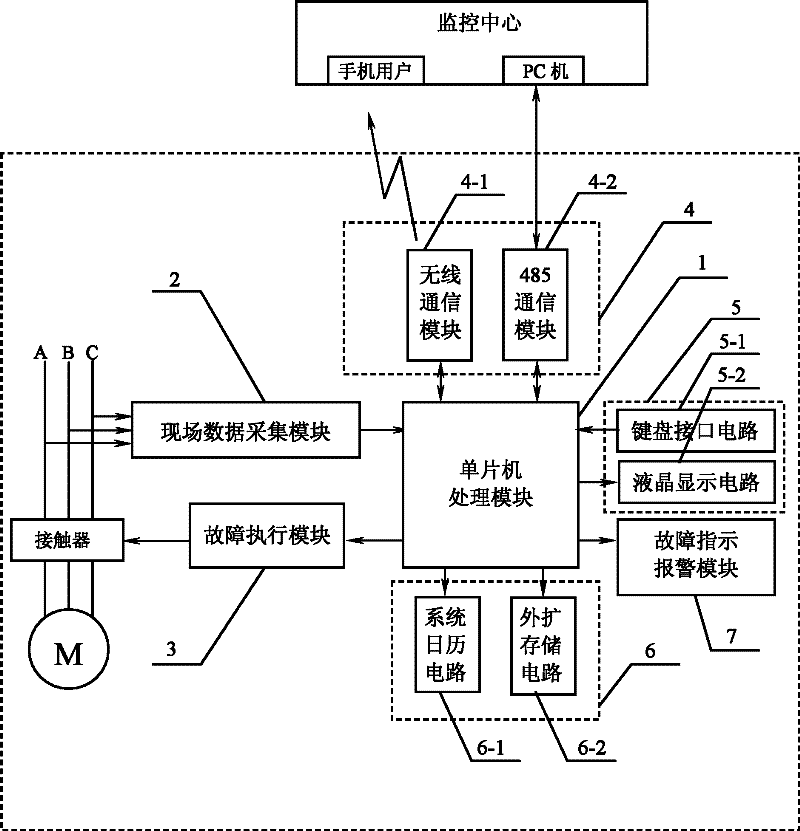

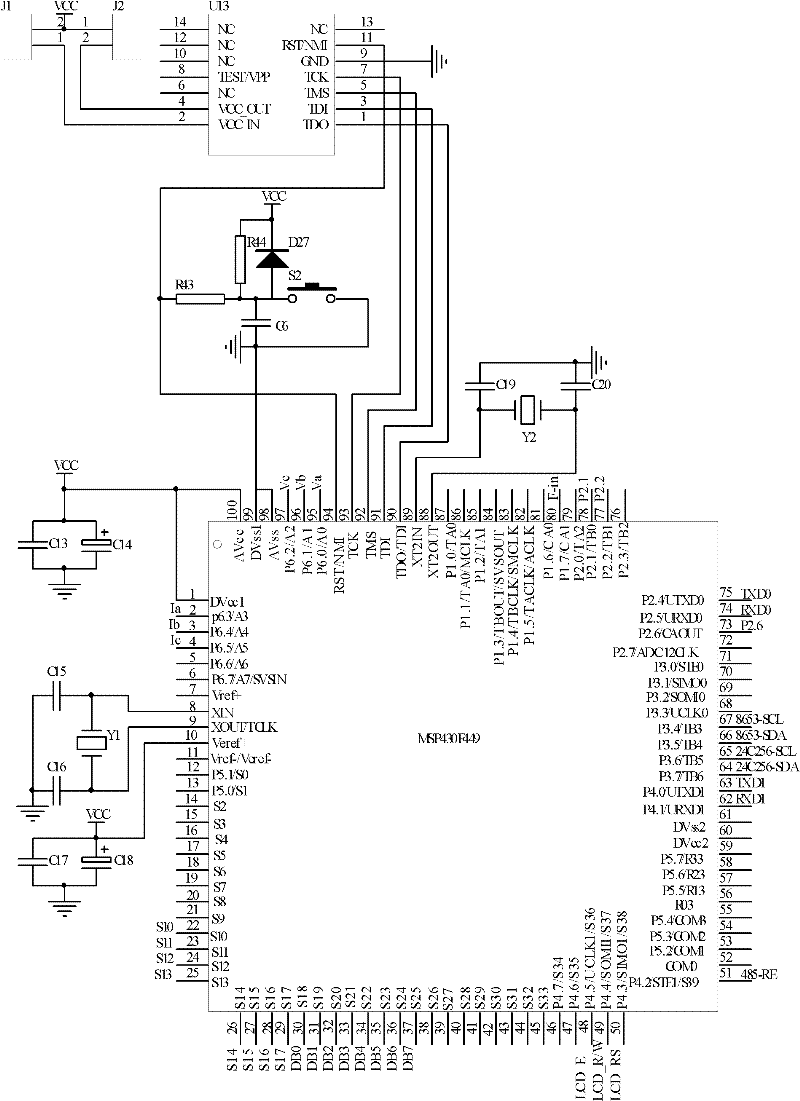

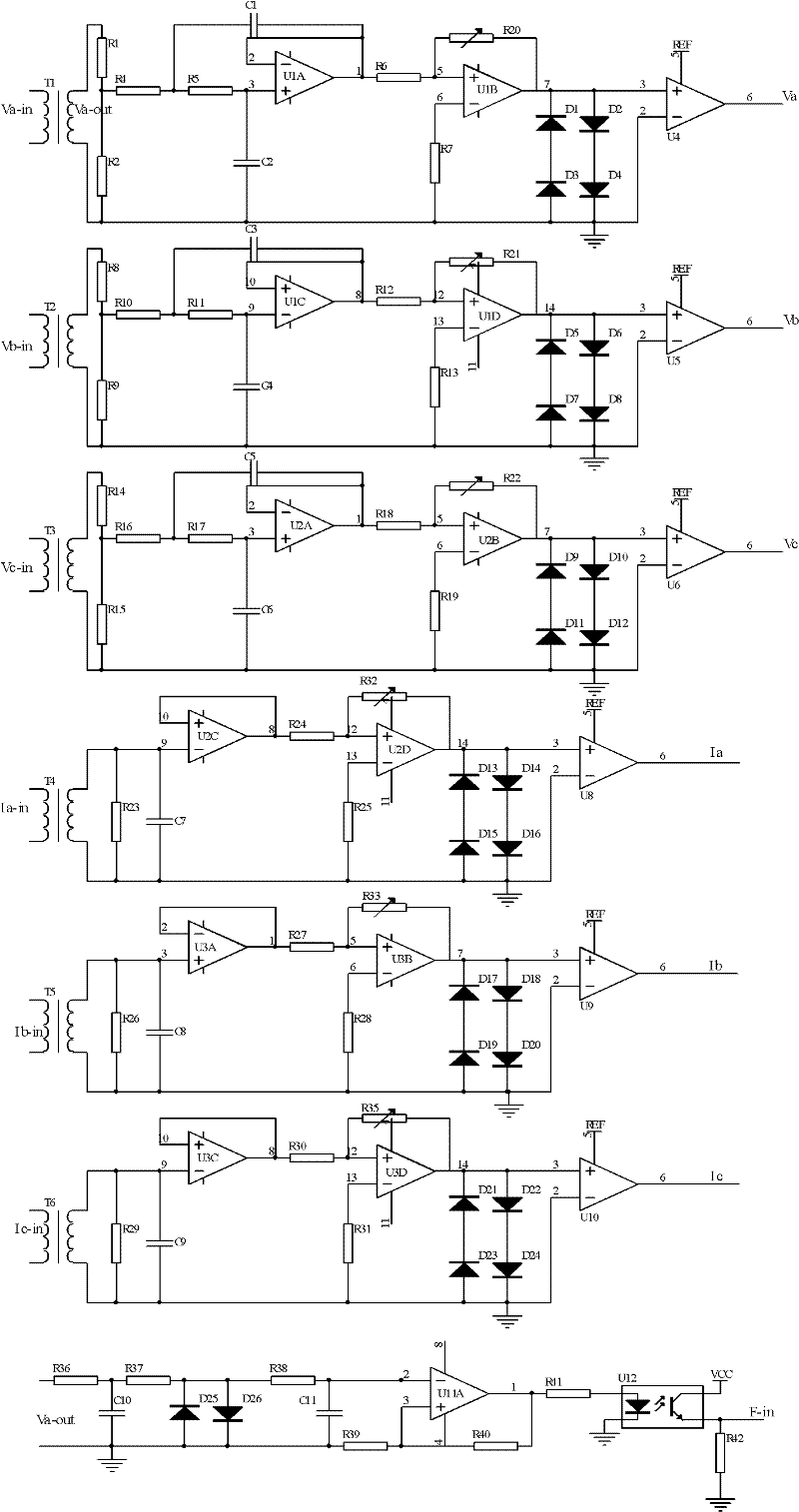

Safety monitoring terminal device for mine motor

The invention relates to a safety monitoring terminal device for a mine motor and belongs to the field of monitoring, and the device provided by the invention is designed for solving the problem that monitoring through the existing mine motor can not transmit acquired data to technical staff immediately. The safety monitoring terminal device comprises a single-chip microcomputer processing module, a field data acquisition module, a failure execution module, a communication processing module, a human-computer interaction module and an I2C (intel-integrated circuit) interface peripheral module, wherein the communication processing module comprises a wireless communication module and a 485 communication module, the human-computer interaction module comprises a keyboard interface circuit and a liquid crystal display circuit, and the I2C interface peripheral module comprises a system calendar circuit and an external expansion storage circuit; the field data acquisition module is used for acquiring the three-phase alternating current voltage, alternating current and frequency of the motor and sending to the single-chip microcomputer processing module, and the acquired data is sent to a PC (personal computer) of a monitoring center through the 485 communication module; the wireless communication module is used for sending short messages to a mobile phone user of a monitoring center through a GSM (global system for mobile communication) network; and the output end of the failure execution module is connected with the control end of a contactor used for controlling the operation of the motor.

Owner:HEILONGJIANG UNIVERSITY OF SCIENCE AND TECHNOLOGY

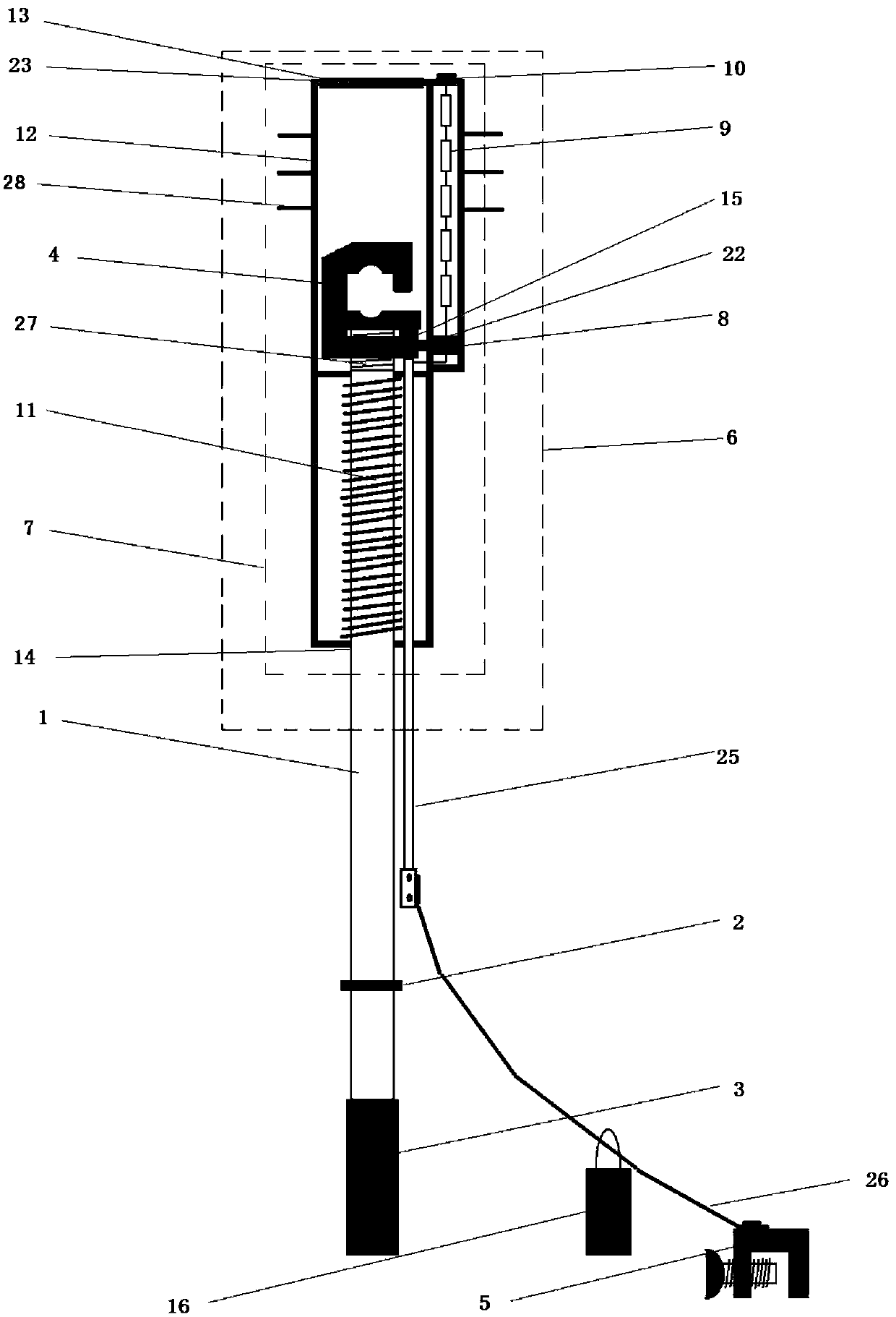

Short circuit grounding wire device with locking function

ActiveCN104201485AWith reminder functionWith locking functionElectrical testingConnection contact member materialGround lineShort circuit

The invention relates to a short circuit grounding wire device with a locking function. The short circuit grounding wire device comprises an operation rod (1), a grounding chuck (4), a grounding wire guide-out end (25), a grounding lead (26) and a grounding end chuck (5). The grounding chuck (4) is connected with the grounding lead (26) through the grounding wire guide-out end (25). The grounding lead (26) is connected with the grounding end chuck (5). The side, close to the grounding chuck (4), of the operation rod (1) is provided with an electrified pre-warning device (6). The pre-warning device (6) comprises a locking device (7) for preventing misoperation. Locking can be performed through the locking device (7) when grounding misoperation occurs, and personal safety of operators is guaranteed. Compared with the prior art, the short circuit grounding wire device is safe and reliable, convenient to operate, and the like.

Owner:STATE GRID CORP OF CHINA +1

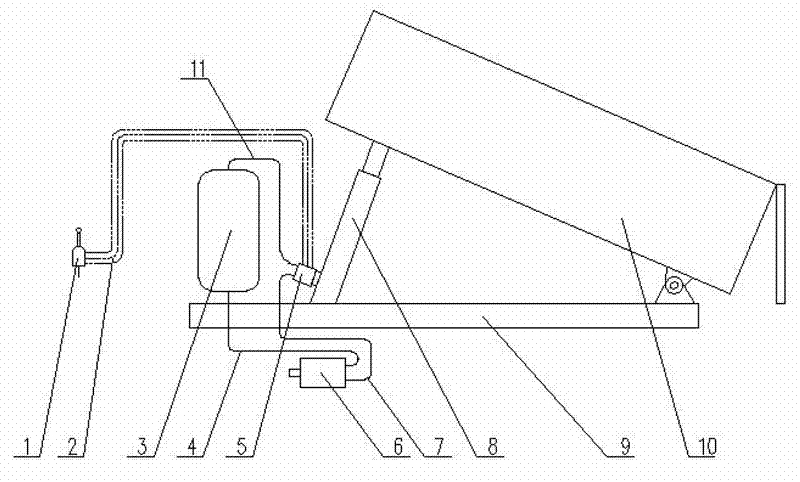

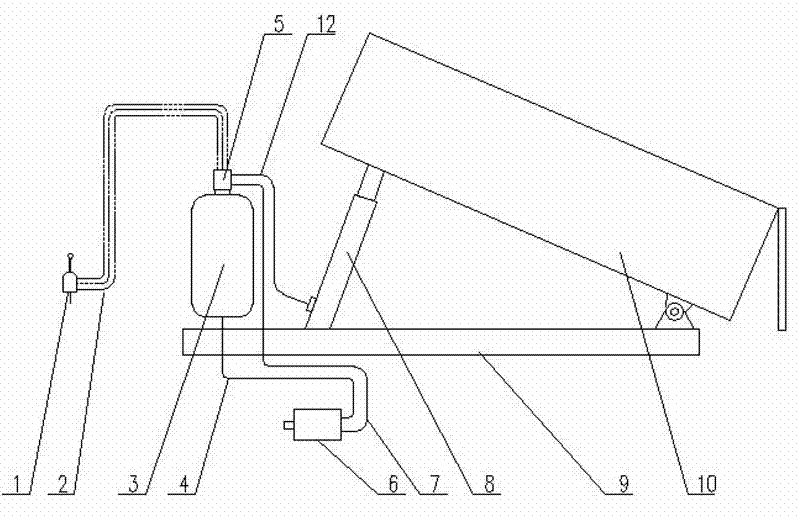

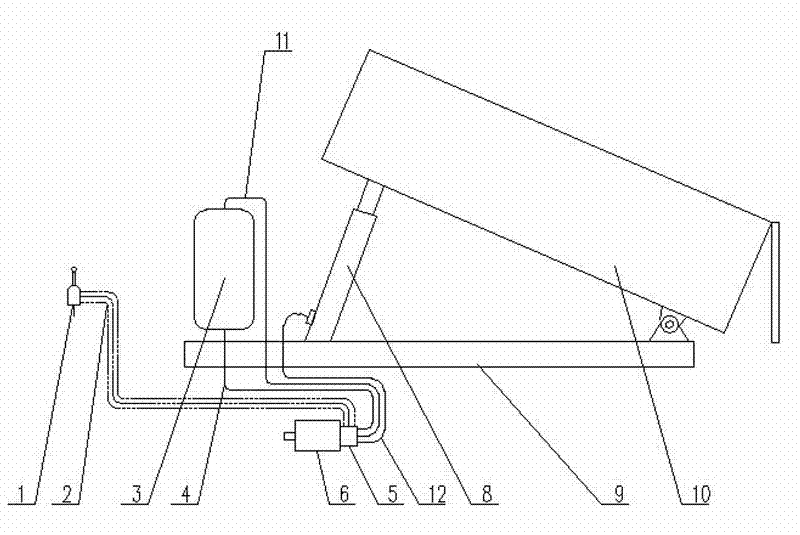

Hydraulic lifting device for dump truck

InactiveCN102390306AProtect personal safetyProtect vehicle safetyVehicle with tipping movementHigh pressureTipper truck

The invention discloses a hydraulic lifting device for a dump truck, and the hydraulic lifting device comprises a hydraulic oil tank, a hydraulic oil pump, a hydraulic distribution valve and a lifting oil cylinder, wherein the oil outlet of the hydraulic distribution valve is directly connected with the lifting oil inlet of the lifting oil cylinder. A hydraulic oil cylinder and the hydraulic distribution valve are installed in an integral way, and a high-pressure oil pipe arranged between the lifting oil inlet of the hydraulic oil cylinder and the oil outlet of the hydraulic distribution valve in the lifting configuration of the existing dump truck can be omitted. When a carriage of the dump truck is lifted, and the high-pressure oil pipe bursts suddenly, a reverse oil return way arranged in the lower cavity of the oil cylinder is automatically cut off by a one-way valve arranged at the outlet of the hydraulic distribution valve, the carriage is maintained at the stop position and does not fall off, and the carriage can be reliably and stably arranged on an auxiliary frame after the high-pressure oil pipe is replaced, so that terrible accidents are effectively prevented, and the personal safety of a driver and the safety of a vehicle can be well protected.

Owner:JINAN HYDRAULIC PUMP

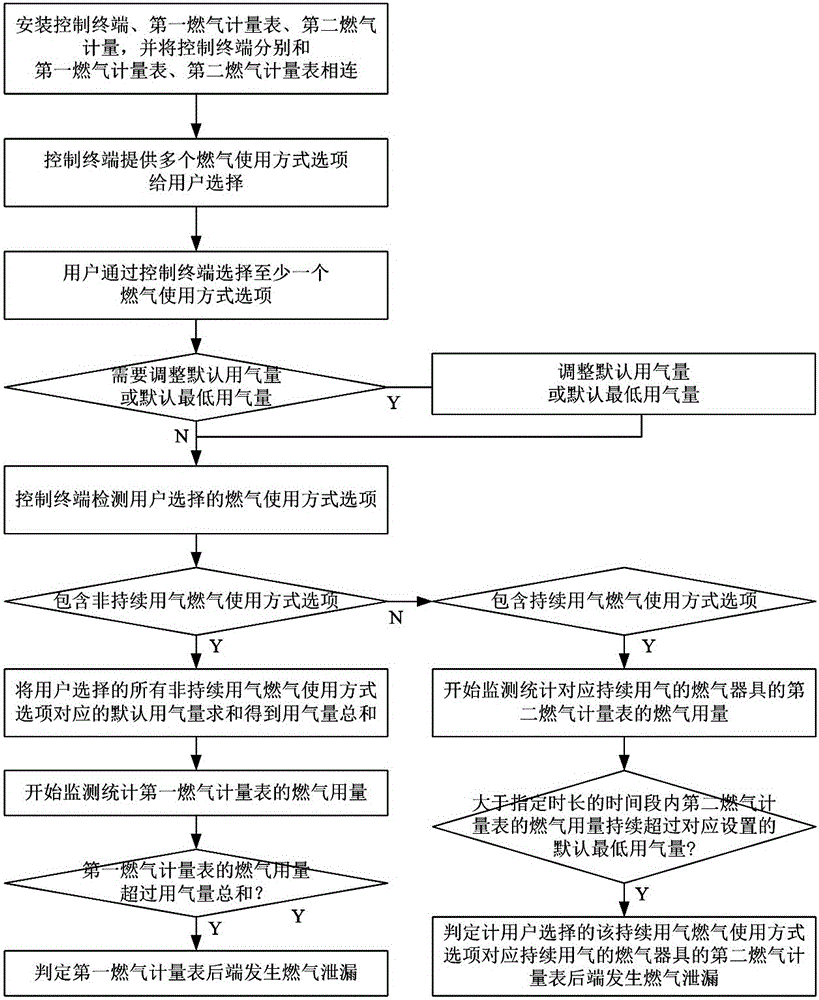

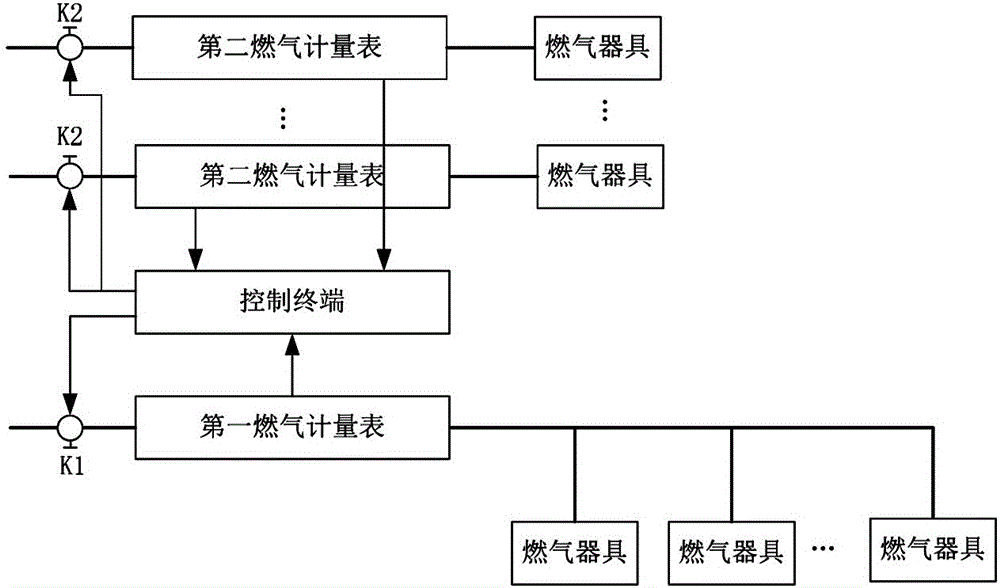

Gas leakage monitoring method and system based on gas metering

ActiveCN106052971ATimely maintenancePrecise screeningMeasurement of fluid loss/gain rateGas meterComputer terminal

The invention discloses a gas leakage monitoring method and system based on gas metering. The method comprises the following steps: a control terminal, a first gas meter and second gas meters are installed at a detected target area, the control terminal provides a plurality of gas usage mode options to a user to choose, the user chooses at least one gas usage mode option through the control terminal, each gas usage mode option corresponds one modifiable default gas consumed volume or default minimum gas consumed volume, and whether gas leakage occurs is determined according to gas metering values of the first and second gas meters and the default gas consumed volume or the default minimum gas consumed volume. The system comprises the control terminal, the first gas meter and the second gas meters, and the control terminal is connected with the first gas meter and the second gas meters. User's normal usage and the gas leakage can be accurately discriminated, leakage monitoring accuracy is high, a fault is convenient to timely handle by a user, occurrence of a vicious accident brought by the gas leakage is prevented, and a comprehensive disposal with a traditional gas leakage method is convenient.

Owner:谷振宇

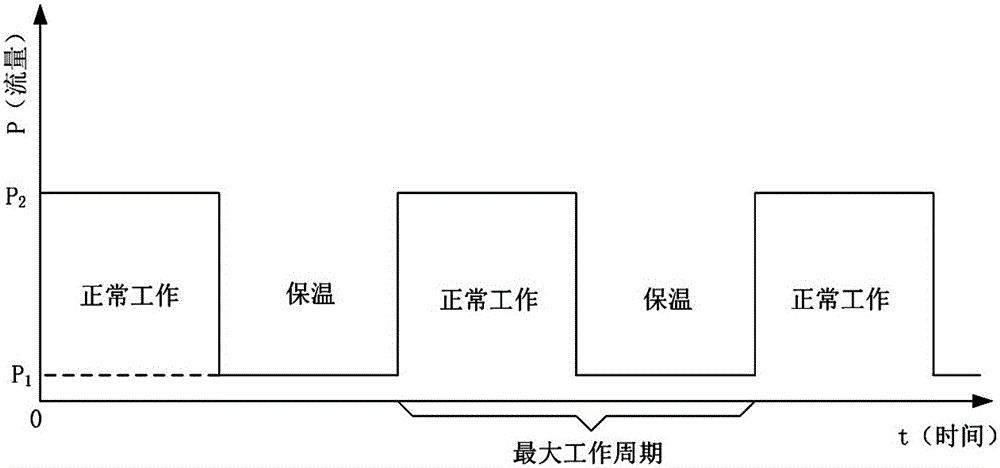

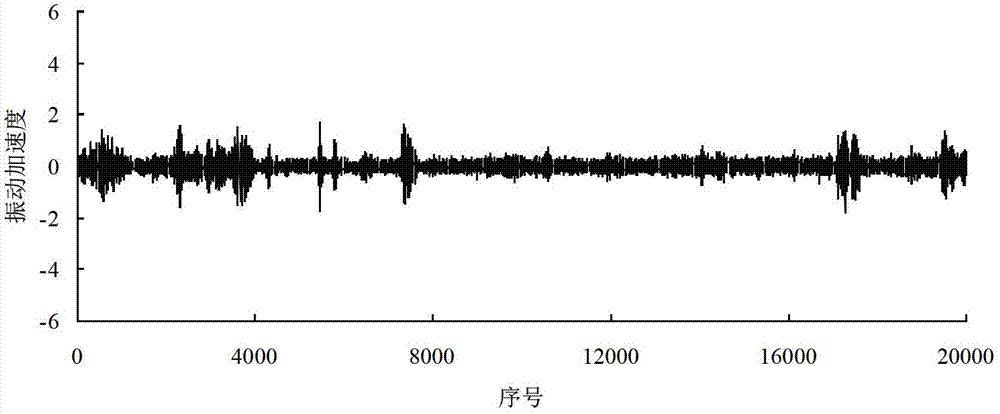

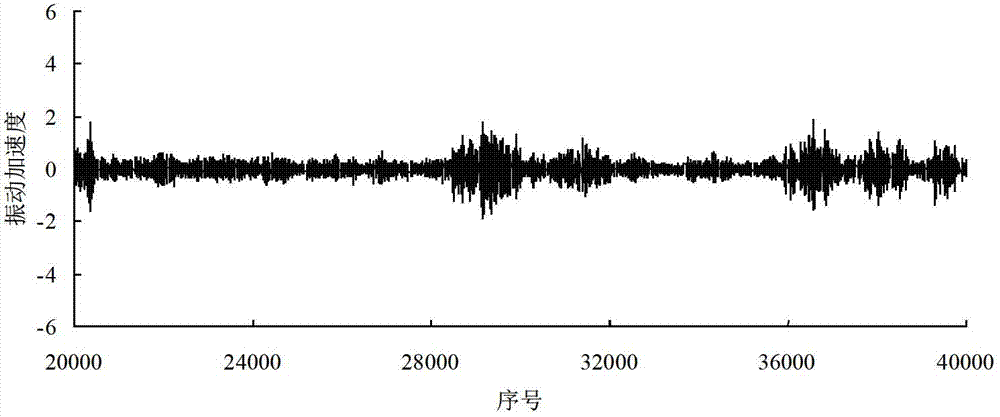

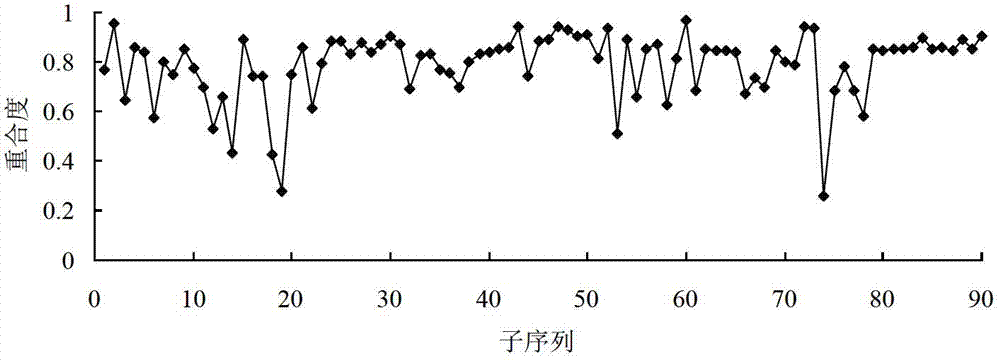

Significance testing method for rolling bearing performance variation process

InactiveCN103246803AAvoid nasty accidentsSpecial data processing applicationsPrior informationNormal density

The invention discloses a significance testing method for a rolling bearing performance variation process. The method includes: regularly sampling the performance of a rolling bearing during service to obtain an r-th time sequence, equally dividing the r-th time sequence into D subsequences, and setting a d-th subsequence data as Xrd; processing the subsequences by bootstrapping to obtain origin moments of all orders of each subsequence; establishing a probability density function of each subsequence according to the principle of maximum entropy; selecting a reference time sequence; establishing a posterior probability density function; establishing contact ratio; giving a significance level alpha; if the contact ratio is smaller than 1-alpha, determining the d-th subsequence Xrd in the r-th time sequence varies significantly; if not, determining no significant variation occurs. By the method under the condition that probability distribution and trend prior information is absent, variation information of the performance of the rolling bearing during service can be checked timely, failure risk of the bearing is found so that measures can be taken as soon as possible, and serious accidents are avoided.

Owner:HENAN UNIV OF SCI & TECH

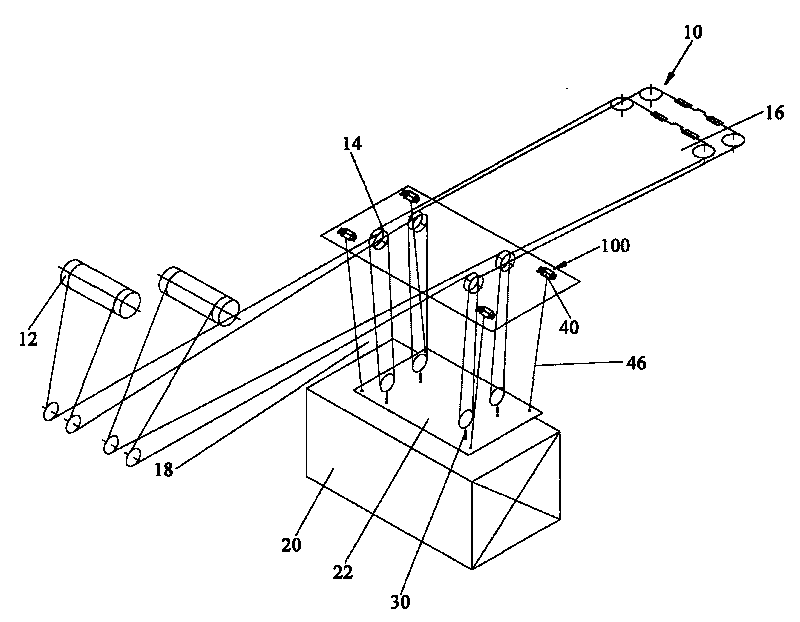

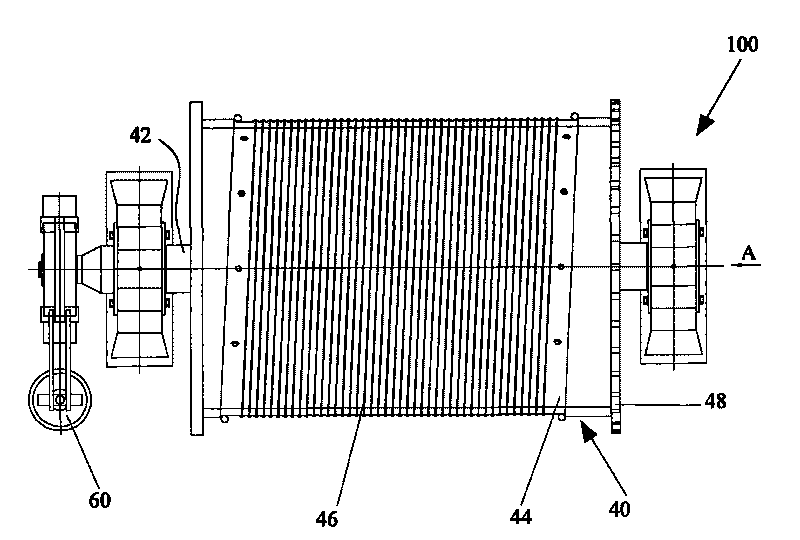

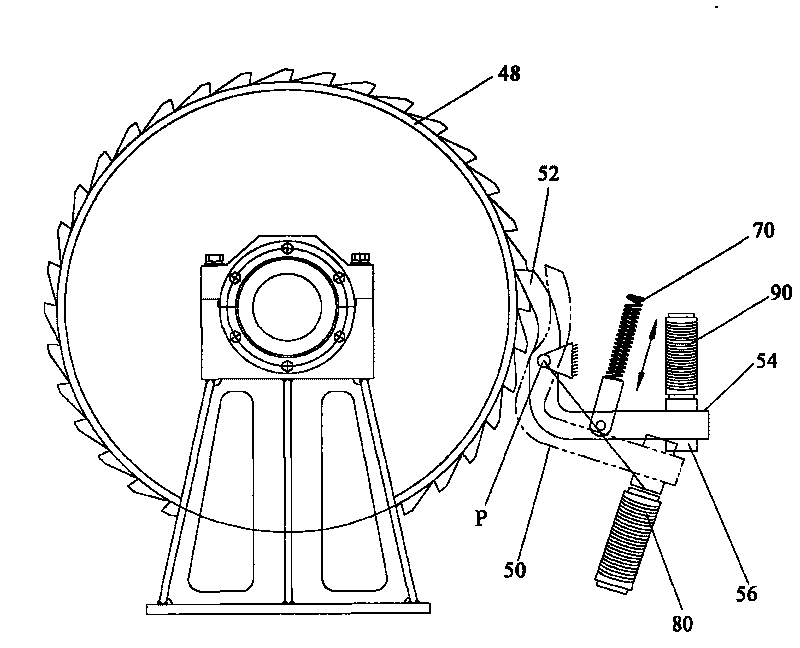

Cut cable protection device and hoisting equipment provided with same

InactiveCN101734568AGuaranteed operational safetyAvoid nasty accidentsWinding mechanismsOperations securityForce sensor

The invention provides a cut cable protection device (100) and a hoisting equipment provided with the same (10); the cut cable protection device (100) is used for carrying a main mechanism cable (18) of a workpiece (20), wherein, the protection device (100) comprises a tension sensor (30) and a protection drum (40), the tension sensor (30) is connected to the main mechanism cable (18) and senses the tension of the main mechanism cable (18), the protection drum (40) is driven by a rotating shaft (42) and comprises a cable part (44) and a first brake piece, the cable part is winded with a protection cable (46), and the end of the cable part (44) is connected to the workpiece (20); a second brake piece is arranged near the first brake piece, responds to the preset sensing signal of the tension sensor (30) and joints with the first brake piece to brake the protection drum (40). By using the protection device, the safety of operation when the main mechanism cable is cut can be guaranteed, thus greatly improving the reliability of the hoisting equipment and effectively avoiding occurrence of severe accidents.

Owner:SANY MARINE HEAVY IND

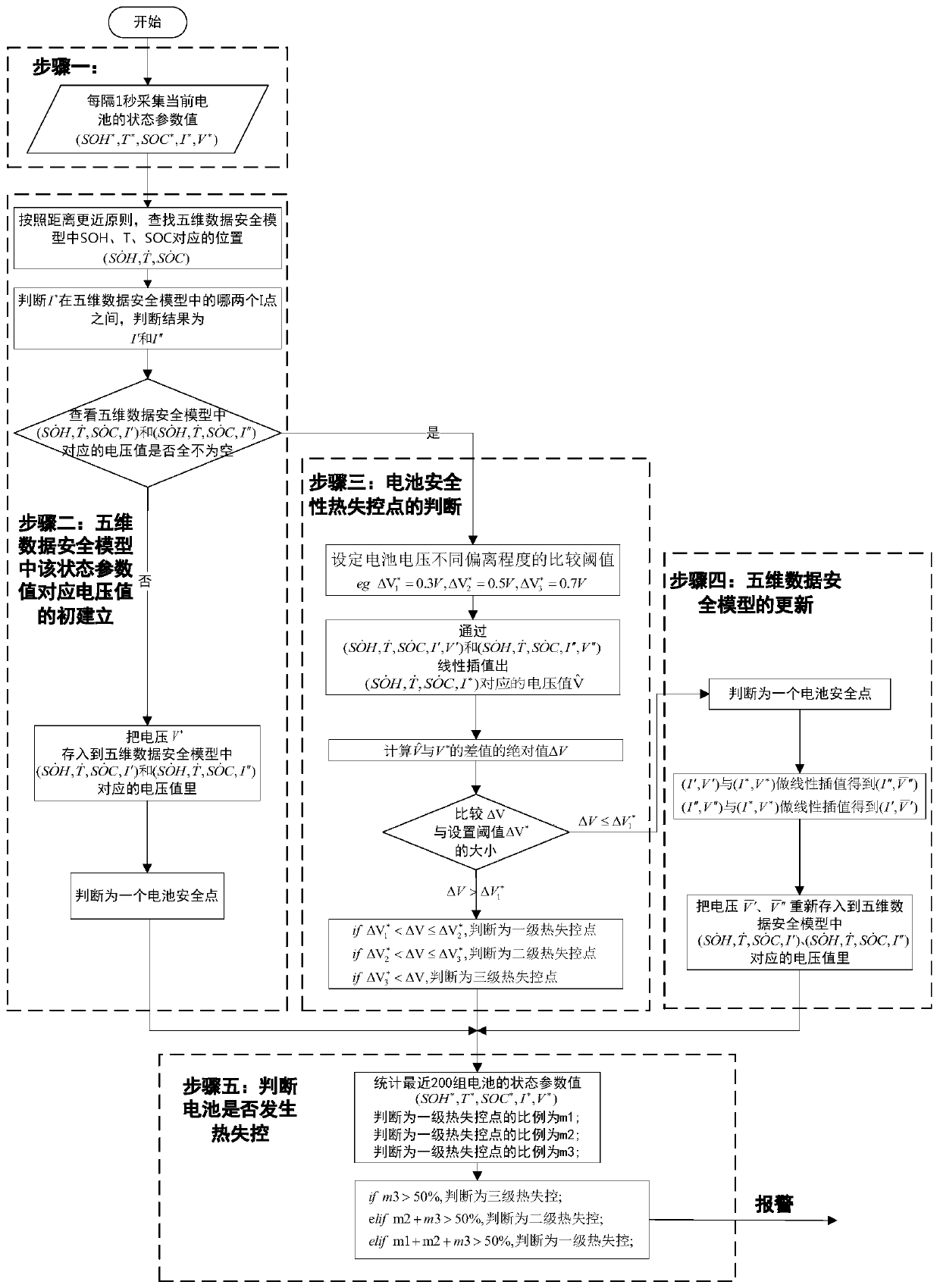

Power battery thermal runaway early warning method

InactiveCN111381169AEarly detection of thermal runawayAvoid nasty accidentsElectrical testingPower batteryElectrical battery

The invention belongs to the technical field of new energy automobile power batteries, and relates to a power battery thermal runaway early warning method. The method comprises the steps: establishingan initial power battery five-dimensional data security model; collecting five-dimensional data of the power battery in real time, comparing the difference degree between the real-time five-dimensional data and the five-dimensional data in the safety model, judging the number and the deviation degree of thermal runaway points of the battery, and updating the five-dimensional data safety model ofthe power battery in real time; and finally, performing comprehensive analyzing to obtain the thermal runaway grade of the power battery according to the number and the deviation degree of the thermalrunaway points. The power battery thermal runaway early warning method provided by the invention is suitable for all working conditions of the vehicle and the whole life cycle of the battery, can effectively detect the battery thermal runaway phenomenon in advance, and avoids malignant accidents.

Owner:DALIAN UNIV OF TECH

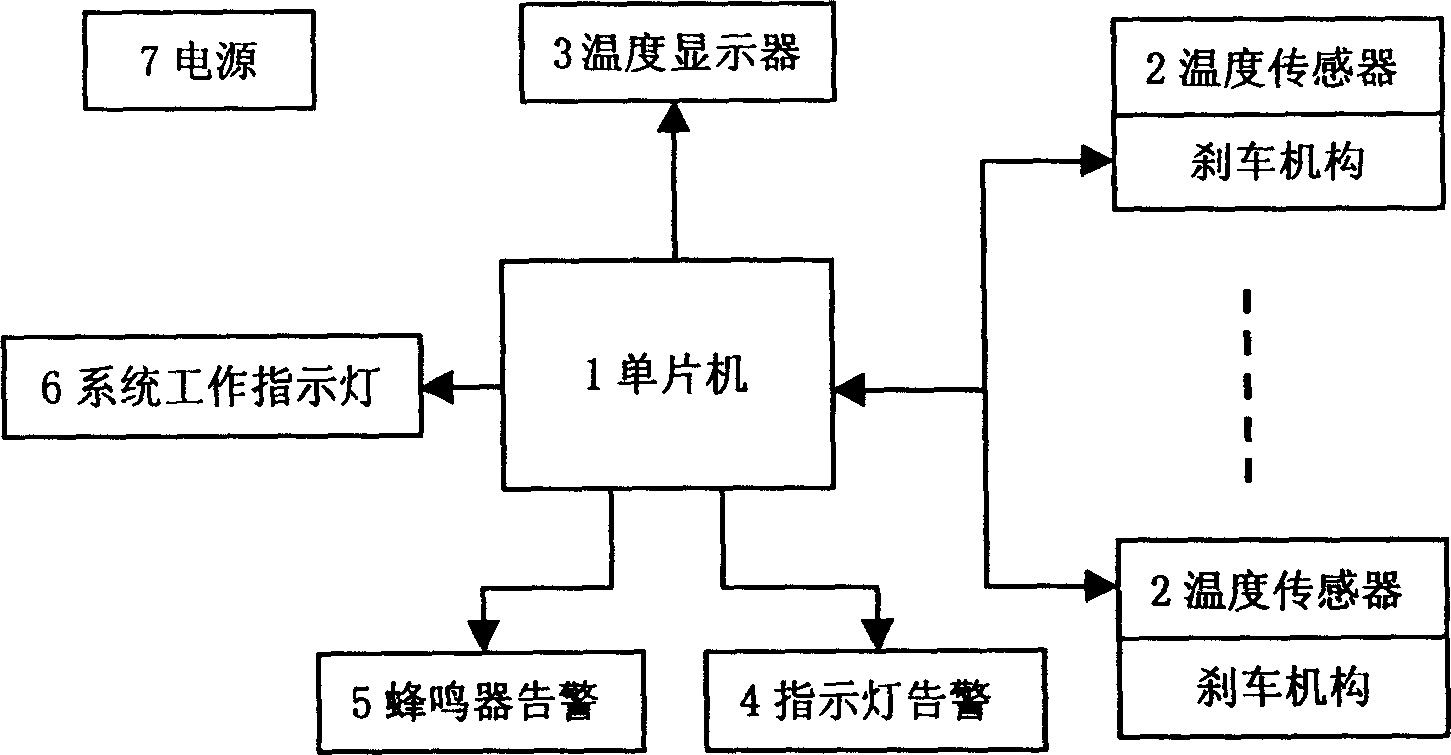

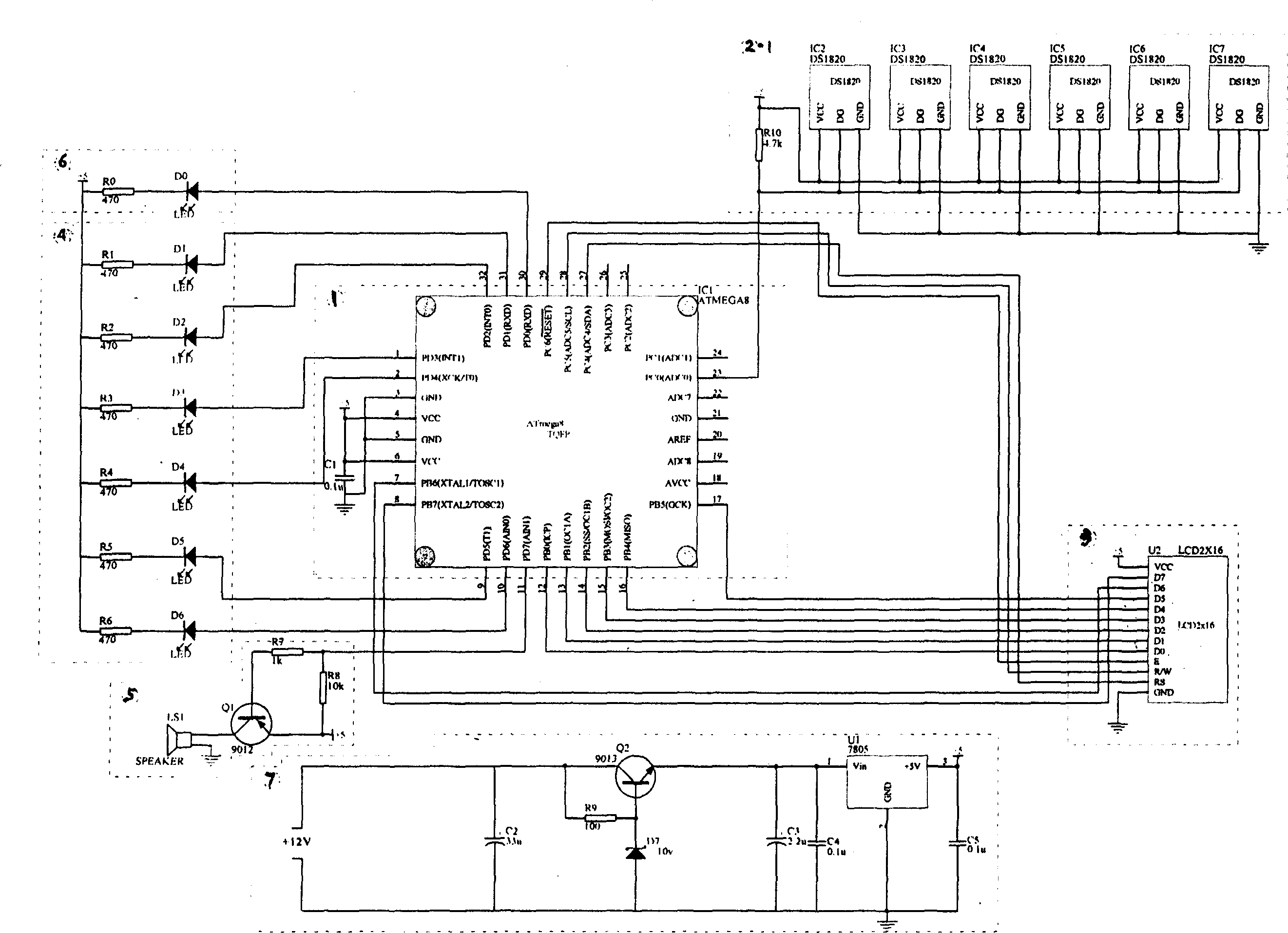

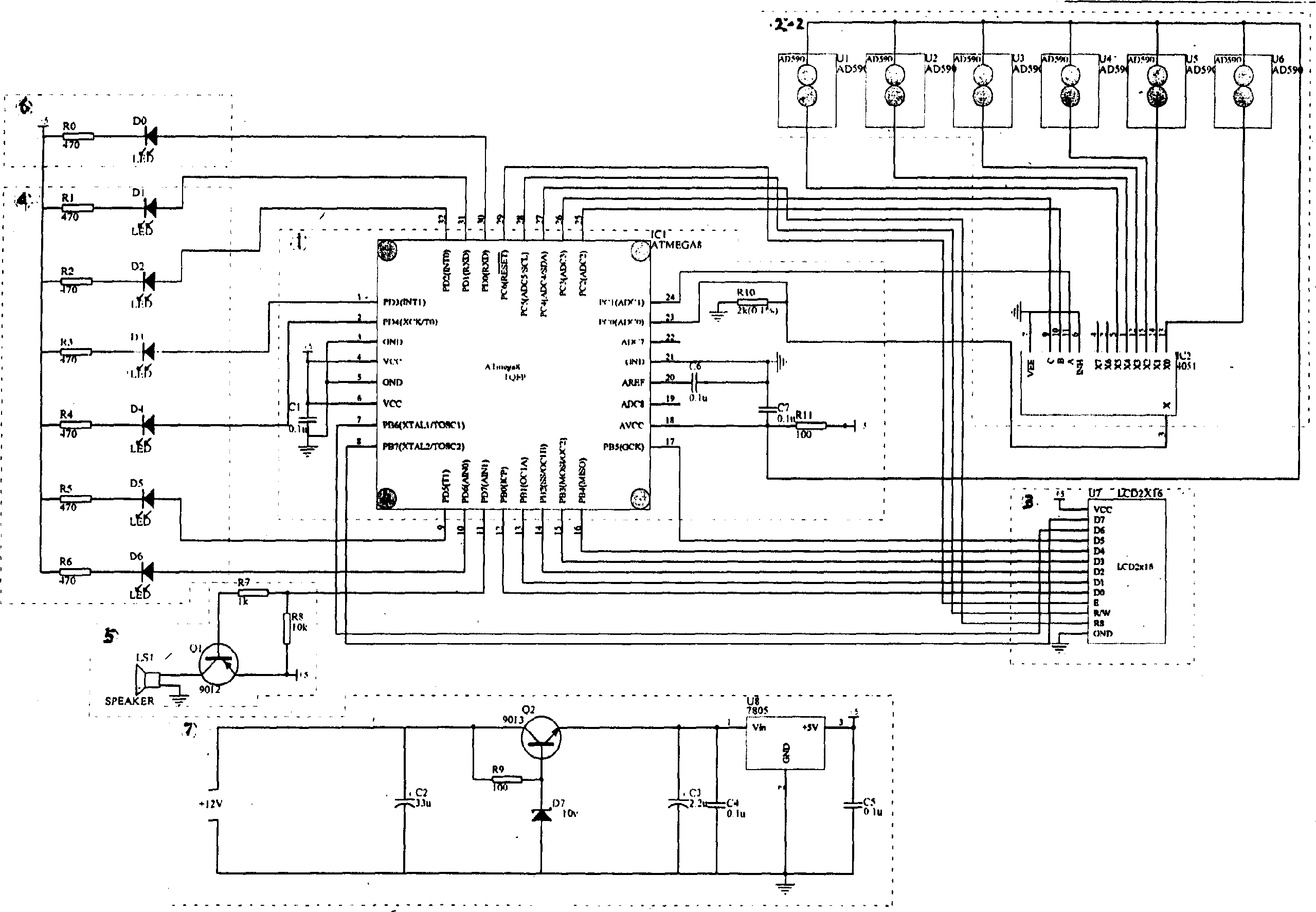

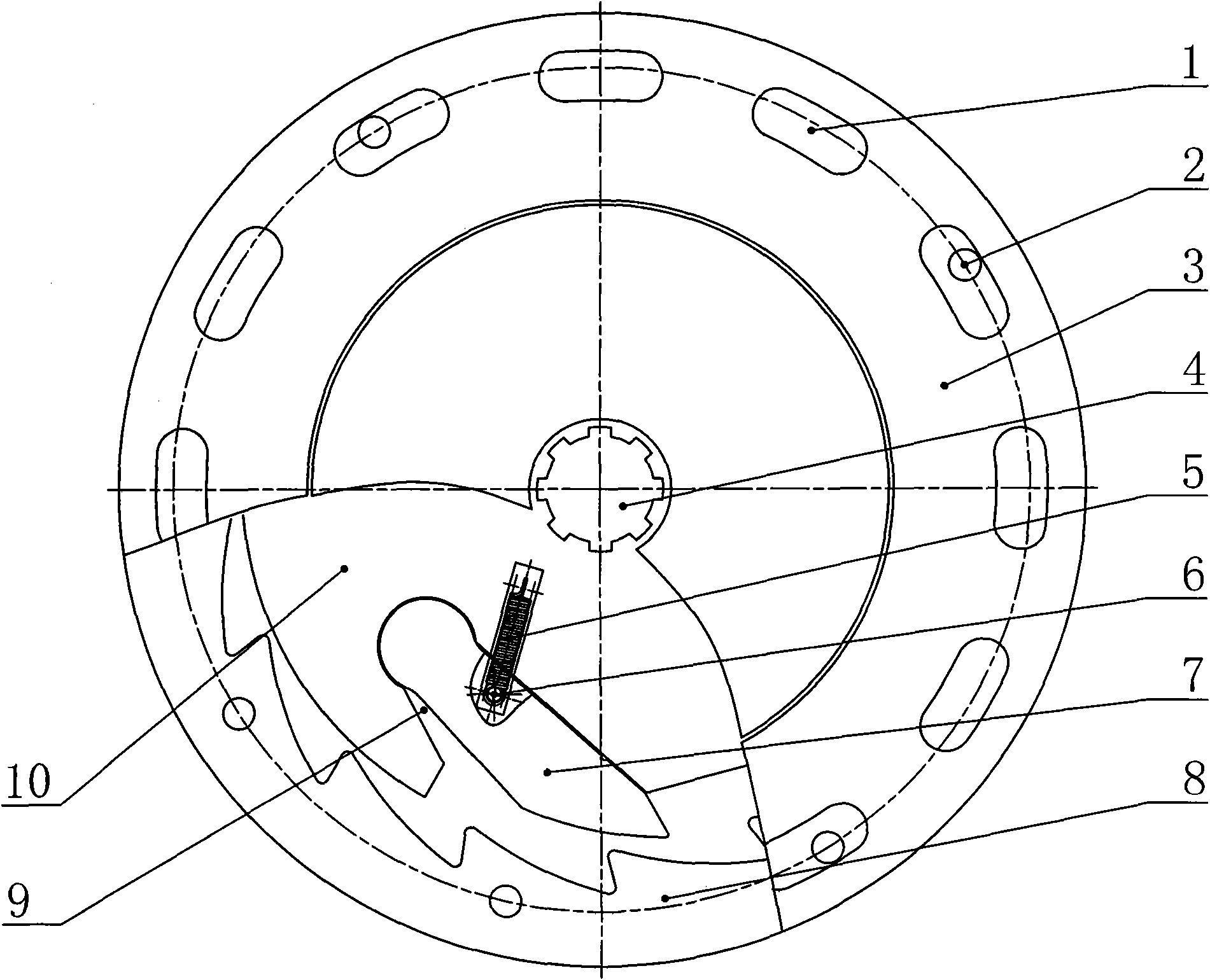

Method and device for monitoring fault of motor vehicle brake system

InactiveCN1557662ATimely repairAvoid nasty accidentsBrake safety systemsMicrocontrollerPower circuits

The present invention relates to one kind of early on-line brake system fault monitoring method and device for motor vehicles. Temperature sensor and electronic circuit are used in real-time monitoring and display of the temperature of wheel braking mechanism, photoacoustic warning abnormal temperature of failed braking mechanism and realizing the on-line detection of fault in braking system. The device includes temperature sensors installed onto the braking mechanisms, temperature measuring, display and warning circuit with monolithic computer in the driver cab, connecting wire and power source circuit. The monitoring device may be also used in motor vehicle maintaining unit for detecting braking system.

Owner:王元虎

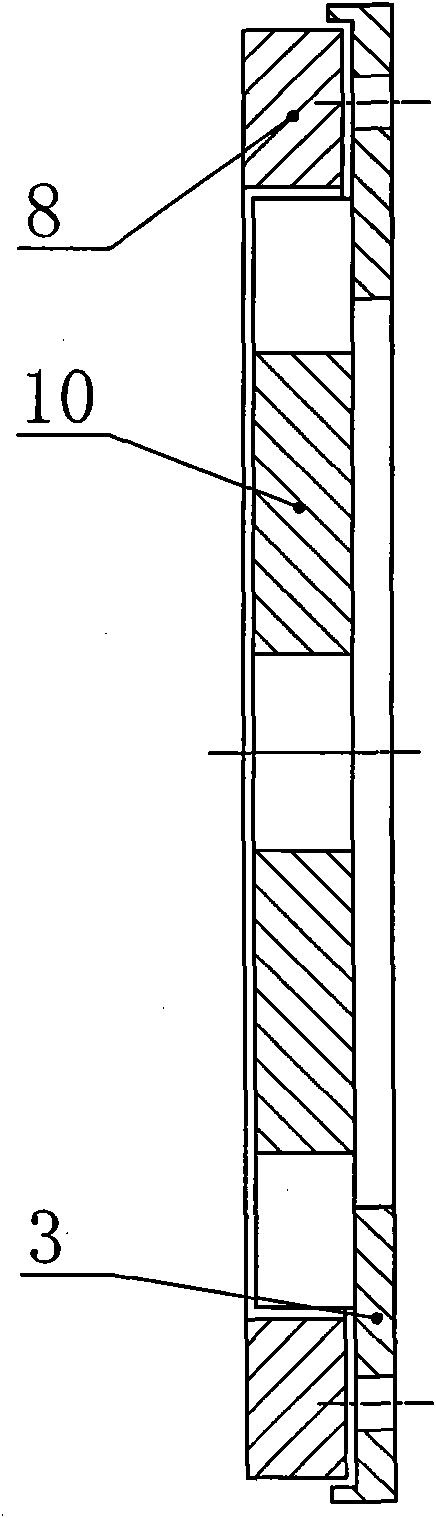

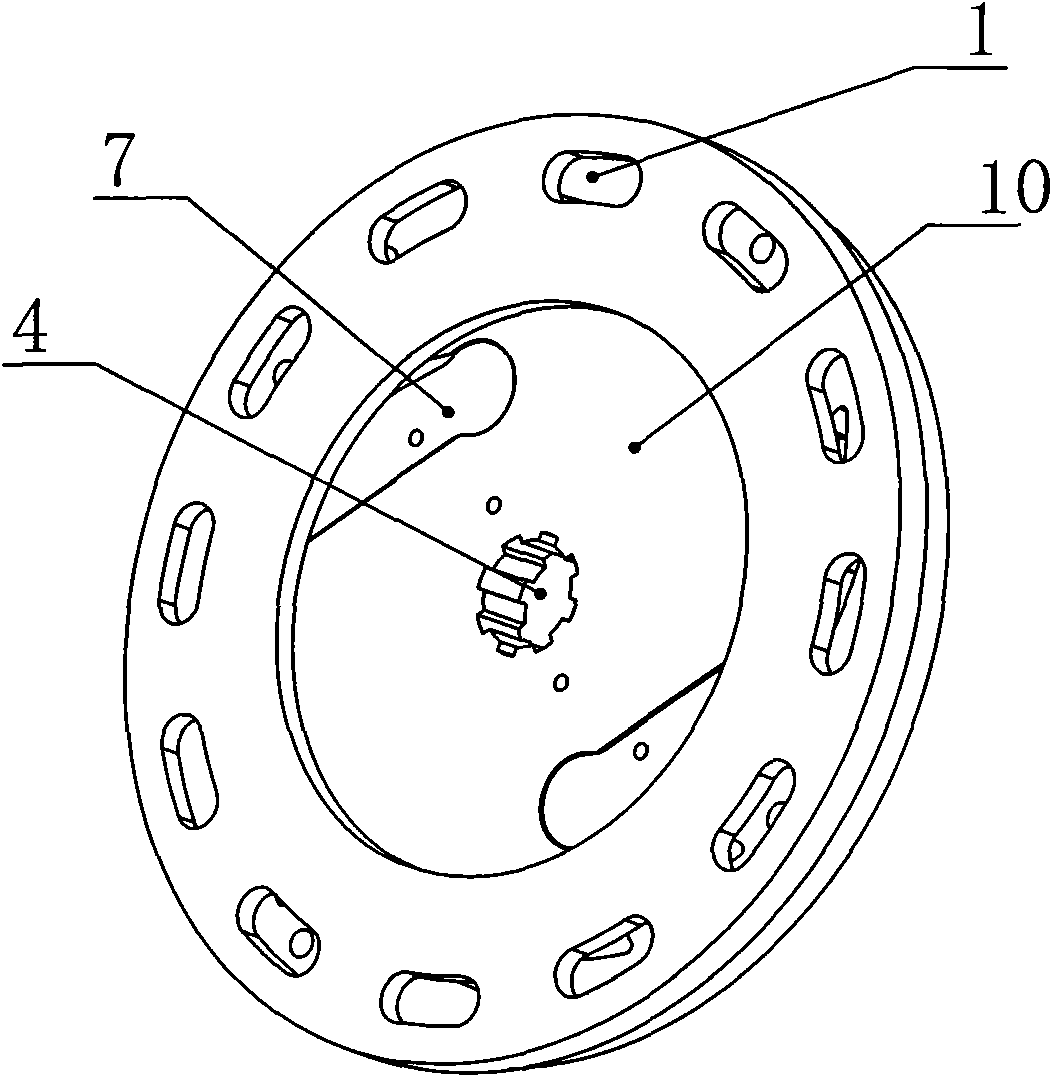

Centrifugal fly claw ratchet wheel braking locker and contact net compensation device

The invention discloses a centrifugal fly claw ratchet wheel braking locker in the technical field of contact nets, comprising an inner tooth ratchet wheel, a fly claw and a fly wheel, wherein the inner tooth ratchet wheel is sleeved on the fly wheel, the outer circumference of the fly wheel is at least provided with a fly claw slot, and the fly claw is plugged in the fly claw slot; an elastic mechanism for driving the fly claw to be contracted in the fly claw slot is arranged between the fly claw and the fly wheel; and the end part of the fly claw corresponds to ratchet teeth of the inner tooth ratchet wheel. After the line of a contact net is suddenly broken, the fly wheel is quickly forced to brake. The invention also discloses a contact net compensation device with the centrifugal fly claw ratchet braking locker, comprising a rotatable spindle arranged on a bracket, wherein a large-diameter tensioning thread wheel and a small-diameter thread wheel which are mutually linked are arranged on the spindle; a steel wire rope for suspending a sliding weight is wound outside the large-diameter tensioning thread wheel, and a steel wire rope connected with a lead or a carrier cable is wound outside the small-diameter tensioning thread wheel; the inner tooth ratchet wheel is fixedly connected with the bracket; and the fly wheel is fixedly connected with the spindle. The invention can thoroughly avoid the clamping and the eccentric wear of the steel wire ropes.

Owner:YANGZHOU DONGFANG HANGER FRAME CO LTD

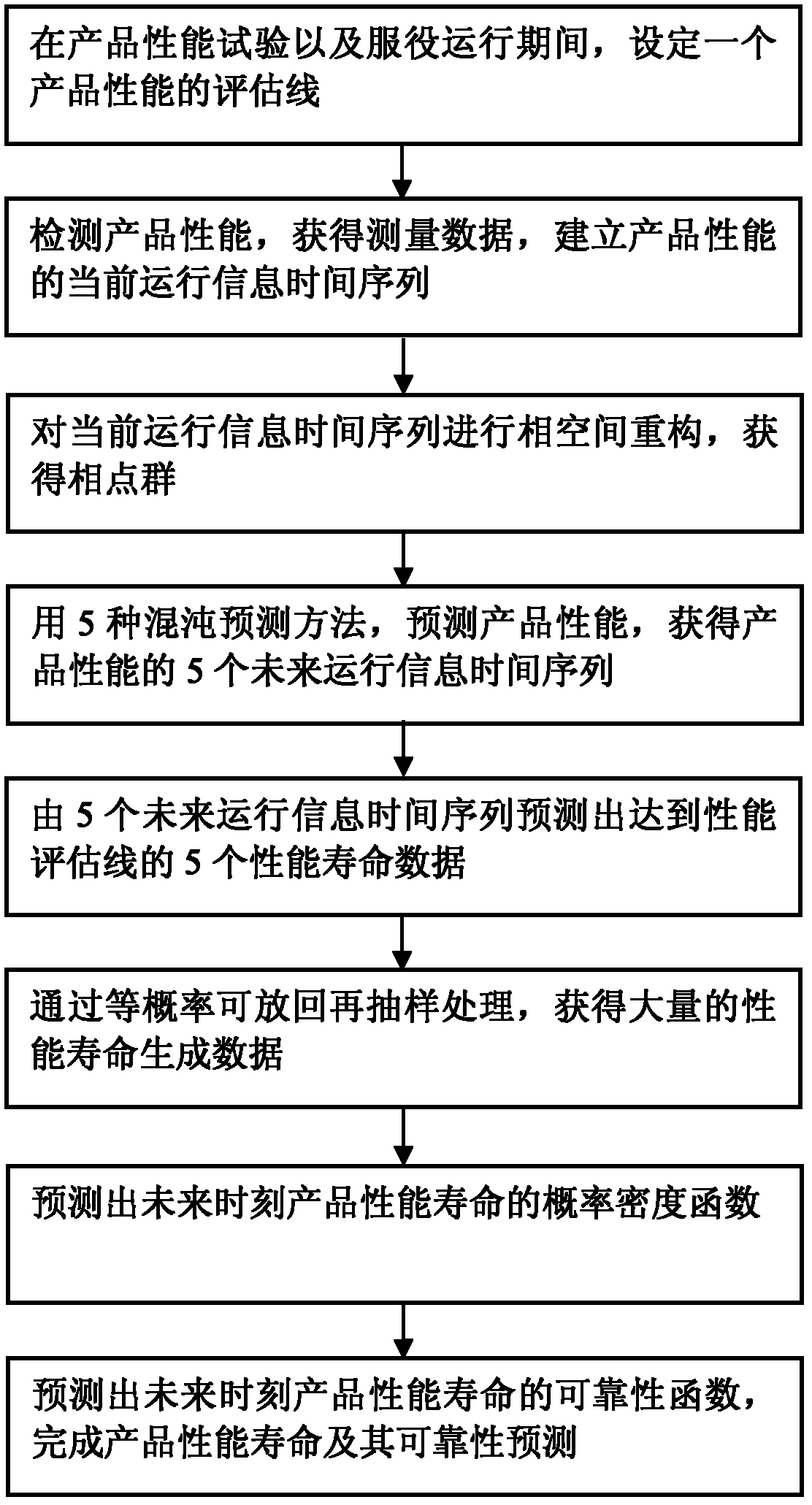

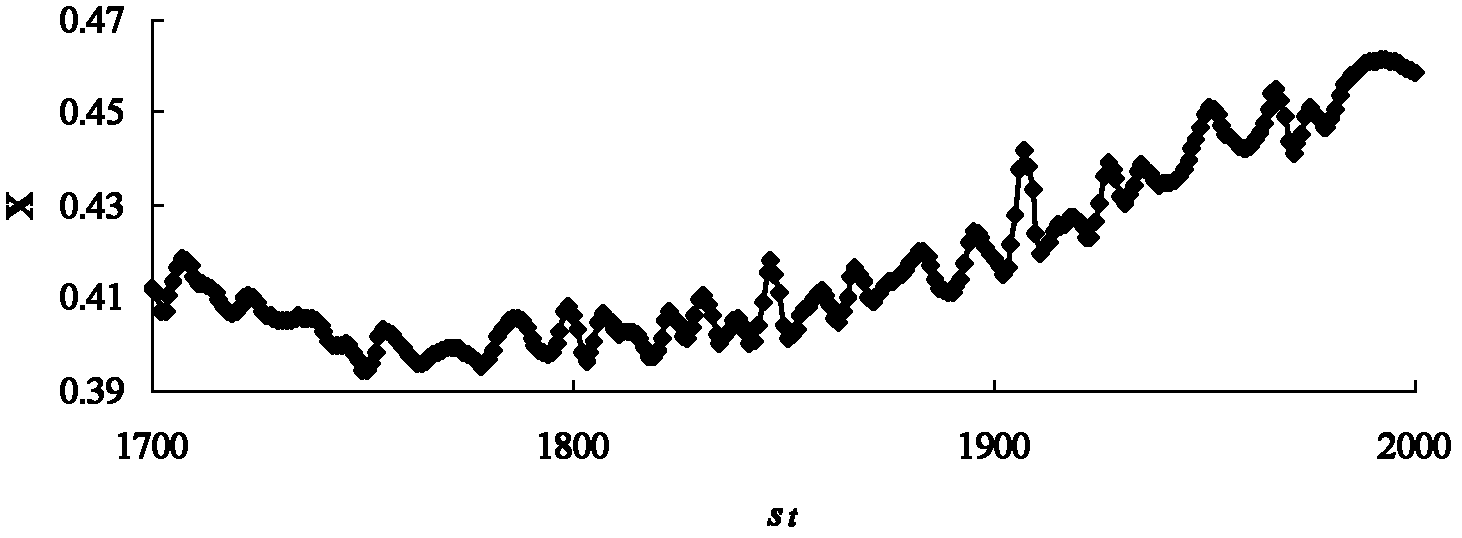

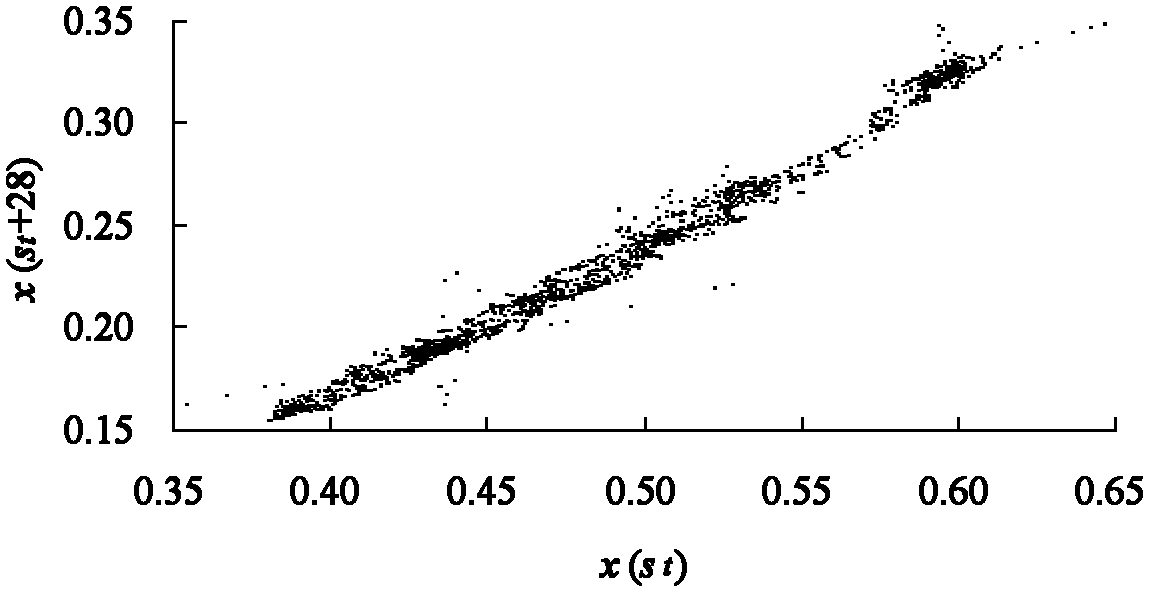

Performance data accompanying product service life and reliability predicting method thereof

The invention relates to a performance data accompanying product service life and a reliability predicting method thereof. The method comprises the following methods that firstly, an evaluation line of the product performance is set, the product performance measuring data is obtained, and the current operation information time sequence is built; the phase space reconstruction is carried out, and a phase point group is obtained; the product performance is predicted, and five future operation information time sequences of the product performance are obtained; five pieces of performance service life data reaching the performance evaluation line are predicted; a large amount of performance service life generation data is obtained; and the probability density function of the future product performance service life is predicted, the reliability function is further predicted, and the performance service life and reliability prediction of the product are completed. The method has the advantages that the probability density function of the future time product performance service life can be obtained according to the current operation information of the product performance, further, the future service life and reliability function of the product are built, the future time performance service life and reliability of the product are favorably predicted in real time, the product performance change / degeneration and failure hidden troubles are found in time, and the occurrence of serious accidents is avoided.

Owner:HENAN UNIV OF SCI & TECH

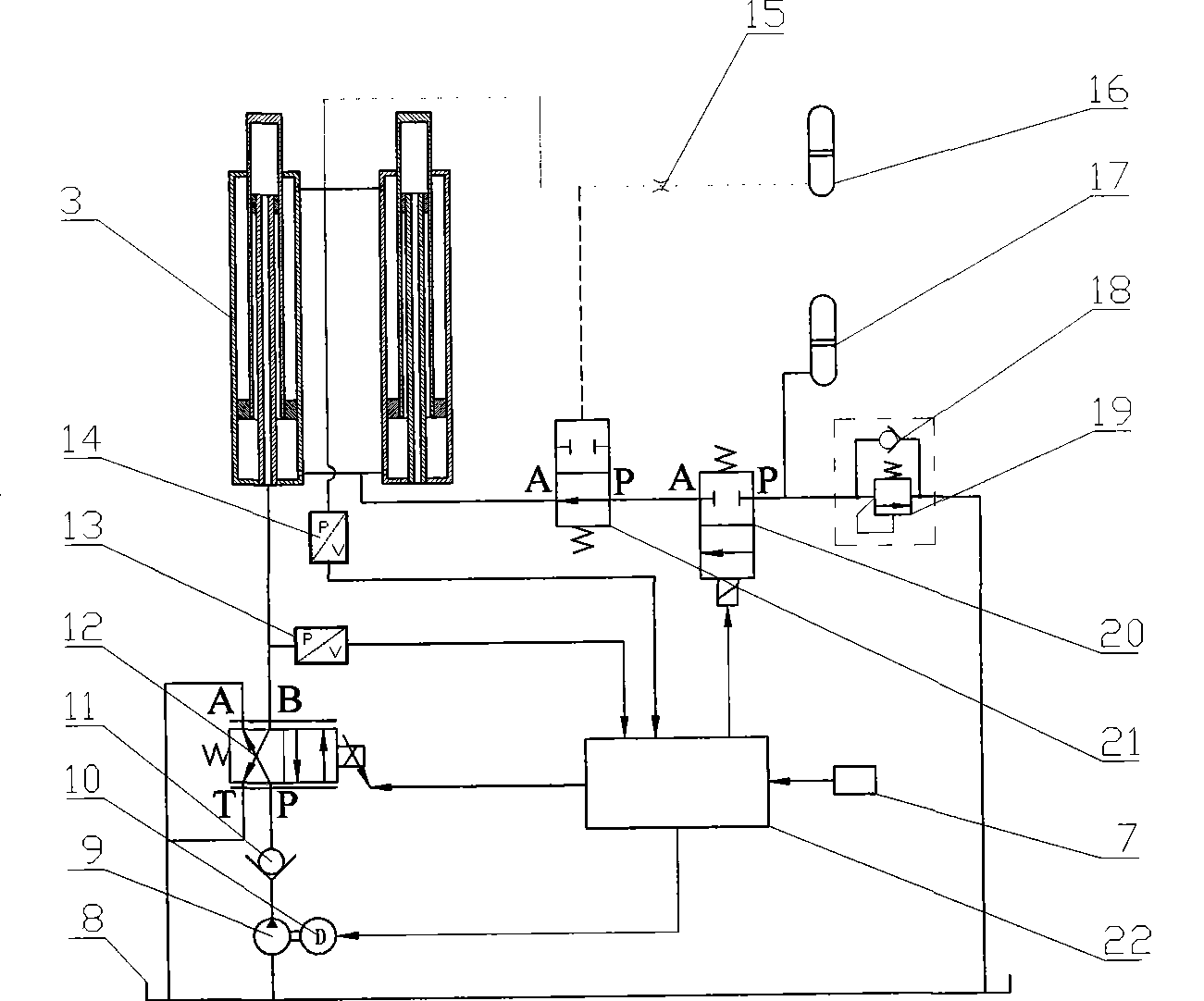

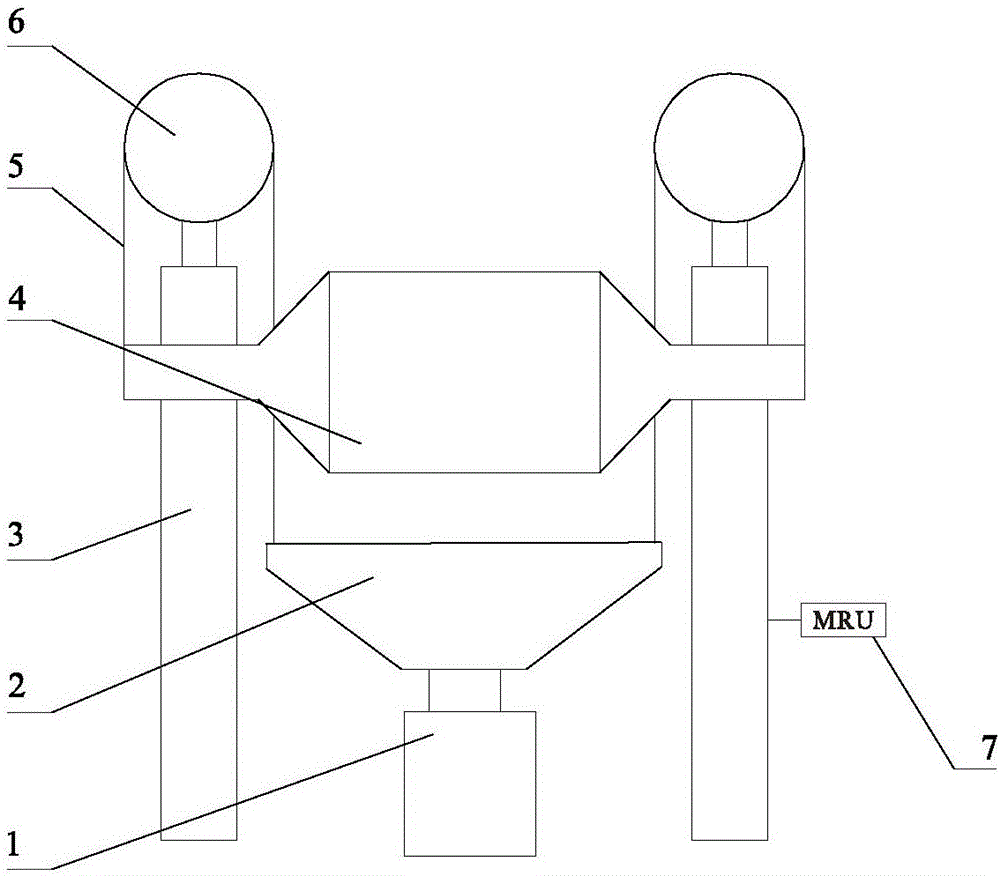

Heave compensation device of hook block assembly for marine floating drilling

ActiveCN106321534AOvercome frictionOvercome system inertiaDrilling rodsServomotorsLoop controlHydraulic pump

The invention discloses a heave compensation device of a hook block assembly for marine floating drilling. Double piston type hydraulic cylinders are taken as compensation hydraulic cylinders, and high pressure cylinders are connected to high pressure air cavities of the double piston type hydraulic cylinders, so that a passive compensation force is provided to piston rods; meanwhile, hydraulic oil output by a high pressure pump is introduced to upper and lower high pressure oil cavities of the double piston type hydraulic cylinders through a proportional direction valve, so that an active compensation force, the magnitude and direction of which can be controlled, is provided to the piston rods, and the passive and active compensation forces drive a drill jointly to load to realize a heave compensation function. A PLC drives the piston rods to realize the heave compensation function through displacement closed-loop control according to a platform heave movement signal detected by a movement reference unit and a compensation hydraulic cylinder piston rod movement signal detected by a laser range finder. According to the device disclosed by the invention, the compensation control precision can be improved, the system energy consumption and manufacturing cost can be reduced and the service life of the compensation hydraulic cylinder can be prolonged.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

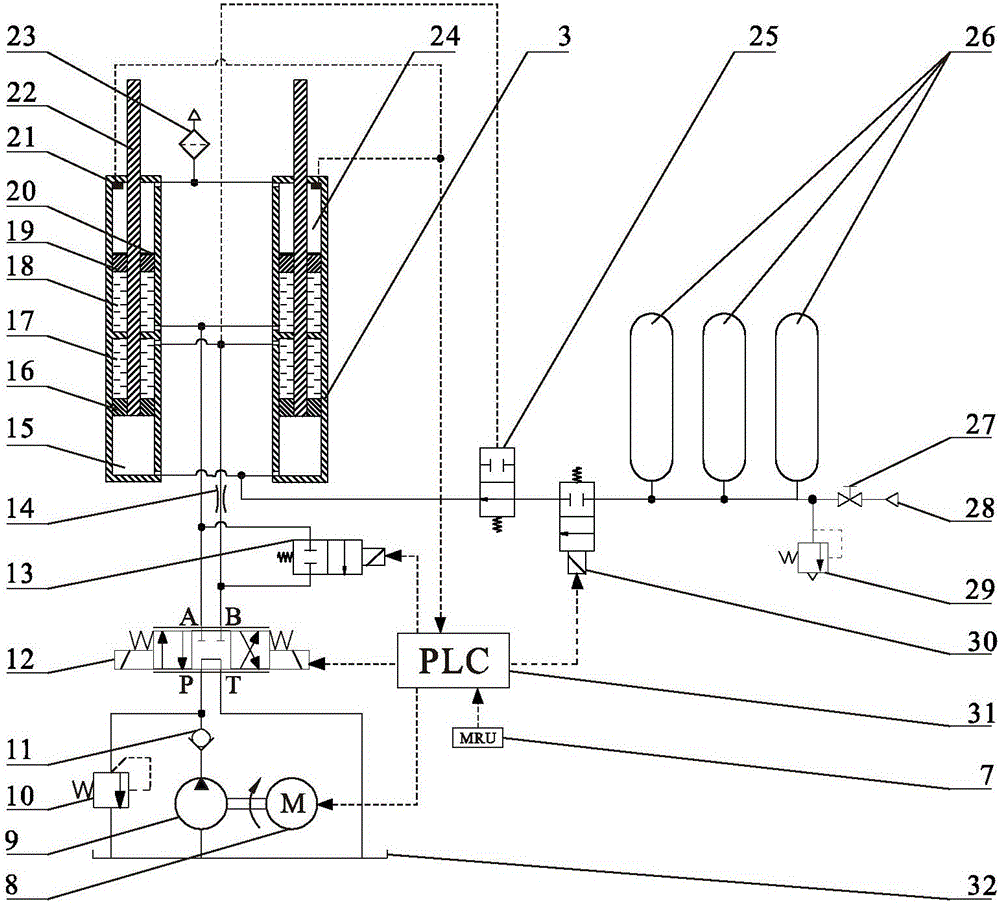

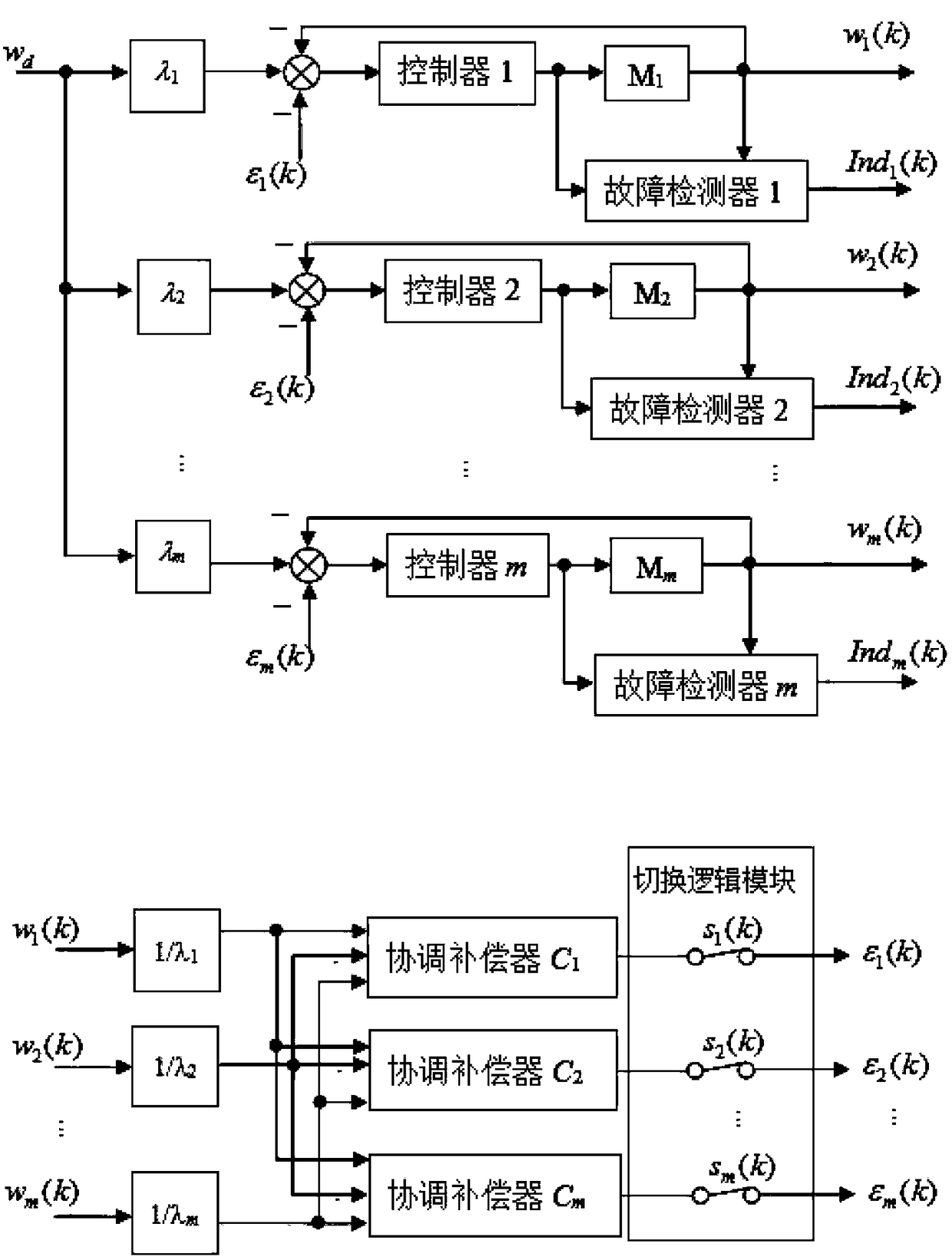

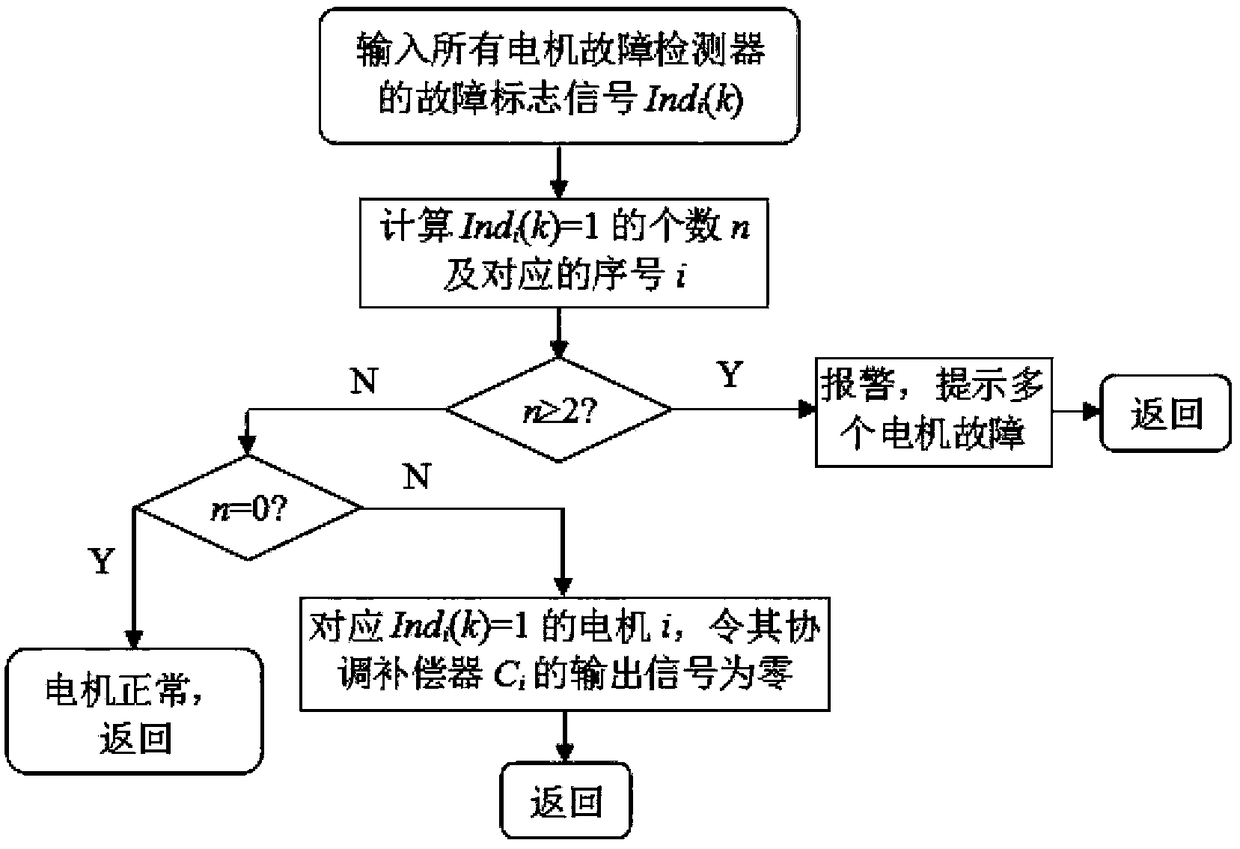

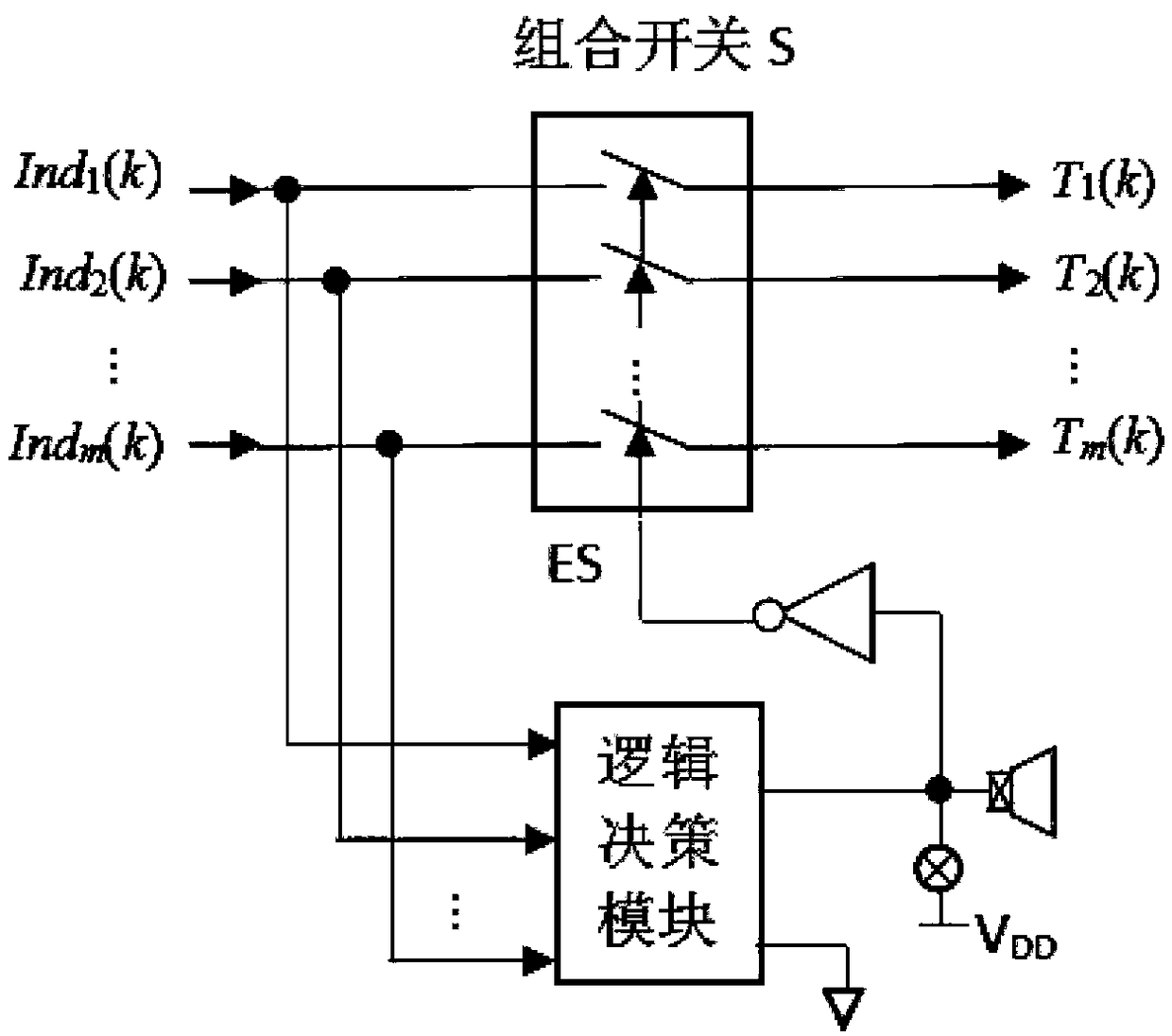

Fault tolerant proportional coordinated control method for multi-motor servo drive system under coupling control structure

ActiveCN108233823AFault detection in real timeSimple detection algorithmElectric motor controlMultiple dynamo-electric motors speed regulationFault toleranceEngineering

The invention discloses a fault tolerant proportional coordinated control method for a multi-motor servo drive system under a coupling control structure. A fault detector of a motor servo control system is used for detecting the faults of motors and electric drive modules of the motors in real time, based on the coupling control structure of the multi-motor system, a logic switching module of a motor coordinated compensator mixed with fault detection information is designed, and the working mode of the coordinated compensator is improved. When the motor control system fails, the output path ofthe coordinated compensator is cut off, so that the multi-motor system is transformed from the coupling control structure to a master-slave control structure. In the master-slave control structure, amain motor is a fault motor, a slave motor is a normal motor, which ensures that the proportion relationship of the output of each motor in the multi-motor servo drive system remains unchanged so asto achieve a fault tolerance function; when the fault motor returns to normal, the output path of the coordinated compensator of the motor is connected by a fault logic decision-making module, the whole system is restored to the original coupling control structure, and the proportional relationship between the output of each motor remains unchanged.

Owner:NANJING UNIV OF SCI & TECH

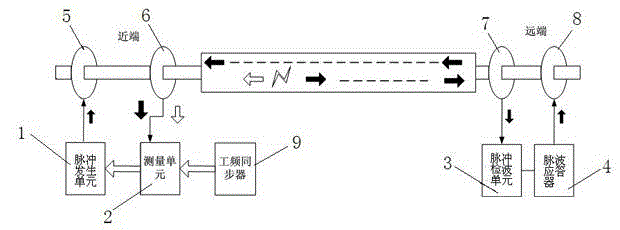

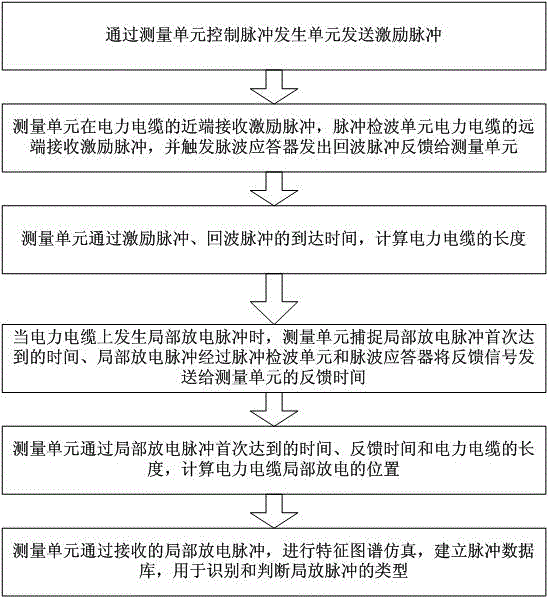

Power cable partial discharge simulation system and testing method

InactiveCN104569769AAvoid nasty accidentsImprove anti-interference abilityTesting dielectric strengthEngineeringElectric power

The invention discloses a power cable partial discharge simulation system and testing method. The system comprises a pulse generating unit, a measuring unit, pulse detecting unit and a pulse transponder, wherein the control output end of the measuring unit is connected with the drive pulse control input end of the pulse generating unit, the drive pulse output end of the pulse generating unit is connected with the near end of a power cable through a first high-frequency current transformer, the input end of the measuring unit is connected with the near end of the power cable through second high-frequency current transformer, the input end of the pulse detecting unit is connected with the far end of the power cable through a third high-frequency current transformer, the output end of the pulse detecting unit is connected with the pulse transponder, and the pulse transponder is connected with the far end of the power cable through a fourth high-frequency current transformer. The power cable partial discharge simulation system has the advantages that partial discharge signal positions can be detected accurately, cable faults can be discovered in advance to facilitate prevention, and the system is high in interference resistance and promising in application prospect.

Owner:STATE GRID CORP OF CHINA +3

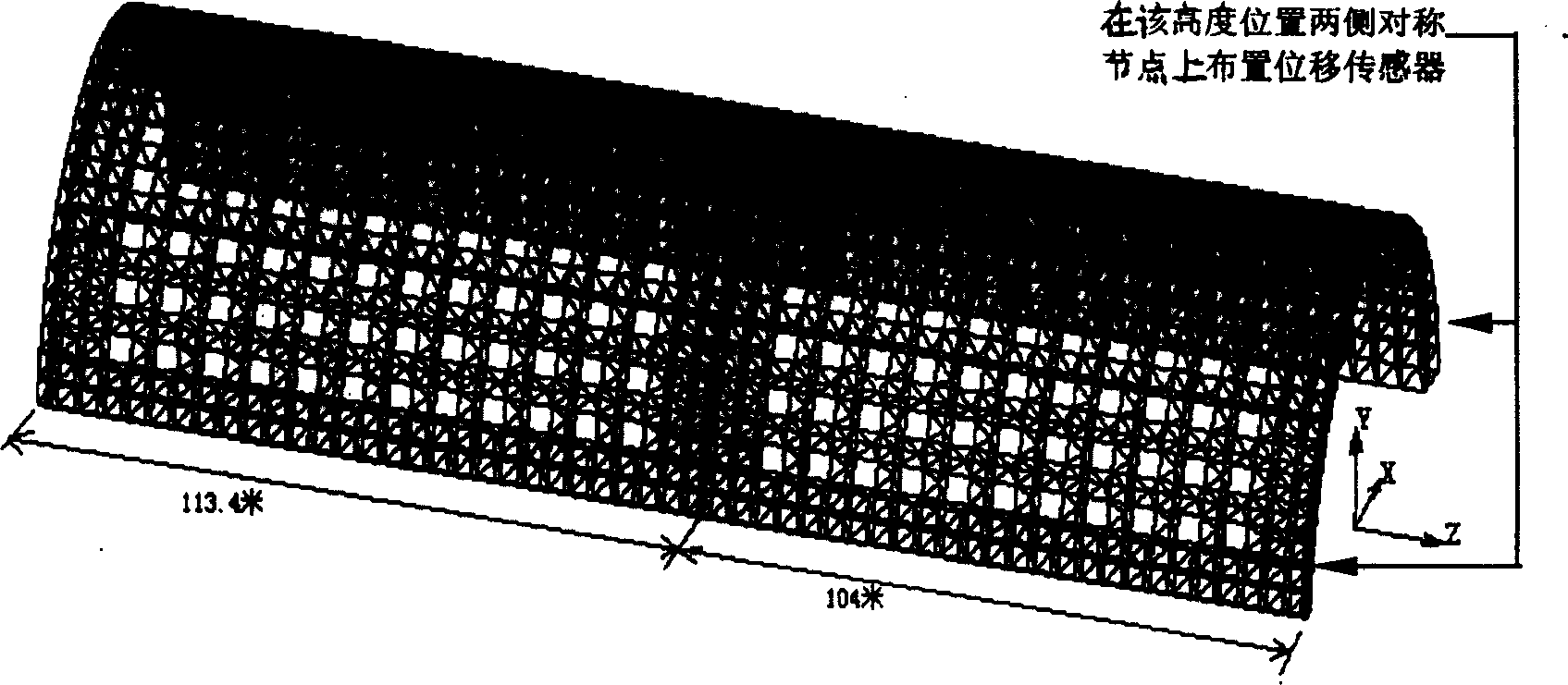

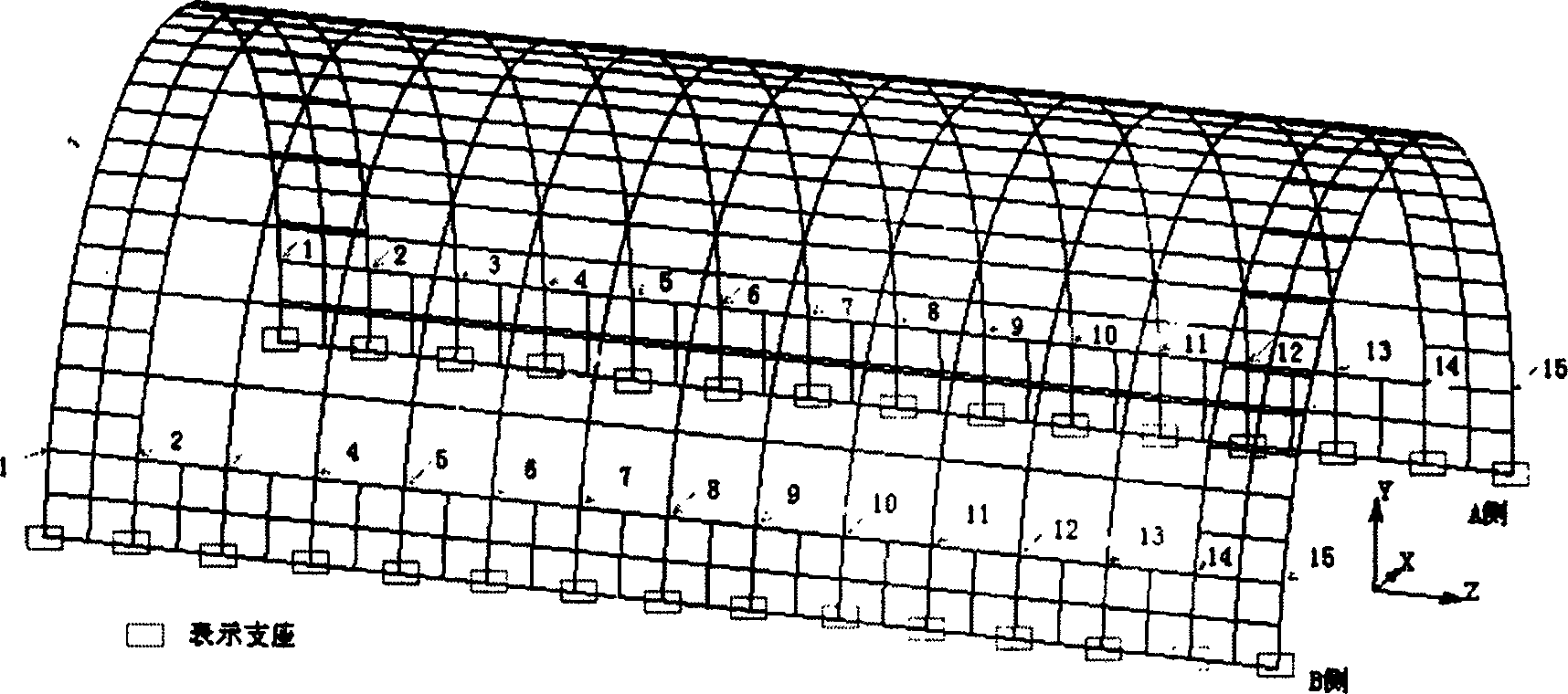

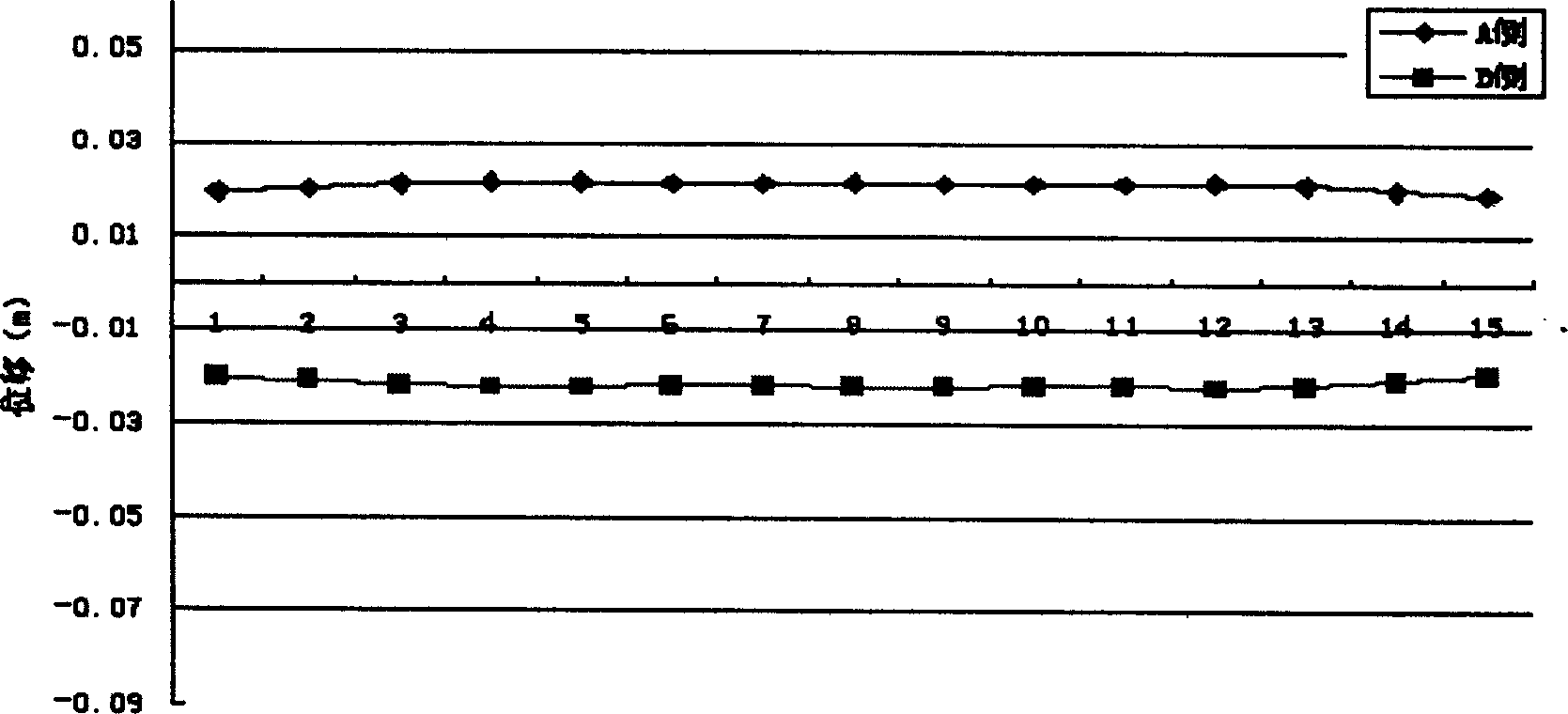

Metod for monitoring safety of architecture of circular arch net rack

InactiveCN1540506AReliable Safety MonitoringAvoid nasty accidentsSoftware simulation/interpretation/emulationElectrical/magnetic length/width measurementsTransducerInformation acquisition

The invention relates to structural characteristics of mechanics, failure mode, monitoring strategy, information acquisition and handling information, and safety diagnosis etc. The invention includes main points: selecting nodes at second layer of net rack as characteristic nodes of displacement to be monitored; calculating out allowable limit data series of characteristic nodes by using method of finite element, and drawing out relevant graph of displacement curve and graph of difference of displacement; installing displacement transducers on characteristic nodes to monitor 3D displacement of characteristic nodes continuously and to determine integral deformation. Forecast is given in advance when deformation reaches danger limit.

Owner:黄树红

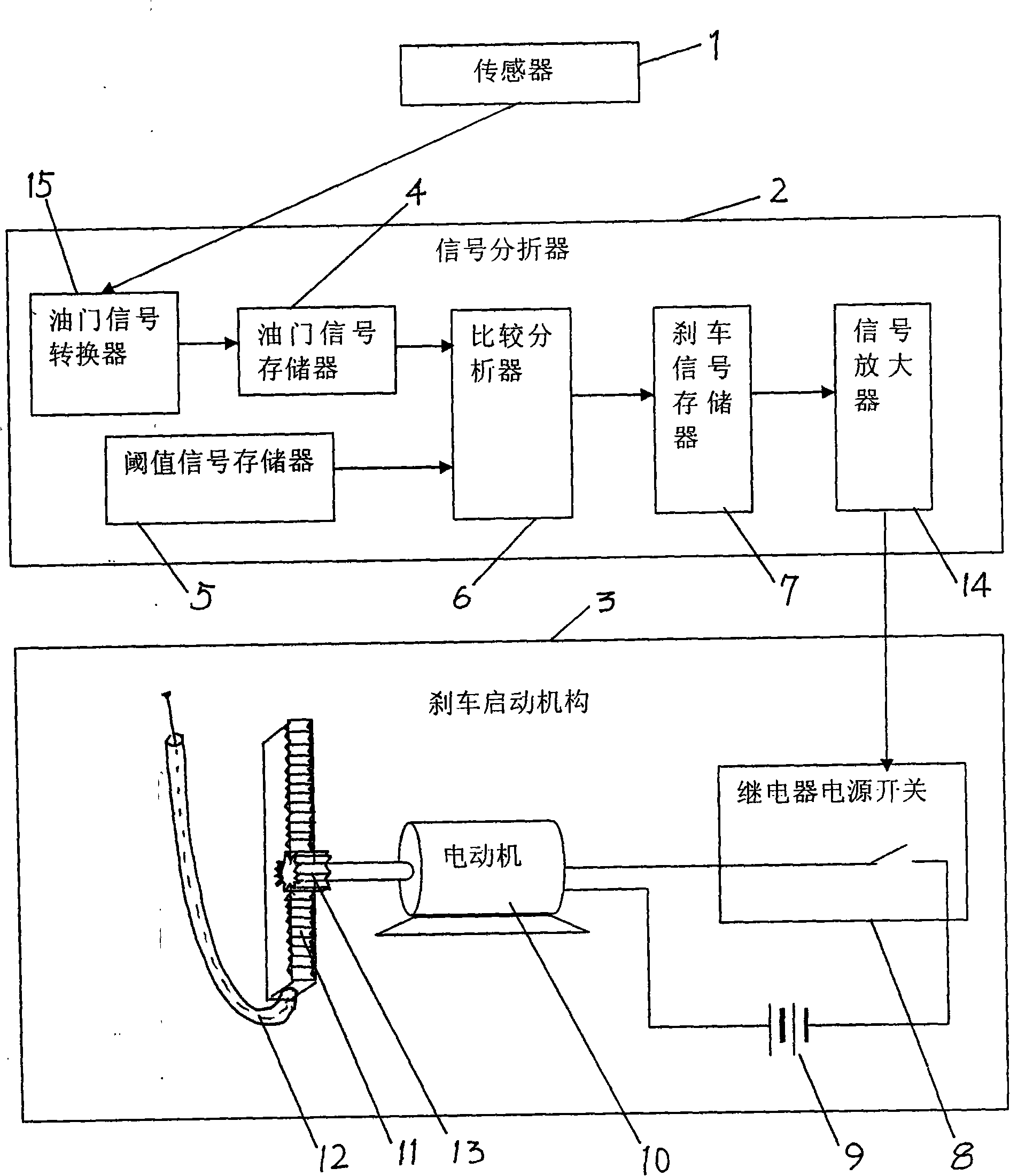

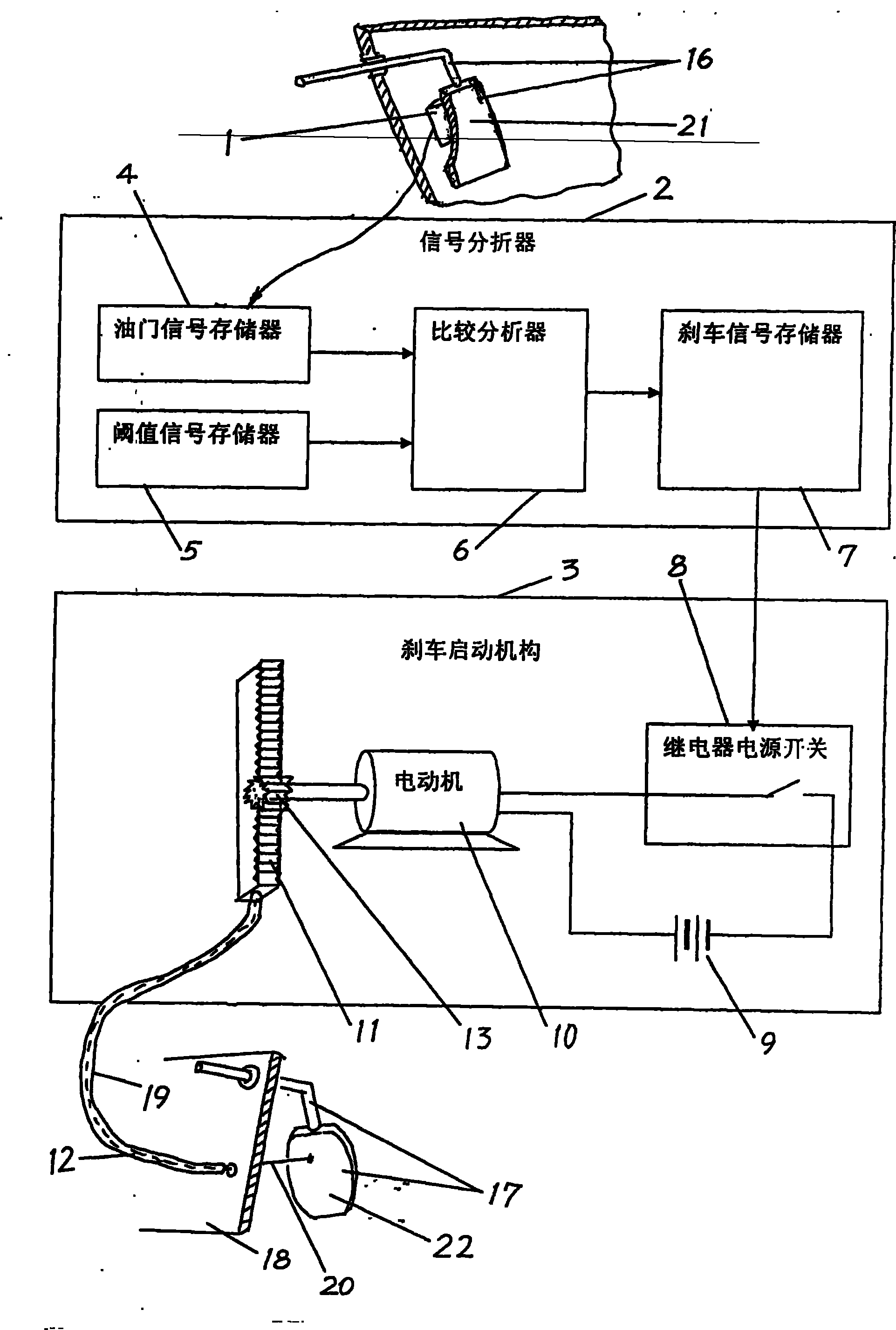

Motor vehicle with device for correcting operation of stepping on accelerator by mistake as operation of braking

InactiveCN102114777AAccurate responseRapid responseFoot actuated initiationsPropulsion unit arrangementsAutomatic brakingSignal analyzer

The invention discloses a motor vehicle with a device for correcting an operation of stepping on an accelerator by mistake as an operation of braking, and belongs to a motor vehicle which can correct a mechanical operation of stepping on an accelerator by mistake as a mechanical operation of automatic braking through electrical signal conversion. The motor vehicle disclosed by the invention is characterized in that a sensor of the device for correcting the operation of stepping on the accelerator by mistake as the operation of braking is connected with a signal analyzer and used for transmitting accelerator signals to the signal analyzer; the signal analyzer is connected with a brake startup mechanism and used for transmitting brake startup signals to the brake startup mechanism; and the sensor of the device for correcting the operation of stepping on the accelerator by mistake as he operation of braking is connected with a movable mechanism of an auto accelerator system, and the brake startup mechanism of the device for correcting the operation of stepping on the accelerator by mistake as he operation of braking is connected with the movable mechanism of the auto accelerator system. The motor vehicle disclosed by the invention has the advantages that by using the motor vehicle, the mechanical operation of automatic braking can be obtained quickly and accurately by using a mechanical operation of viciously stepping on the accelerator by mistake, the installation and maintenance of the motor vehicle are convenient, and the reliability of mechanical transmission of the motorvehicle is good. When a driver viciously steps on the accelerator by mistake excessively or violently, the motor vehicle disclosed by the invention can be stopped automatically so as to avoid the occurrence of traffic accidents.

Owner:ZHEJIANG XIANAN AUTOMOBILE BREAKING SYST

Winch heave compensation device of marine floating drilling platform

InactiveCN102691484BLower center of gravityReduce loadDrilling rodsWinding mechanismsHydraulic motorProgrammable logic controller

The invention discloses a novel winch heave compensation device of a marine floating drilling platform. A differential planet gear train is adopted as a transmission mechanism for heave compensation of a winch; power from an active compensation motor and a passive compensation hydraulic motor is input from an outer gear ring; the power from a drilling motor is input by a sun gear; a planet carrier outputs power to drive a winch roller to move; a PLC (programmable logic controller) control unit controls the active compensation motor to drive the outer gear ring of a differential gear reducer to rotate based on the detected platform heave signal; the heave movement of the platform is compensated by driving the roller to rotate forwardly and reversely, and the drilling motor is controlled to drive the sun gear to rotate based on the detected drill pressure change signal so as to achieve automatic drilling movement. A pneumatic hydraulic convertor bears a part of static load of a drilling column through the passive compensation hydraulic motor; and the active compensation motor overcomes the other loads in the movement compensation process so as to reduce the energy consumption of the system and improve the compensation precision.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com