Prediction method of leakage rate of bolted flange connection structure

A technology of bolted flange and connection structure, which is applied in the field of accurate prediction of leakage rate, and can solve problems such as strength evaluation and inability to predict leakage rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

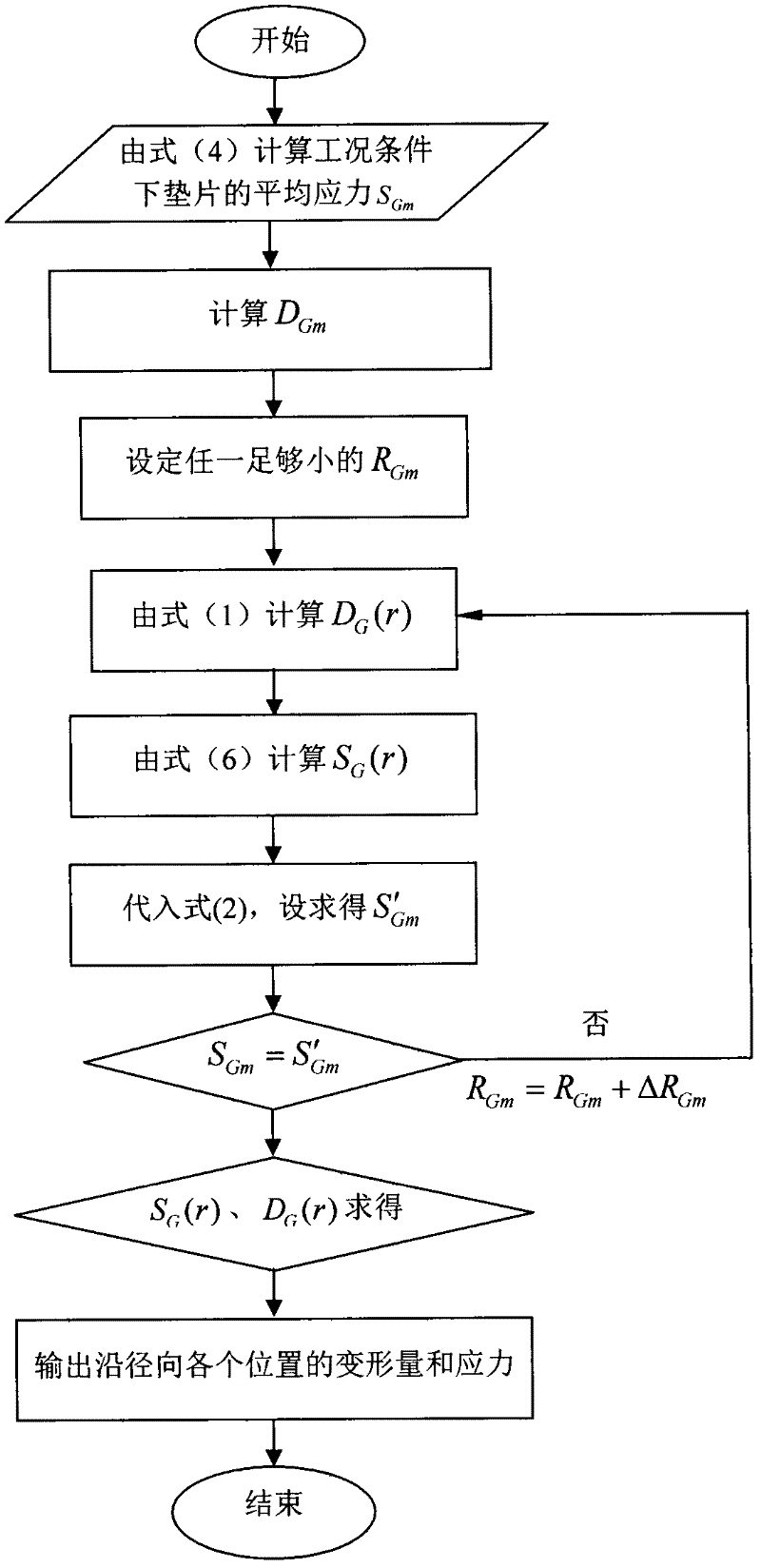

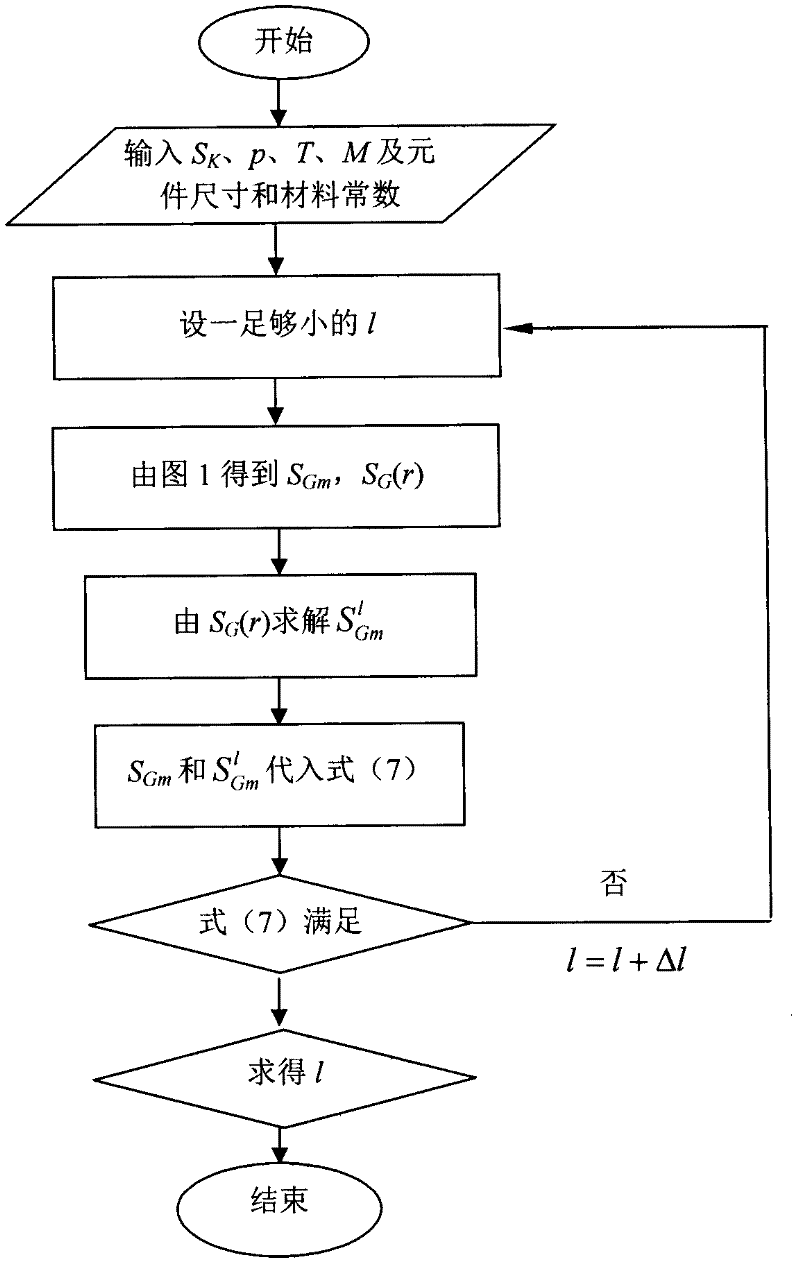

Method used

Image

Examples

Embodiment

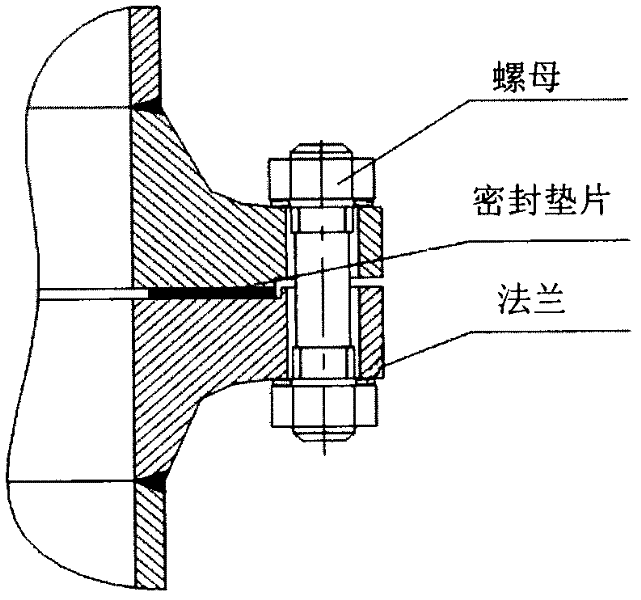

[0066] A petrochemical company's platinum reforming unit reactor is flanged to connect the material inlet and outlet. The working pressure is 1.19MPa, the working temperature is 543°C, and the medium is a mixture of hydrogen and hydrocarbons. The flange is NPS30Class150 neck butt welding flange conforming to ANSI B16.47 standard, the inner diameter of the sealing surface is 720mm, the outer diameter of the sealing surface is 858mm, and the material is 10CrMo910; the bolts are standard stud bolts conforming to ANSI N18.2.1a, and the nominal diameter of the bolts is The size is NPS1-3 / 4, the quantity is 28, the material is 25Cr2MoVA; the gasket is a stainless steel flexible graphite wound gasket that meets the ASME B16.20a standard. Gasket nominal size NPS30, outer diameter D o =846mm, inner diameter D i =794mm, preload specific pressure y=70MPa, gasket coefficient m=3.0.

[0067] At working temperature, the basic properties of stainless steel flexible graphite wound mat are: ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com