Fault tolerant proportional coordinated control method for multi-motor servo drive system under coupling control structure

A servo-driven, system fault-tolerant technology, applied in control systems, multiple motor speed adjustments, motor control, etc., can solve problems such as difficult to achieve online fast real-time fault tolerance, rarely consider motor faults at the same time, and complex fault-tolerant control algorithms, etc., to achieve The effect of avoiding system vicious accidents, ensuring proportional coordination, and simple detection algorithm

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0098] The following is an example of the design of the proportional coordination fault-tolerant control method under the deviation coupling control structure composed of three DC servo motor drive systems.

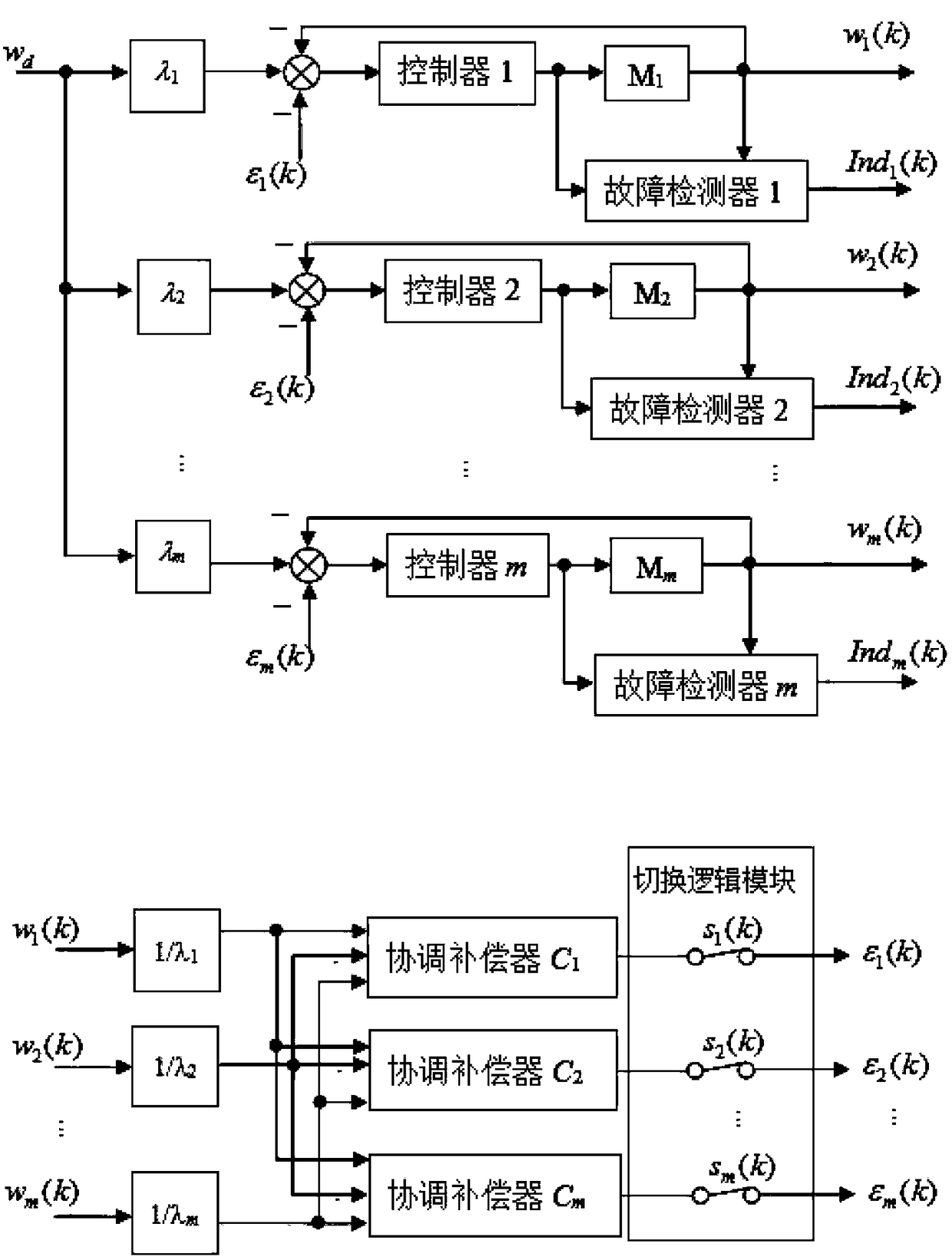

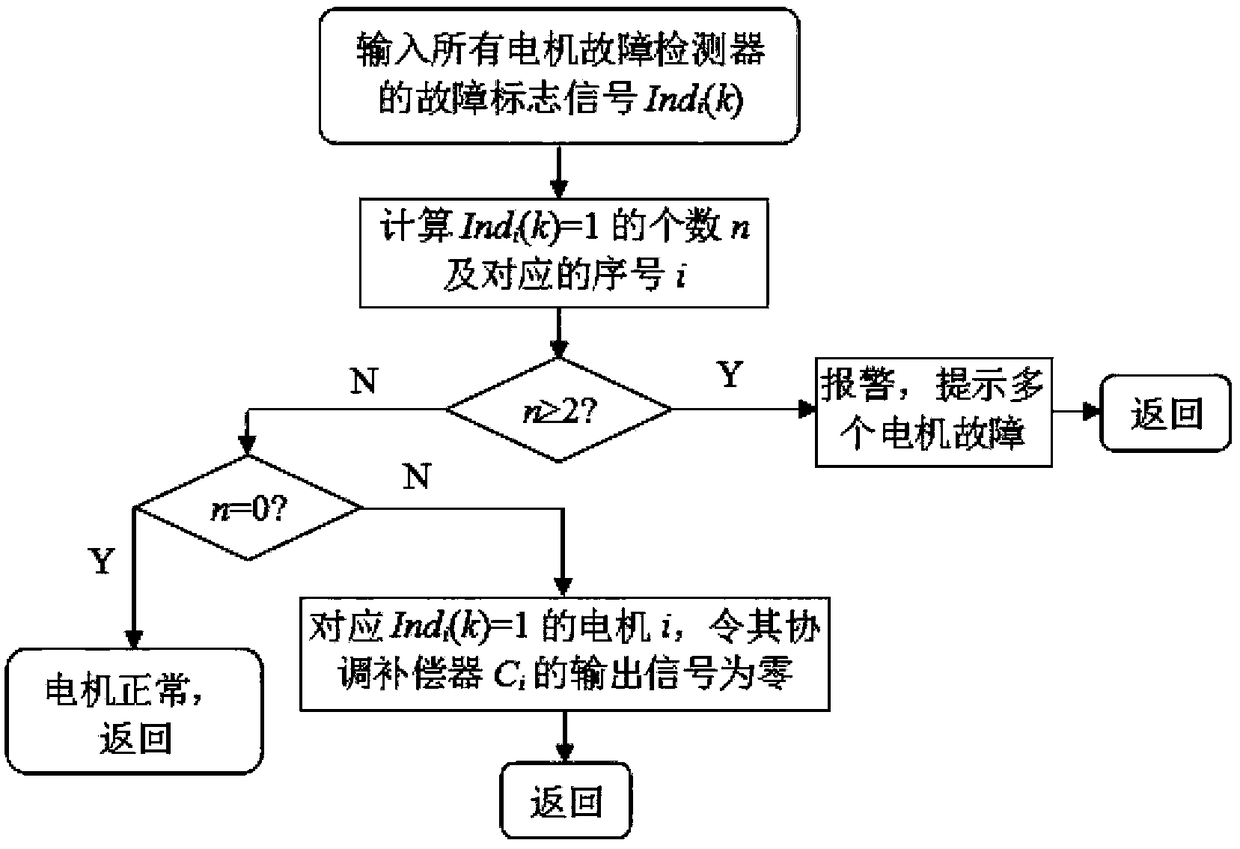

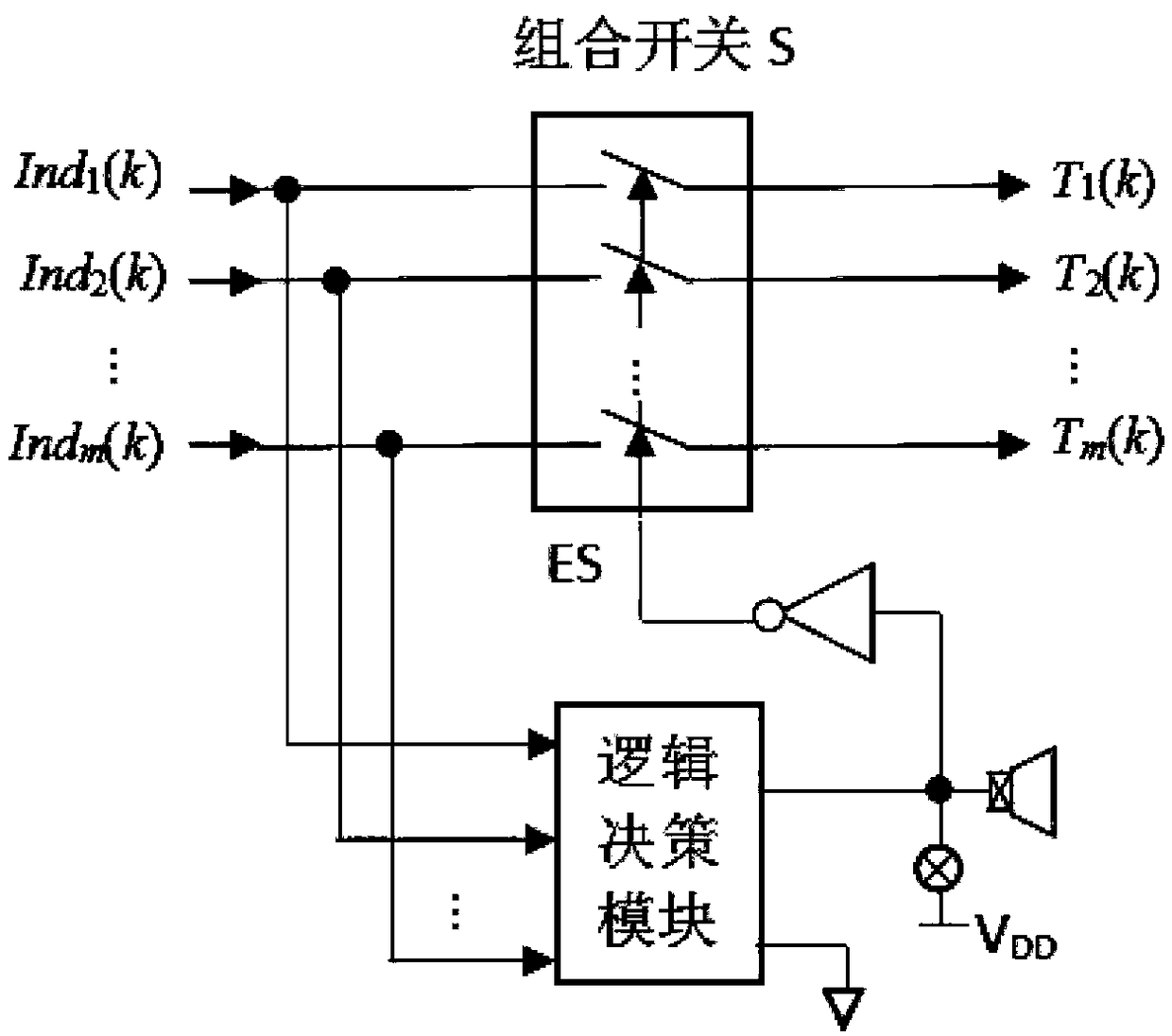

[0099] A fault-tolerant proportional coordinated control system of a three-motor servo drive control system with a coupled control structure, such as figure 1 shown. figure 1 In, λ 1 , lambda 2 and lambda 3 is the proportional coordination coefficient of the set three motor angular velocities, w d is the given amount of desired speed, ε i (k) is the output signal of the coordinated compensator, s 1 (k), s 2 (k) and s 3 (k) are the normally closed node switches set on the output channels of the coordination compensator respectively. The three fault detectors detect the faults of the motor and its electric drive module in the single motor control system in real time, and obtain the fault flag signal Ind i (k). The improved coordinated compensator according to the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com