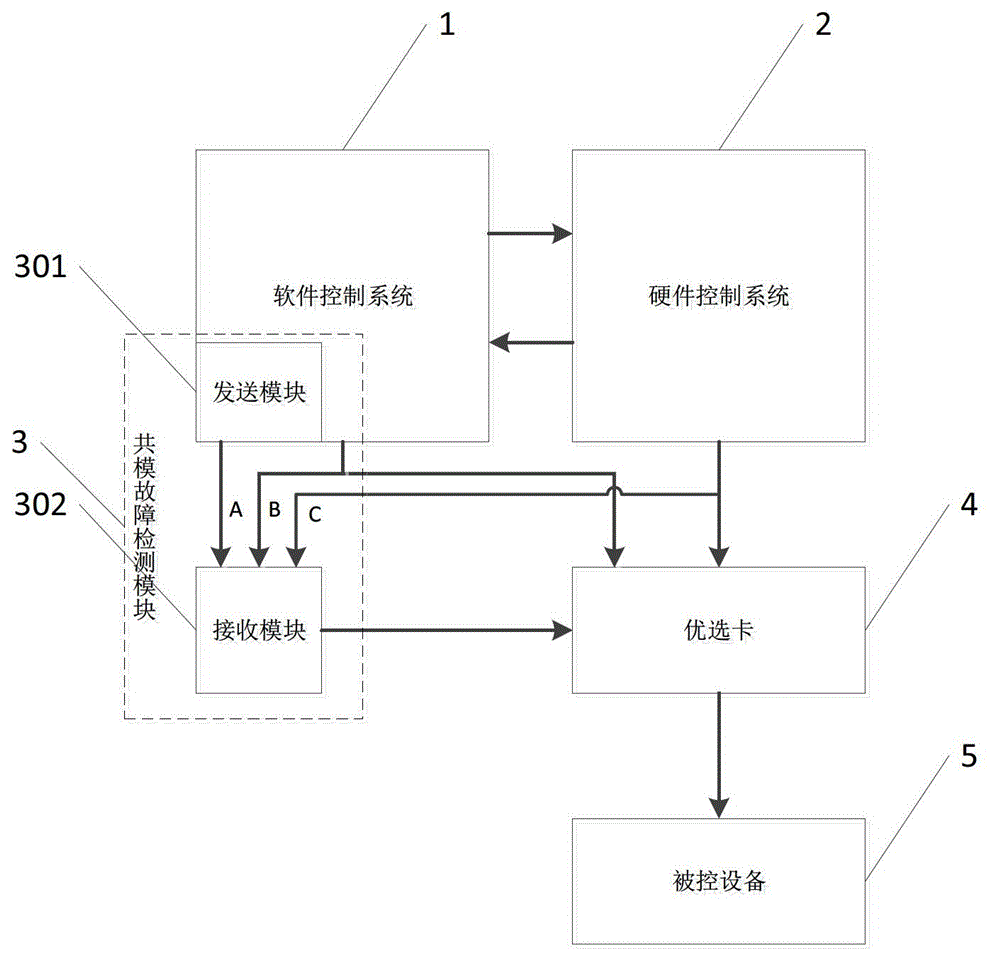

Software common mode fault detection system and its control method for safety level dcs of nuclear power plant

A common-mode fault, software-controlled technology, applied in the field of nuclear power plants, can solve problems such as easy mutual influence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

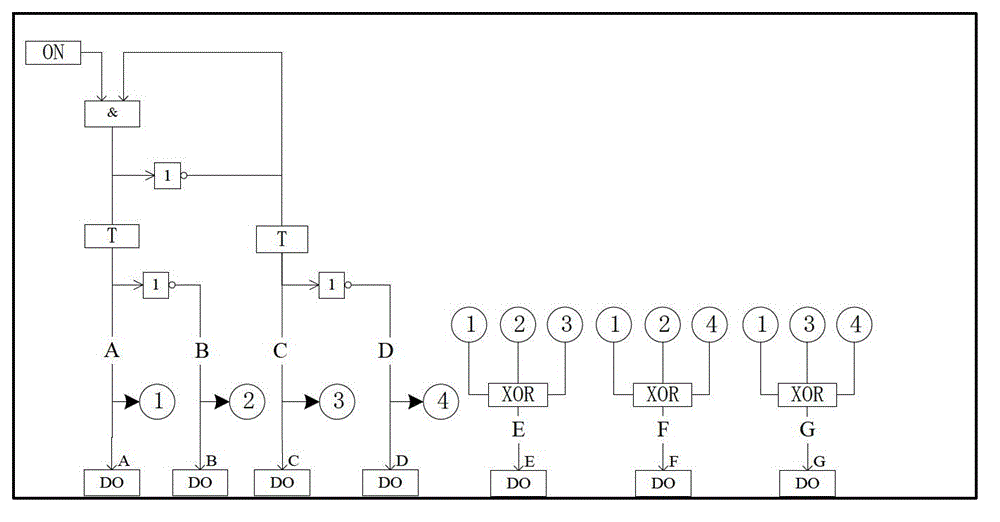

[0045] like figure 1 As shown, the sending module of the common mode fault detection module receives the specific codes of the software control system. The composition of the specific codes is shown in Table 1, where A, B, C and D respectively give four Different combinations of data, use these four data to compare with the corresponding data generated in the receiving module to detect the occurrence of software common mode faults, and E, F, G are the Hamming code effect check bits used to meet the single fault principle , the purpose of doing this is that if there is a problem with one bit of data when the receiving module receives the data, it can also be corrected in time without affecting the subsequent judgment of the common mode fault of the software.

[0046] cycle

A

B

C

D

E

F

G

1

0

1

1

0

0

1

1

2

1

0

1

0

0

1

0

3

1

0

0

1

1

0

0

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com