Marine floating type drilling riser flexible hanger

A flexible suspension and riser technology, applied in drill pipes, drilling equipment, drill pipes, etc., can solve the problems of cumbersome operations, threaten the safety of riser suspension, and be unfavorable to personnel safety, and simplify the suspension operation steps and shorten the suspension operation. time, the effect of avoiding overloading of the suspension beam

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in conjunction with drawings and embodiments.

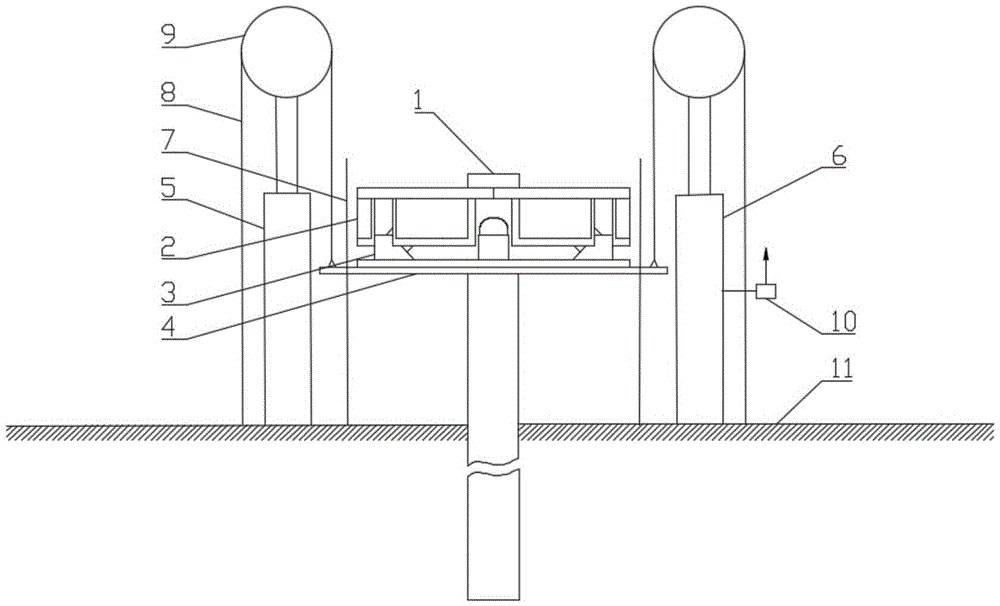

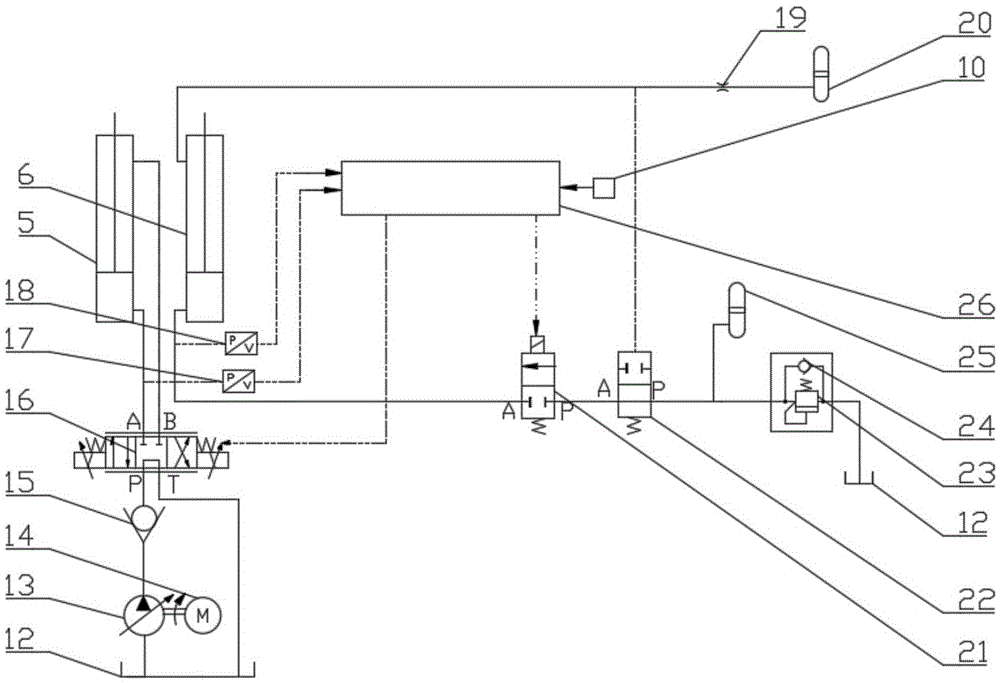

[0019] As shown in the drawings, the chuck 2 is composed of jaws, jaw box and upper plate. The jaws and their driving hydraulic cylinders are placed in the jaw box. The claws can be stretched and extended to lock and release the riser string. The supporting jaws of the claw box are connected with the upper plate; the universal joint 3 is mainly composed of rubber columns and the lower plate, and the lower plate is connected with the bottom plate. The upper end is closer to the center of the universal joint 3 than the lower end, and the chuck 2 is embedded on the universal joint 3 to support the riser 1 to realize horizontal rotation within a certain range. The heave compensation device is mainly composed of an active compensation cylinder 5, a passive compensation cylinder 6, a sprocket 9 and a guide mechanism 7. The active compensation cylinder 5 and the passive compe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com