Ocean floating drill platform string heave compensation device

A technology for drilling platform and heave compensation, applied in drilling equipment, underwater drilling, supporting devices, etc., can solve the problems of high manufacturing cost, large energy consumption, large drill string quality, etc., so as to limit energy consumption and avoid accidents. , Improve the effect of compensation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with drawings and embodiments.

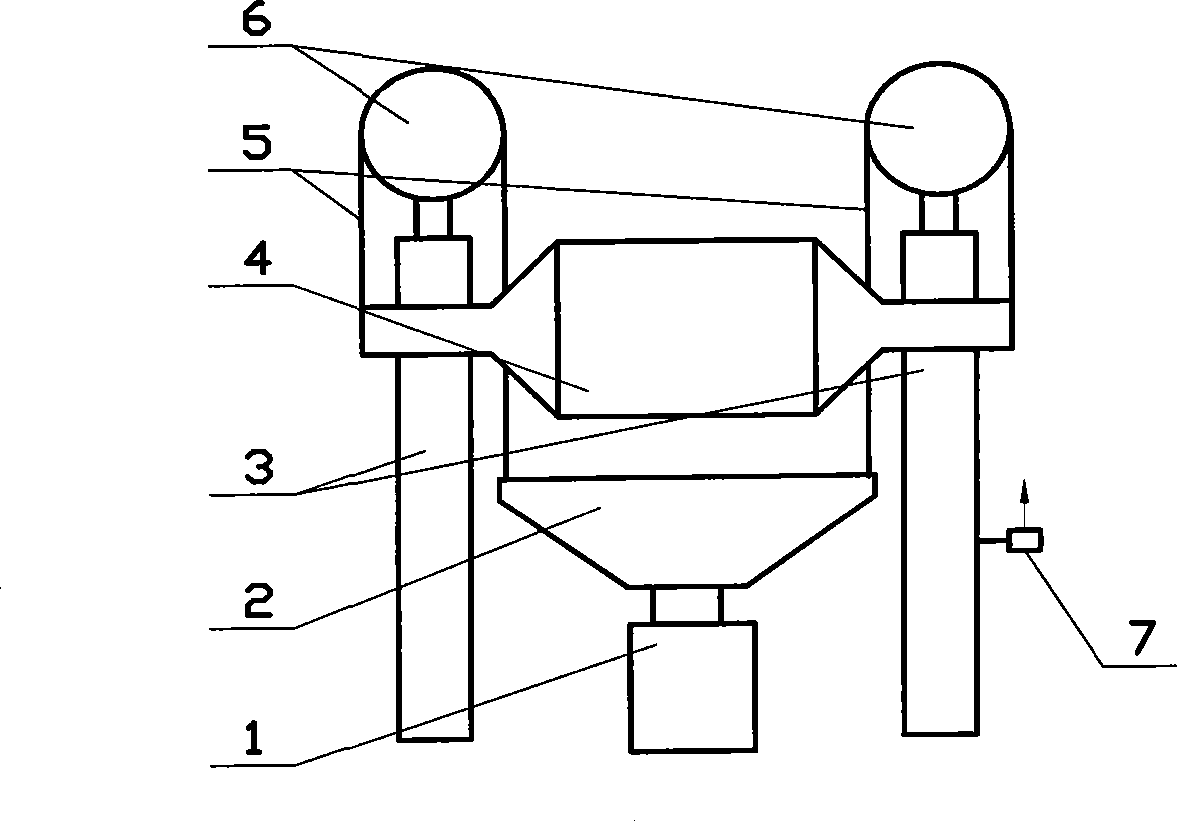

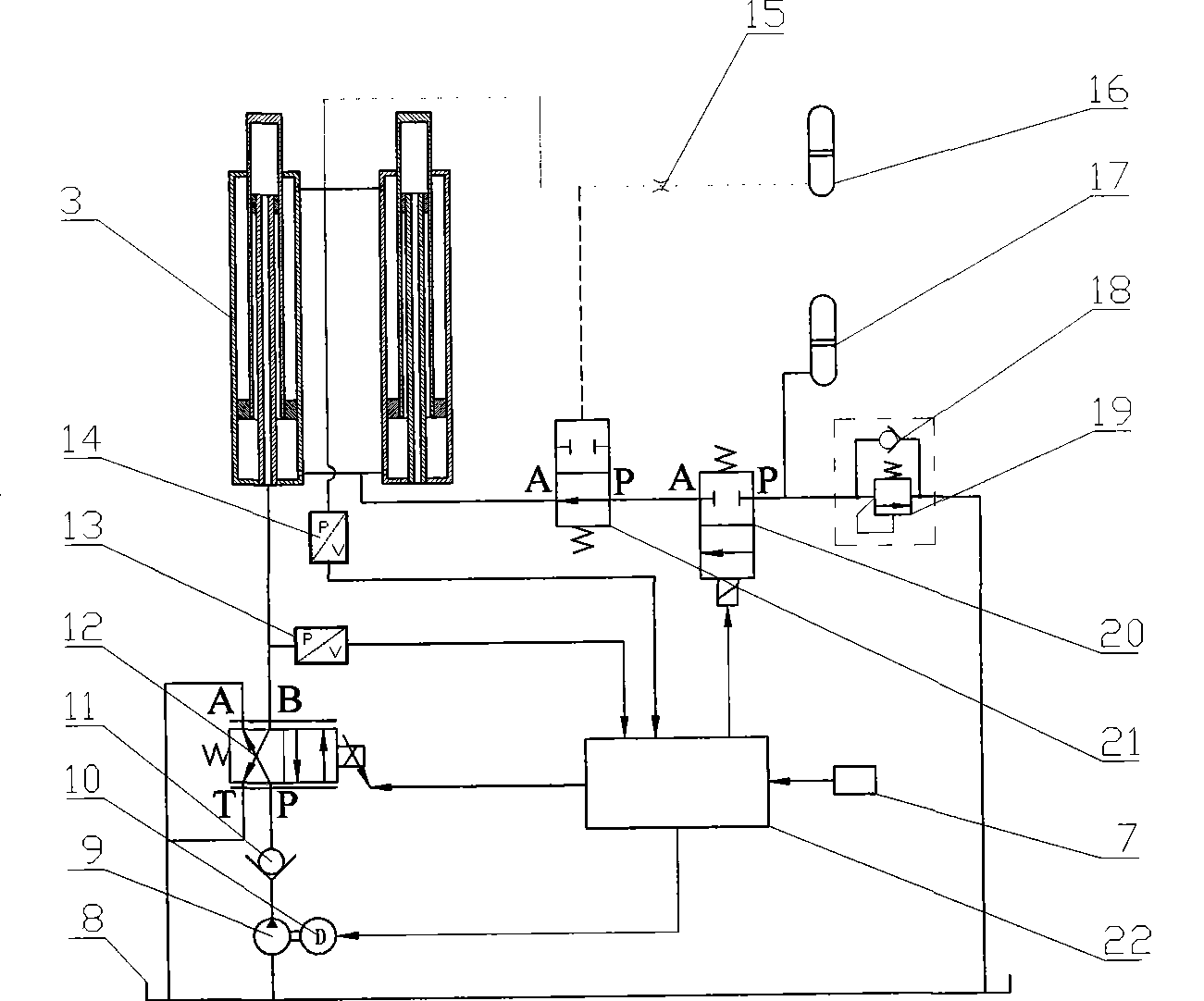

[0020] As shown in the figure, the crossbeam 2 is fixedly connected with the hook 1, and is connected with the traveling carriage and the compensation hydraulic cylinder 3 which are fixedly connected together through a chain 5 . A pressure sensor 14 is installed in the rod chamber of the compensation hydraulic cylinder 3 and a pressure sensor 13 is installed in the rodless chamber. The ratio of the piston diameters of the inner cylinder and the outer cylinder of the composite compensation hydraulic cylinder 3 is 1:3 to 1:5. A pressure sensor 13 is installed in the rodless chamber of the inner cylinder of the composite compensation hydraulic cylinder 3, a pressure sensor 14 is installed in the rod chamber of the outer cylinder of the composite compensation hydraulic cylinder 3, and the acceleration sensor 7 is fixedly connected with the platform; the inlet of the hydraul...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com