Weaving machine with lubricating systems

A lubricating system and loom technology, applied in the direction of engine lubrication, textile, mechanical equipment, etc., can solve the problems of shortening the use time of lubricating oil and reducing the lubricating performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

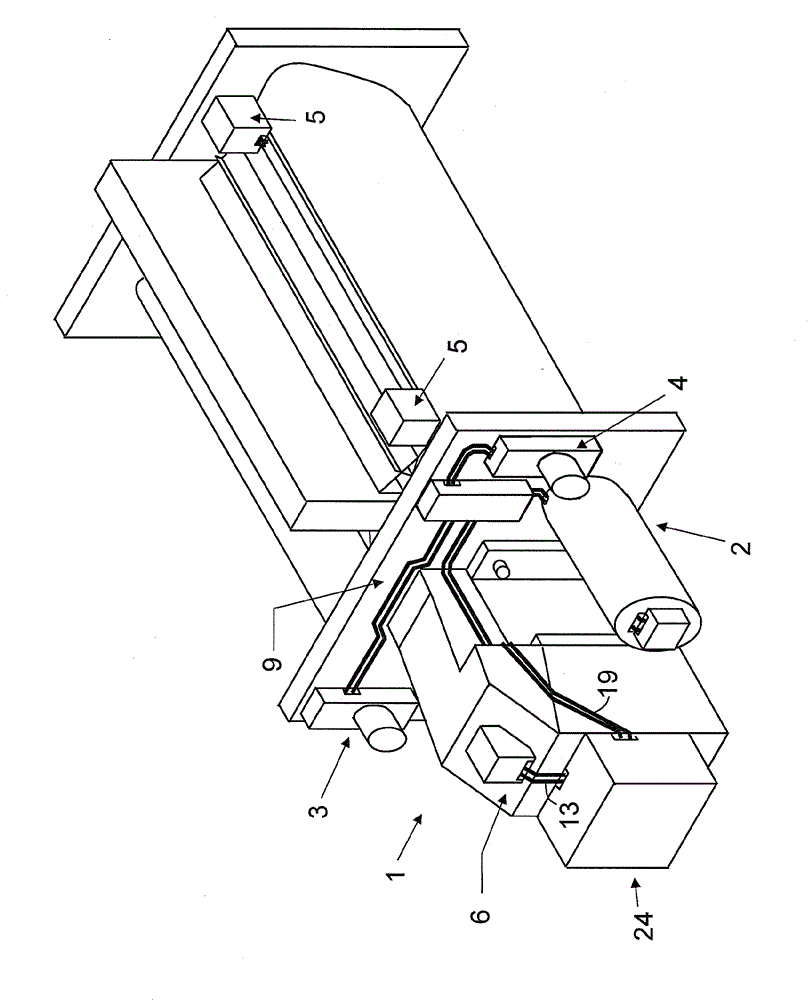

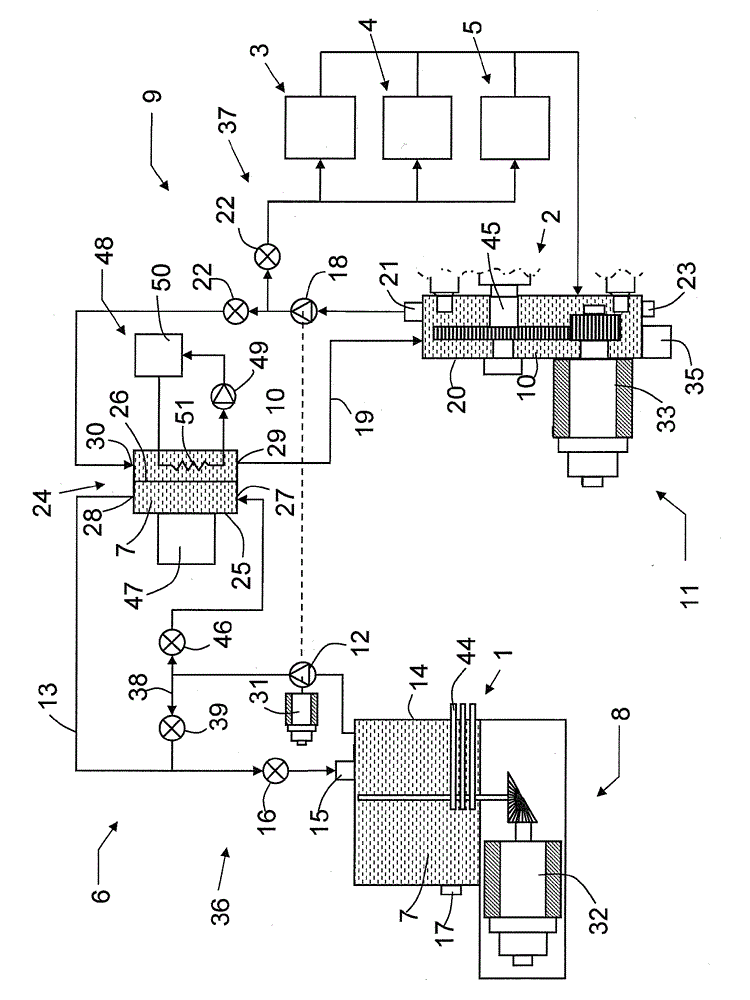

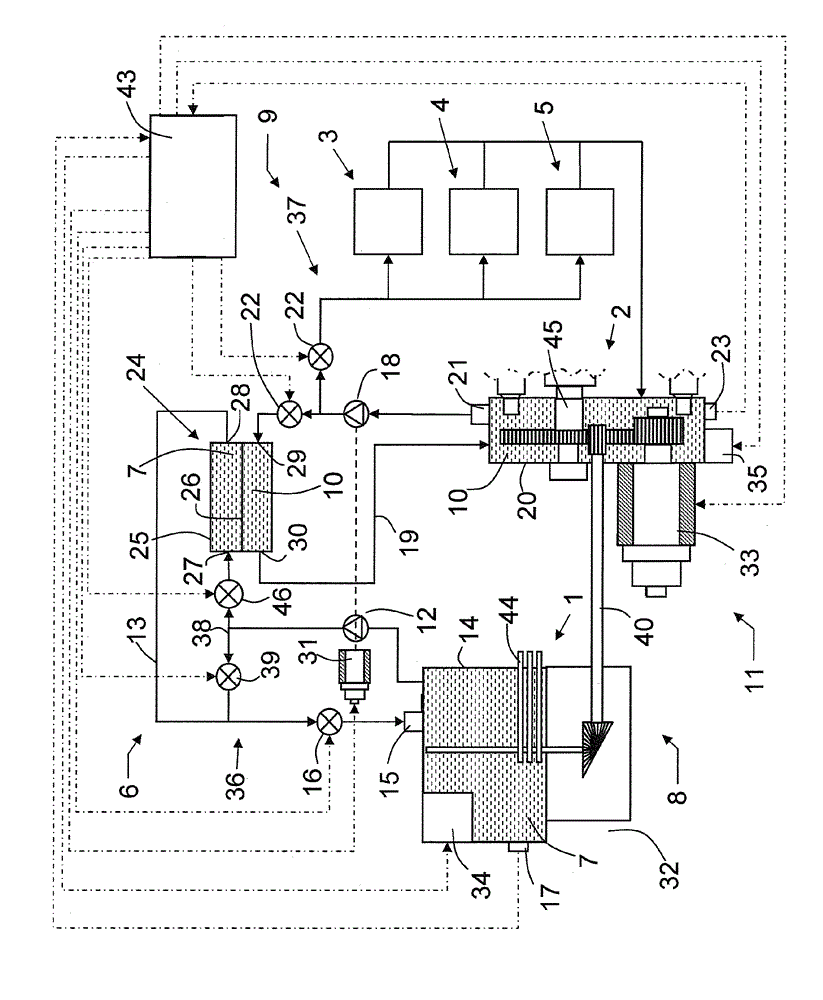

[0024] figure 1 and figure 2 A loom with a shed forming device 1 , a weft beating device 2 , a warp beam device 3 , a cloth beam device 4 and a selvedge tucking-in device 5 is schematically shown. The weaving machine comprises a first lubricating system 6 supplying a first lubricating fluid 7 to an element 44 of a first machine arrangement 8 comprising a shedding arrangement 1 . The loom also comprises a second lubricating system 9 which supplies a second lubricating fluid 10 to the elements of a second machine device 11 comprising a beating device 2 , a warp beam device 3 , a beam cloth device 4 and a selvage tucking device 5 45. The shedding device 1 can be a dobby, a cam box, an eccentric system and a jacquard device. As the lubricating fluid 7, 10, lubricating oil having an appropriate viscosity is used.

[0025] The first lubricating system 6 comprises a pump 12 for the lubricating fluid 7, a pipe 13 for leading the lubricating fluid 7 to and from the machine arrange...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com