Predicting method of leakage rate of bolted flange connection structure with anti-loosing washer

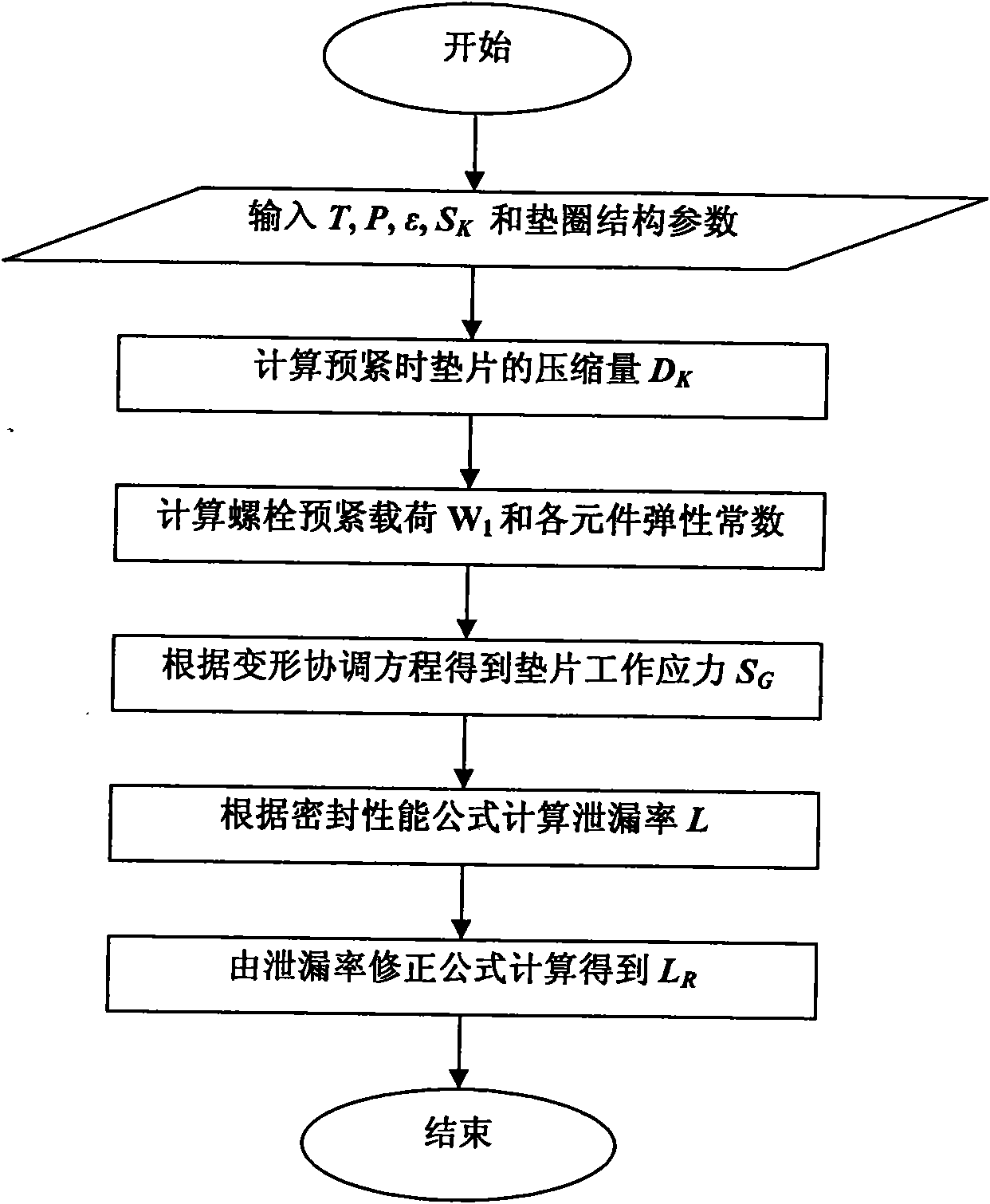

A bolted flange and connection structure technology is applied in the field of leakage rate prediction of bolted flange connection structures, which can solve problems such as unpredictable leakage rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

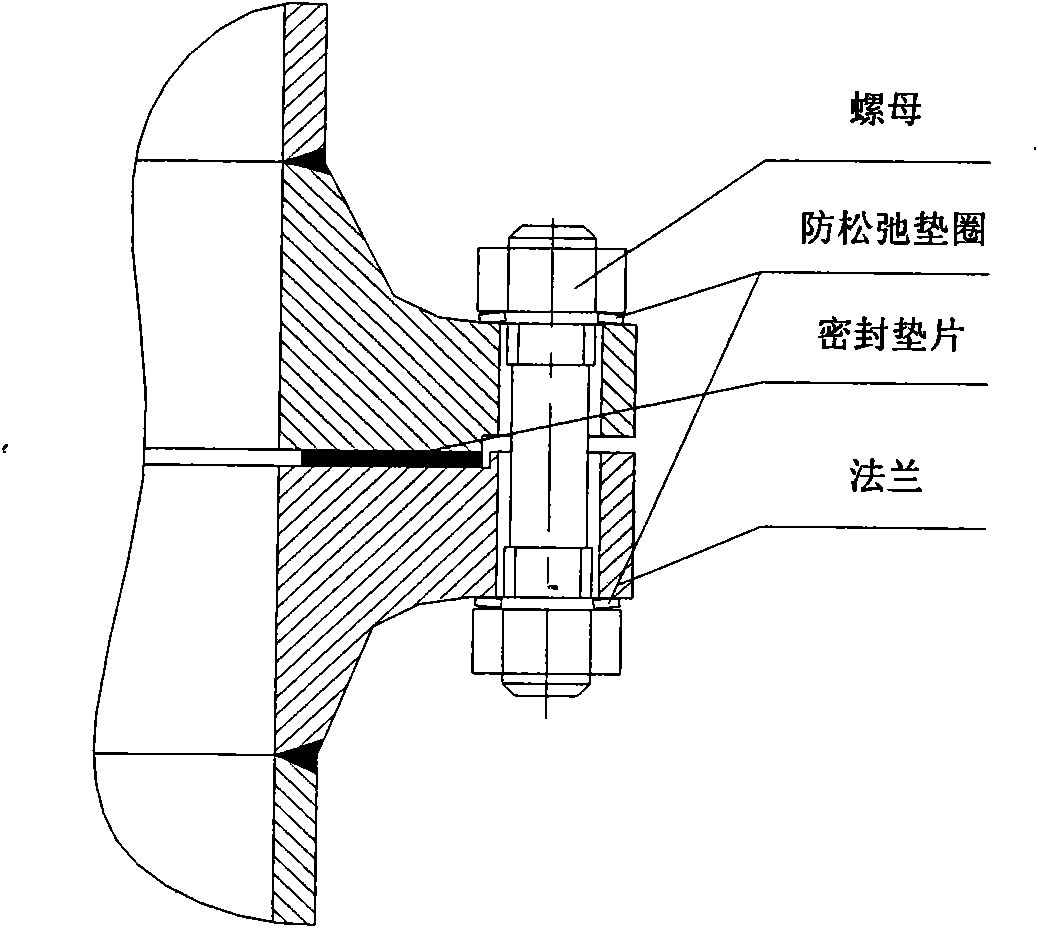

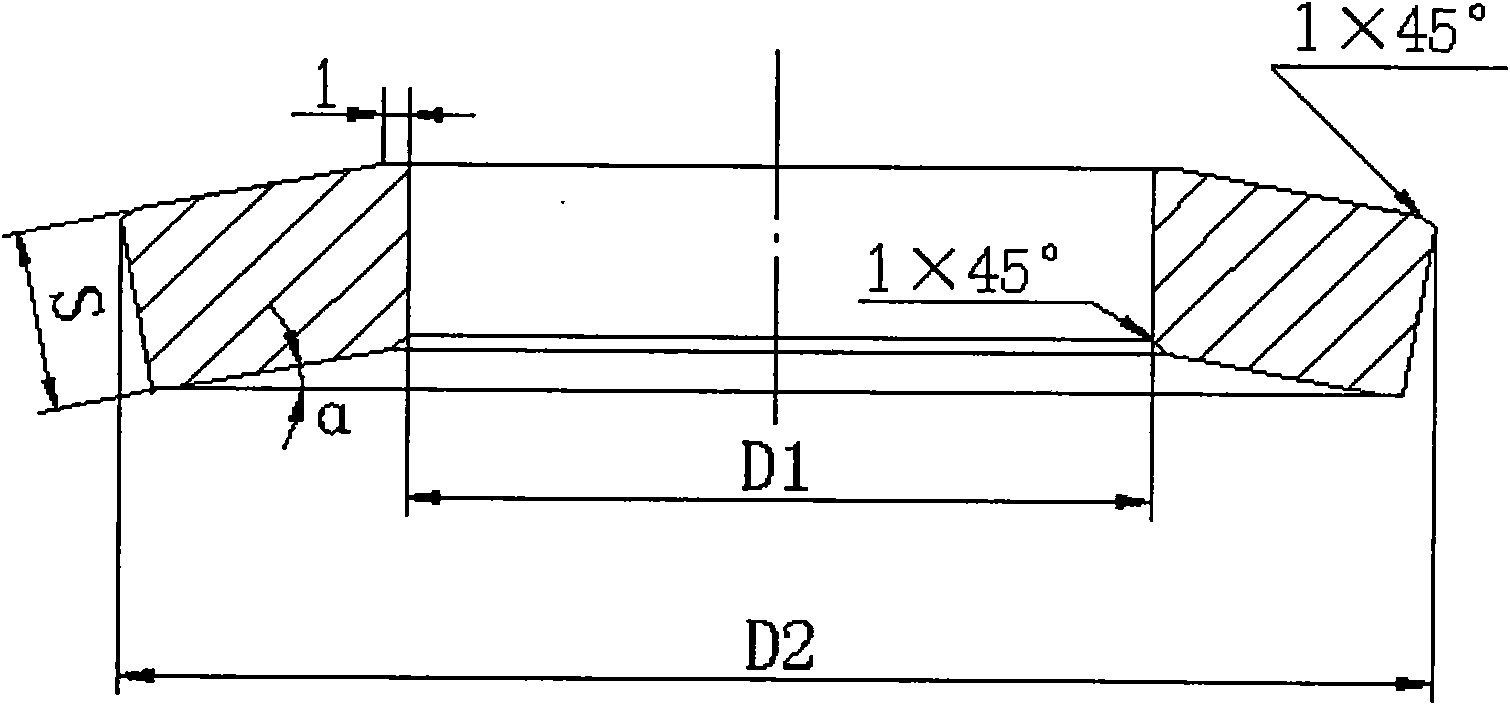

[0071] The pipeline is bolted and flanged, the working pressure is 3.88MPa, the working temperature is 500°C, and the medium is hydrogen, hydrogen sulfide gas and hydrocarbon mixture. The connecting flange is a concave-convex face-to-face welded steel pipe flange in accordance with GB / T 9115.2-2000 standard, PN16, DN200, and the material is 0Cr18Ni9; the connecting element is 12 M33 studs, and the material is 25Cr2MoVA; the sealing gasket Spiral wound gasket for flexible graphite Refer to the relevant provisions of GB150-1998 to take the pre-tightening stress of the gasket as 70MPa; 24 anti-loosening washers, and its structural parameters are: inner diameter D 1 =34mm, outer diameter D 2 =75mm, thickness S=6.5mm, washer inclination α=7°.

[0072] When the working temperature is 500°C, the basic properties of the flexible graphite wound gasket are:

[0073] Compression performance: S K = 38.7 D ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com