Patents

Literature

57results about How to "The calculation principle is simple" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

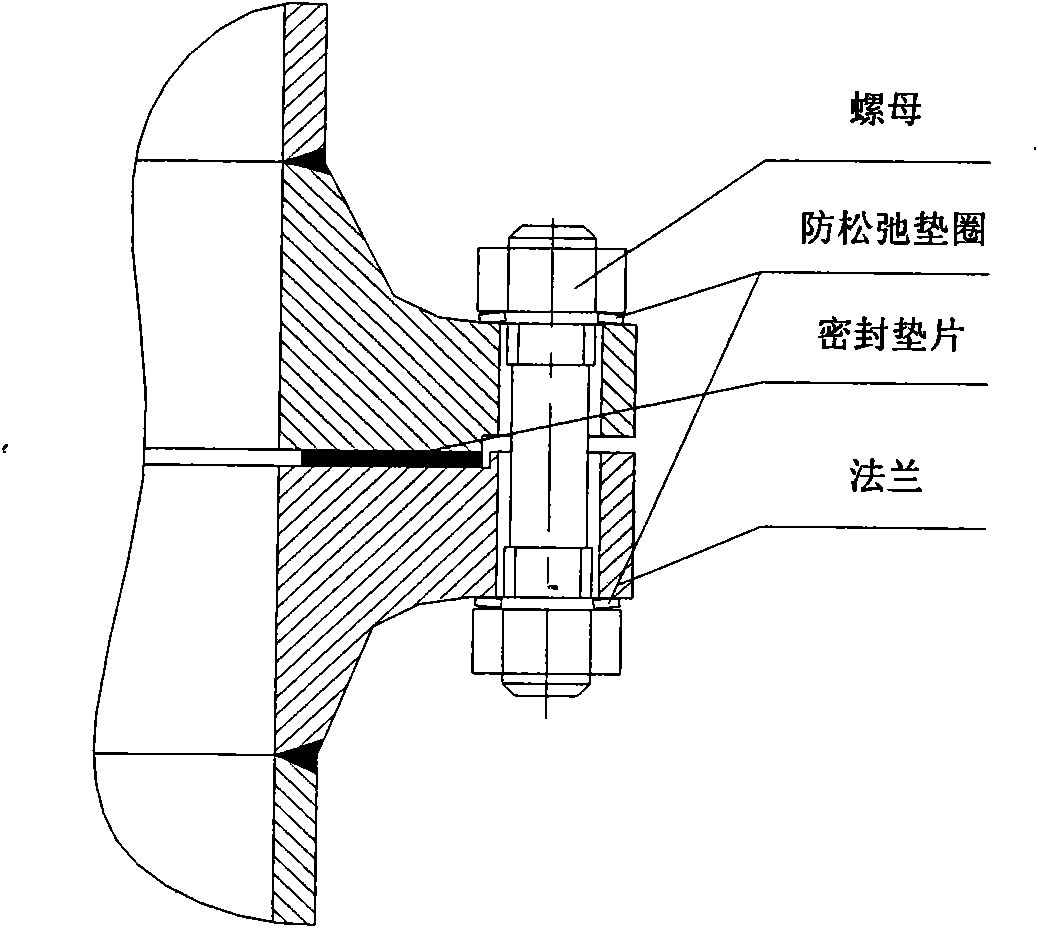

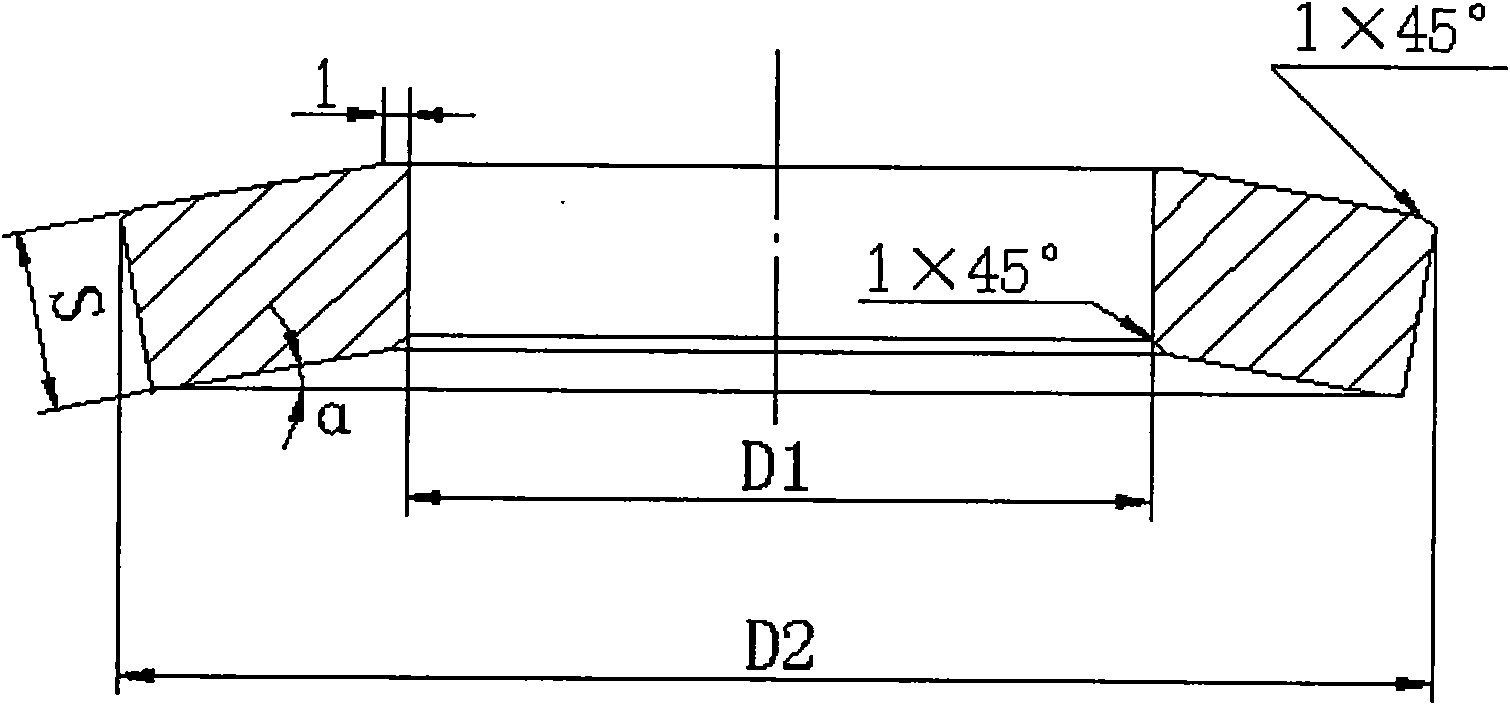

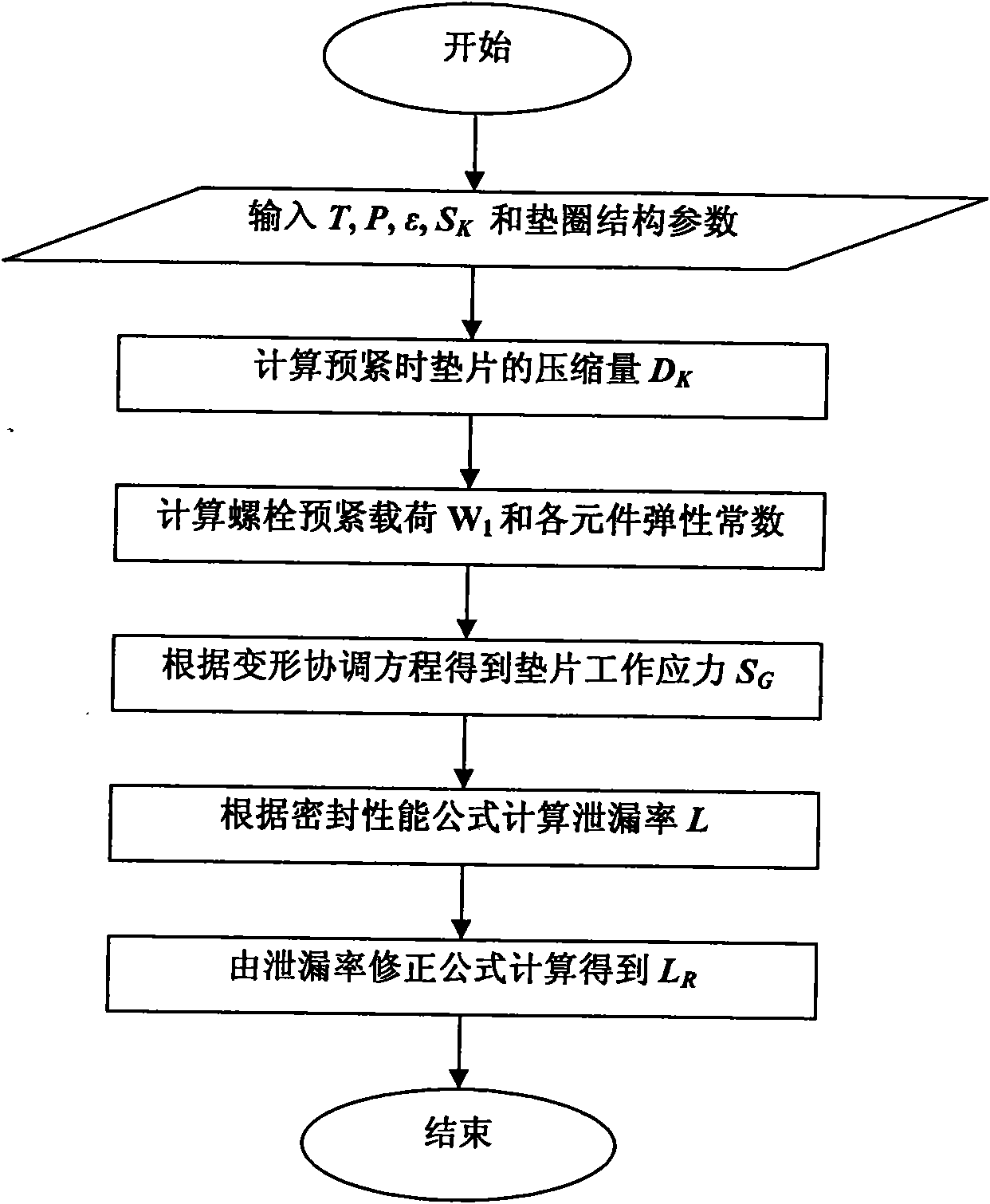

Predicting method of leakage rate of bolted flange connection structure with anti-loosing washer

InactiveCN101667229AAccurate predictionThe calculation principle is simpleFluid-tightness measurementSpecial data processing applicationsEngineeringHigh pressure

The invention relates to a predicting method of the leakage rate of a bolted flange connection structure with an anti-loosing washer. Aiming at the defect that the leakage rate of the prior bolted flange connection structure with the anti-loosing washer can not be predicted, by establishing the deformation compatibility equation of the bolted flange connection with the anti-loosing washer and calculating the pretightening force and the working stress of a gasket, and according to the tightness principle, the predicting method of the leakage rate of the bolted flange connection structure with the anti-loosing washer is established, so that the prediction of the leakage rate of the connection structure is realized. The predicting method of the invention has simple calculation principle and method and accurate prediction result, and can be widely applied to the prediction and calculation of the leakage rate of the connection structure in the circumstance of high temperature and high pressure and larger fluctuation of temperature and pressure.

Owner:NANJING UNIV OF TECH

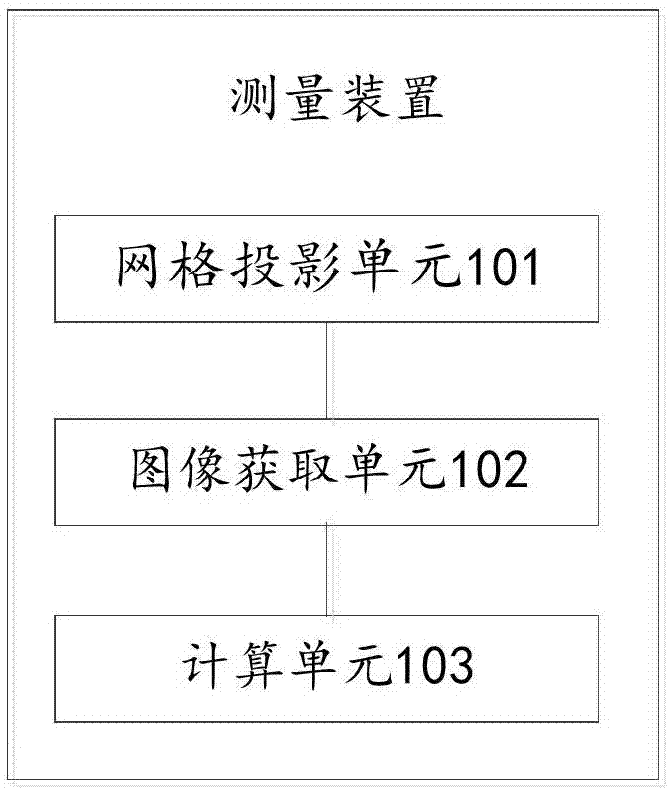

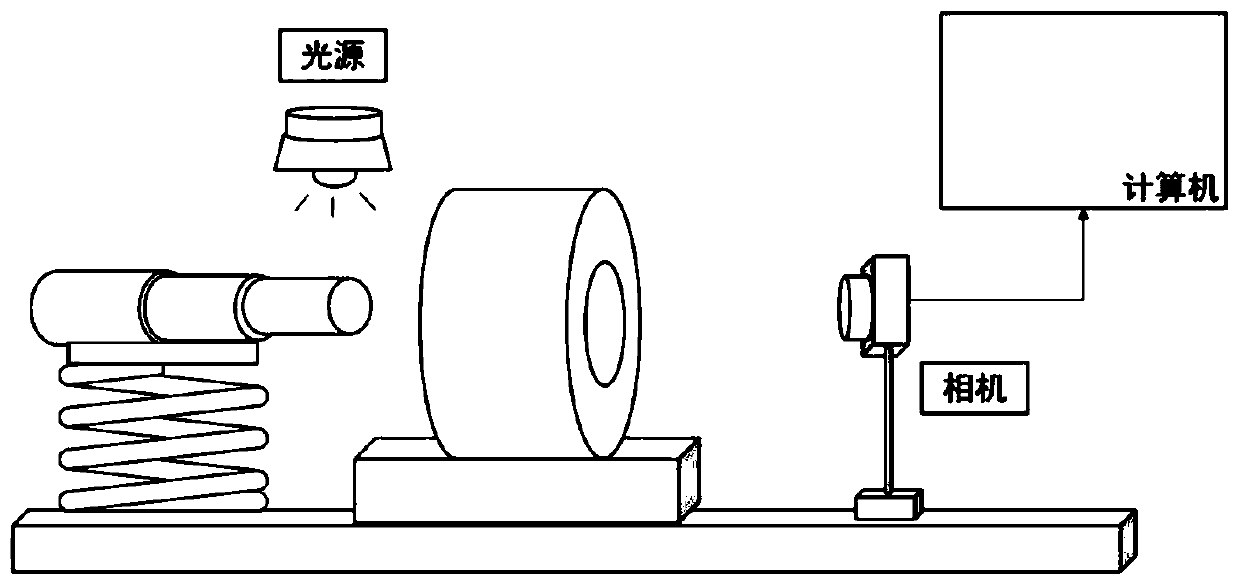

Measuring device and method for digital image built-in virtual ruler

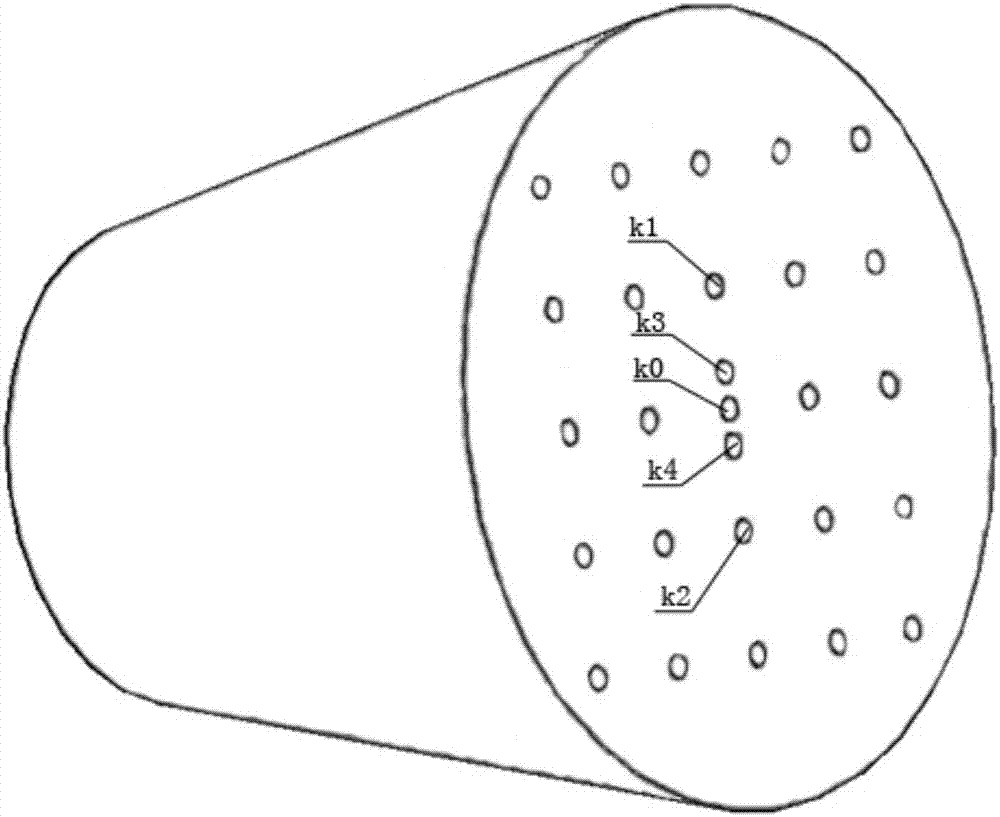

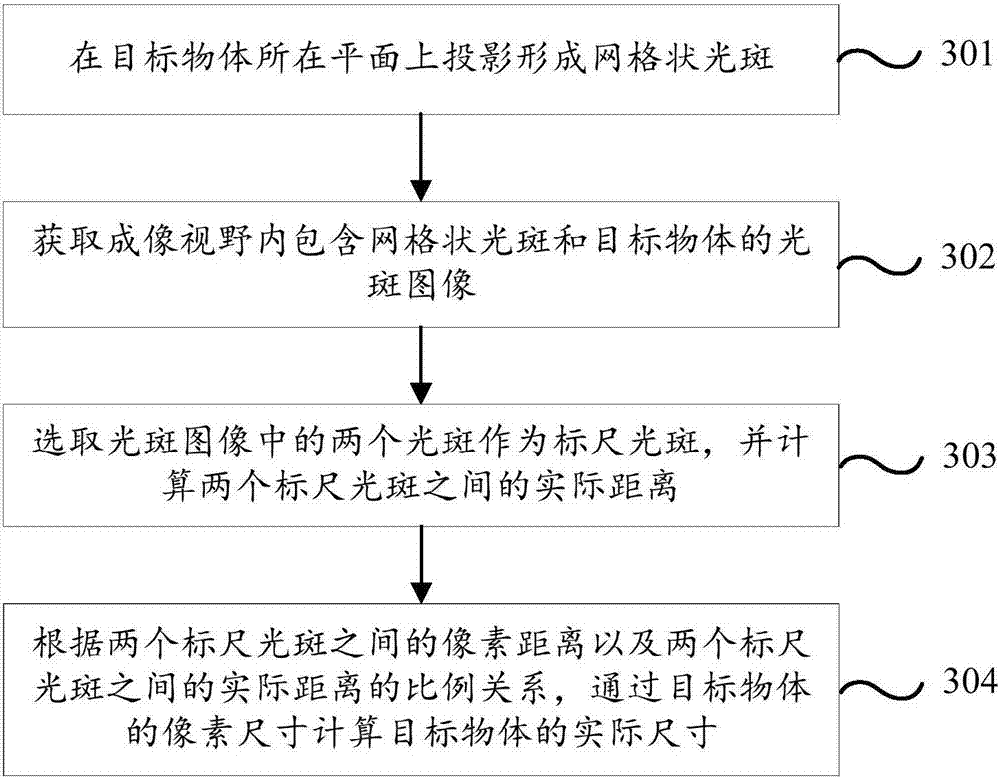

InactiveCN107289858AIncrease the field of view imaging areaRealize the imaging areaUsing optical meansMicro levelNon contact measurement

The invention provides a measuring device and method for a digital image built-in virtual ruler. The device comprises a grid projection unit, an image acquisition unit and a calculation unit, wherein the grid projection unit is used for projecting on the plane of a target object to form grid light spots; the image acquisition unit is used for acquiring a light spot image including the grid light spots and the target object in the imaging view; and the calculation unit is used for analyzing and processing the light spot image, and calculating the actual size of the target object via the pixel size of the target object according to the proportional relation between the pixel distance between two light spots in the selected light spot image and the actual distance between the two light spots. By carrying the virtual ruler in the digital image, the problems brought by an external ruler are solved; and the noncontact measuring method can be used for measuring the size of any macro or micro object, particularly has obvious advantages on measurement of some target objects that are difficult to touch, and is high in measuring precision and small in error.

Owner:广州市九州旗建筑科技有限公司

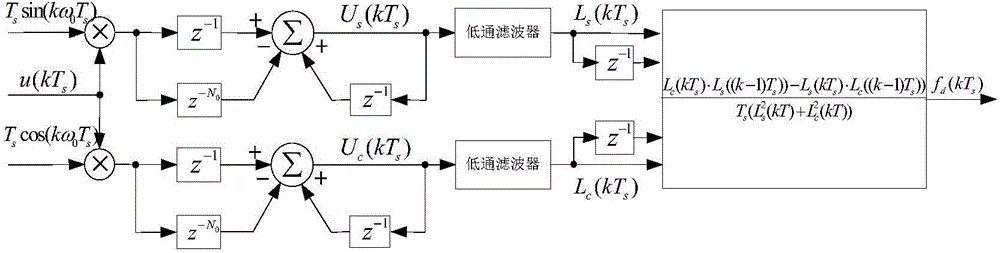

Harmonic and inter-harmonic separation detecting method and device suitable for vessel electric power system

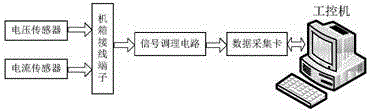

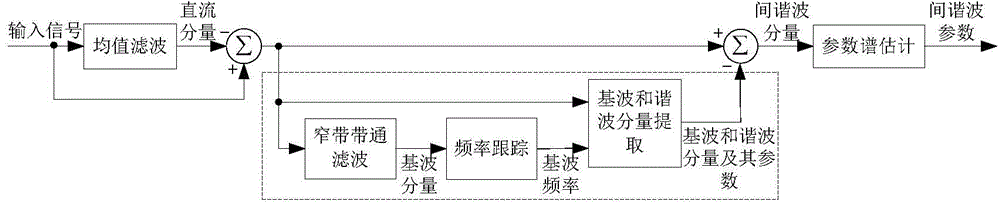

InactiveCN104155520ARealize separation detectionEasy to manageFrequency analysisElectrical engineering technologyLabview software

The invention discloses a harmonic and inter-harmonic separation detecting method and device suitable for a vessel electric power system, and belongs to the technical field of vessel electrical engineering. The device comprises a voltage transducer, a current sensor, a chassis wiring terminal, a signal conditioning circuit, a data acquisition card and an industrial control computer, wherein the wiring terminal, the data acquisition card and the signal conditioning circuit are mounted inside the industrial control computer; the industrial control computer acquires input data through a standard serial port, and LabVIEW software of a virtual instrument is used for restoring collected signals according to the transformation ratio, and original signals are recorded; the comprehensive detection on parameters such as frequency, amplitude value and phase of fundamental wave, harmonic and inter-harmonic can be completed; the detection result can be directly displayed on the liquid crystal display of the industrial control computer. According to the invention, a frequency tracking algorithm, a fundamental wave and harmonic extraction algorithm and an inter-harmonic detection algorithm are adopted to implement the fundamental wave, harmonic and inter-harmonic separation detection.

Owner:NO 719 RES INST CHINA SHIPBUILDING IND

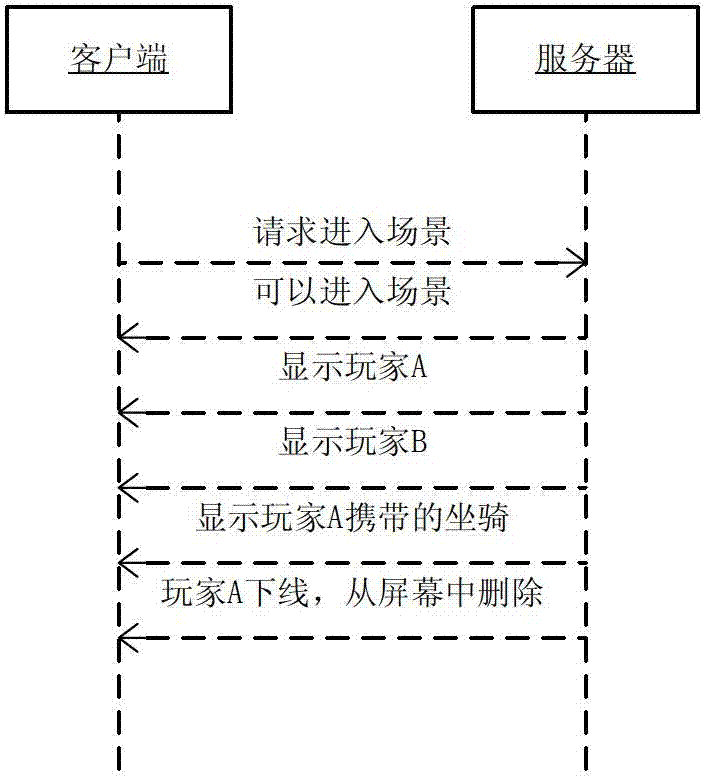

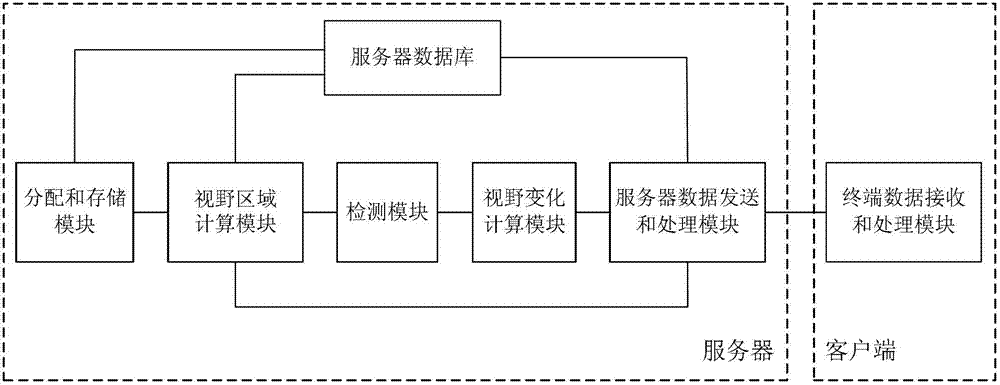

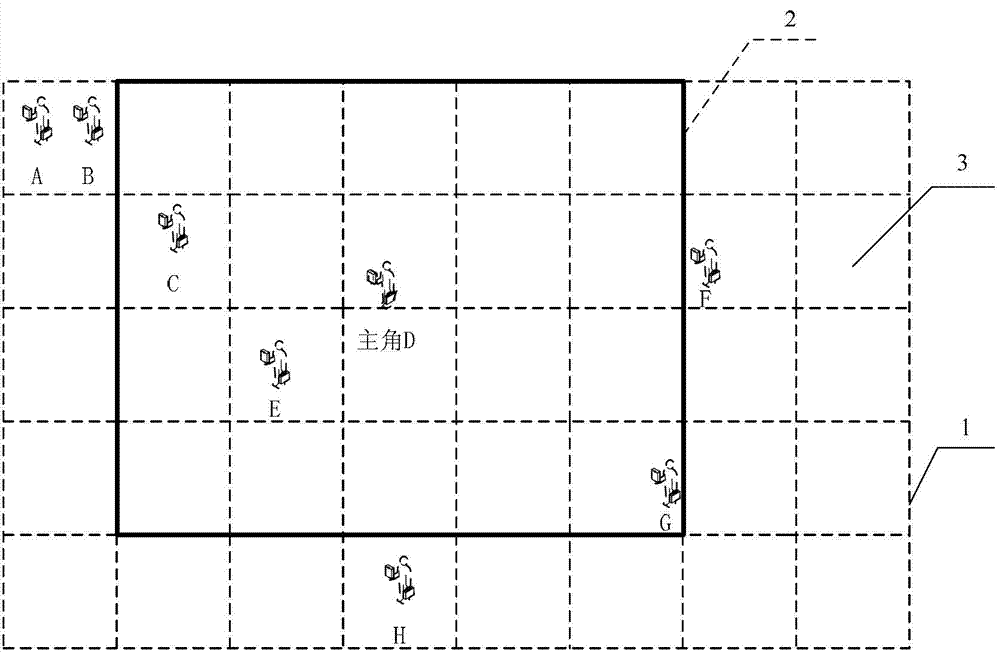

System and method for processing visual field of online role-playing network game

InactiveCN102819680AIncrement and decrement role changesAvoid computationSpecial data processing applicationsVisual field lossComputer module

The invention provides a system and a method for processing a visual field of an online role-playing network game. The system comprises a server and a client; the server comprises a distribution and storage module, a visual field area calculation module, a detection module, a visual field change calculation module and a server data transmitting and processing module which are orderly connected; the server also comprises a server database; the server database is respectively connected with the distribution and storage module, the visual field area calculation module and the server data transmitting and processing module; and the client comprises a terminal data receiving and processing module, and the terminal data receiving and processing module is connected with the server data transmitting and processing module. According to the system, by carrying out visual field calculation treatment on the basis of visual field area change of a player, the server calculated quantity and data processing quantity can be reduced, and the performance of the server is improved.

Owner:北京天神互动科技有限公司

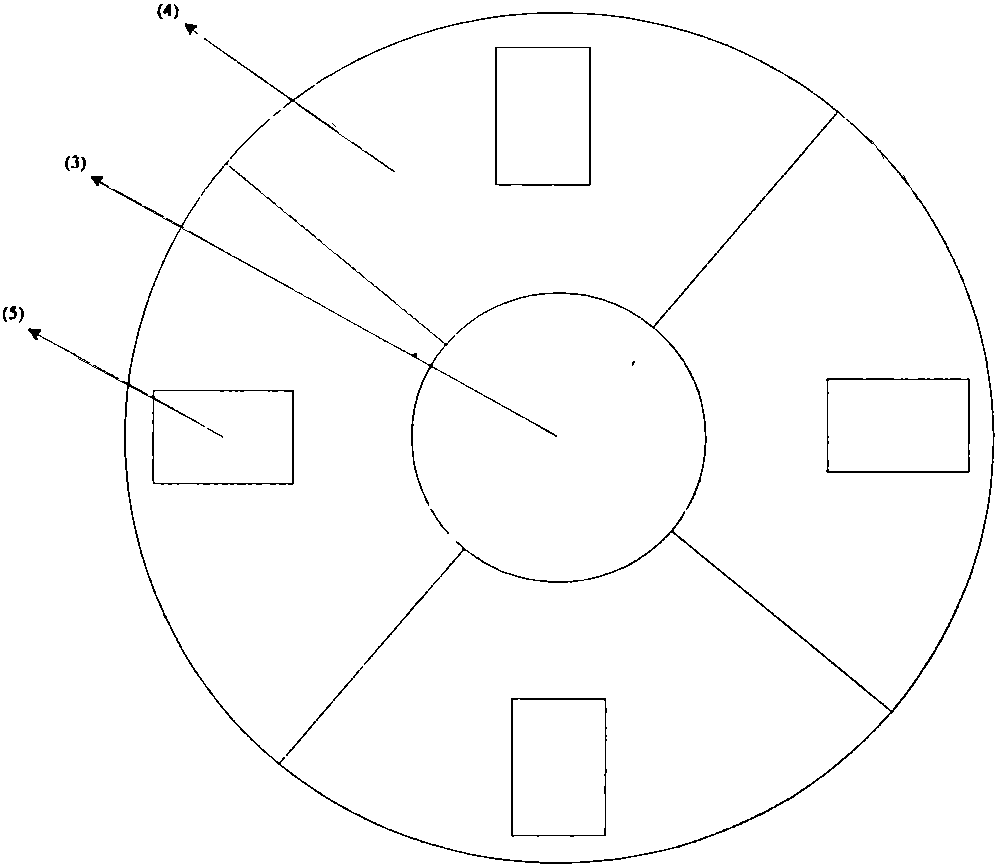

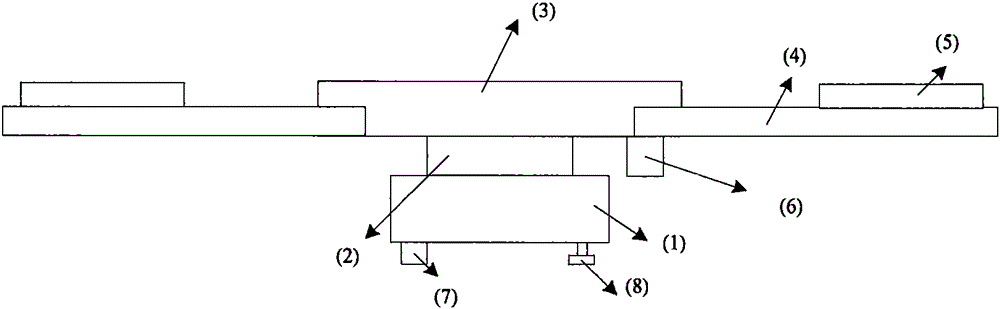

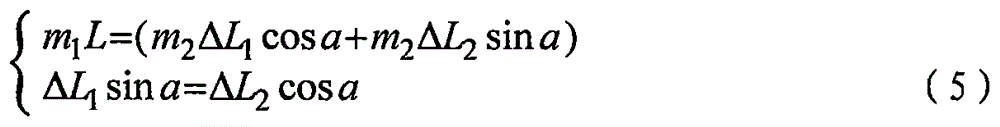

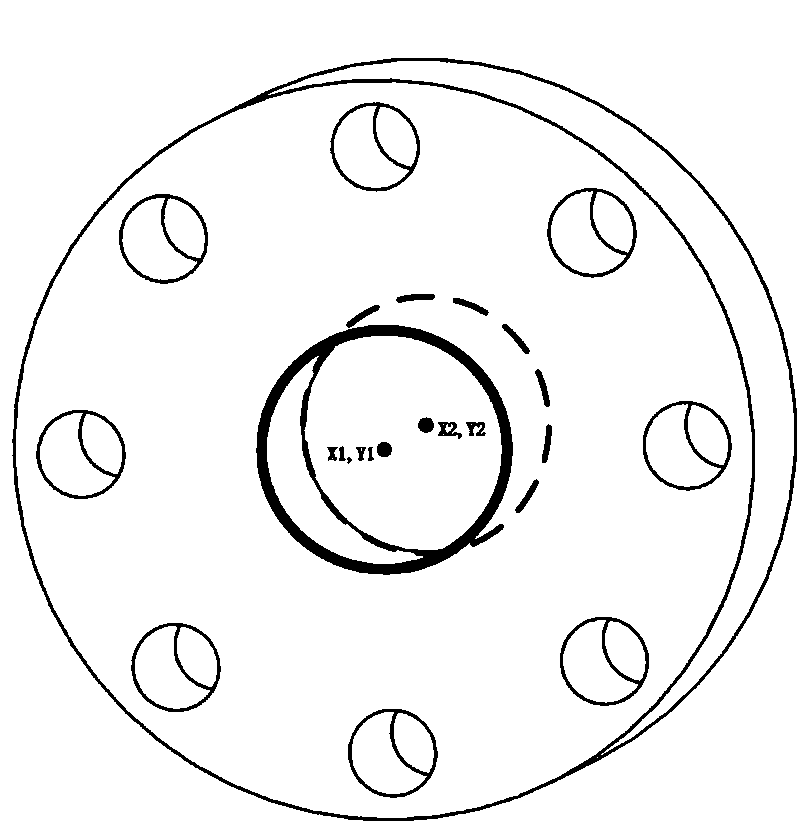

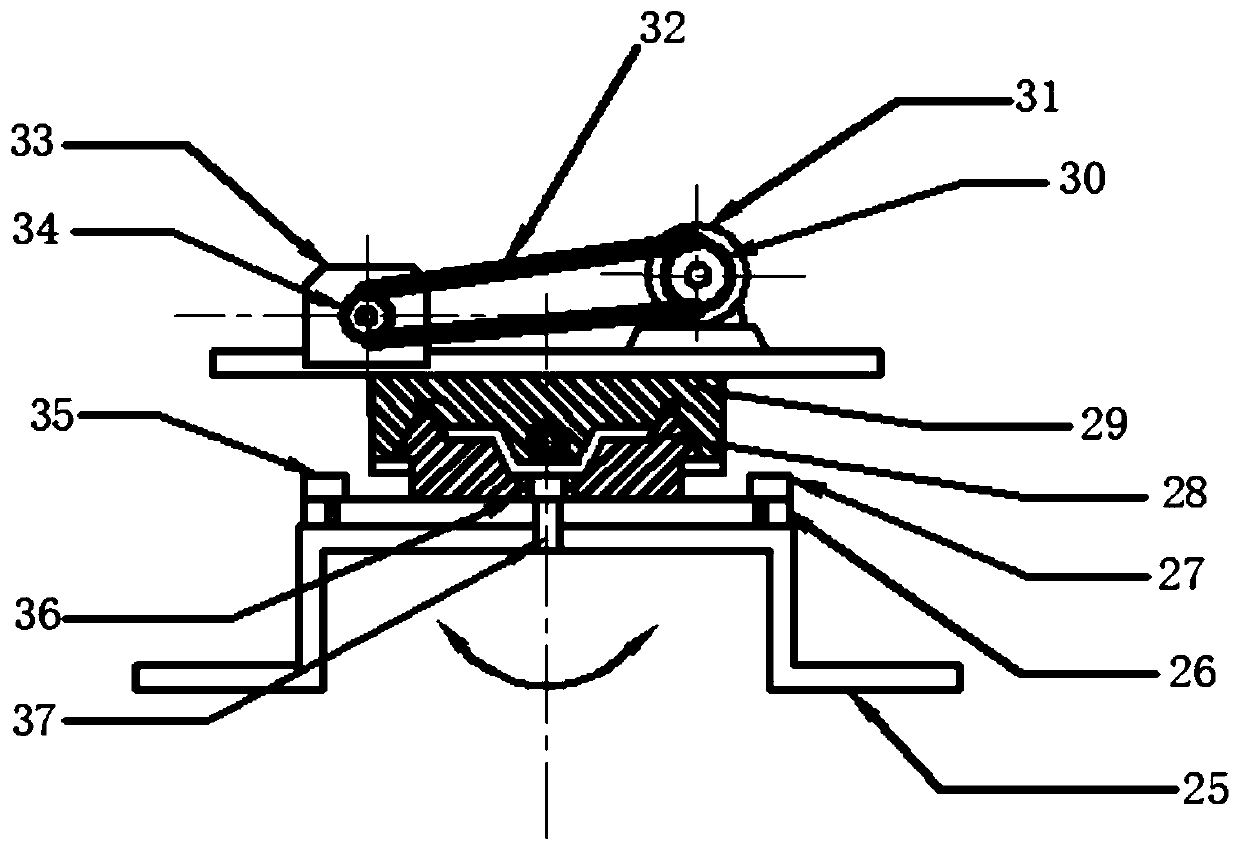

Device and method for adjusting mass characteristic of aircraft-simulated air bearing table

ActiveCN105217058AEasy to adjustEasy maintenanceCosmonautic condition simulationsAir bearingEngineering

The invention provides a device and method for adjusting mass characteristic of an aircraft-simulated air bearing table. The adjusting device comprises a base, an air bearing pair, a loading platform surface, an inertia ring, a coarse-adjusting balancing mechanism, two fine-adjusting balancing mechanisms, a shim plate and a hydraulic jack adjusting shim plate, wherein the loading platform surface is mounted on the air bearing pair; the inertia ring is mounted on the external side of the loading platform surface; the coarse-adjusting balancing mechanism is mounted on the inertia ring; the fine-adjusting balancing mechanisms are mounted under the loading platform surface; and the bottom of the base is supported on the foundation through the shim plate and the hydraulic jack adjusting shim plate. The smaller the unbalance mass is, the larger the single pendulum period is; therefore, the balance degree of the system can be judged through the amplitude of the single pendulum period; and moreover, the time when the system can finish the coarse-adjusting process to perform the fine-adjusting process can be calculated by using the single pendulum period. The invention is advantaged in that the calculating principle is simple and the adjusting processes are easy to realize in engineering and easy to maintain.

Owner:HARBIN INST OF TECH

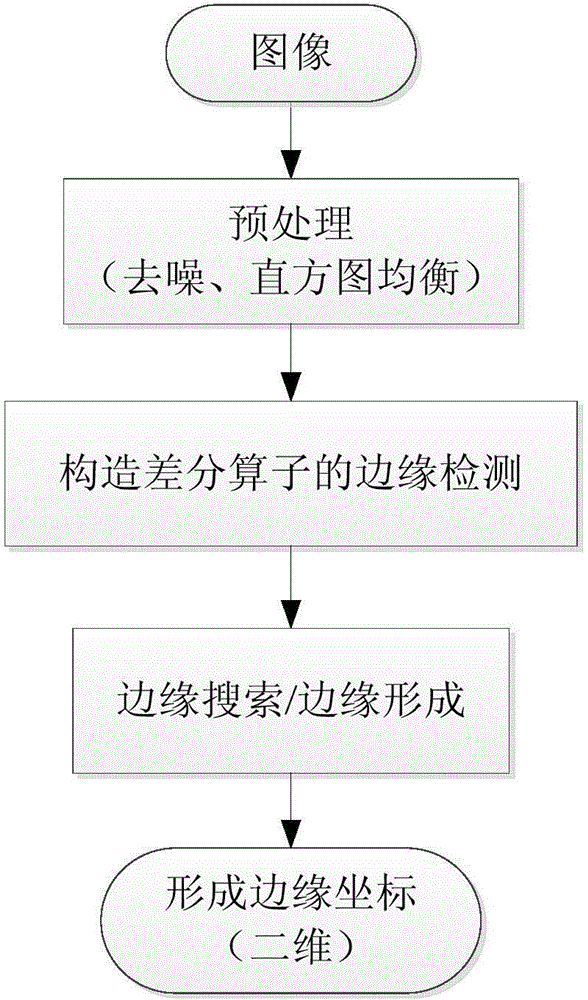

Grading material specific area determining method based on three-dimensional laser scanning and image processing technology

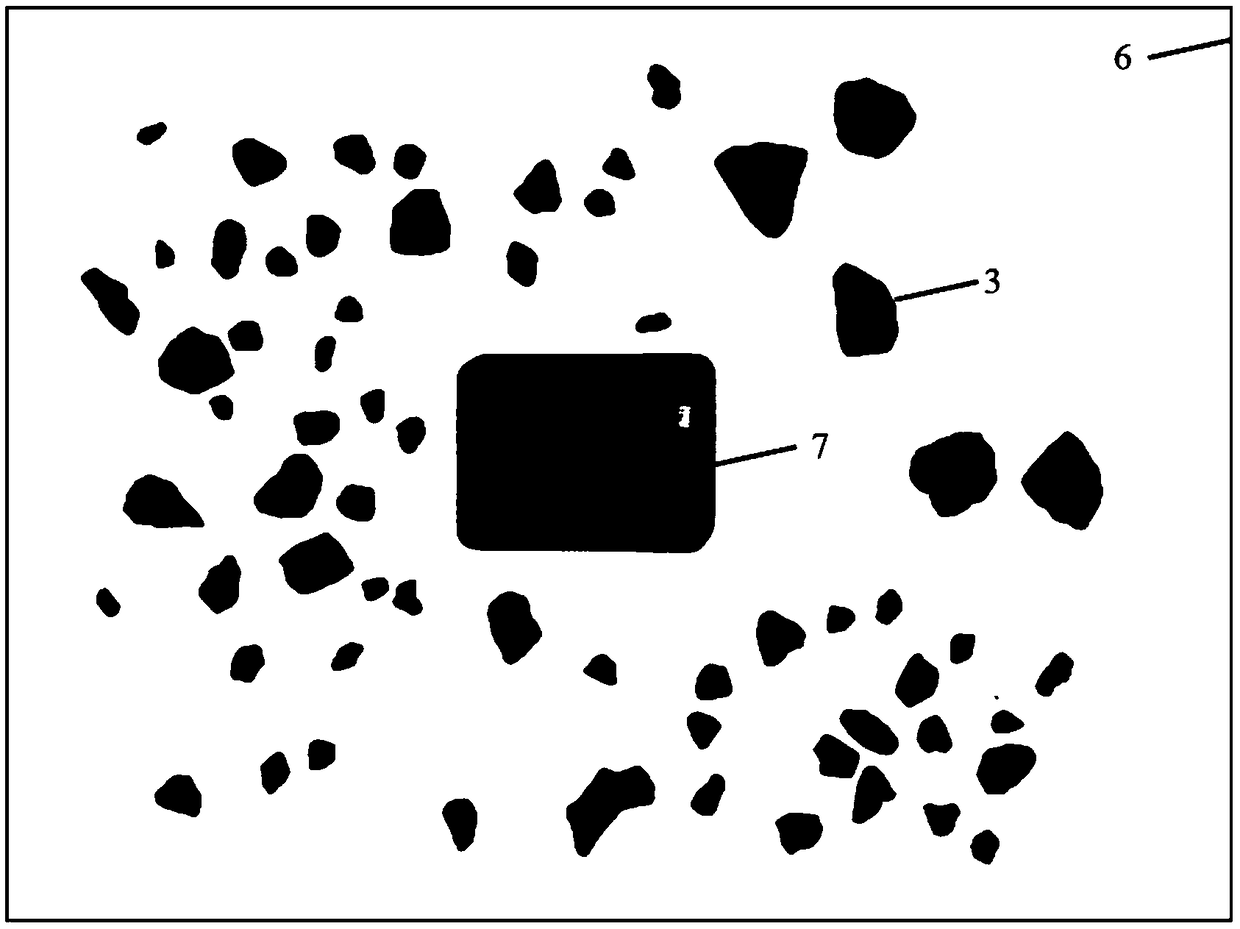

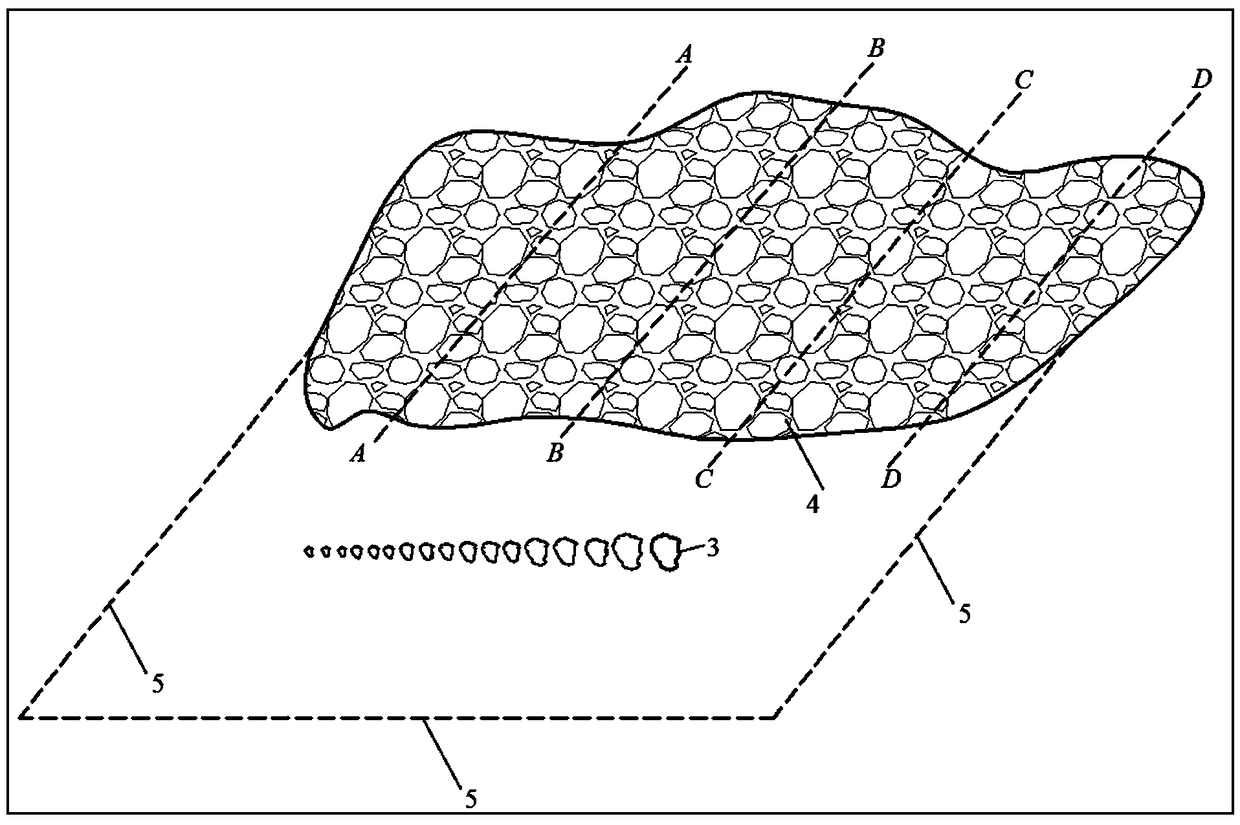

ActiveCN109030305AGuaranteed calculation accuracyDistinctive featuresUsing optical meansPermeability/surface area analysisImaging processingPoint cloud

The invention discloses a grading material specific area determining method based on three-dimensional laser scanning and the image processing technology. For a rock mass larger than 50mm, three-dimensional scanning point clouds are obtained; a rock mass three-dimensional model is established by using the scanning point clouds to obtain the volume and the surface area of the rock mass; and the specific area is the rock mass larger than 50mm is obtained by calculating based on a specific area definition. For a rock mass with the size being 5-50mm, the circumference and area are calculated by using image processing; and the specific area of the rock mass with the size being 5-50mm is calculated by using a spherical model. The specific area of a powder particle being smaller than 5mm is obtained by referring to specific area test results of existing powder materials. A rock mass size-specific area variation curve is drawn based on specific area data obtained by the three modes. A gradation distribution curve of rockburst is obtained. The rock mass size-specific area variation curve and the gradation distribution curve of the rockburst are drawn in one diagram to obtain a grading material specific area curve.

Owner:WUHAN UNIV

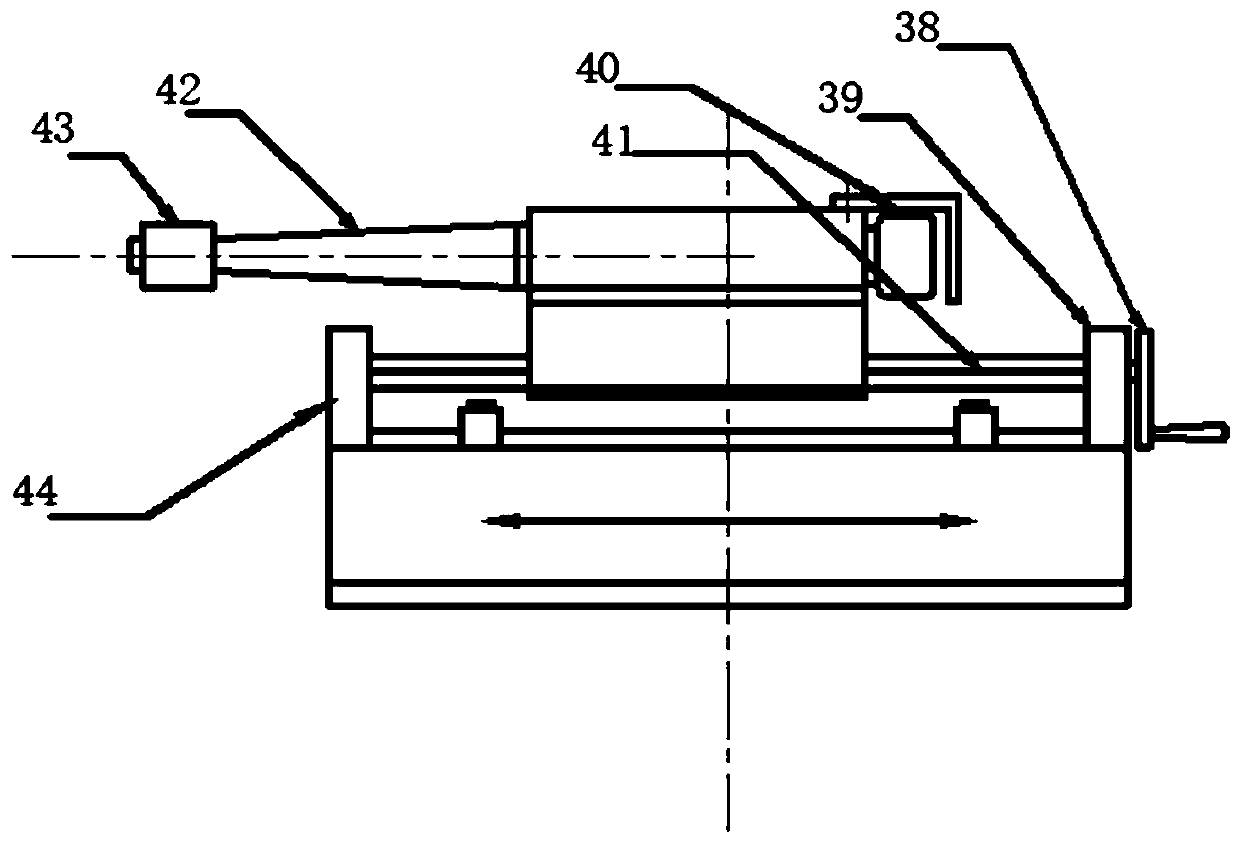

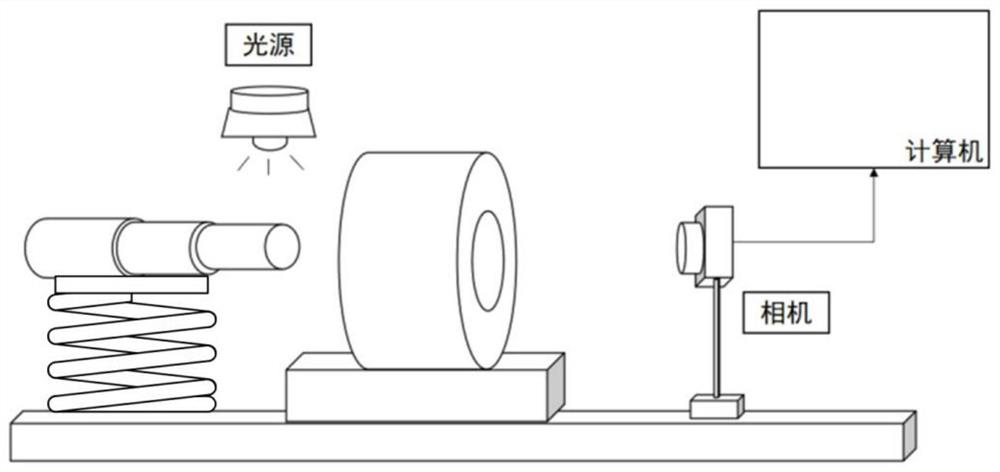

Centering method for stepped shaft and hole assembling process

ActiveCN111322967AGuaranteed accuracyReduce complexityImage enhancementImage analysisMachine visionEllipse

The invention provides a centering method for a stepped shaft and hole assembly process, and the method comprises the steps: photographing an image of a hole part through a calibrated camera, and obtaining the centering deviation of the hole part through an image recognition and ellipse fitting method; adjusting the position of the to-be-assembled hole part by utilizing the centering deviation until the axis of a through hole in the hole part coincides with the axis of the camera, and fixing the hole part and the position of the camera at the moment; shooting an image of each end surface in the assembling process of the stepped shaft through the calibrated camera; obtaining coordinates of a stepped shaft small-diameter end face fitting circle center and a stepped shaft medium-diameter endface fitting circle center by using an image recognition and ellipse fitting method; connecting the two circle centers, calculating the midpoint coordinate of the connecting line, and comparing the midpoint coordinate with the axis coordinate of the hole part to adjust the pose of the stepped shaft to be assembled, so as to realize the centering monitoring of the stepped shaft and the hole. Real-time monitoring and feedback of the centering condition of the stepped shaft and the hole are achieved based on machine vision.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

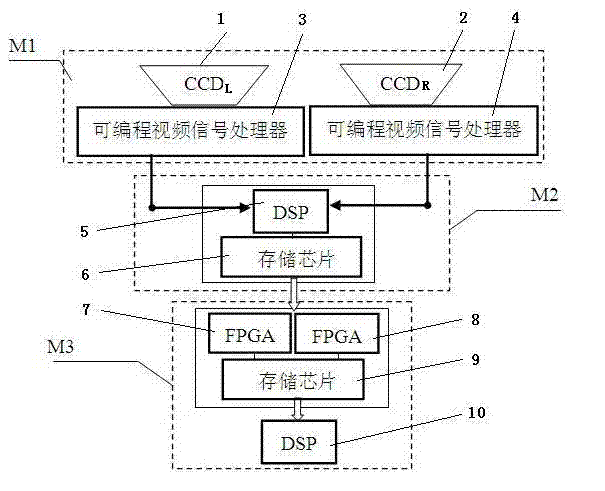

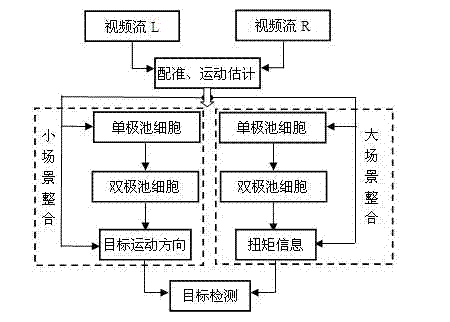

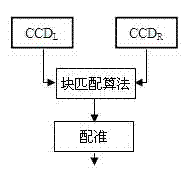

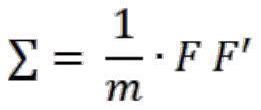

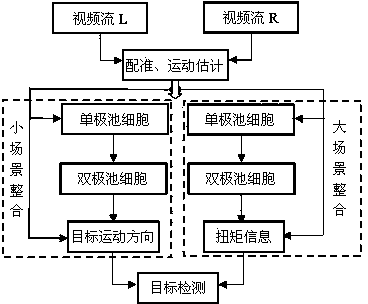

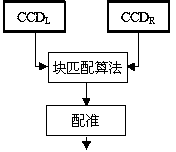

Device and method for detecting high-speed tiny target online in real time by simulating fly vision

ActiveCN102510436ASimple algorithmLow costTelevision system detailsColor television detailsVision processingJet aeroplane

The invention discloses a device and method for detecting a high-speed tiny target online in real time by simulating fly vision. The method comprises the following steps of: acquiring scene video information by using a binocular camera, transmitting the scene video information into a DSP (digital signal processor) chip, and performing primary vision processing; performing large scene and small scene integration and target detection on primary motional information by using an FPGA (field programmable gate array) chip; and tracking a tiny target moving at high speed by taking an integration result of a large scene and a small scene as a target detection evidence. The device and method disclosed by the invention have the advantages that: the target detection is realized by virtue of a biological principle; the device and method have relatively strong antijamming capability and are applicable to the target detection under the condition of a low signal-to-noise ratio in various severe natural environments; a neuron integrating mechanism of a fly vision system has the characteristics of simple computing principle, high real-time performance and the like; the fly vision neuron is simple in tissue structure and can be easily realized by hardware; and the device can be installed on an automobile, panzer, airplane and other appliances which move at high speed, and has the capability of accurately detecting the high-speed tiny target on line in real time in a dynamically changing background.

Owner:HOHAI UNIV CHANGZHOU

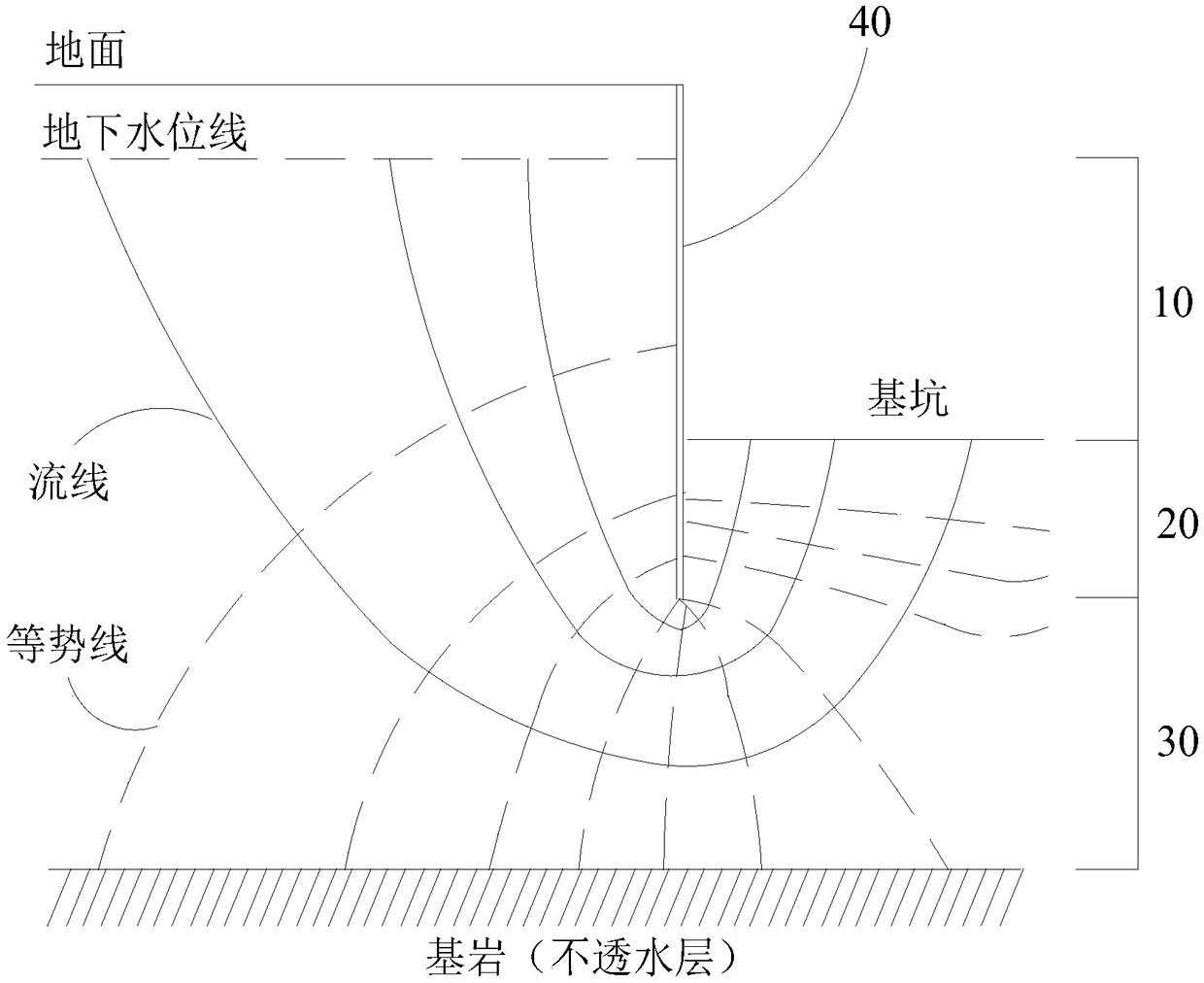

Calculation method of seepage inflow around hanging water-intercepting curtain

ActiveCN109213966AEasy to calculateThe calculation principle is simpleFoundation engineeringComplex mathematical operationsBedrockWeight coefficient

The invention relates to the technical field of calculation of seepage inflow amount around hanging water-intercepting curtain, a method for calculating the amount of seepage flow around the hanging water cut-off curtain includes such steps as determining hw value, hd value and he value, wherein hw is the distance from the groundwater level line to the foundation pit bottom, hd is the length of the wat cut-off curtain bottom embedded in the foundation pit bottom, and he is the distance from the water cut-off curtain bottom to the top surface of bedrock; 2) obtaining the maximum hydraulic gradient value imax and the minimum hydraulic gradient value immin according to the influence radius R of the groundwater level descent and the equivalent radius ro of the foundation pit, and combining with the equivalent values of hw, hd and he; 3) according to the weight coefficient xi of the maximum hydraulic gradient and the weight coefficient 1 of the minimum hydraulic gradient; The average hydraulic gradient (img file = 'DDA000181065539000011. TIF' wi= '66' he= '74' / ) 4) is obtained according to the seepage area A at the foundation pit bottom and the equivalent permeability coefficient keq, the water inflow quantity Q around the bottom of the water interception curtain into the foundation pit is obtained. The imax value and the imin value are corrected by the coefficient xi. The average hydraulic gradient (img file = 'DDA0001810655390000012. TIF' wi= '59' he= '73' / ) is obtained by weighted averaging, which is simple in principle, convenient in use and high in precision.

Owner:SHENZHEN GONGKAN GEOTECHN GRP

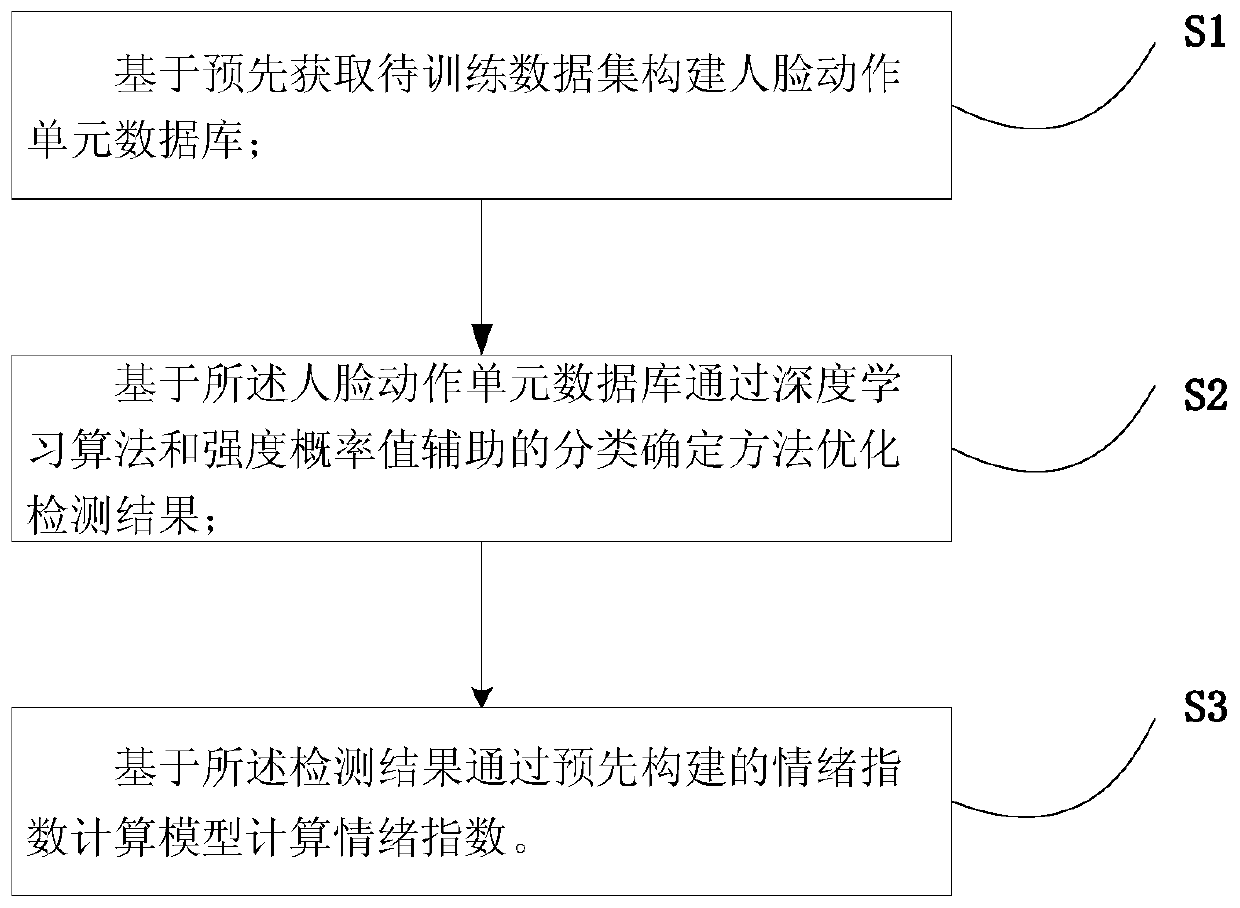

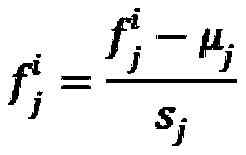

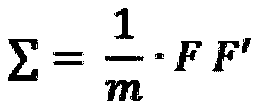

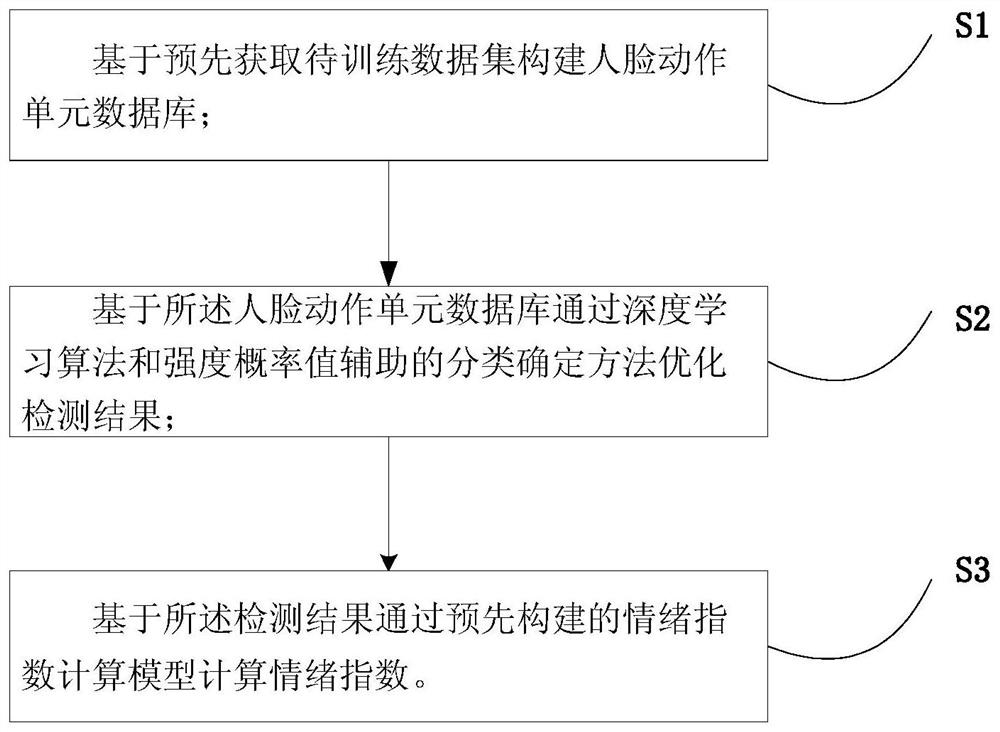

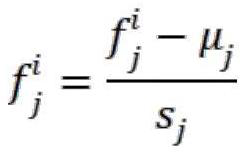

Emotion index calculation method based on face action unit detection

InactiveCN110147822AAccurate and objective communicationThe calculation principle is simpleCharacter and pattern recognitionPattern recognitionData set

The invention belongs to the technical field of face recognition and emotion calculation, and particularly relates to an emotion index calculation method based on face action unit detection. The emotion index calculation method comprises the following specific steps: establishing a to-be-trained data set to form a face action unit database; detecting the action intensity of the face action unit; and calculating an emotion index. According to the emotion index calculation method, the emotional process expressed through facial expressions is achieved; detail information can be more accurately and objectively transmitted; deep information which cannot be described and transmitted by languages can be made up for; and a very feasible scheme is provided for scene applications where language expression obstacles are caused and language information cannot be normally obtained.

Owner:BEIJING NORMAL UNIVERSITY

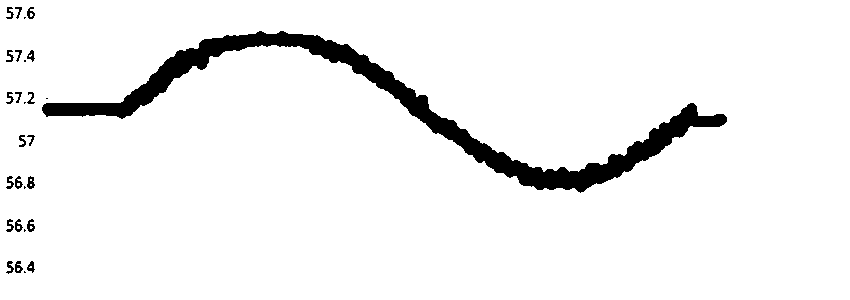

Non-contact extreme value method inner diameter detection method and device

InactiveCN110906876ALow rotational control accuracy requirementsRealize non-destructive testingUsing optical meansEngineeringComputational physics

The invention belongs to the technical field of high-precision non-contact detection. Only qualitative detection can be carried out by adopting contact detection; the surface of the part is possibly scratched during detection; sampling points are few, the detection efficiency and precision are low; by adopting a laser non-contact measurement three-point method, a least square method, normal and cosine laws and other methods, the calculation formula is tedious, the process is complex, the system operation is slow, and the efficiency is low. The invention provides a non-contact extreme value method inner diameter detection method and device. The rotation radius of the sensor is determined after the device is calibrated through a standard part; the sensor mounting rod extends into the inner cavity of the to-be-measured piece for measurement, and the inner diameter of the to-be-measured piece is calculated according to measured data and the rotation radius of the sensor. According to the method, nondestructive measurement is achieved, the detection precision is high, calculation is simple and efficient, large-batch offline or online detection can be met, and the requirement for the rotation control precision of the sensor is low.

Owner:SHANXI DIMAI WOKE PHOTOELECTRIC IND CO LTD

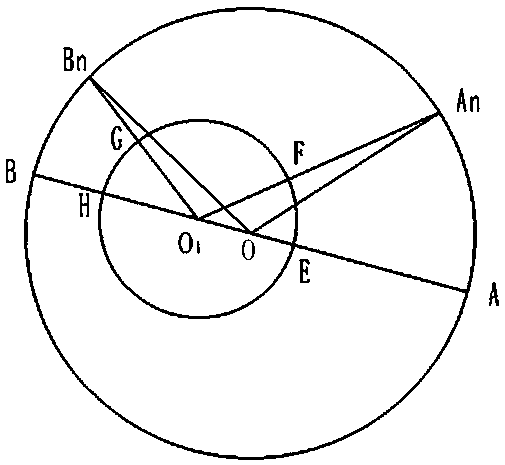

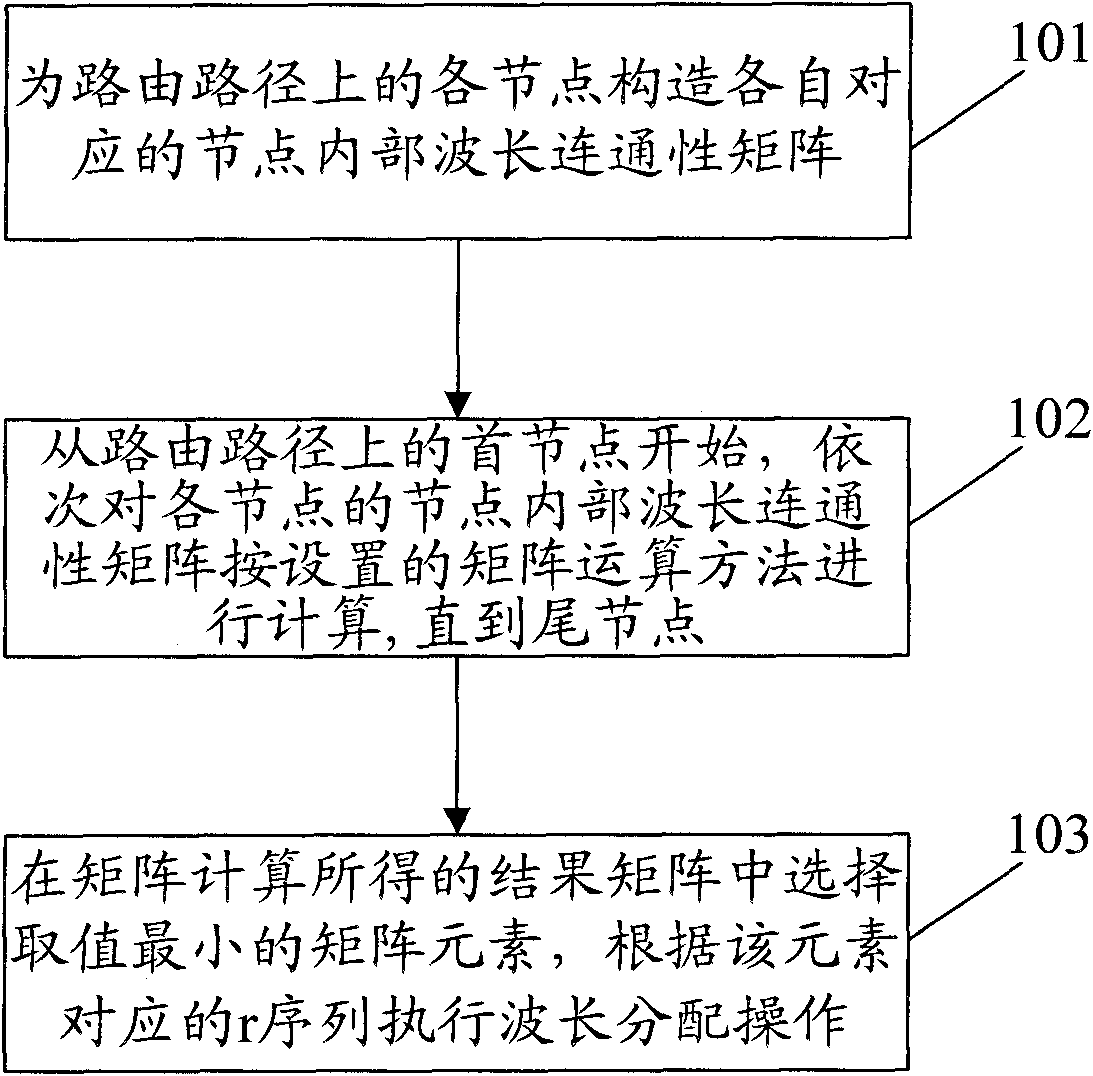

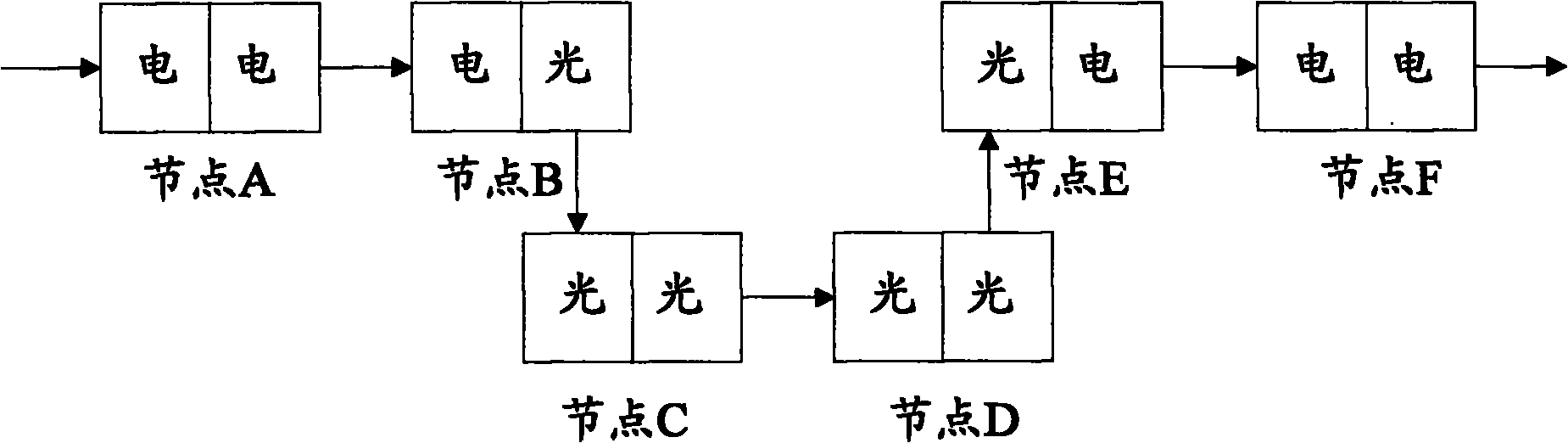

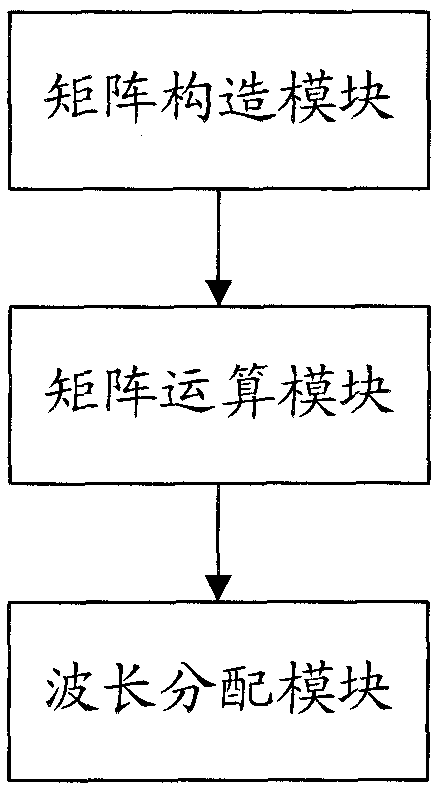

Calculation method and device for wavelength allocation

ActiveCN101834690AThe calculation principle is simpleEasy to implementWavelength-division multiplex systemsDistributed computingCalculation methods

The invention discloses a calculation method for wavelength allocation, which comprises the steps of: constructing internal node wavelength connectivity matrixes corresponding to nodes for the nodes on a route path; and calculating the internal node wavelength connectivity matrix of each node by a set matrix operation method from the initial node on the route path till the tail node on the route path. The invention also discloses a calculation device for wavelength allocation. The method and the device can be used to shorten the time on the calculation of wavelength allocation.

Owner:ZTE CORP

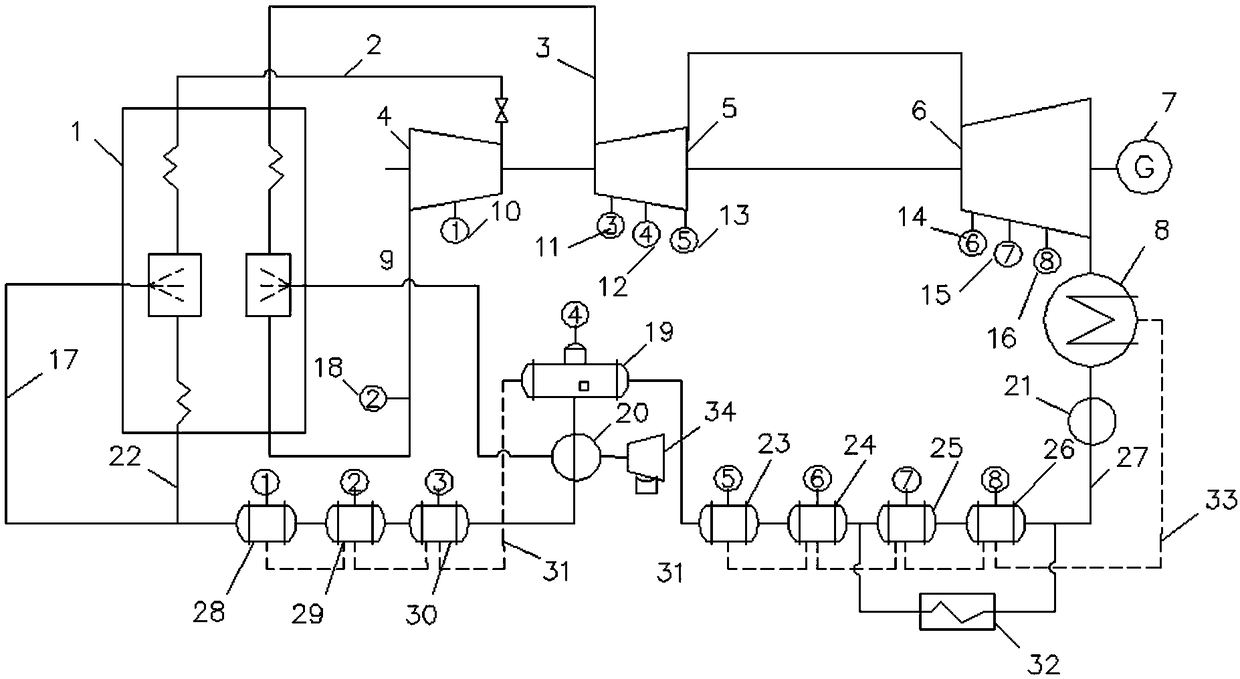

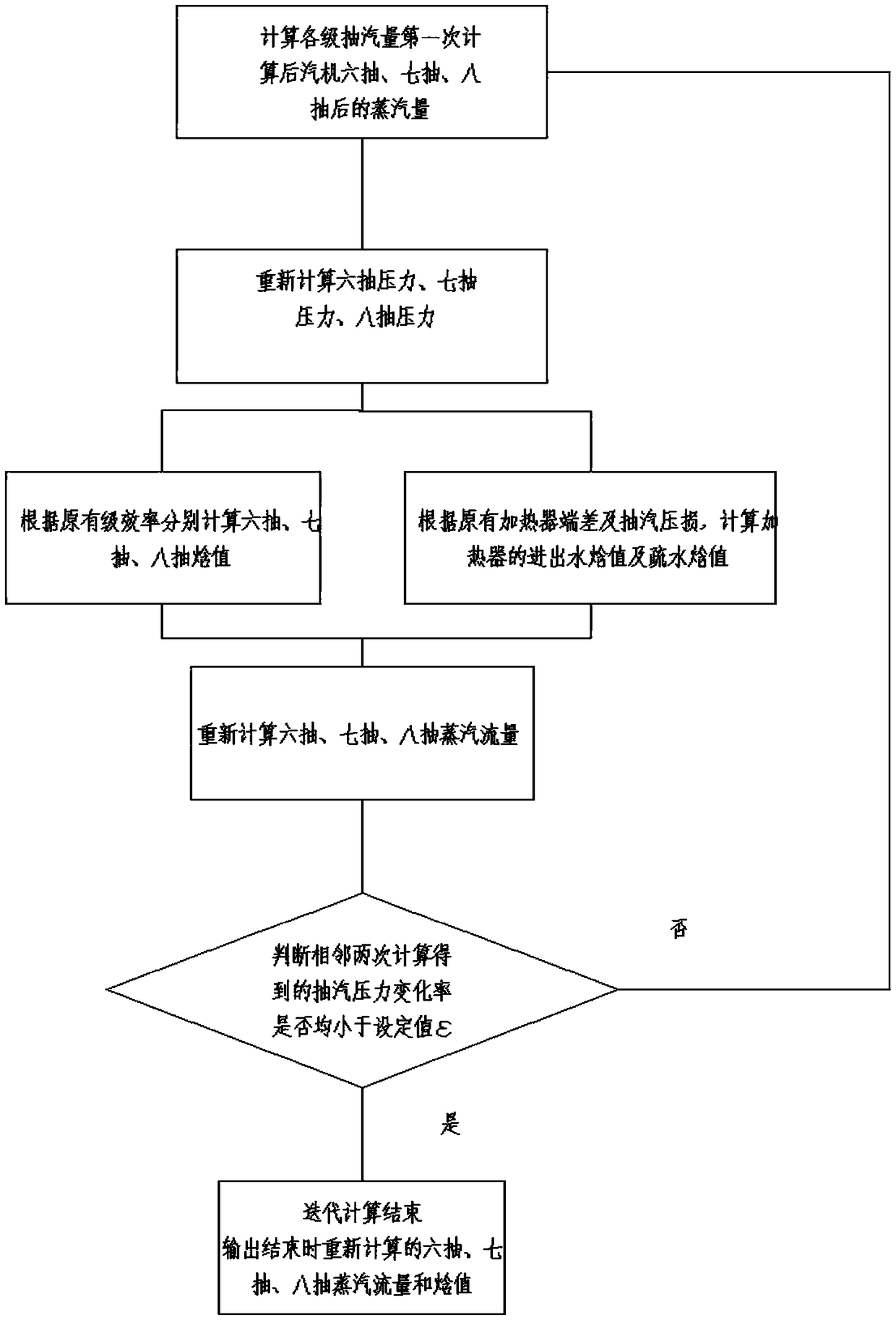

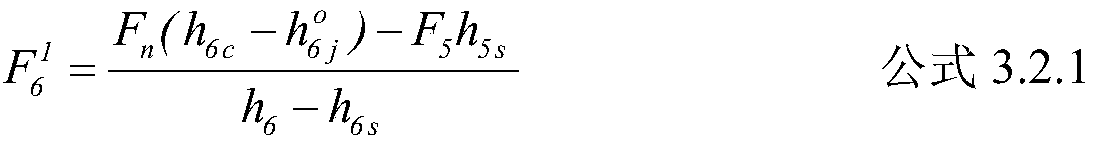

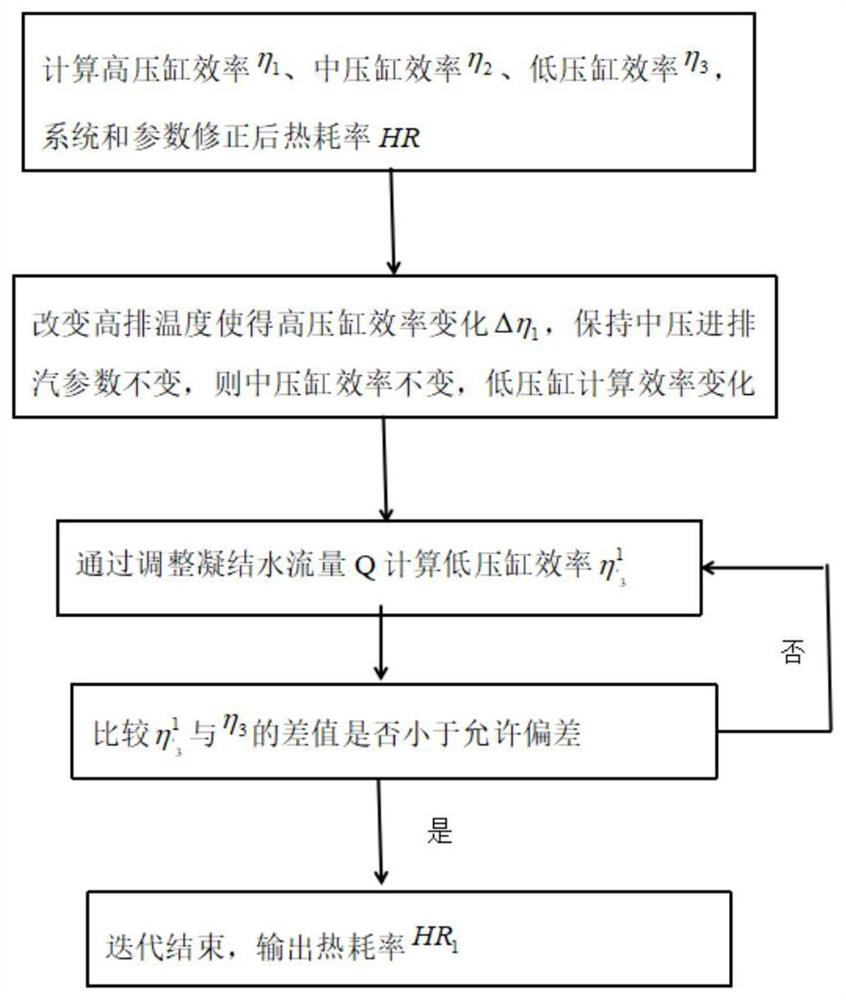

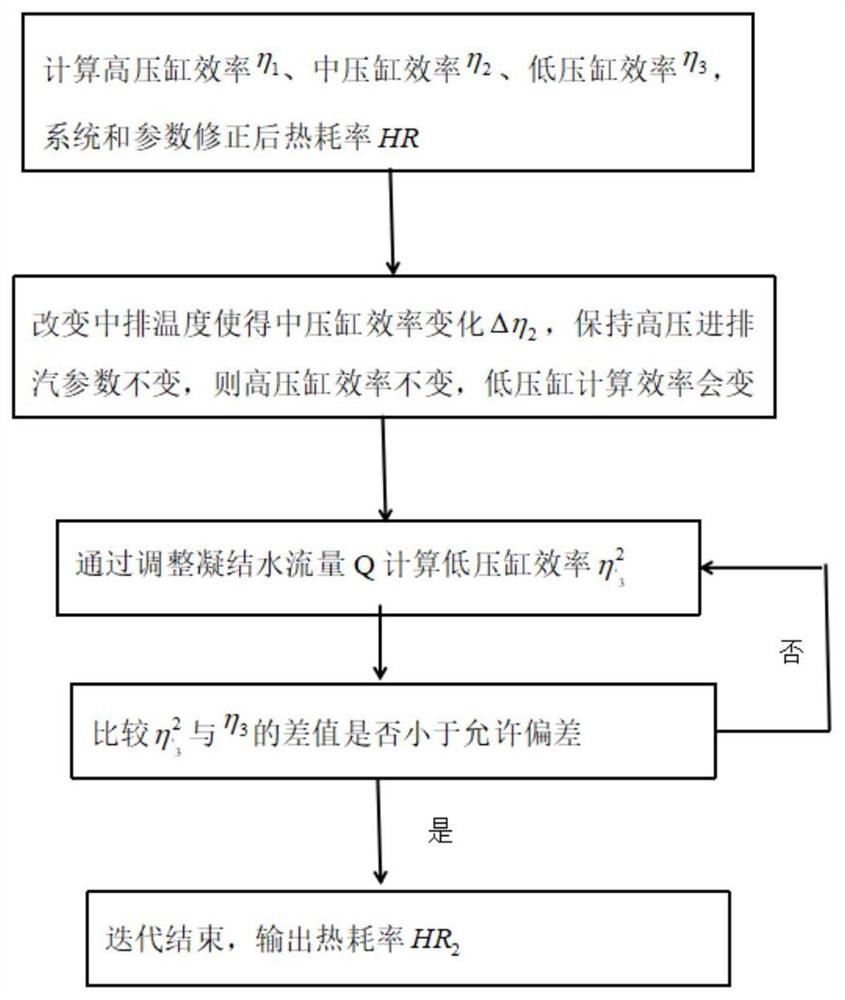

A method for calculating the influence of a low-temperature economizer on the heat consumption rate of a steam turbine unit

ActiveCN109447483AThe calculation principle is simpleEasy to understandResourcesEnergy balancingOff design

The invention provides a method for calculating the influence of a low-temperature economizer on the heat consumption rate of a steam turbine unit, which comprises the following specific steps of 1) collecting original data; 2) putting the first calculation of the steam extraction amount of each stage after the low-temperature economizer into operation; 3) iteratively calculating that steam extraction amount of each stage to convergence; 4) calculating a new generator power according to the energy balance; 5) calculating that heat consumption rate reduction value of the unit after the low-temperature economize is put into use. The calculation principle of the invention is simple and easy to understand, and has strong practical value; the invention fully considers the operation characteristic of the steam turbine under the off-design condition, and the calculation method for calculating the influence quantity of the low-temperature economizer on the heat consumption rate of the steam turbine unit can more accurately calculate the energy-saving quantity.

Owner:GUODIAN SCI & TECH RES INST +1

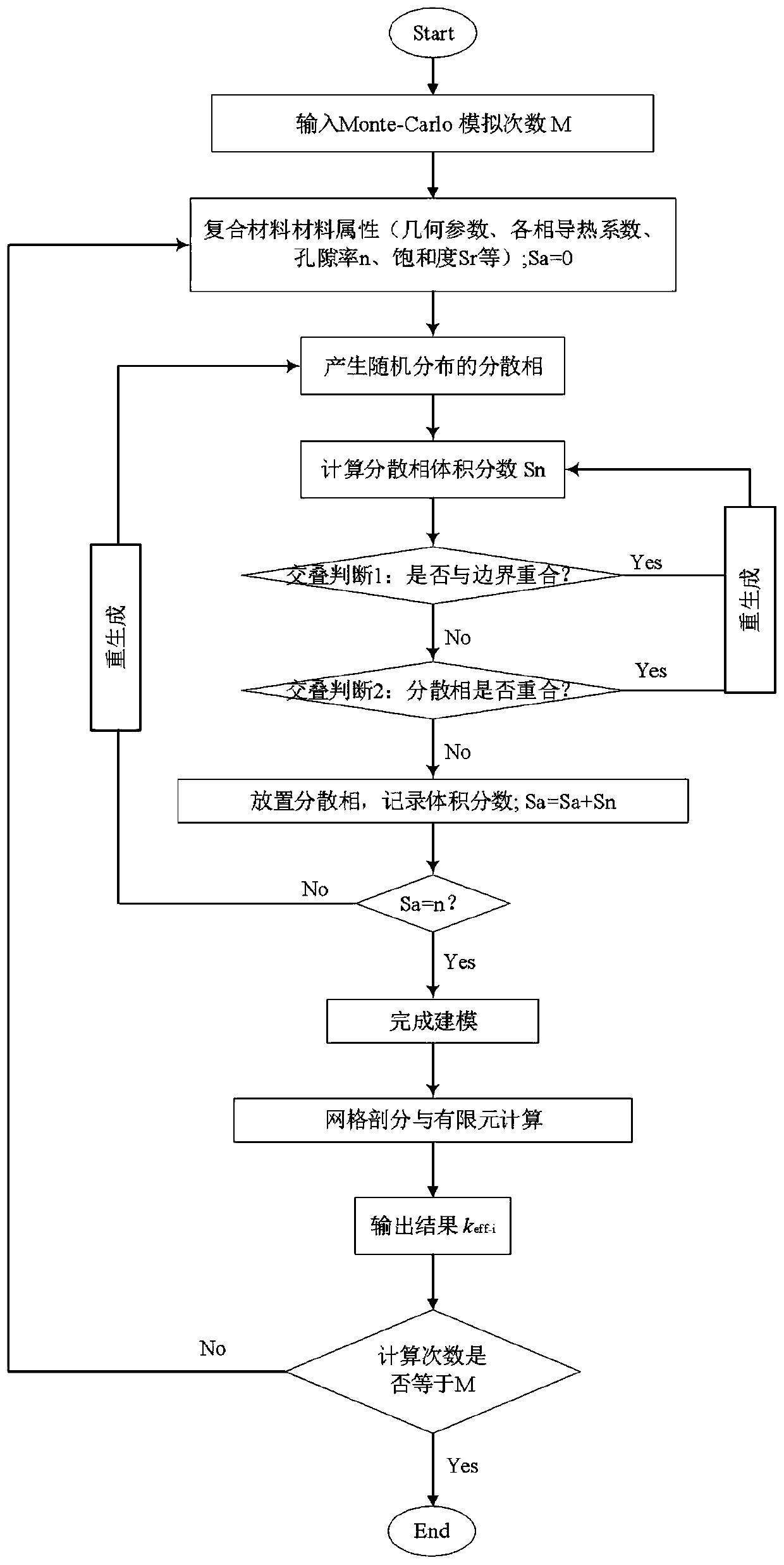

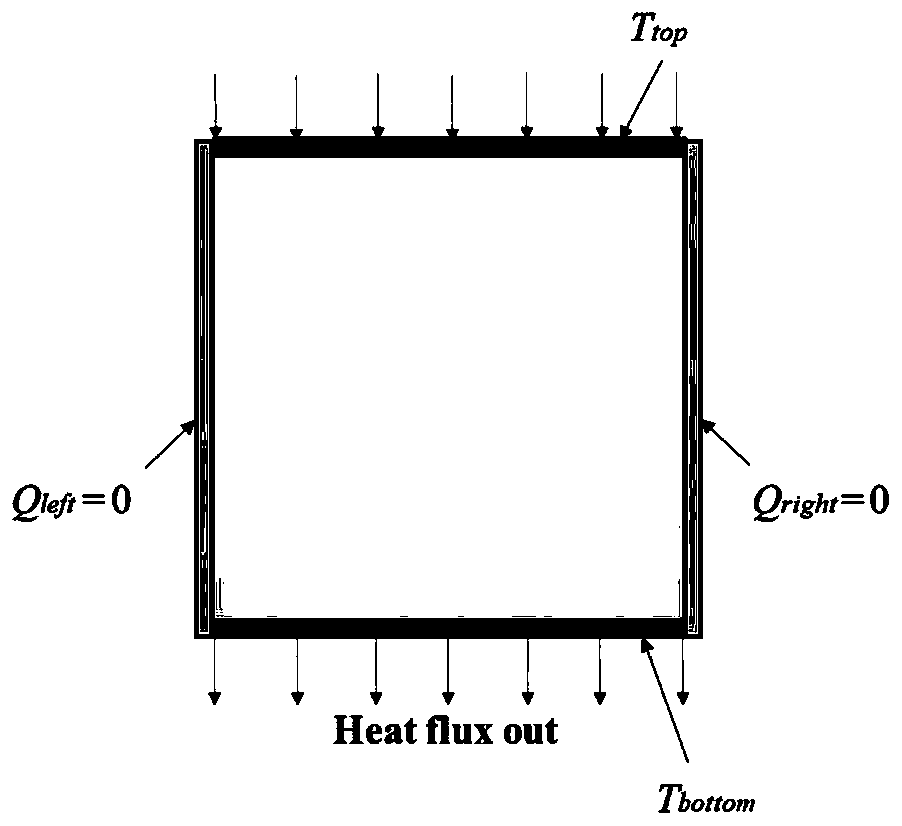

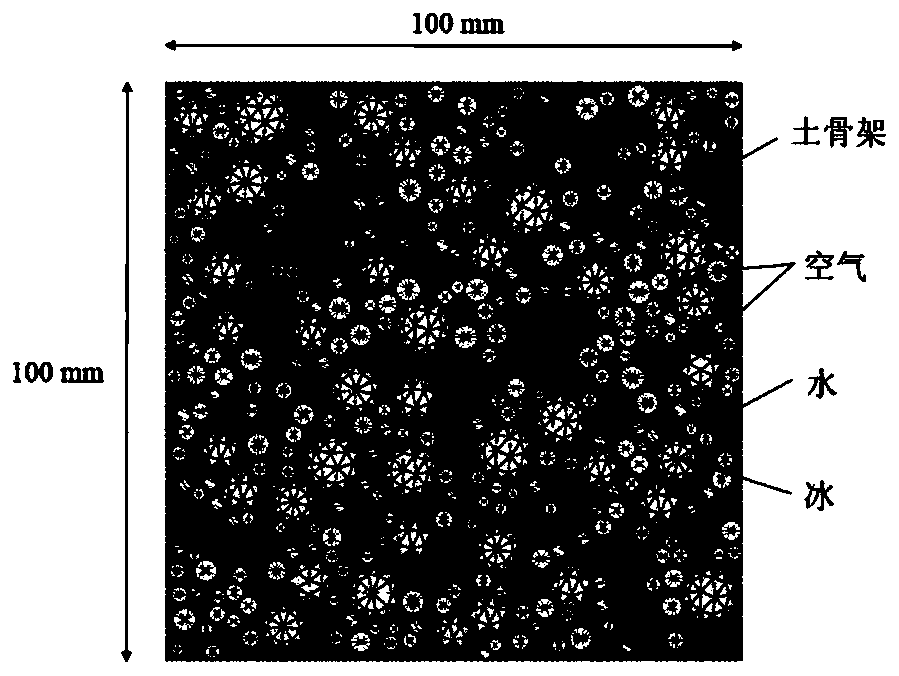

Mesoscopic scale research method for equivalent heat conductivity coefficient of multiphase composite material

ActiveCN111027236AAchieve heterogeneityThe calculation principle is simpleMaterial heat developmentDesign optimisation/simulationNumerical modelsSoil science

The invention relates to a mesoscopic scale research method of an equivalent heat conductivity coefficient of a multiphase composite material. Aiming at the heterogeneous characteristic of the composite material and aiming at the most common material-soil body in geotechnical engineering from the microcosmic scale perspective, a numerical model is established based on a finite element method so asto estimate the equivalent heat conductivity coefficient of the composite material. The established numerical model performs simulation through a Monte Carlo algorithm;to obtain a soil body structurewith spatial randomness, comparative analysis is performed on equivalent heat conductivity coefficients of a soil body under three conditions by combining a finite element calculation method and a Fourier formula based on steady-state analysis, and the influence of factors such as soil body type, porosity, saturation, spatial arrangement of a dispersed phase and the like on the equivalent heat conductivity coefficients of the soil body is explored. Starting from the mesoscopic scale, the invention provides the method capable of simulating the heterogeneity of the internal structure of the multi-phase composite material, a new thought is provided for analyzing the heat conduction characteristic of the multi-phase composite material, and the simulation method is simple, feasible, rapid andconvenient.

Owner:WUHAN UNIV

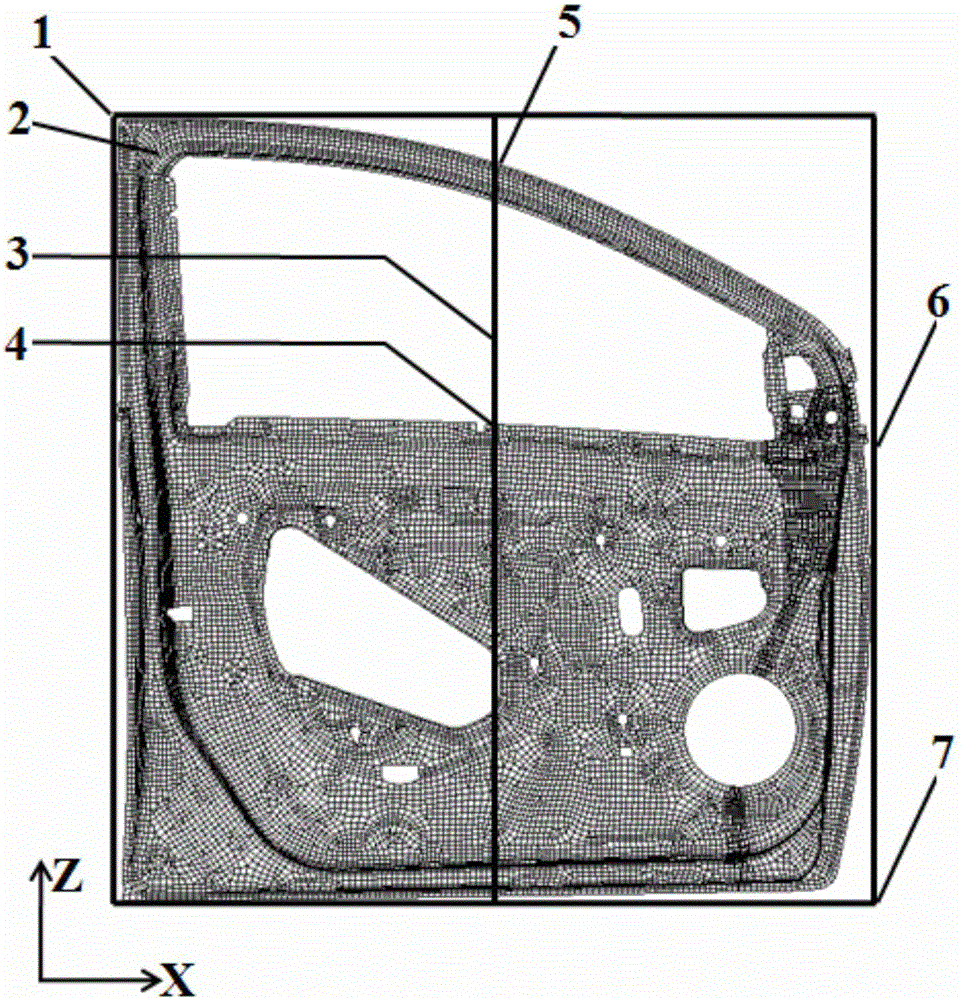

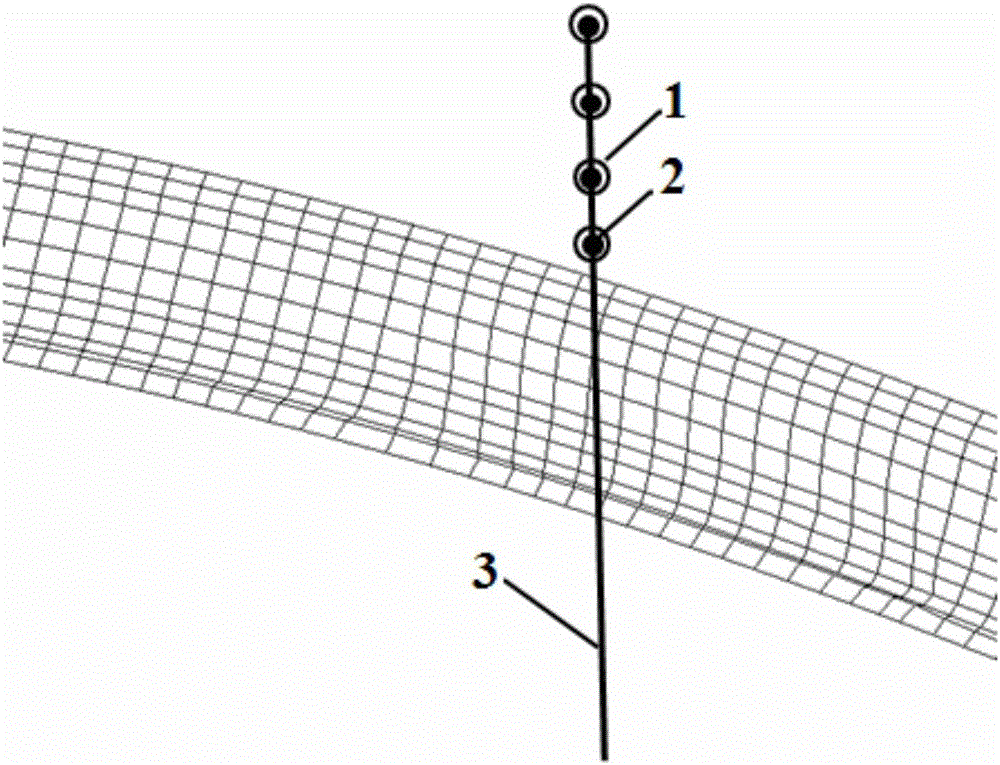

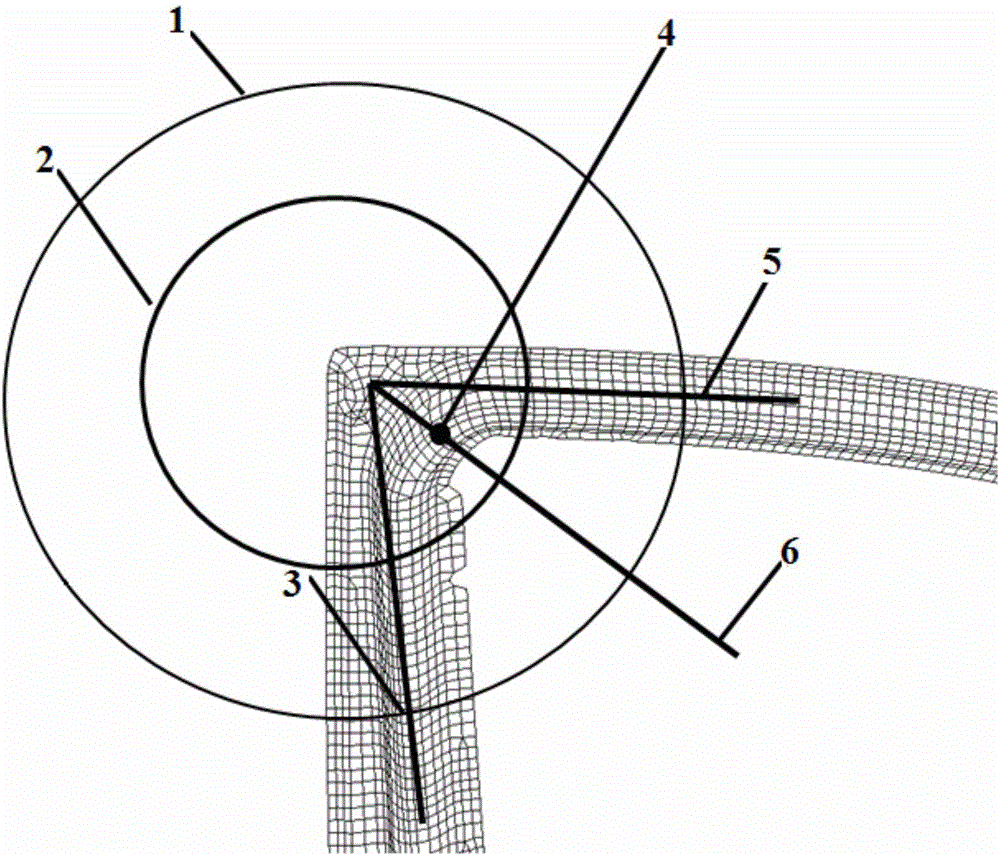

Car side door overall rigidity analysis and loading point locating method

ActiveCN106202621AImprove work efficiencyFully automatedDesign optimisation/simulationSpecial data processing applicationsEngineeringMiddle line

The invention discloses a car side door overall rigidity analysis and loading point locating method. The method comprises the following steps of 1, selecting a basic point; 2, creating a projection surface; 3, creating a central line; 4, determining a window frame middle rigidity loading point; 5, determining a window frame extrusion rigidity loading point; and 6, determining a window frame topmost corner rigidity loading point. With the adoption of the technical scheme, the locating method for a determined side door rigidity loading point can provide a side door finite element according to an analyst, and accurately search for the positions of the window frame middle rigidity, window frame extrusion rigidity and topmost corner rigidity loading points, so that errors caused by manual operation are avoided; and a calculation principle is simple and clear, the feasibility of writing by software is very high, and the calculation principle can be easily embedded into finite element software, so that the automation of an analytic process is realized and the working efficiency of analysts is improved.

Owner:CHERY AUTOMOBILE CO LTD

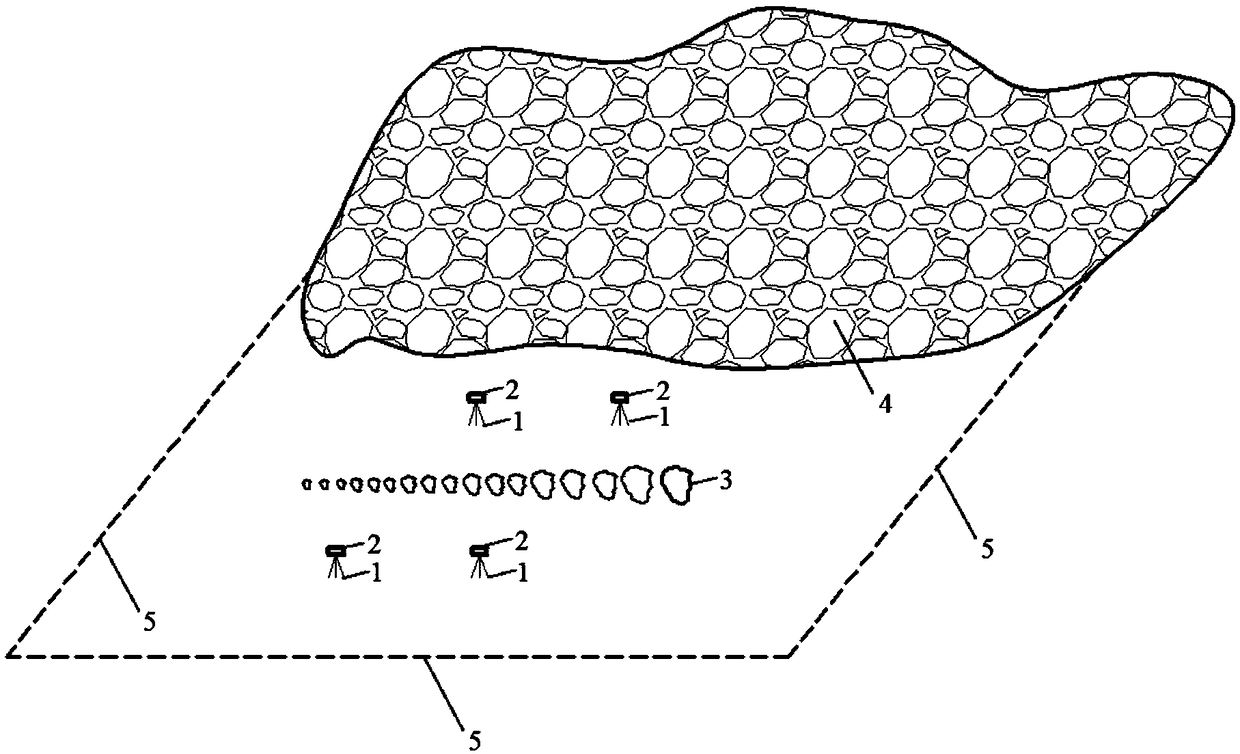

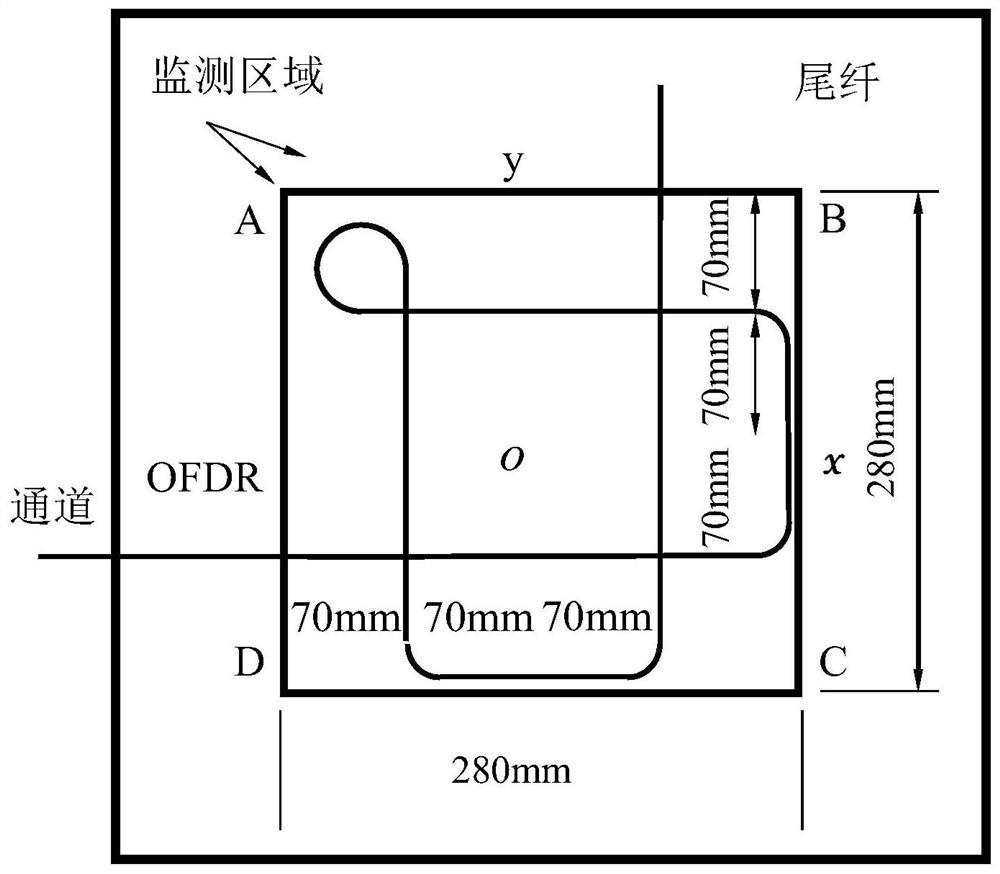

Composite material laminate optical fiber impact position identification method based on strain nonlinear weighting

ActiveCN113049410AEasy to identifyOptimize layoutDesign optimisation/simulationMaterial strength using single impulsive forceStructural health monitoringMechanical engineering

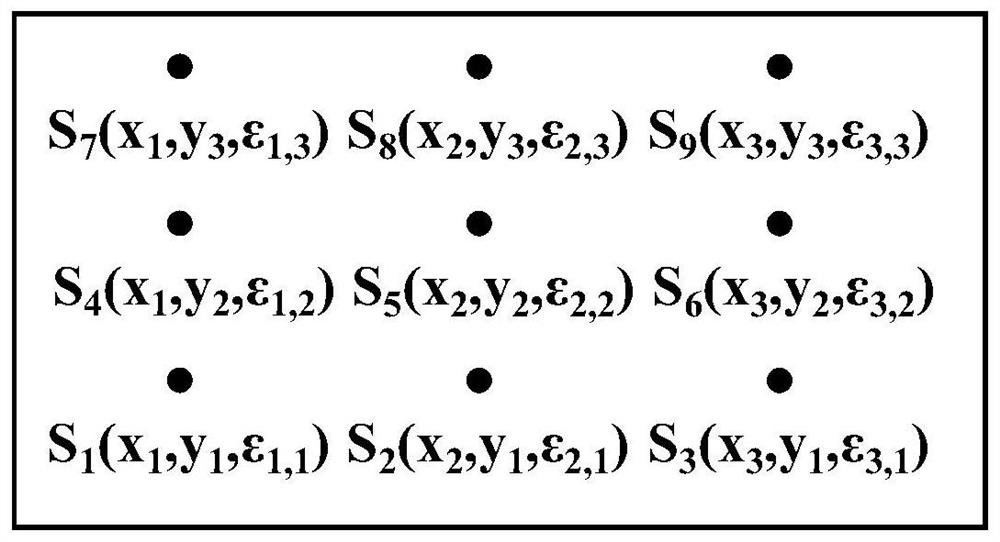

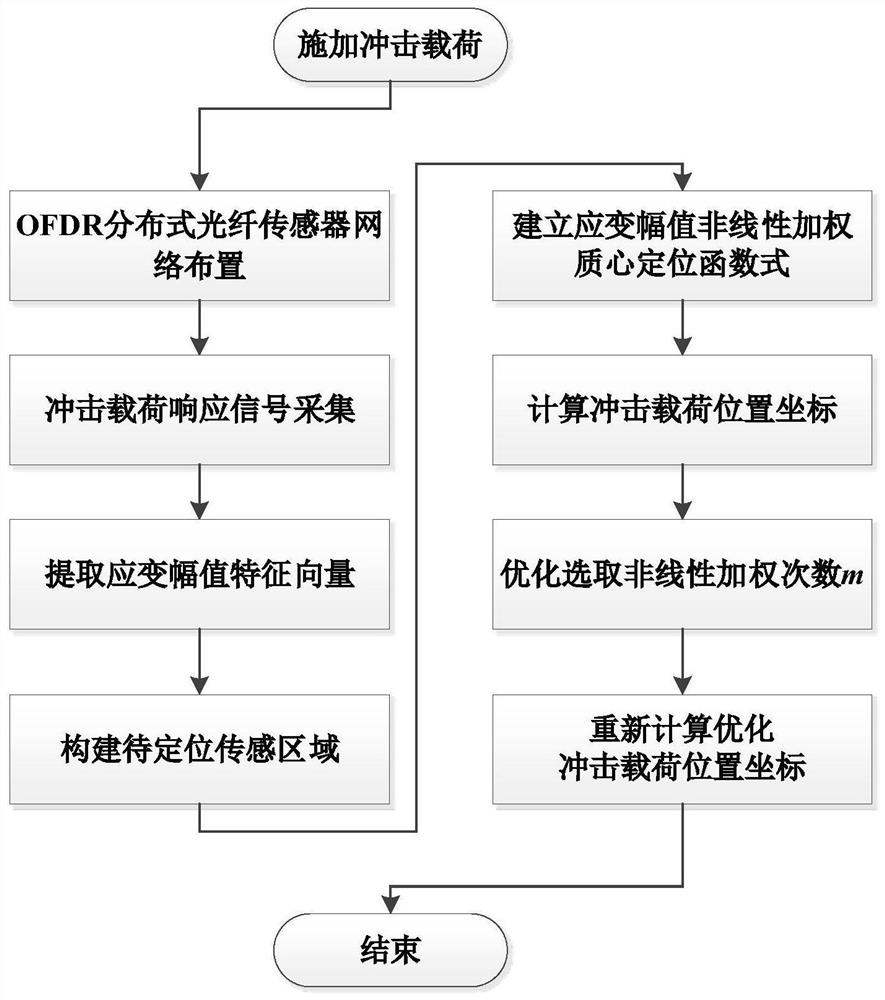

The invention discloses a composite material laminate optical fiber impact position identification method based on strain nonlinear weighting, and belongs to the technical field of structural health monitoring. The method comprises the following steps of 1, arranging an OFDR distributed optical fiber sensor network; 2, acquiring an impact load response signal of an OFDR distributed optical fiber sensor; 3, according to a stress concentration phenomenon at the impact load acting point of a composite material plate structure, extracting a strain amplitude feature vector; 4, constructing a to-be-positioned sensing area through the strain amplitude feature vector; 5, establishing a strain amplitude nonlinear weighted centroid positioning functional expression, and solving to obtain an impact load positioning coordinate; and 6, optimizing and selecting nonlinear weighting times m by taking the minimum target function value of the positioning error of the sample impact point as a criterion, and recalculating the prediction coordinate of the impact point. The method is simple, convenient and high in practicability.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

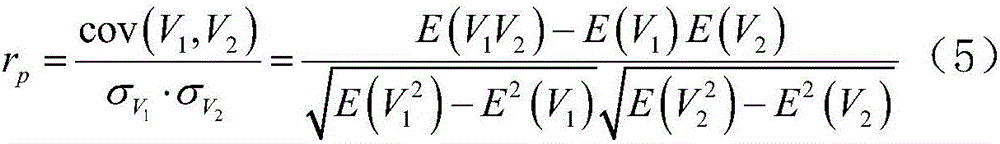

Alloy grade identification method based on pearson correlation coefficient

ActiveCN106250527AThe calculation principle is simpleDifficult to judge the differenceCharacter and pattern recognitionOther databases queryingCorrelation coefficientSpearman's rank correlation coefficient

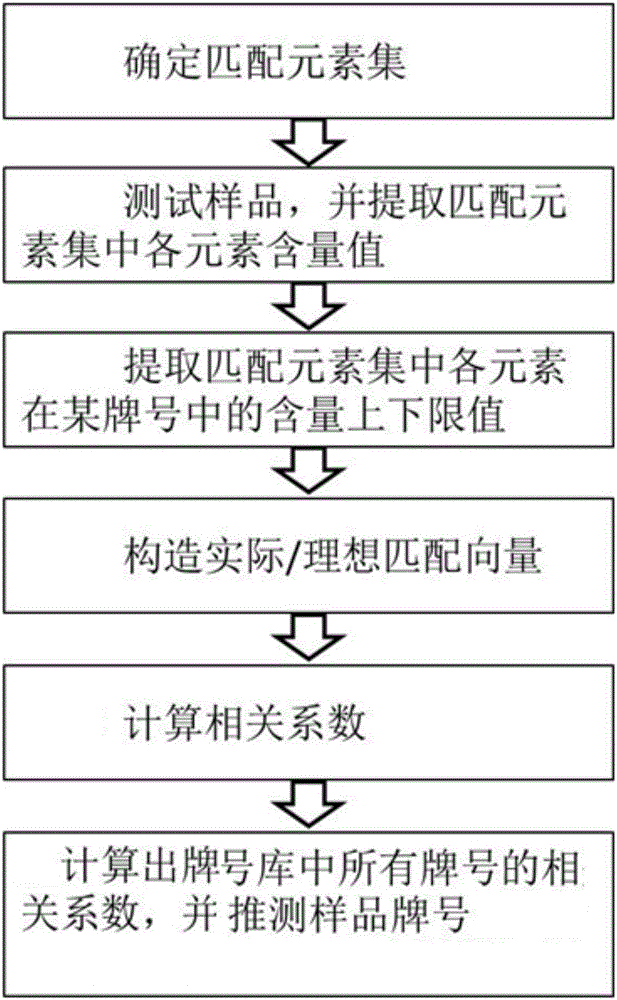

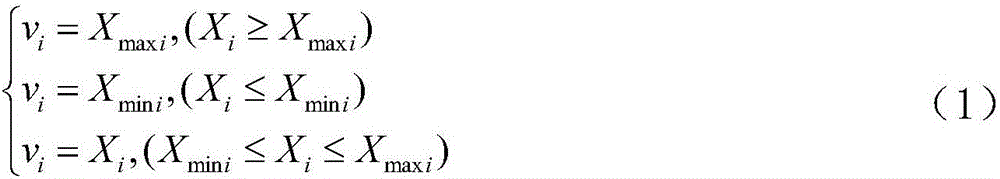

The invention discloses an alloy grade identification method based on a pearson correlation coefficient. The method comprises the steps of (1), determining a matching element set; (2), testing element content information of a to-be-identified sample through a spectrograph and extracting each element content value Xi in the matching element set; (3) extracting a content upper limit Xmaxi value and a lower limit Xmini value of each element of the matching element set in certain grade; (4), establishing a real matching vector Vreal and an ideal matching vector Videal; (5), calculating the pearson correlation coefficient between the real matching vector Vreal and the ideal matching vector Videal; and (6), repeating the steps (3)-(5), until the pearson correlation coefficients of all grades in a grade library are calculated, wherein the grade with the maximum correlation coefficient is the grade to which the to-be-identified sample belongs. According to the method, an operation process is simple, operation results are normalized data, there is no dimension, values are between -1 to 1, the value 1 indicates that the grade matches the test result completely, under the other condition, the more the value is approximate to 1, the higher the matching degree is, and the more the value is approximate to -1, the lower the matching degree is.

Owner:台州高视通智能科技有限公司

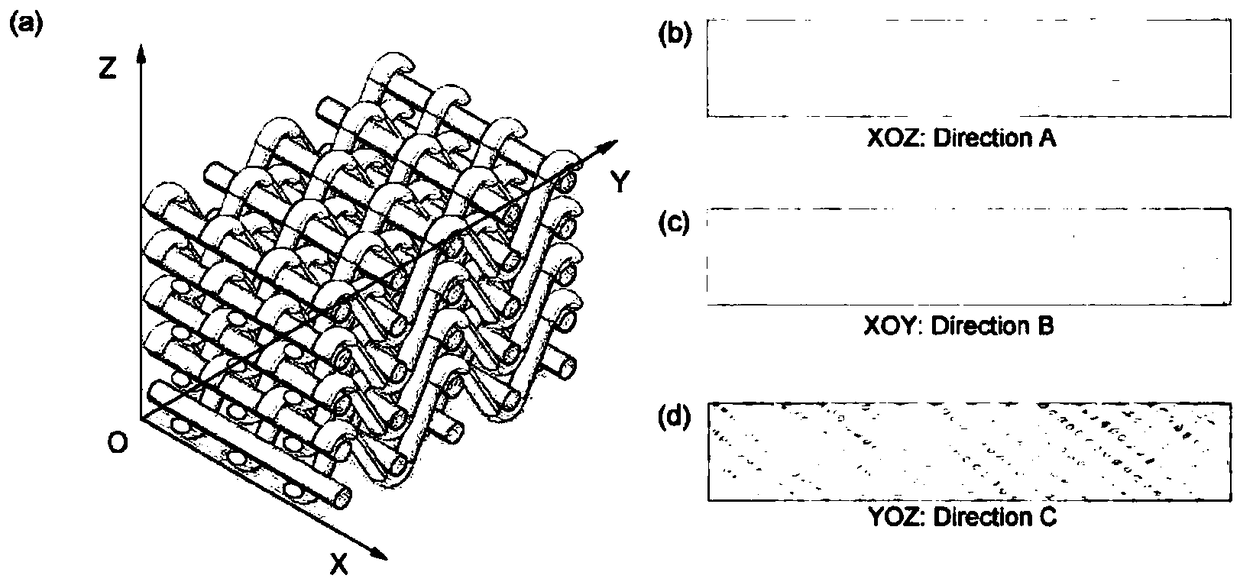

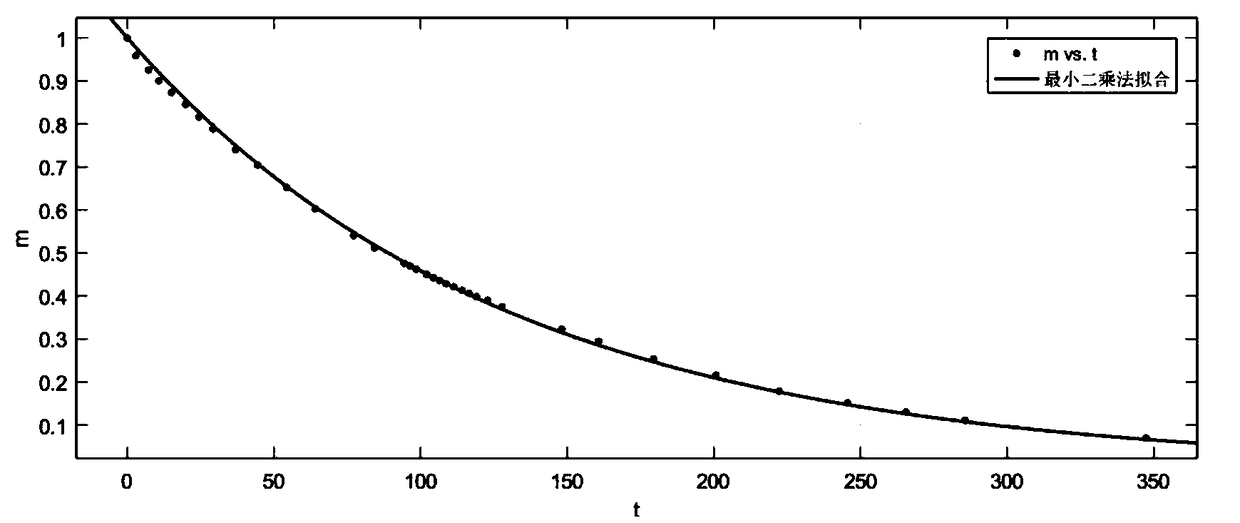

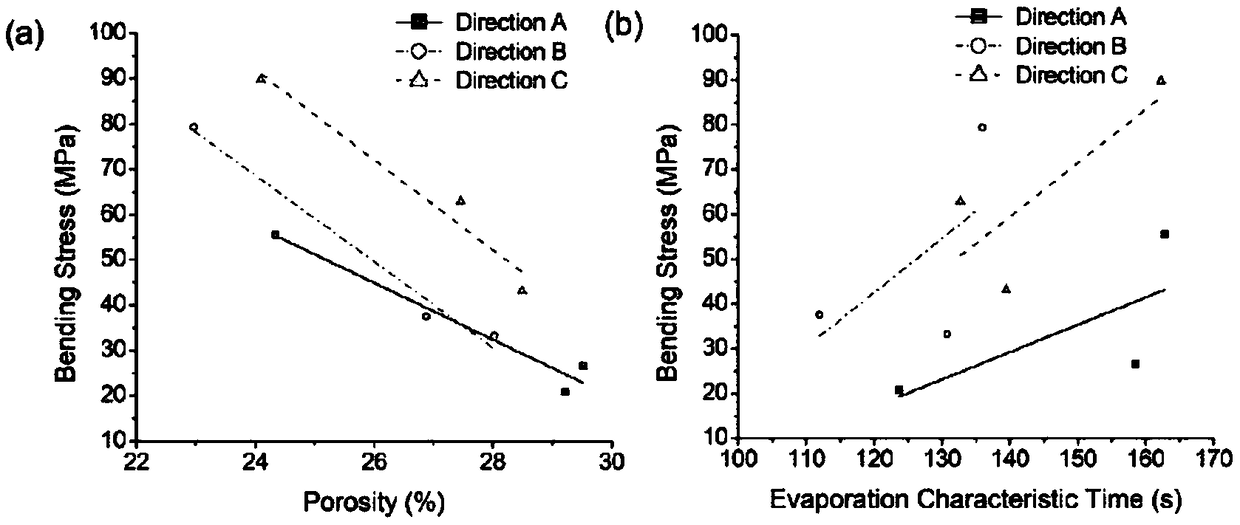

Rapid characterization method for mechanical properties of composite material

ActiveCN109507021ASimplify the measurement stepsReduce measurement errorWeighing by removing componentMaterial strength using tensile/compressive forcesPorosityEvaporation

The invention relates to a rapid characterization method for the mechanical properties of a composite material. The method comprises the steps that a plurality of groups of blocky composite material experimental samples with different internal porosity conditions are prepared; the material porosity Por% measurement experiment is carried out on each group of experimental samples respectively; material evaporation characteristic time (ECT) measurement is carried out on each group of experimental samples respectively; and after the porosity Por% and the evaporation characteristic time (ECT) of each group of experimental samples are measured, the mechanical failure experiment is carried out on a press machine, and the corresponding mechanical strength indexes are obtained through measurement.

Owner:TIANJIN UNIV

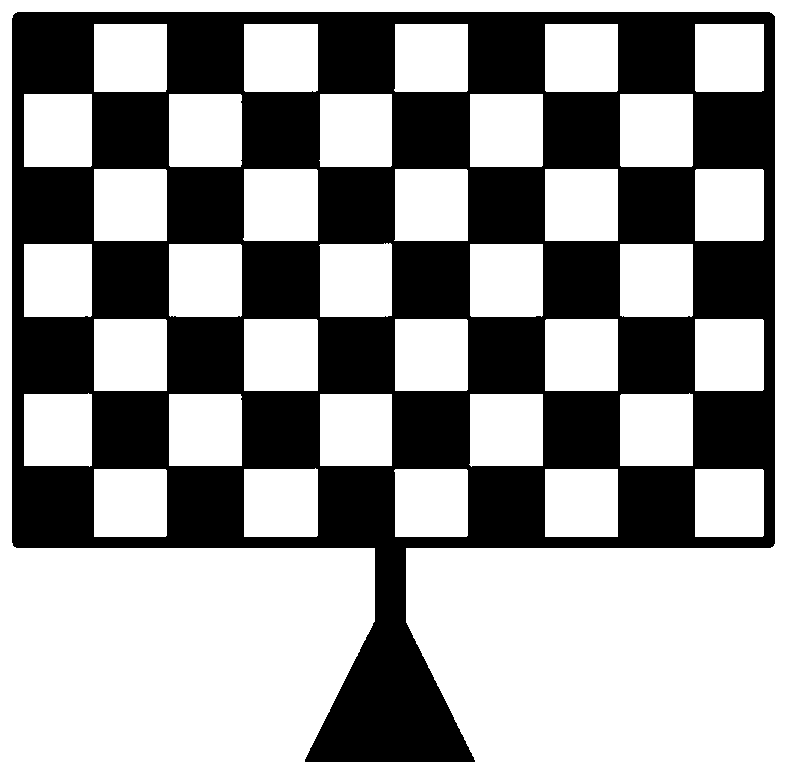

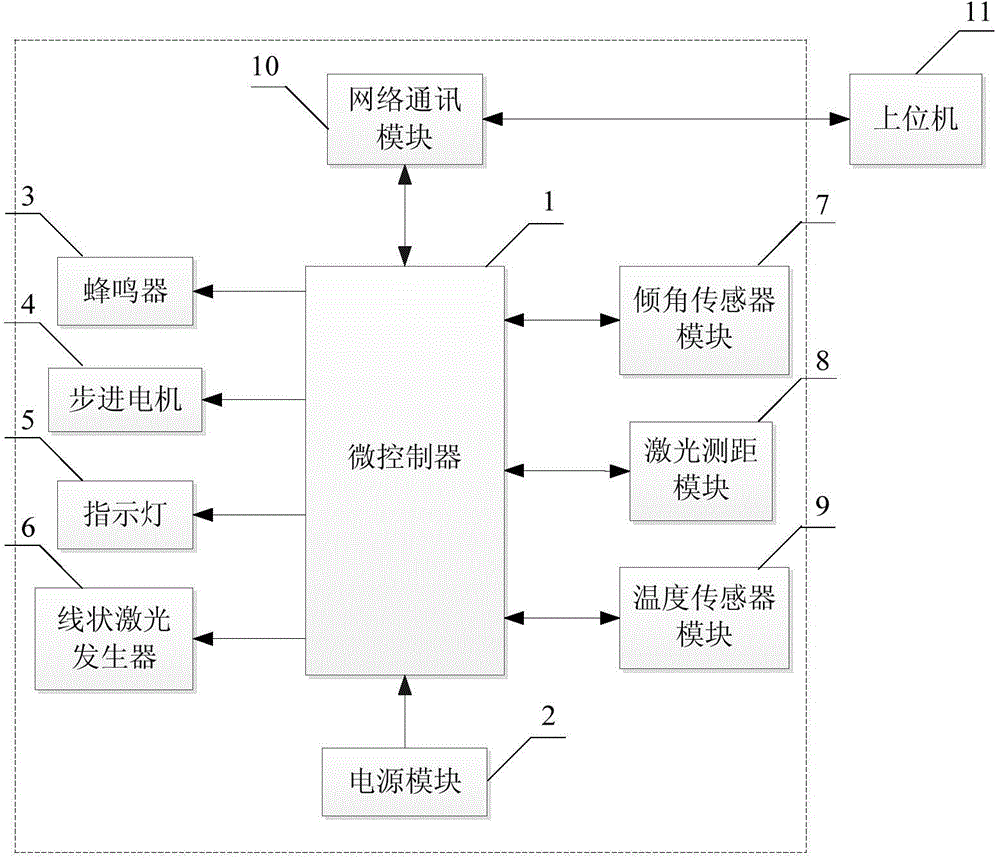

Intelligent layer-burning boiler extinguishing boundary detecting system

ActiveCN104864411AThe calculation principle is simpleSmall amount of calculationChamber safety arrangementThird partyBoundary data

The invention provides an intelligent layer-burning boiler extinguishing boundary detecting system. The system comprises a layer-burning boiler image collection subsystem, an extinguishing boundary calibration subsystem and an image processing subsystem. Firstly, according to the system, through a real-time video system with a set of refrigerating device, dynamic combustion image information of a layer-burning boiler is obtained; then through the extinguishing boundary calibration subsystem, image errors generated by an imaging system are eliminated and the fish eye effect of a wide angle video camera is calibrated; finally, through the view screen image processing subsystem, the accurate layer-burning boiler extinguishing boundary data can be obtained. The system is accurate in final extinguishing boundary data, simple in calibration principle and less in calculated amount, and the final extinguishing boundary data can also be published to the public according to the standard OPC protocol for development and application of a third party.

Owner:XIAMEN OPTIKOM AUTOMATIC CONTROL TECH CO LTD

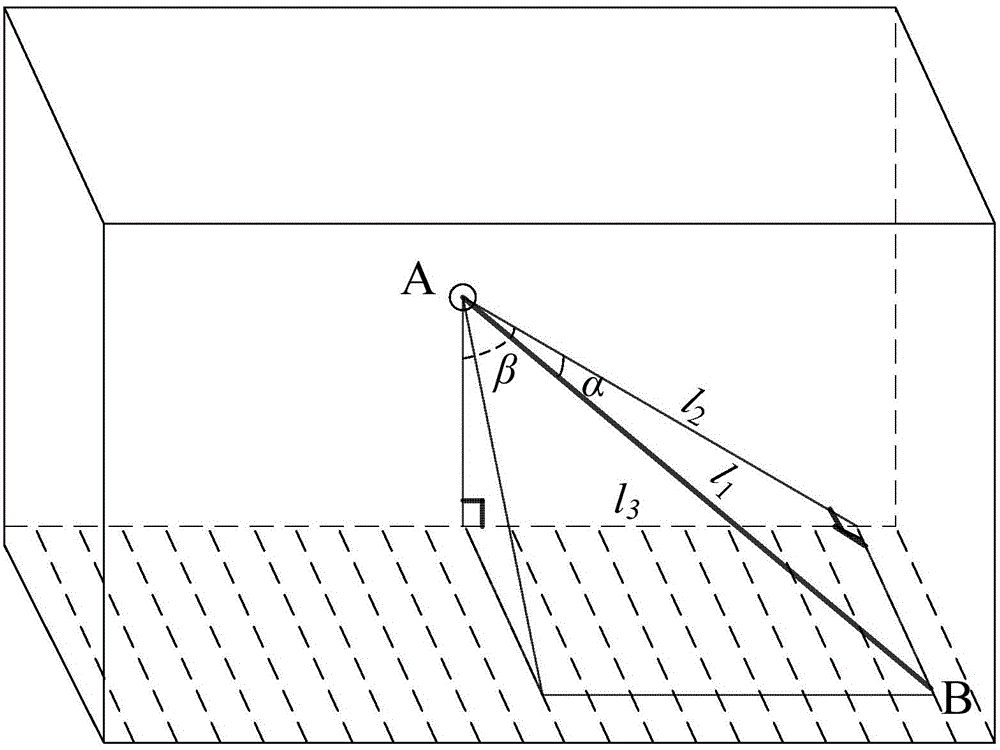

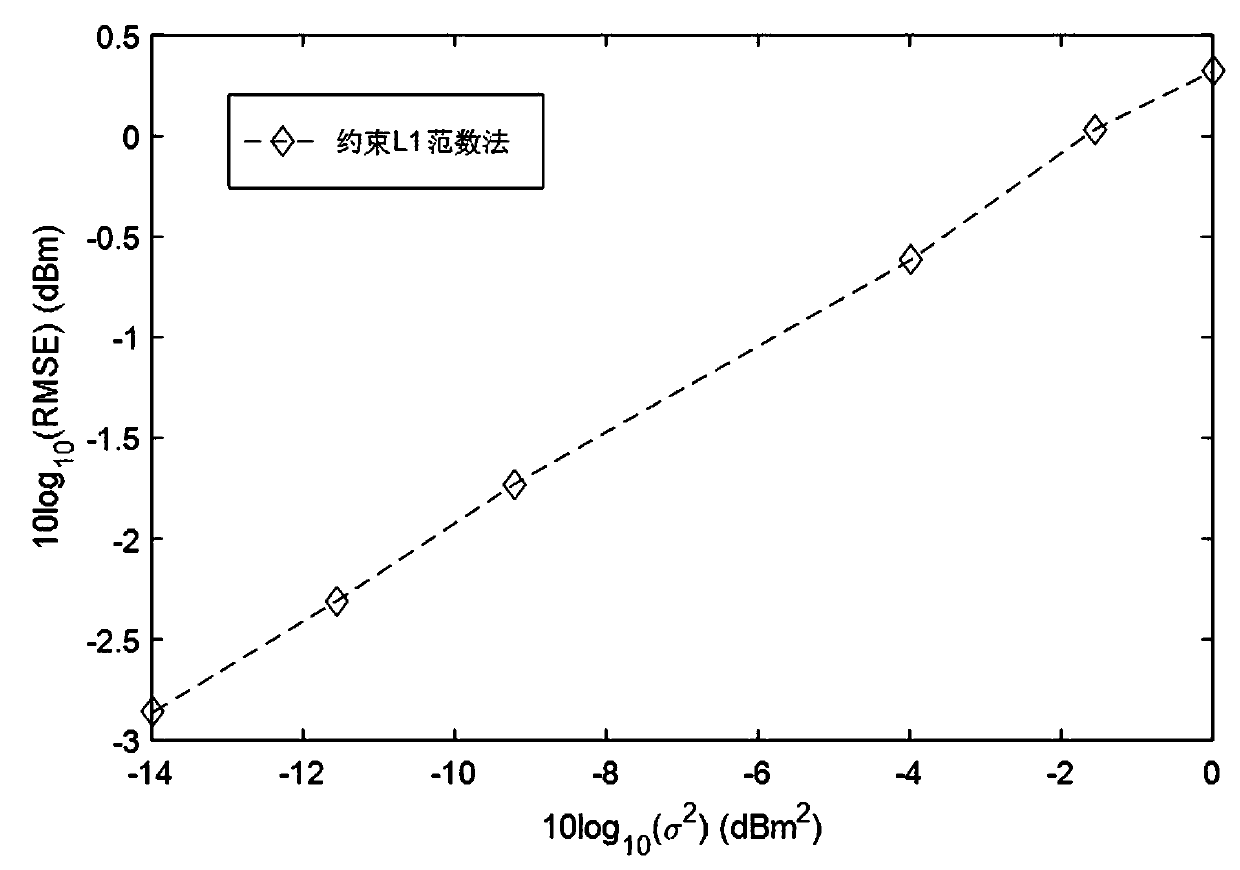

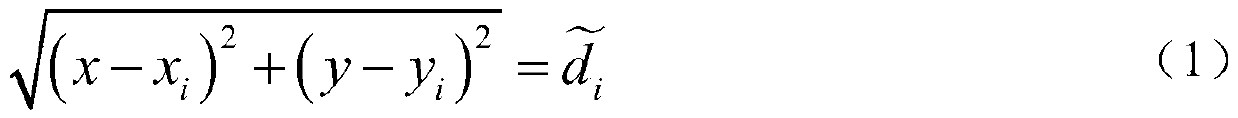

Method for constraining L1 norm under sparse LOS (light of sight)/NLOS (non-light of sight) scene on basis of distance observation value positioning

The invention discloses a method for constraining an L1 norm under a sparse LOS (light of sight) / NLOS (non-light of sight) scene on the basis of distance observation value positioning. According to the method, the known coordinates of each positioning base station and distance observation values received by a receiver are obtained, so that an observation equation can be built; square expansion iscarried out on the observation equation in the previous step, so that the observation equation can be converted into a standard least square form; the least square form is solved with an L1 norm criterion, and an equation constraint condition existing between unknown variables in the least square form is added into the L1 norm criterion, so that an additional equation constrained L1 norm can be constructed; and a CVX toolbox of Matlab software is adopted for performing solving, so that a high-precision positioning solution is obtained. The method is used for a distance observation-based positioning system and is suitable for sparse LOS / NLOS scenes. The method has the advantages of simple principle, easiness in implementation and high positioning precision, and can promote the development of industrial application and commercial positioning systems to a certain extent.

Owner:INST OF GEODESY & GEOPHYSICS CHINESE ACADEMY OF SCI

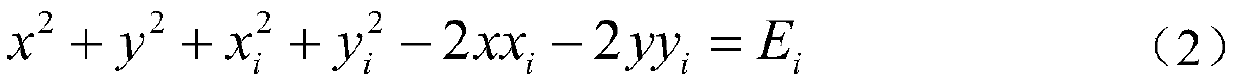

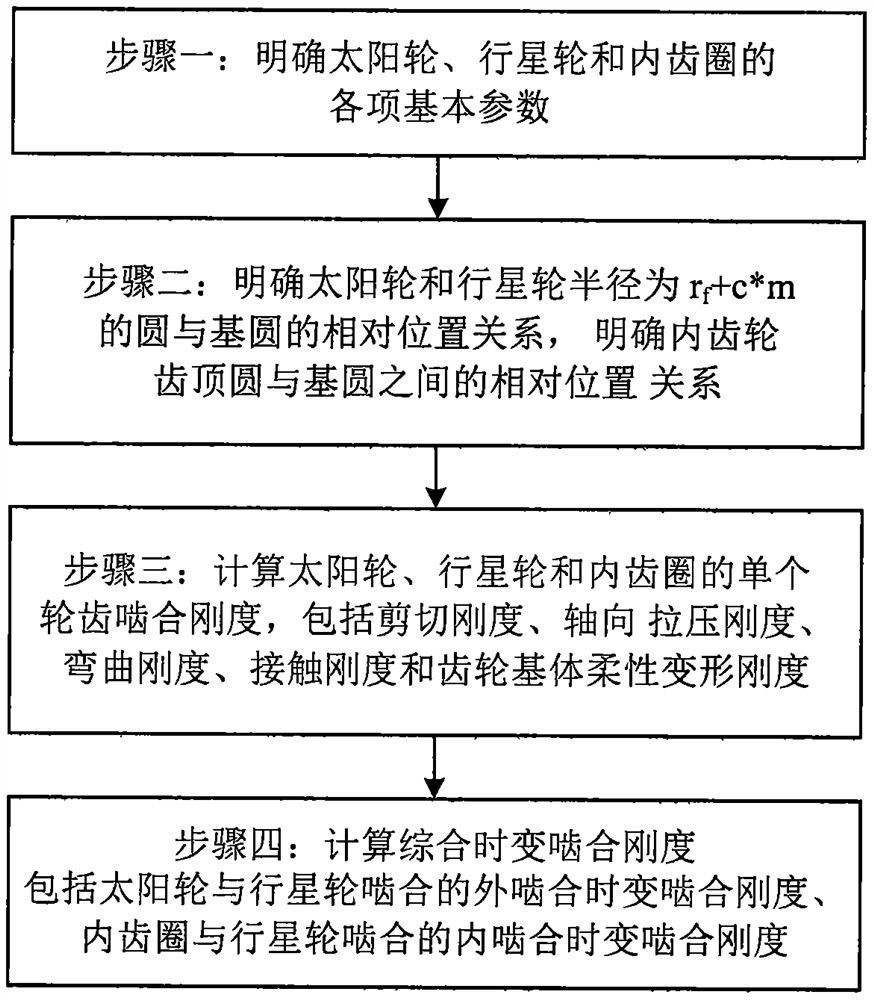

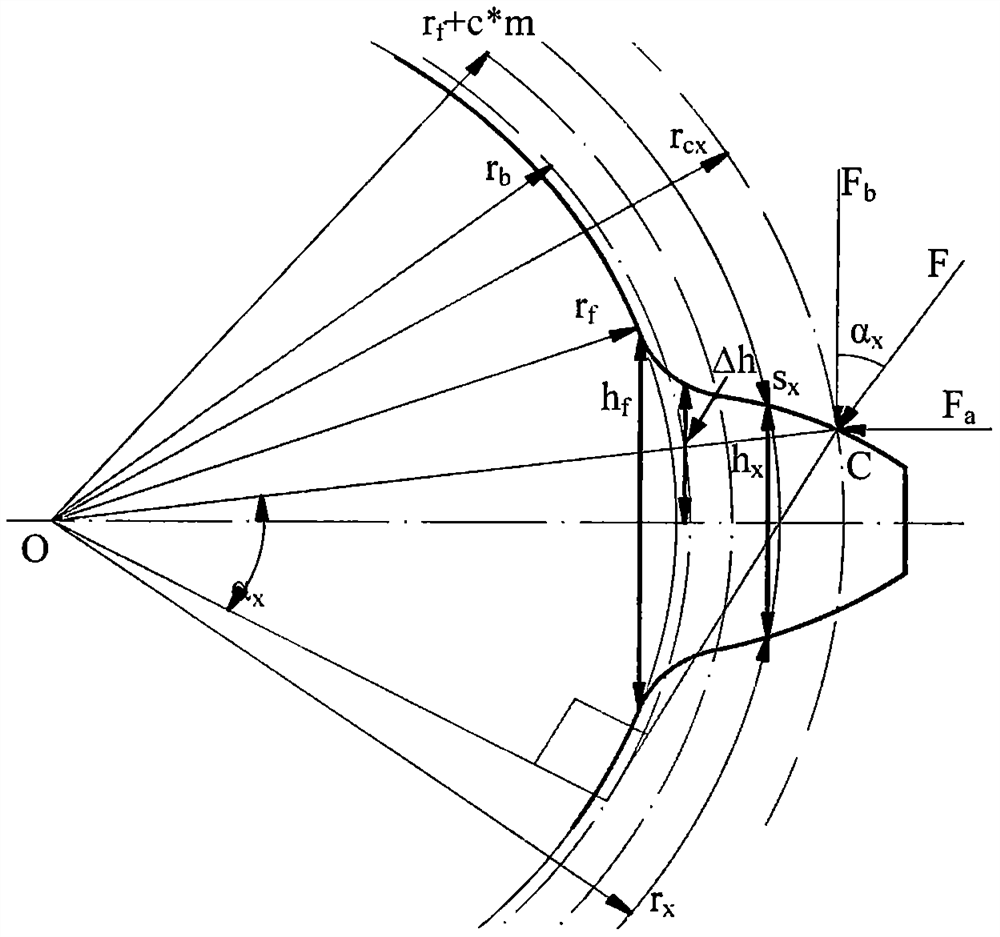

Planetary gear time-varying meshing stiffness calculation method based on tooth profile correction method

ActiveCN111625758AAccurate divisionImprove accuracyGearing detailsComplex mathematical operationsGear wheelShear stiffness

The invention discloses a planetary gear time-varying meshing stiffness calculation method based on a tooth profile correction method and belongs to the technical field of mechanical dynamics, the influence of the tooth form on the comprehensive meshing stiffness calculation is fully considered; the calculation accuracy of the planetary gear time-varying meshing stiffness is improved; the method comprises the following specific steps: firstly, defining various basic parameters of a sun gear, a planet gear and an inner gear ring; then, defining the relative position relationship between a circle with the radius of rf + c * m of the sun wheel and the planet wheel and the base circle; determining the relative position relationship between the addendum circle and the base circle of the inner gear ring; calculating the meshing stiffness of single gear teeth of the sun gear, the planet gear and the inner gear ring; wherein the rigidity comprises shearing rigidity, axial tension and compression rigidity, bending rigidity, contact rigidity and gear base body flexible deformation rigidity; finally, calculating the comprehensive time-varying meshing stiffness , wherein the stiffness comprises the outer meshing time-varying meshing stiffness of meshing of the sun gear and the planet gear and the inner meshing time-varying meshing stiffness of meshing of the inner gear ring and the planetgear, and the invention has the advantages of being simple in principle, easy to calculate and high in practicability.

Owner:TIANJIN POLYTECHNIC UNIV

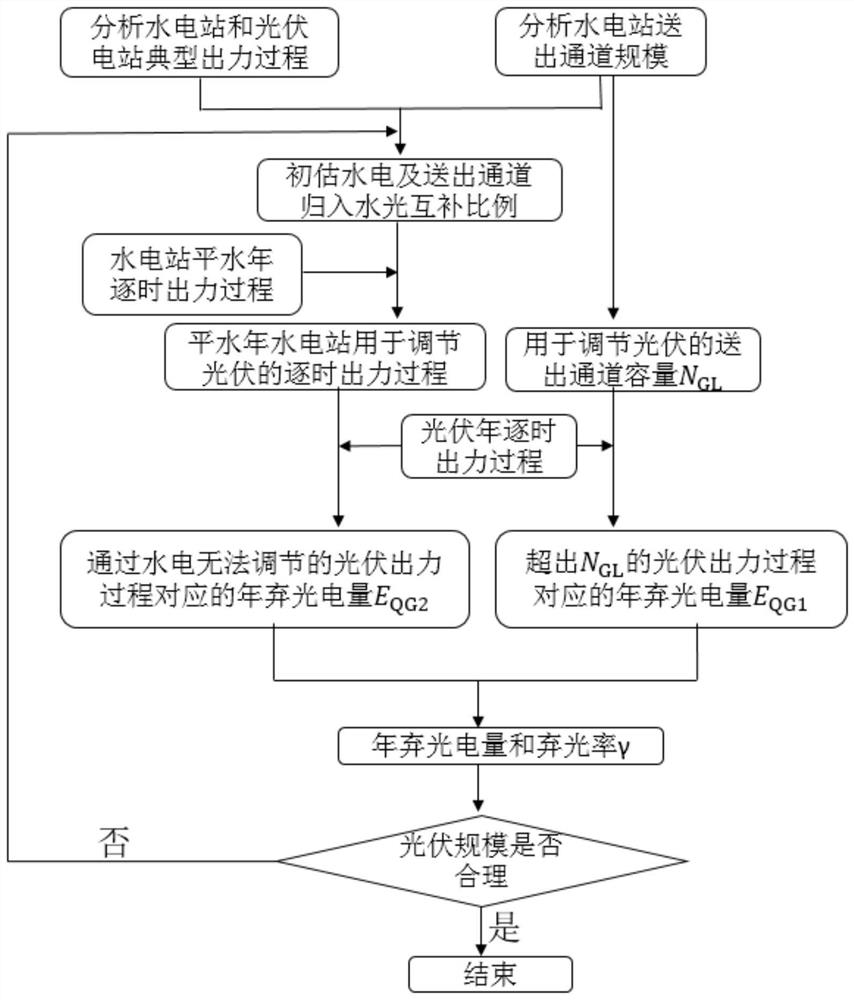

Method for conveniently judging hydraulic-solar complementary integrated photovoltaic scale under complex power grid

The invention discloses a method for conveniently judging a hydraulic-solar complementary integrated photovoltaic scale under a complex power grid. The method comprises the following steps: S1, analyzing or collecting hourly output processes of a hydropower station and a photovoltaic power station in each typical year; S2, collecting and analyzing the sending-out channel scale of the hydropower station; S3, in combination with the water-electricity and sending-out channel attribution hydraulic-solar complementation situation, a hydraulic-solar attribution complementation proportion scheme is formulated to calculate complementary water-electricity and channel capacity used for complementation; S 4, calculating a light abandoning rate; and S5, calculating the photovoltaic absorption rates ofthe photovoltaic installation scale schemes of different scales under the condition of different hydropower incorporation complementation proportions based on the hydropower incorporation complementation proportions and the light abandonment rates until an optimal solution is obtained. The invention provides a method capable of quickly judging whether the hydraulic-solar complementary integratedphotovoltaic scale is proper or not for the condition that whether the photovoltaic scale is reasonable or not is difficult to quickly judge due to many analysis data, various target functions and complex constraint conditions during large-scale photovoltaic grid-connected consumption of a complex power system.

Owner:CHINA POWER CONSRTUCTION GRP GUIYANG SURVEY & DESIGN INST CO LTD

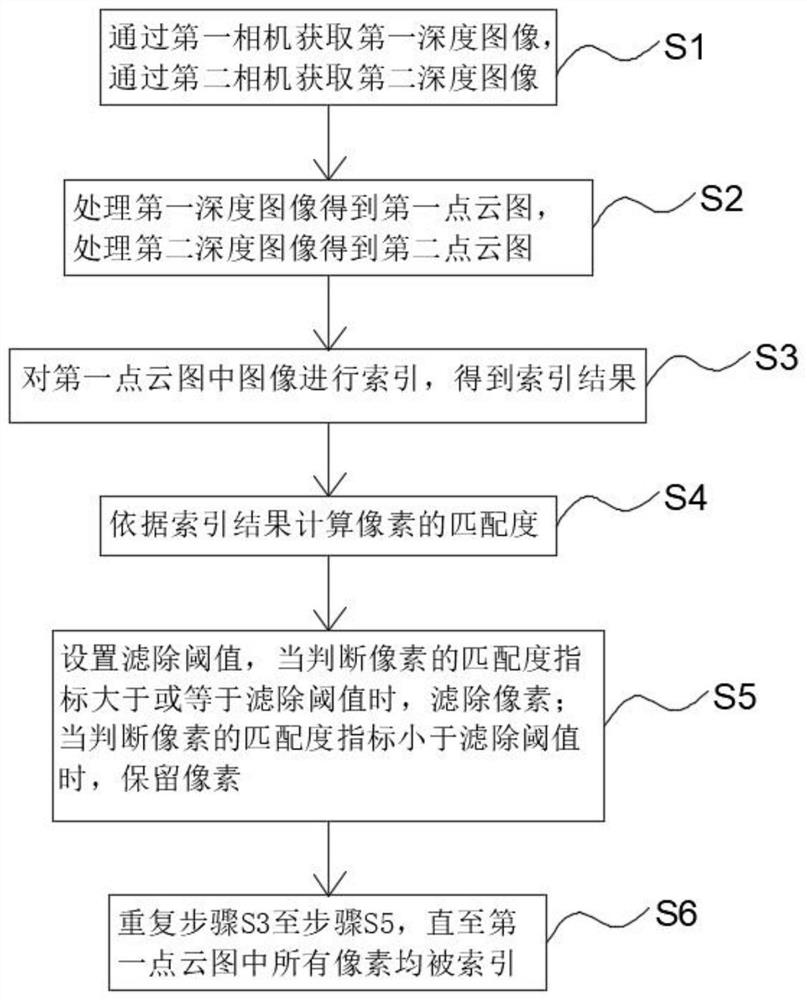

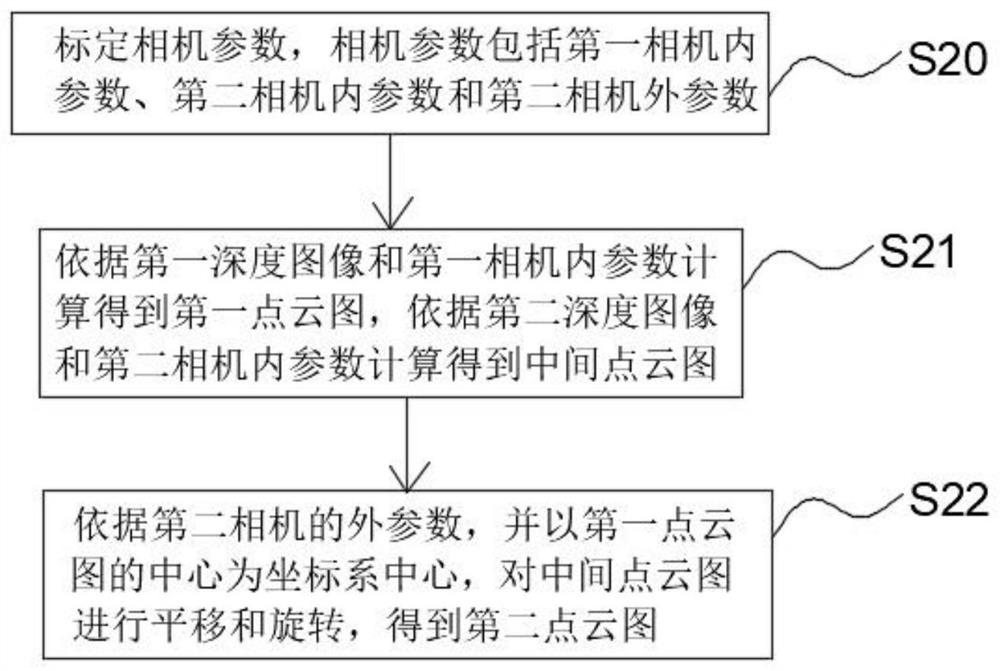

Abnormal pixel filtering method and device

PendingCN113379812AReduce calculation stepsReduce computational complexityImage enhancementImage analysisImaging processingPoint cloud

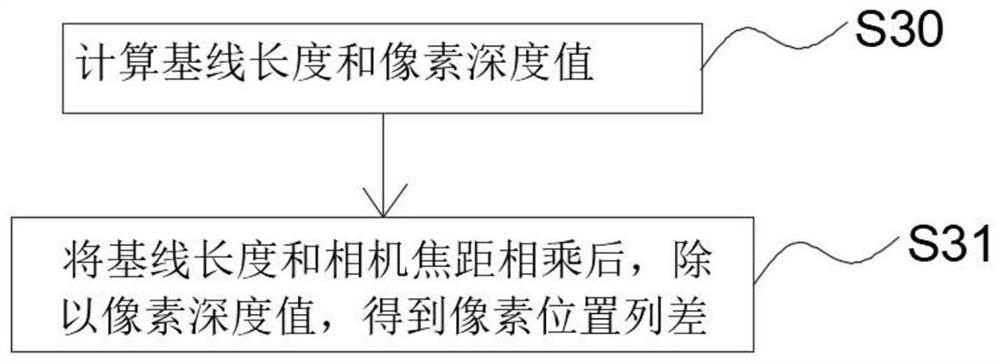

The invention provides an abnormal pixel filtering method and device. The filtering method comprises the steps: acquiring a first depth image through a first camera, and acquiring a second depth image through a second camera; processing the first depth image to obtain a first point cloud image, and processing the second depth image to obtain a second point cloud image; indexing pixels in the first point cloud picture to obtain an indexing result; calculating a matching degree index of the pixels according to the index result; and setting a filtering threshold value, and filtering the pixel when the matching degree index of the pixel is judged to be greater than or equal to the filtering threshold value. The method has the advantages of few calculation steps, low calculation complexity and simple calculation principle, and can greatly improve the efficiency of judging abnormal pixels, thereby further improving the speed of filtering pixel noise. The device comprises a first camera, a second camera, an image processing unit, an index unit, a calculation unit, a judgment unit and a filtering execution unit, and the efficiency of filtering abnormal pixels is improved.

Owner:SHANGHAI INTEGRATED CIRCUIT MFG INNOVATION CENT CO LTD

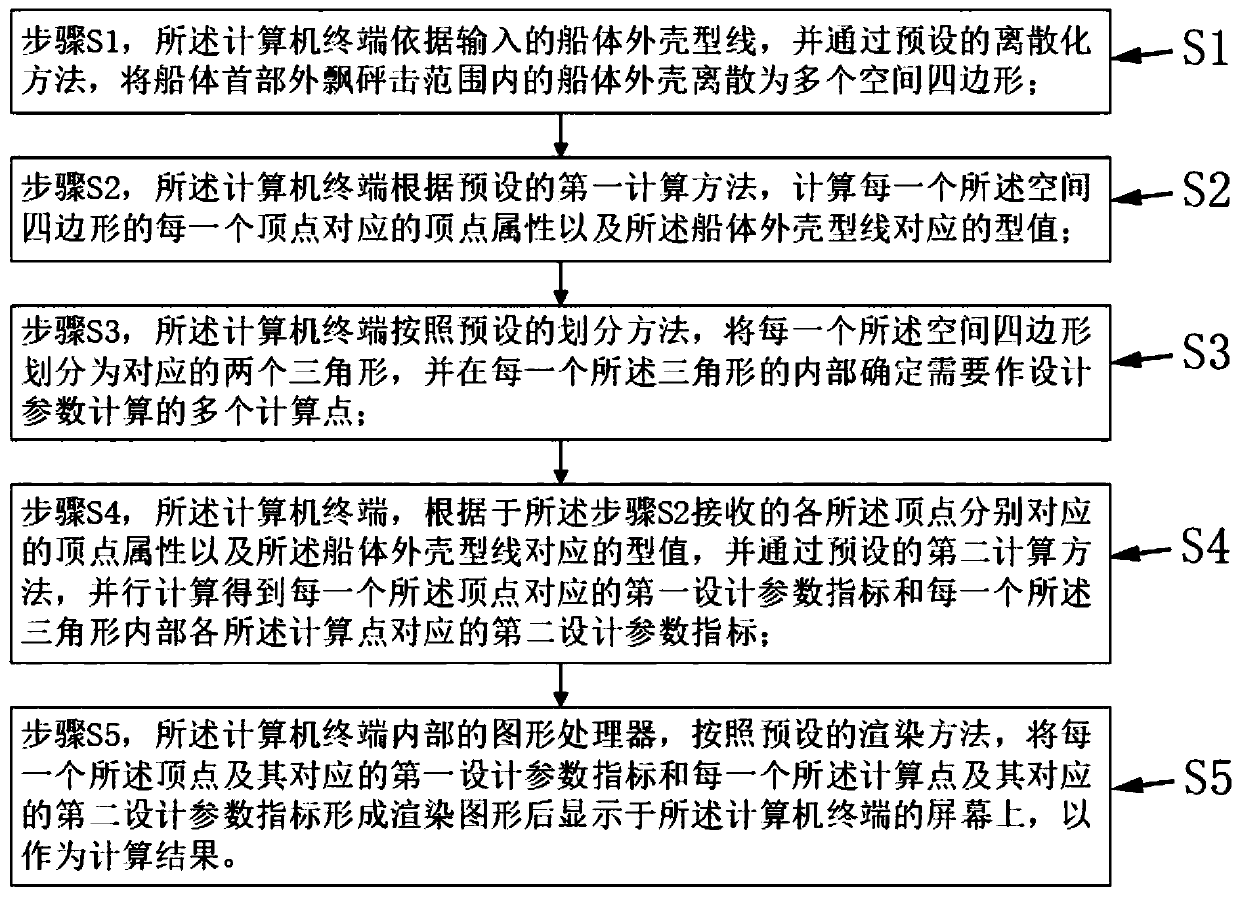

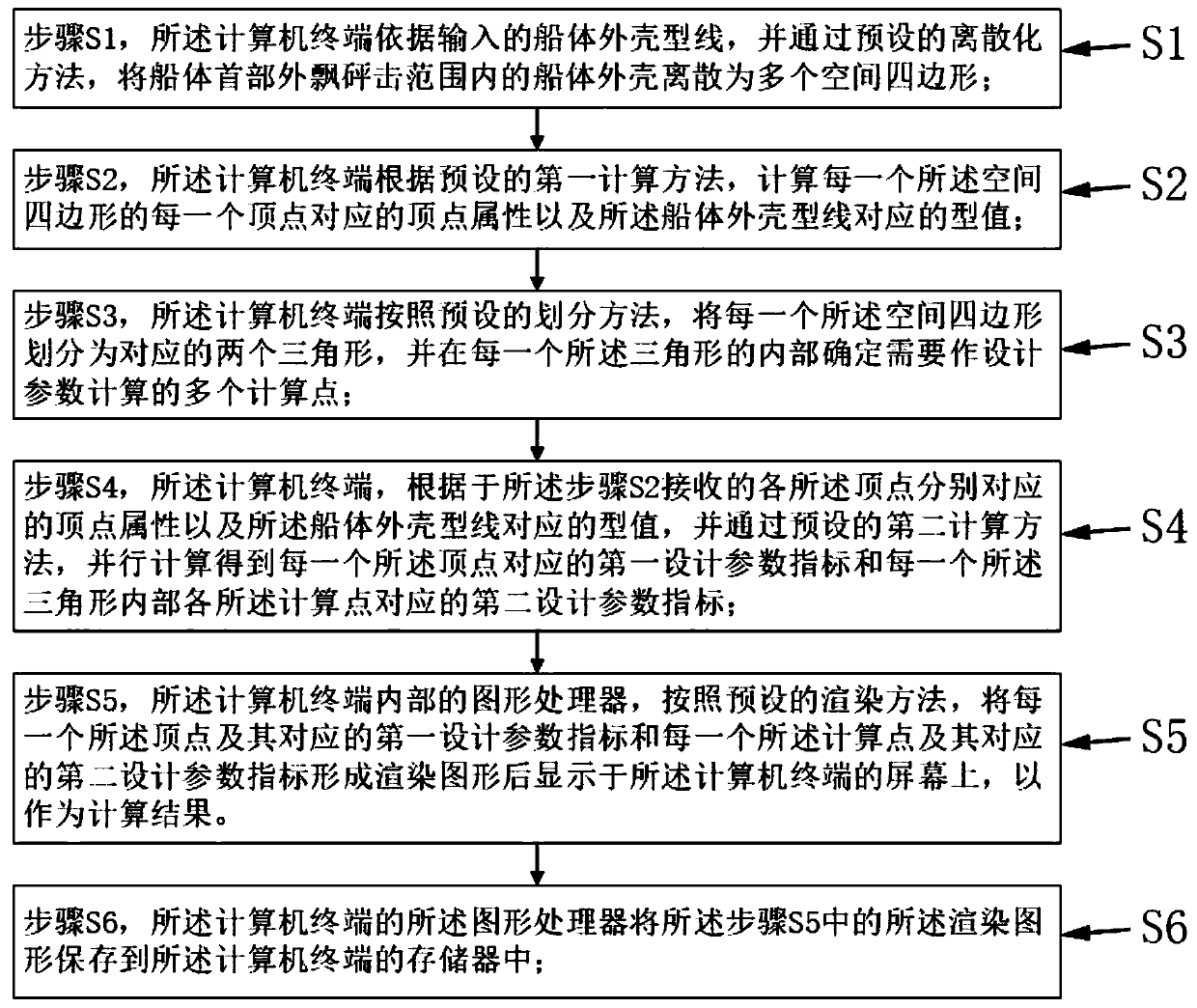

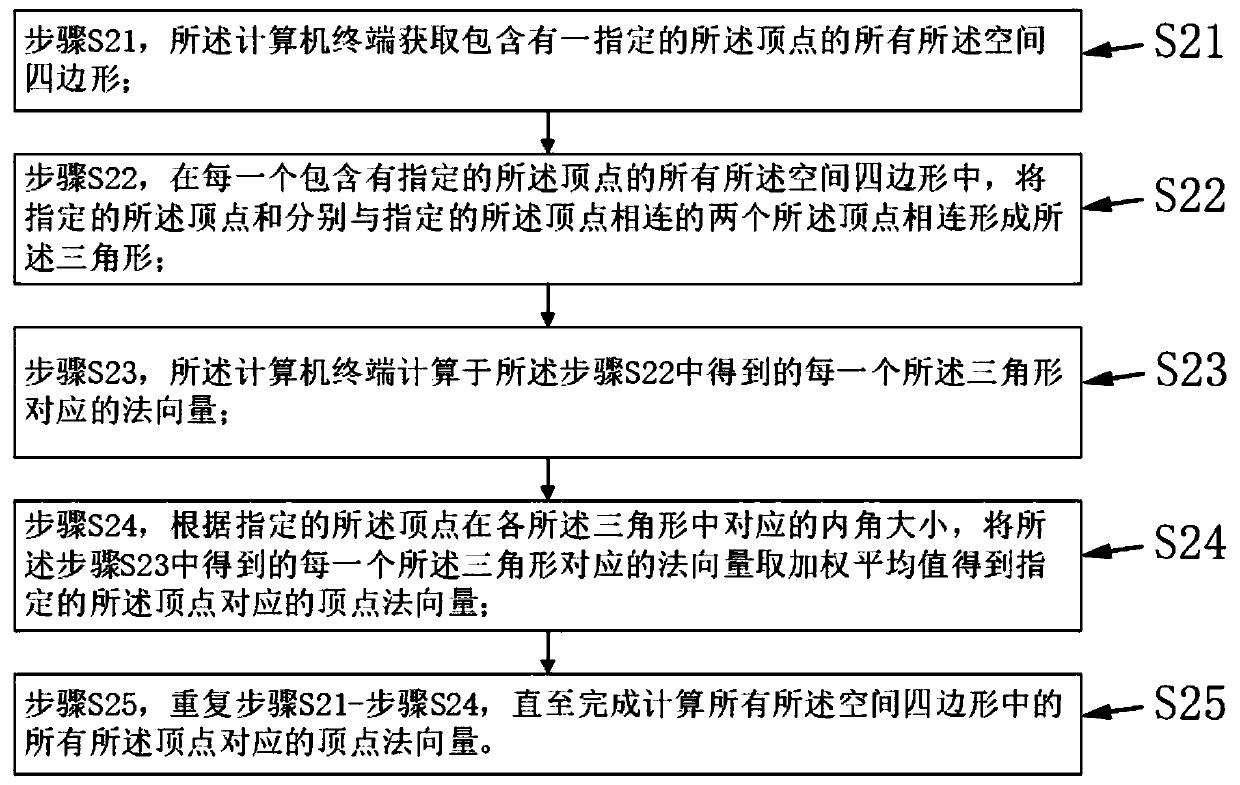

A hull head drift flare-out slamming parallel computing method based on a three-dimensional model

PendingCN109726359AThe calculation principle is simpleCalculation speedComplex mathematical operationsSustainable transportationThree dimensional modelFlare

The invention discloses a hull head flare-out slamming parallel computing method based on a three-dimensional model. The hull head flare-out slamming parallel computing method comprises the followingsteps that S1, dispersing a hull shell within the hull head outwards-floating slamming range into a plurality of spatial quadrangles through a computer terminal; S2, calculating the vertex attribute corresponding to each vertex of each spatial quadrangle; S3, dividing each spatial quadrangle into two corresponding triangles, and determining a plurality of calculation points needing parameter calculation in each triangle; S4, calculating a first design parameter index corresponding to each vertex and a second design parameter index corresponding to each calculation point based on each vertex attribute; And S5, according to a preset rendering method, displaying each vertex, each calculation point and the corresponding first design parameter index and the corresponding second design parameterindex on a computer terminal screen, the principle is simple, the calculation speed is high, and various design parameters of the ship can be visually displayed.

Owner:708TH RES INST OF CSSC

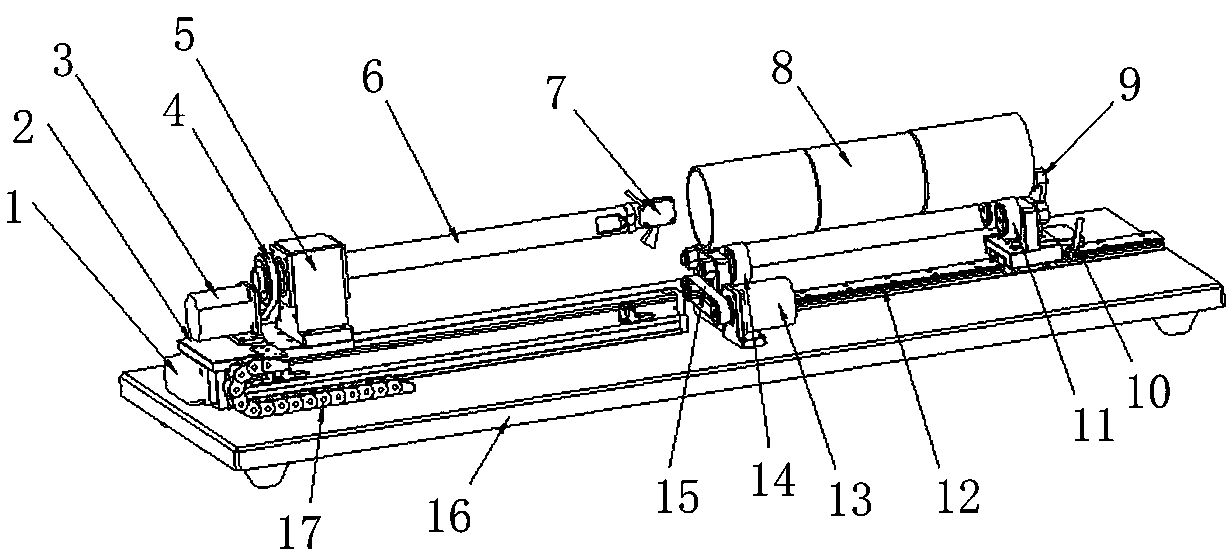

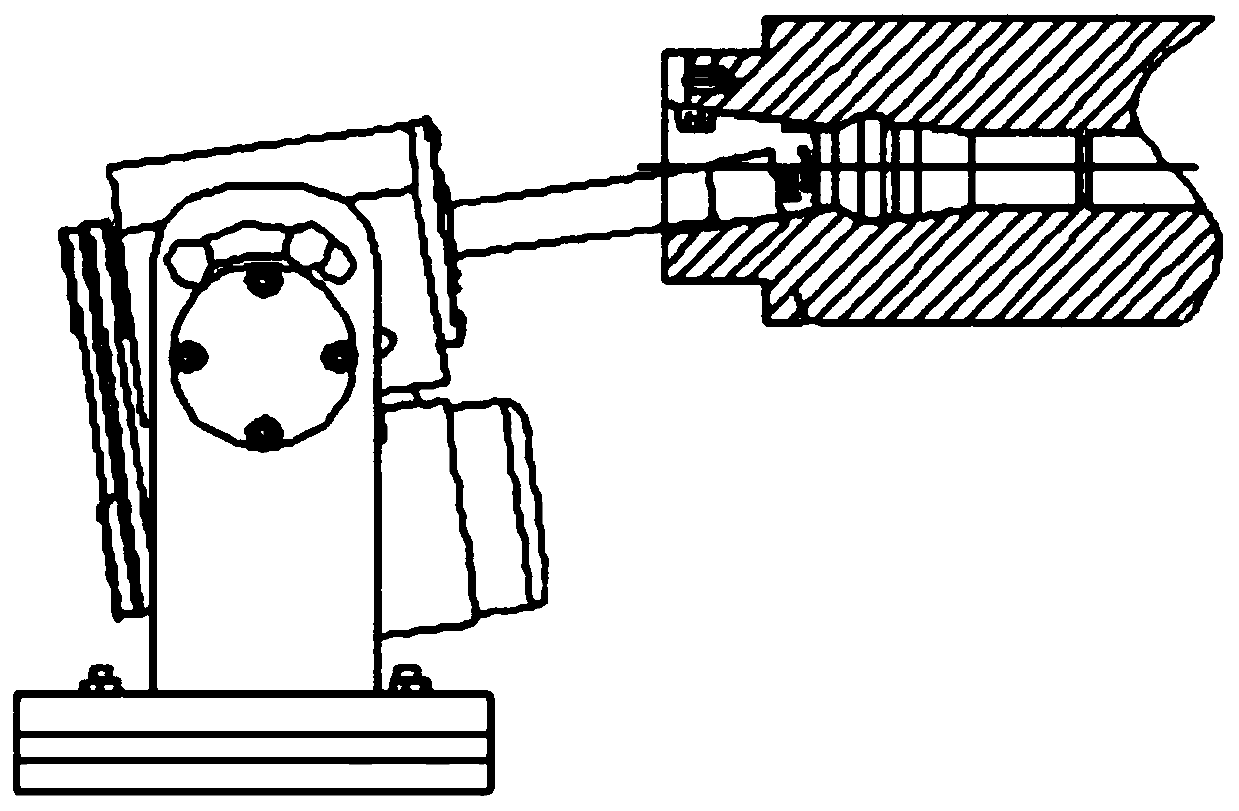

Method for repairing spindle taper hole through autogenous grinding device

ActiveCN110712074AEnsure repair accuracyAvoid excessive grindingGrinding carriagesRevolution surface grinding machinesNumerical controlTransmission belt

The invention discloses a method for repairing a spindle taper hole through an autogenous grinding device, and belongs to the technical field of machine tool maintaining. The method is mainly used forrepairing work of benchmark losses caused by serious numerical control machine tool spindle taper hole damage. The method is suitable for maintaining of the benchmark losses caused by numerical control machine tool spindle taper hole damage. The structure is simple, stability is good, through machine tool feeding, precise control over each time of grinding amount can be achieved, excessive grinding of the spindle taper hole can be avoided, the maintaining cost is greatly reduced, and the spindle taper hole repairing quality is improved. A base, a guide rail bottom plate, a bearing, a rotationshaft, a guide rail, a feeding drag plate, a screw, a screw support and a hand wheel are included, the motor drives a driving belt wheel to rotate, a transmission belt winds around the driving belt wheel and a driven belt wheel, the hand wheel drives the screw to rotate, the guide rail and the feeding drag plate have a fit structure, and relatively axially move, and the method comprises the stepsof using of an autogenous grinder, machine tool precision detection and grinding wheel grinding path performing.

Owner:INNER MONGOLIA FIRST MACHINERY GRP +1

A centering method for the assembly process of stepped shaft and hole

ActiveCN111322967BGuaranteed accuracyReduce complexityImage enhancementImage analysisMachine visionEllipse

The invention proposes a centering method for the assembly process of the stepped shaft and the hole. First, the image of the hole part is taken by a calibrated camera, and the centering deviation of the hole part is obtained by using the method of image recognition and ellipse fitting; The center deviation adjusts the position of the hole parts to be assembled until the axis of the through hole in the hole parts coincides with the axis of the camera, and fixes the position of the hole parts and the camera at this time; The image of the end face, and use the method of image recognition and ellipse fitting to get the fitting circle center of the small diameter end face of the stepped shaft and the fitting circle center coordinates of the middle diameter end face of the stepped shaft, connect the two circle centers and calculate the coordinates of the midpoint of the connection, using The coordinates of the midpoint are compared with the axis coordinates of the hole parts to adjust the pose of the stepped shaft to be assembled, and realize the centering monitoring of the stepped shaft and the hole. The invention realizes real-time monitoring and feedback of the alignment between the stepped shaft and the hole based on machine vision.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

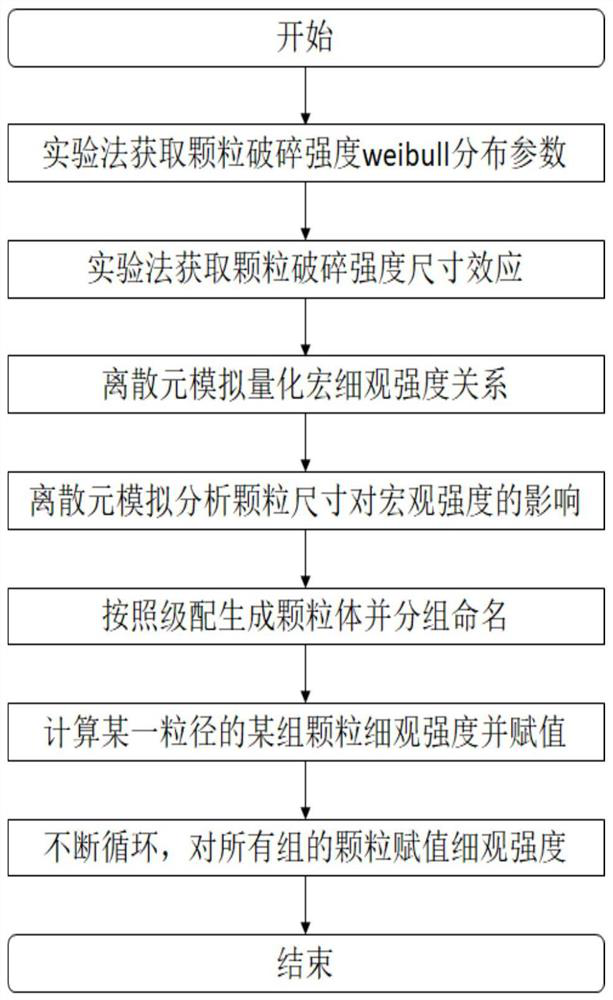

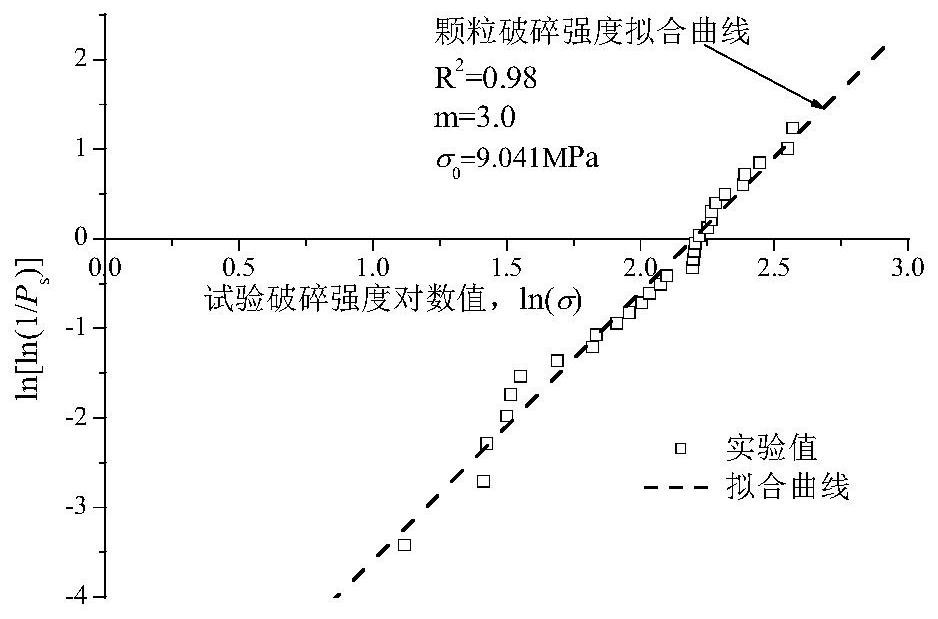

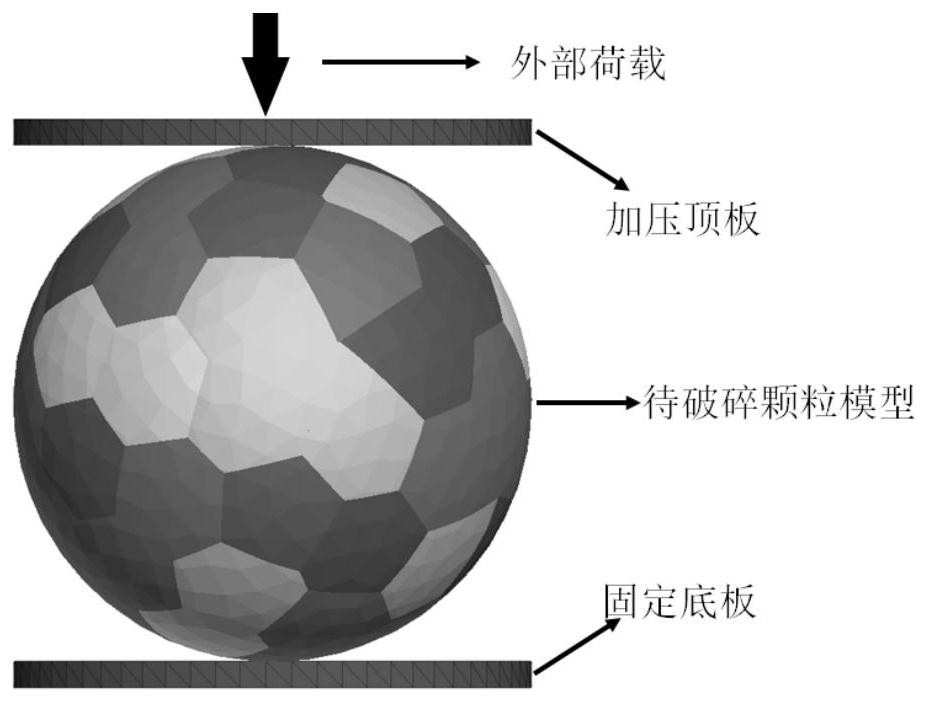

Discrete element model construction method for realizing accurate control of single-particle breaking strength weibull distribution

ActiveCN112380736AThe calculation principle is simpleThe calculation program is concise and efficientDesign optimisation/simulationSpecial data processing applicationsParticle modelMacroscopic scale

The invention discloses a discrete element model construction method for realizing accurate control of single-particle breaking strength weibull distribution. The method comprises the following steps:1, measuring the single-particle breaking strength and counting a strength characteristic value sigma 0 and a weibull modulus m of the weibull distribution, 2, measuring the size effect of the particle strength, 3, determining a macro-micro intensity corresponding relation: f (sigma<mu>)=sigma, 4, determining the corresponding relation between the particle size and the macroscopic strength: f(d)=sigma, 5, generating a particle discrete element model, 6, assigning values to the corresponding BCM particle models, and 7, repeating the step 6, and assigning values to the particles contained in the N groups of each particle size group until all parameters are successfully assigned. The method has the beneficial effect that the particle breaking strength distribution of the constructed discreteelement model is very consistent with the actual situation. The calculation principle is simple, the calculation program is concise and efficient, and the actual particle breaking strength characteristics can be effectively reflected. An effective technical means is provided for further understanding the mechanical behavior of the crushable granular material.

Owner:CENT SOUTH UNIV

A Calculation Method of Emotional Index Based on Face Action Unit Detection

InactiveCN110147822BAccurate and objective communicationThe calculation principle is simpleCharacter and pattern recognitionData setVerbal expression

The invention belongs to the technical field of face recognition and emotion calculation technology, and specifically relates to a method for calculating an emotion index based on human face action unit detection. The specific steps include: establishing a data set to be trained, forming a database of human face action units; Unit action intensity detection; calculation of emotional index; the invention realizes the emotional process expressed through facial expressions, can convey detailed information more accurately and objectively, and can make up for the profound information that cannot be described and conveyed by language, especially for language barriers and Situational applications that cannot normally obtain language information provide a very feasible solution.

Owner:BEIJING NORMAL UNIVERSITY

Device and method for detecting high-speed tiny target online in real time by simulating fly vision

ActiveCN102510436BSimple algorithmLow costTelevision system detailsColor television detailsVision processingJet aeroplane

The invention discloses a device and method for detecting a high-speed tiny target online in real time by simulating fly vision. The method comprises the following steps of: acquiring scene video information by using a binocular camera, transmitting the scene video information into a DSP (digital signal processor) chip, and performing primary vision processing; performing large scene and small scene integration and target detection on primary motional information by using an FPGA (field programmable gate array) chip; and tracking a tiny target moving at high speed by taking an integration result of a large scene and a small scene as a target detection evidence. The device and method disclosed by the invention have the advantages that: the target detection is realized by virtue of a biological principle; the device and method have relatively strong antijamming capability and are applicable to the target detection under the condition of a low signal-to-noise ratio in various severe natural environments; a neuron integrating mechanism of a fly vision system has the characteristics of simple computing principle, high real-time performance and the like; the fly vision neuron is simple in tissue structure and can be easily realized by hardware; and the device can be installed on an automobile, panzer, airplane and other appliances which move at high speed, and has the capability of accurately detecting the high-speed tiny target on line in real time in a dynamically changing background.

Owner:HOHAI UNIV CHANGZHOU

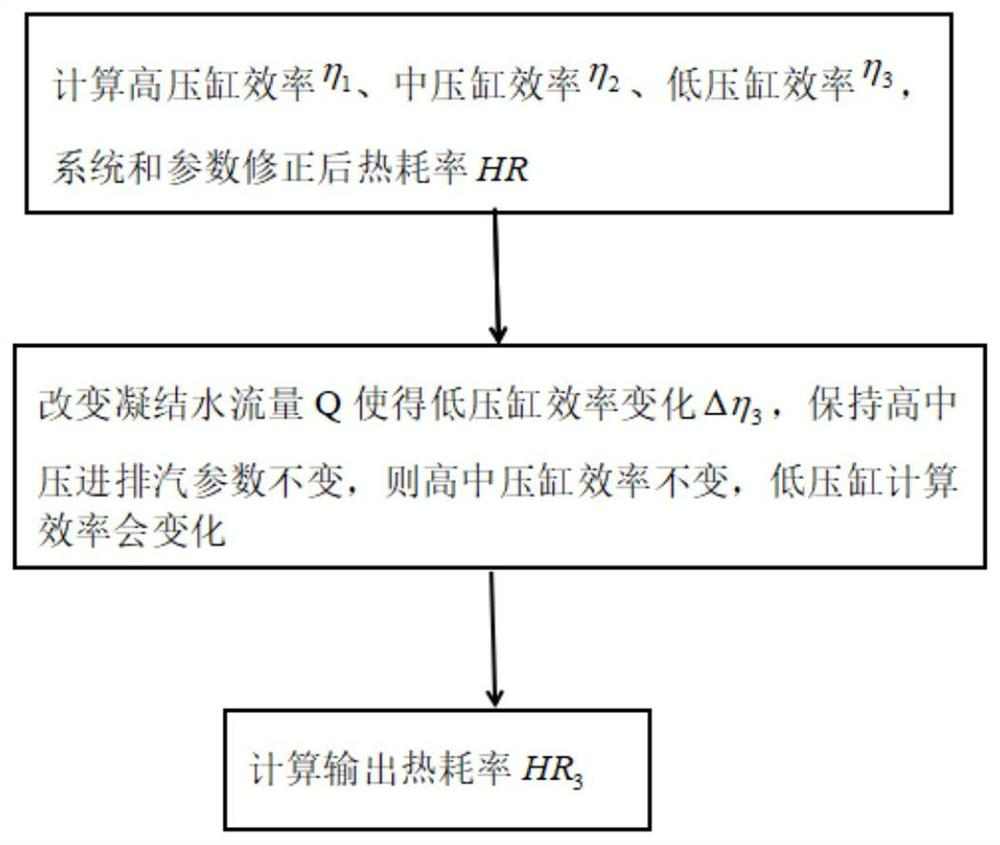

Method for calculating influence quantity of steam turbine cylinder efficiency on heat rate

PendingCN113486472AStrong practical value and operabilityAccurate energy savingGeometric CADSpecial data processing applicationsProcess engineeringDynamic balance

The invention discloses a method for calculating the influence quantity of steam turbine cylinder efficiency on heat rate, and the method comprises the following steps: respectively calculating the change quantity of heat rate before and after the change of high-pressure cylinder efficiency, before and after the change of medium-pressure cylinder efficiency and before and after the change of low-pressure cylinder efficiency; adjusting the efficiency of other cylinders is adjusted to be kept unchanged while the efficiency of the high-pressure cylinder, the efficiency of the medium-pressure cylinder and the efficiency of the low-pressure cylinder are kept in single variable change every time, and calculating the influence quantity of the heat consumption rate. According to the method, the process of calculating dynamic balance under variable working conditions of the steam turbine is fully considered, and the energy saving amount can be calculated more accurately by the provided method for calculating the influence amount of the steam turbine cylinder efficiency on the heat consumption rate.

Owner:GUODIAN NANJING ELECTRIC POWER TEST RES CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com