Car side door overall rigidity analysis and loading point locating method

A technology of stiffness analysis and positioning method, applied in special data processing applications, instruments, electrical and digital data processing, etc., can solve the problems of inconsistent understanding of analysts, deviation of loading point position, manual definition, etc., to achieve simple calculation principles and avoid errors. , to achieve the effect of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

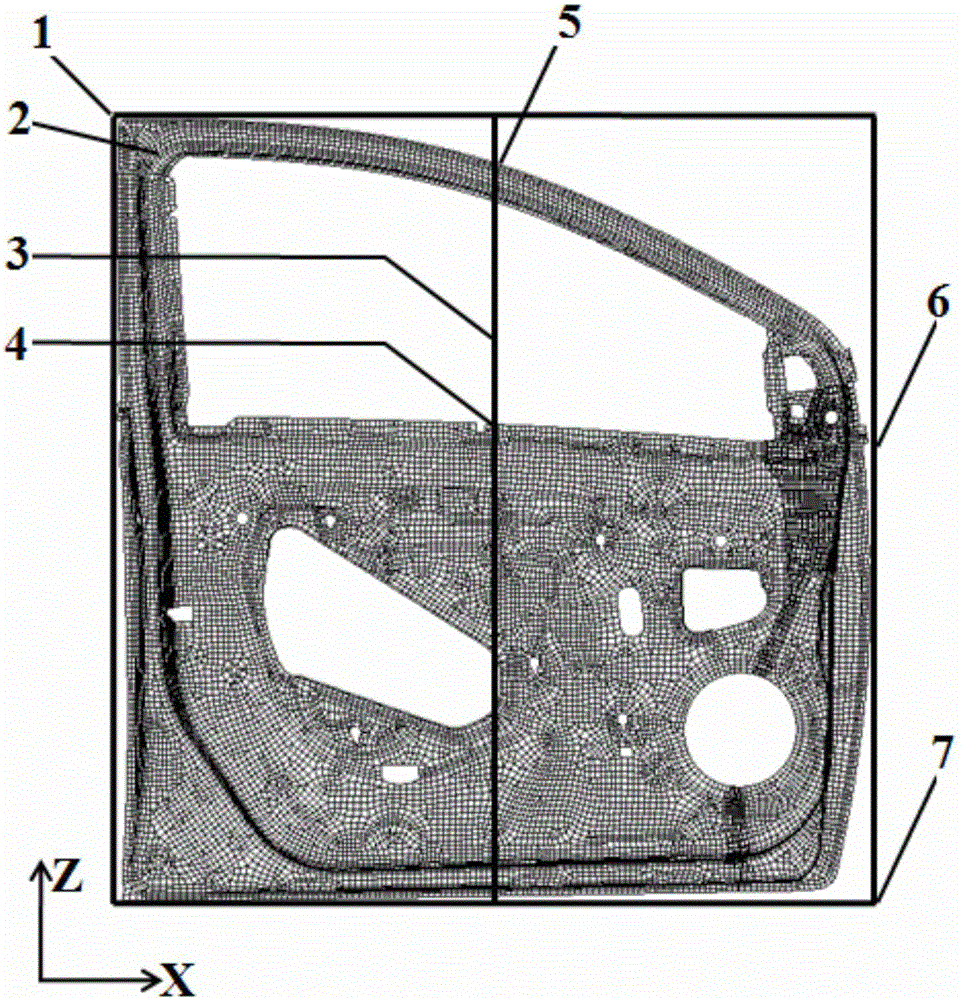

[0052] figure 1 Is the overall schematic diagram of the positioning of the loading point for the side door stiffness analysis.

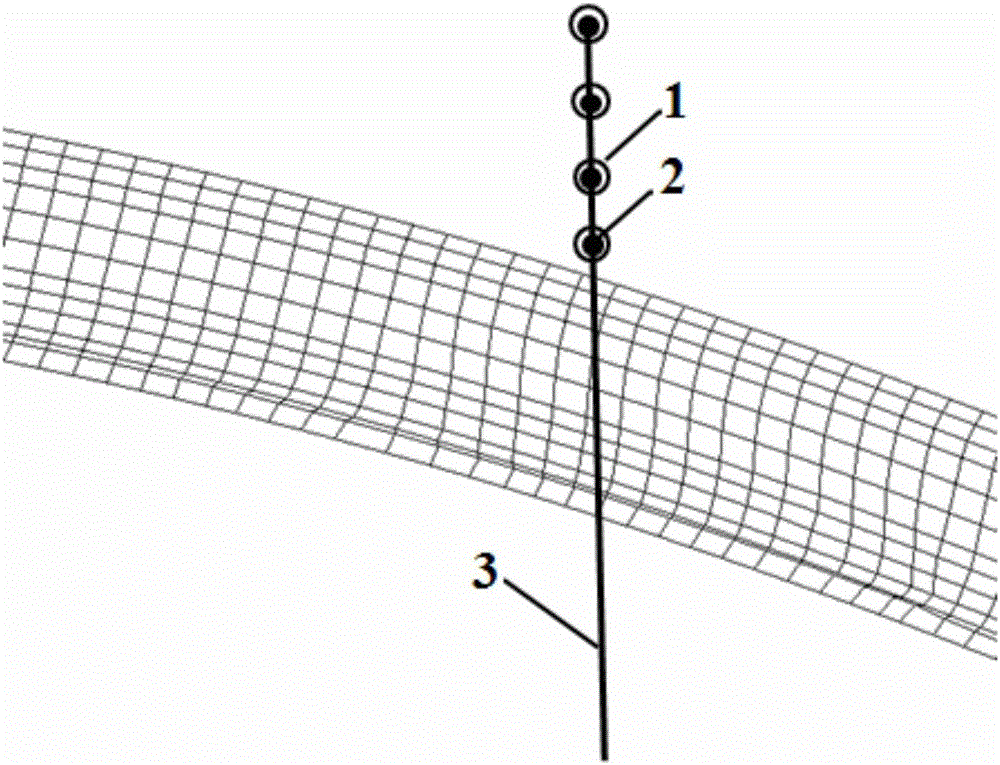

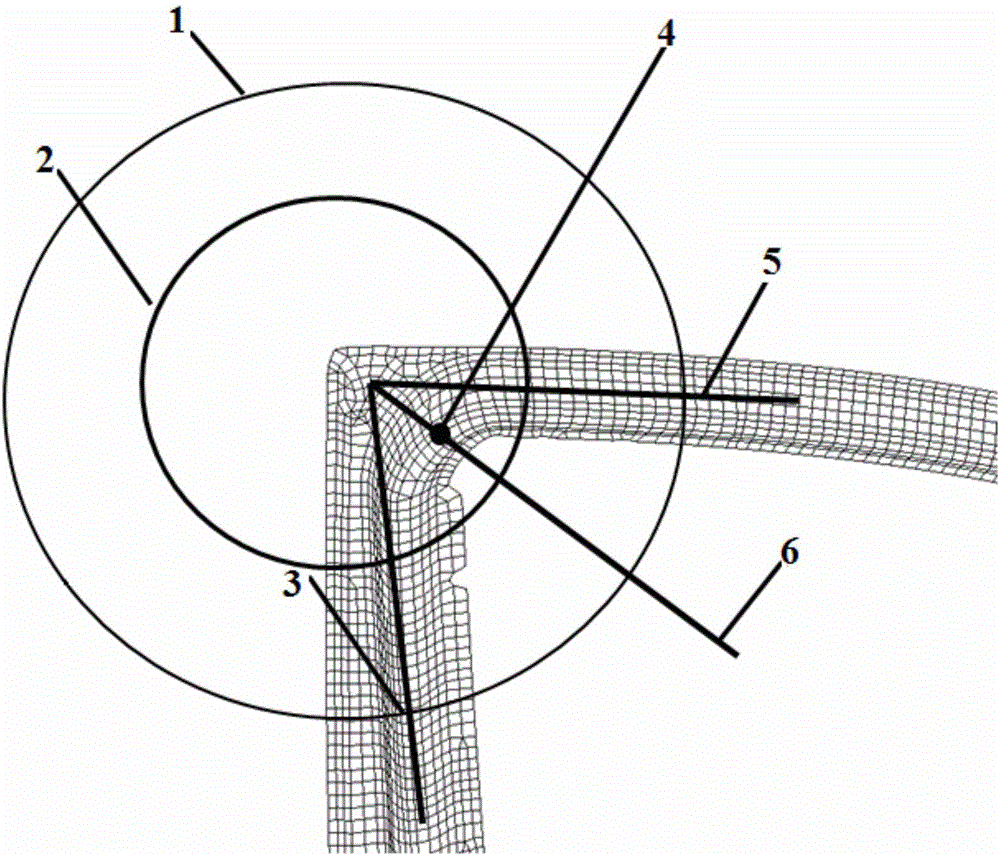

[0053] The present invention can be embedded in the finite element software HYPERMESH commonly used in the automobile industry through the TCL language. The finite element software reads the coordinate values of all nodes in the model, and compares the value of the value through the built-in function library, and screens out the maximum value of the Z coordinate as the base point of the uppermost corner; and then obtains the minimum value of the Z coordinate and the maximum value of the X coordinate Value, create the base point of the bottom corner; take the Y coordinate of the base point of the top corner as the base point of the projection surface, and use Y as the normal direction to determine the plane where the projection surface is located; on the plane where the projection surface is located, take the base point of the top corner and the bas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com