Device and method for adjusting mass characteristic of aircraft-simulated air bearing table

A technology for aircraft simulation and quality characteristics, which is applied in the field of aircraft simulation air bearing platform quality characteristic adjustment devices, can solve problems such as no implementation method given, and achieve the effects of easy maintenance, simple calculation principles, and easy realization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

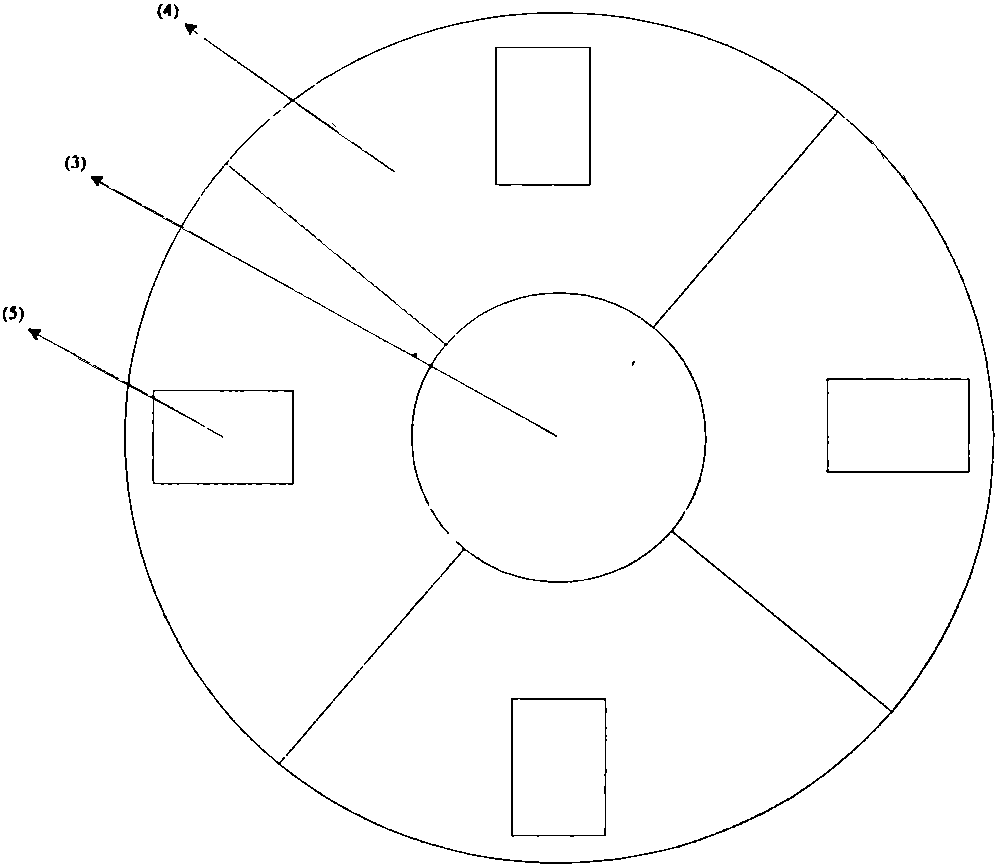

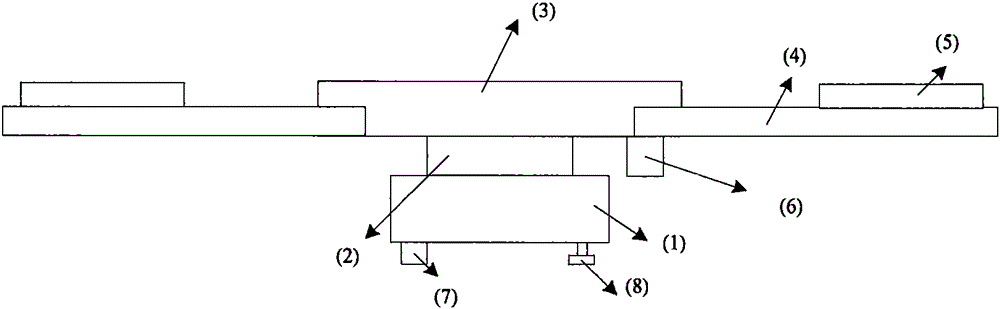

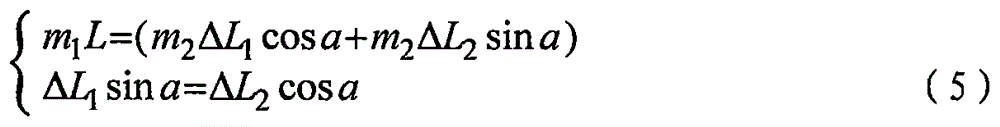

[0037] Such as Figure 1-2 As shown, a device for adjusting the mass characteristics of an aircraft simulated air bearing platform includes a base 1, an air bearing pair 2, a load table 3, an inertia ring 4, a coarse adjustment balance mechanism 5, two fine adjustment balance mechanisms 6, and a pad iron 7 and hydraulic jack adjustment pad iron 8; the air bearing pair 2 is installed on the base 1, the load table 3 is installed on the air bearing pair 2, the inertia ring 4 is installed on the outside of the load table 3, and the coarse adjustment balance mechanism 5 is installed on On the inertia ring 4, the fine-tuning balance mechanism 6 is installed under the load table 3, and the bottom of the base 1 is supported on the foundation through the pad iron 7 and the hydraulic jack adjustment pad 8; the opposite side of the unbalanced position on the load table is corresponding Add a coarse adjustment mass block of the same mass to the coarse adjustment balance mechanism 5, the c...

Embodiment 2

[0039] Adopt a kind of aircraft simulation air bearing platform mass characteristic adjustment device as shown in embodiment 1, draw a kind of aircraft simulation air bearing platform quality characteristic adjustment and measuring method, as follows:

[0040] Step 1: After the air bearing table is installed, power on the system, first move the two mass sliders of the fine-tuning balance mechanism to the middle position of its stroke, and then lift the air bearing table upwards with a hydraulic jack at the bottom of the base Height c, make the air bearing platform tilt angle θ relative to the horizontal plane;

[0041] Step 2: Due to the imbalance of the system, the load table rotates. When the load table stops rotating, the part with the largest mass will rotate to the bottom of the table. At this time, manually rotate the turntable by an angle, and use the angle measuring element to measure the angle. x, after letting go, the turntable will do a single pendulum motion, use t...

Embodiment 3

[0065] Regarding the judgment of the balance of the air bearing system, in theory, the turntable can be stopped at any position, which means that the system is balanced. However, the ideal situation cannot be achieved in actual engineering. The following methods can be used to illustrate the system balance:

[0066] After the fine-tuning mass is adjusted, the turntable will perform a slow single pendulum motion. The speed of the turntable at the initial moment is 0. This moment is taken as the initial moment. When the angle measuring element is used to measure the speed of the turntable to be 0 again, the swing of the turntable is calculated. The half period corresponds to time t, and the entire period 2t is used to compare with the pendulum period T corresponding to the unbalanced torque allowed by the system. If the pendulum period is greater than T seconds, it means that the balance accuracy requirements of the system are met.

[0067] When the system is unbalanced, the tes...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com