Method for calculating influence quantity of steam turbine cylinder efficiency on heat rate

A calculation method and technology of heat rate, which is applied in the field of calculation of the influence of steam turbine cylinder efficiency on heat rate, can solve problems such as no calculation method, and achieve strong practical value, operability, and accurate energy saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] In order to facilitate the understanding of the calculation method of the present invention, the following is a domestic one-time intermediate reheating, single-shaft, three-cylinder, two-exhaust, extraction and condensing steam turbine, and the feedwater reheating is 3 high plus 1 deoxygenation + 4 low plus system, and the unit with steam-driven water pump is described as a column.

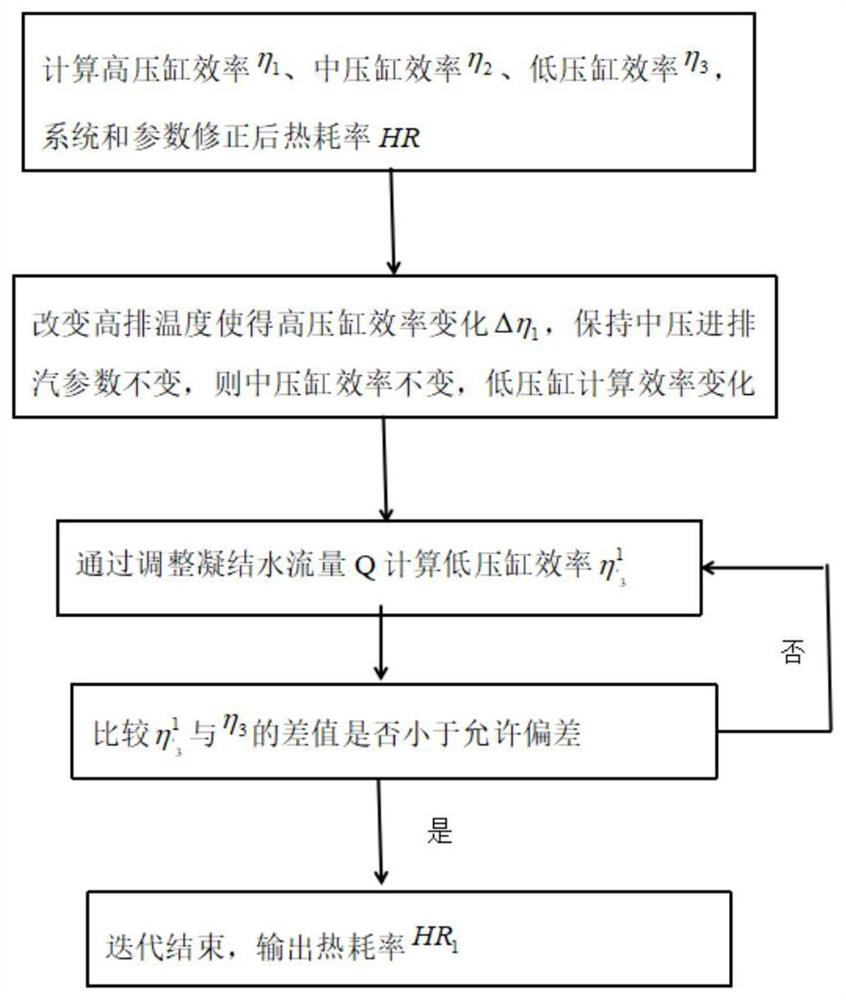

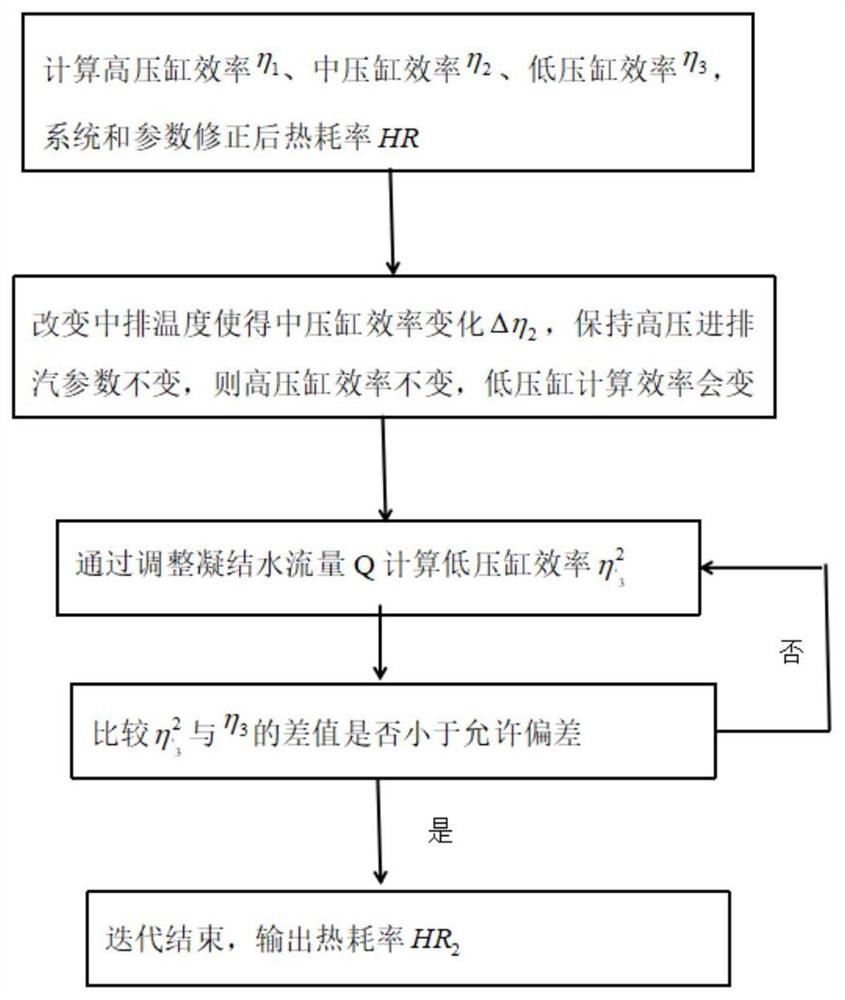

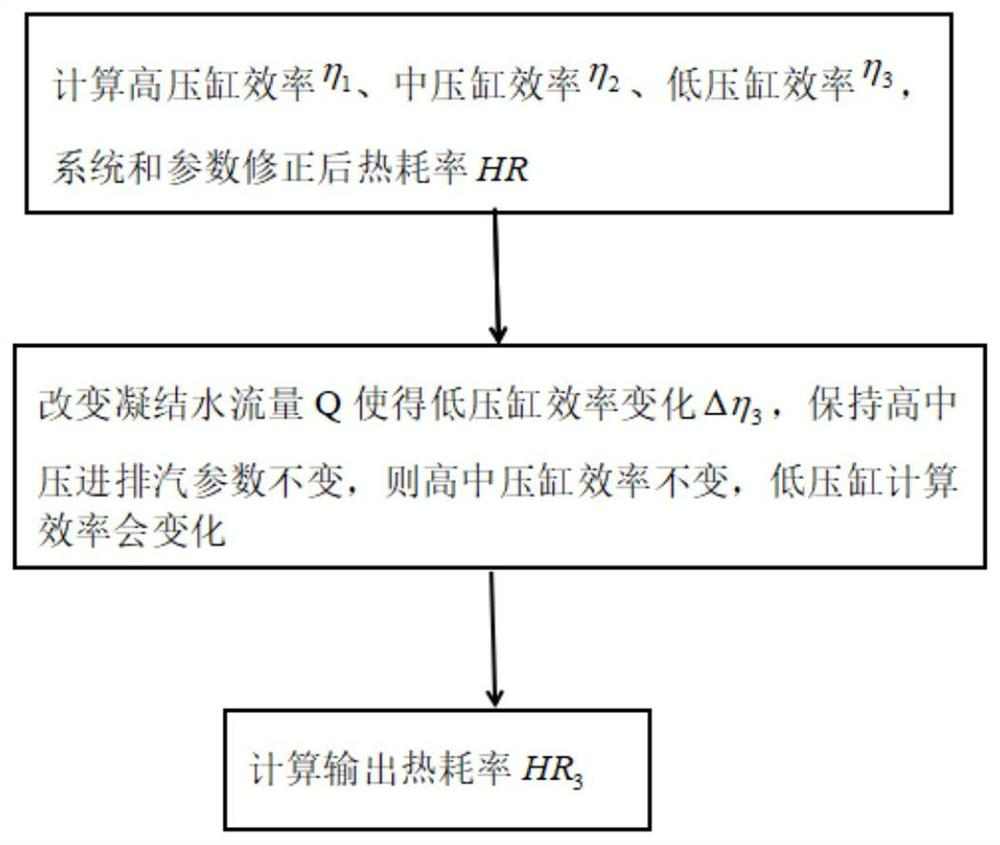

[0042] The invention provides a method for calculating the influence of steam turbine cylinder efficiency on heat rate, which includes the following specific steps:

[0043] (1) Collect raw data;

[0044]

[0045]

[0046]

[0047]

[0048] (2) The first calculation of unit cylinder efficiency and heat consumption rate; calculation of high pressure cylinder efficiency η 1 , Medium pressure cylinder efficiency η 2 , Low-pressure cylinder efficiency η 3 , the heat rate HR after system and parameter correction;

[0049] name unit value High pressure cylinder...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com