Discrete element model construction method for realizing accurate control of single-particle breaking strength weibull distribution

A technology of crushing strength and construction method, which is applied in CAD numerical modeling, special data processing applications, design optimization/simulation, etc., can solve the problems of discreteness, difficult to control Weibull modulus and size effect, etc., and achieves a simple calculation principle. , the calculation program is concise and efficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] see Figure 1 to Figure 9 Shown:

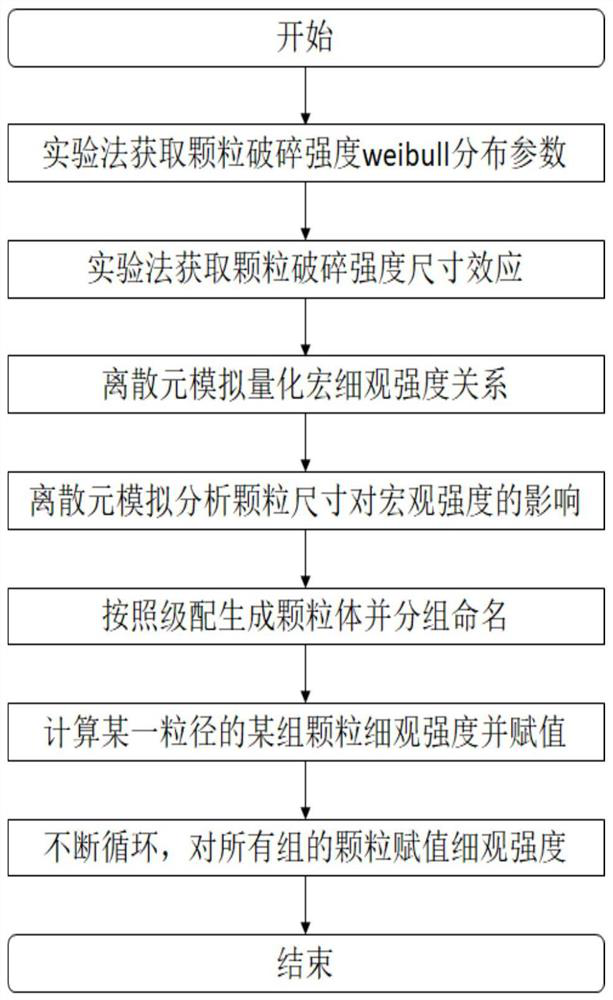

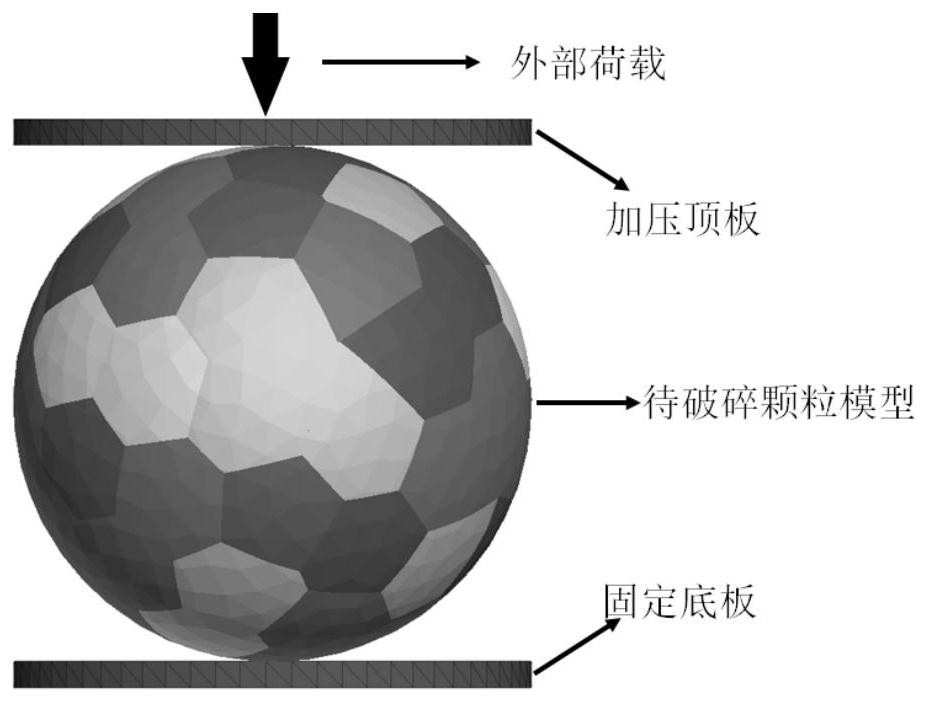

[0035] The discrete element model construction method provided by the present invention to realize the precise control of single particle crushing strength weibull distribution is as follows:

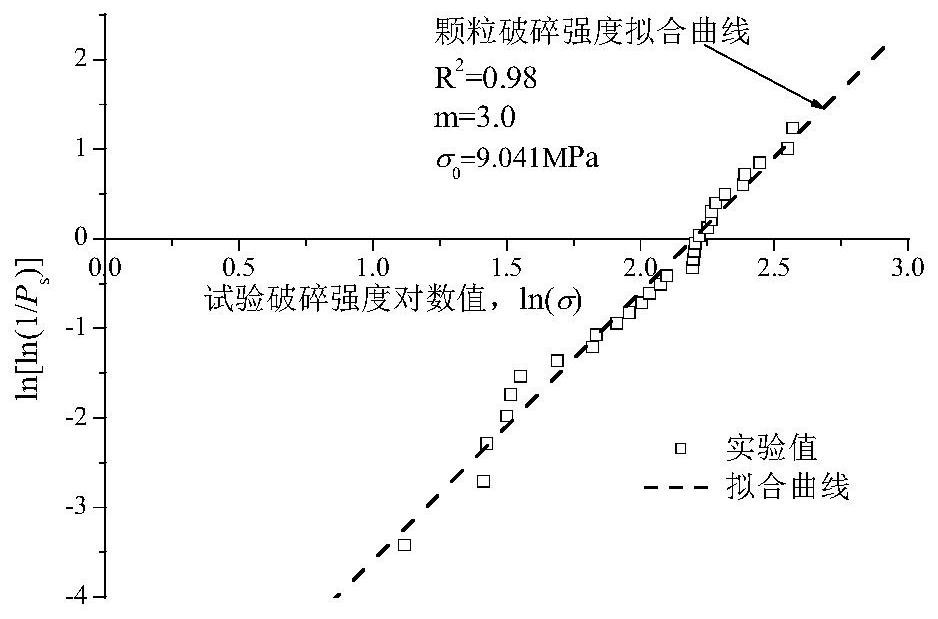

[0036] Step 1. Select a number of particles of equal particle size to conduct a single particle crushing indoor experiment to measure the single particle crushing strength. Select 30 calcareous sand particles with a particle size of 20mm and a shape approximately spherical to carry out the single particle crushing experiment, and obtain the crushing strength value σ of the calcareous sand particles statistically 0 And Weibull modulus m. The weibull distribution is as follows figure 2 Shown: Weibull modulus m = 3, strength eigenvalue σ 0 =9MPa, showing good weibull distribution (R2=0.98).

[0037] Step 2. Continue to select particles of the same particle size different from Step 1 to carry out single-particle compression and crushing indoor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com