Rapid characterization method for mechanical properties of composite material

A composite material and mechanics technology, applied in the direction of analyzing materials, testing the strength of materials by applying a stable bending force, and testing the strength of materials by applying a stable tension/pressure, etc. problem, to achieve the effect of simple calculation principle, simple measurement steps, and small measurement error

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

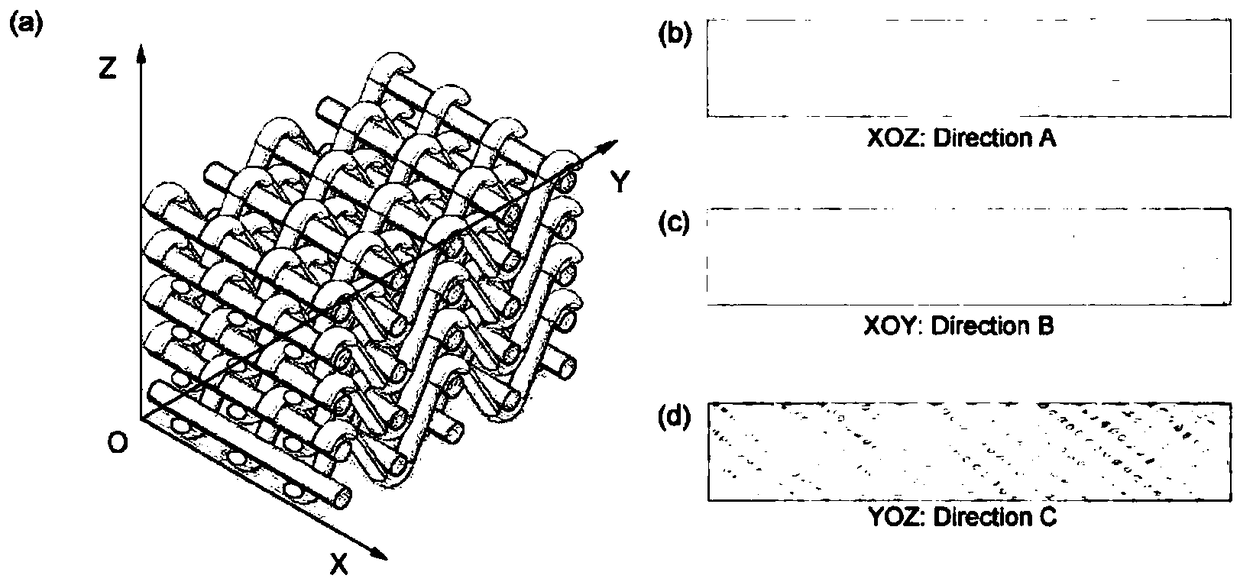

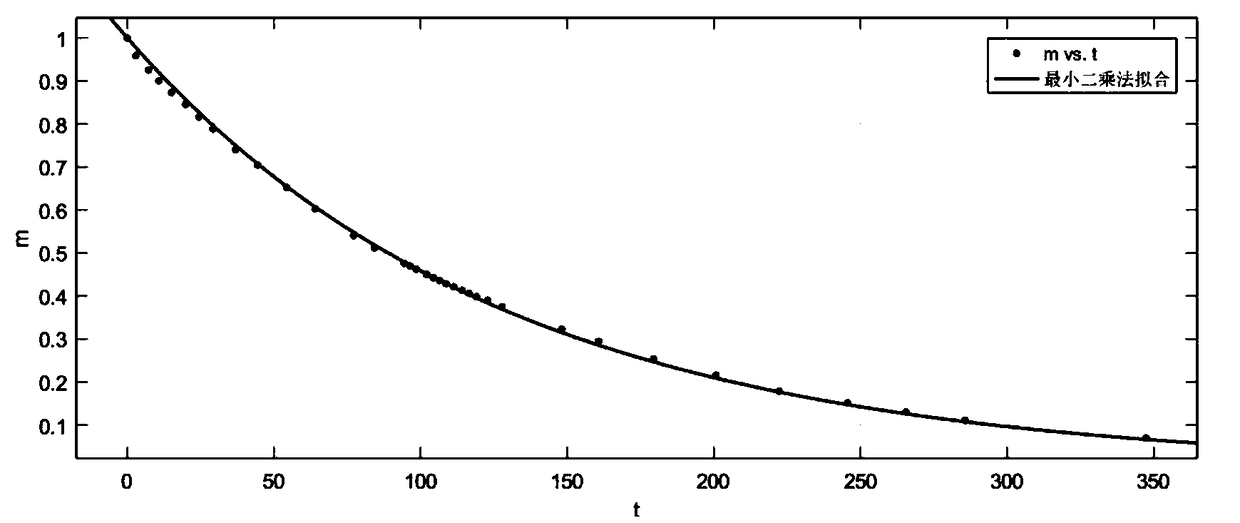

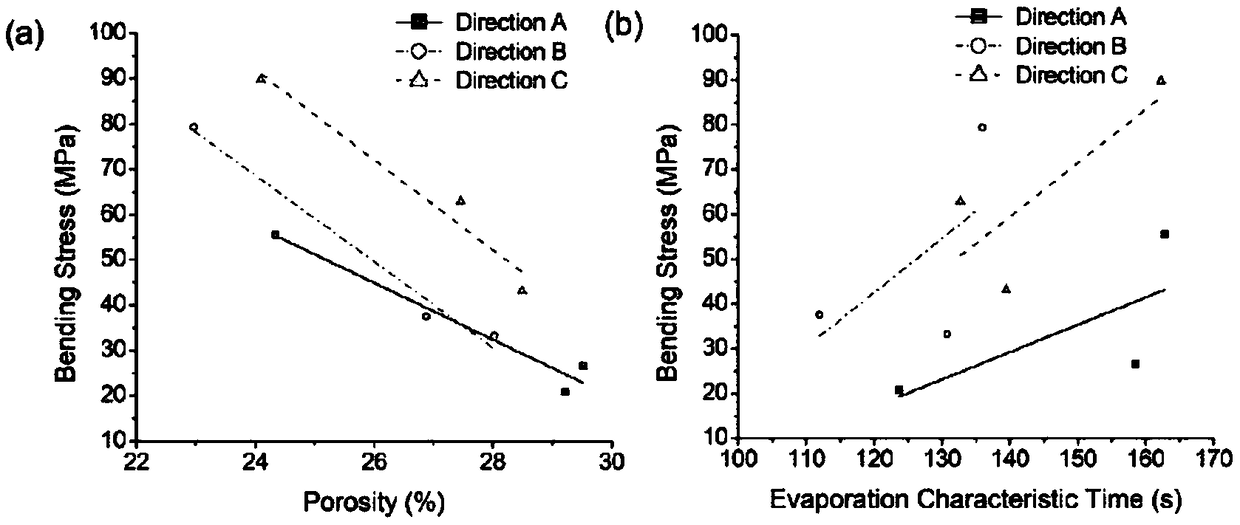

[0035] In order to quickly and non-destructively characterize the mechanical properties of composite materials, before conducting destructive mechanical experiments on the materials, the internal structure of the matrix that has the greatest impact on the strength of the materials should be studied first. A large part of the changes in the internal structure and properties of the matrix is caused by pores. Therefore, the study of the number and distribution of pores in the matrix can play a guiding role in evaluating the mechanical properties of materials. First, two indicators for evaluating the microscopic physical condition of the matrix pores of composite materials—porosity (Por%) and evaporative characteristic time (ECT) are proposed, which are used to describe the ratio of material pores to volume and the uniform distribution of material pores in volume respectively Condition. Proceed as follows:

[0036] 1. Use this kind of matrix and fiber material to prepare multip...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com