Fine-particle sediment underwater repose angle measuring device and measuring method thereof

A measuring device and technology for sediment water, which are applied in the directions of measuring device, angle/taper measurement, flow characteristics, etc., can solve the problems of cumbersome and rough steps of the natural silting method, destroying the slope shape of the sediment cone, affecting the accuracy, etc. Achieve the effect of improving measurement accuracy and reproducibility, smooth cone forming process and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with the accompanying drawings.

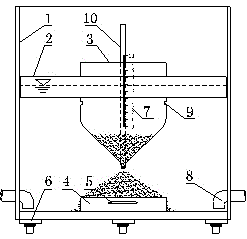

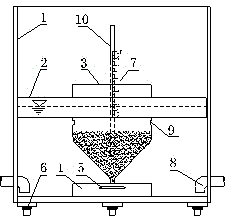

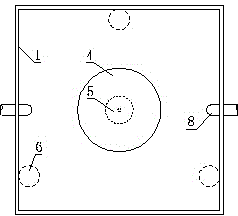

[0024] like Figure 1 to Figure 4 As shown, a kind of fine particle silt underwater angle of repose measuring device described in the present invention comprises a glass water tank 1, a floating plate 2, a funnel 3, a transparent test round table 4 and a plastic rod 10; the four sides of the glass water tank 1 A scale 7 is engraved upward at the same height of the wall; the floating plate 2 is placed in the glass water tank 1, and a hole is opened in the middle for fixing the funnel 3, and the floating plate 2 and the funnel 3 form a whole; the floating plate 2 It is made of hard floating material, and the width of the gap between its edge and the inner wall of the glass water tank 1 is 1 mm so as to float up and down; two flat pressure holes 8 are symmetrically arranged on the side wall of the funnel 3 under the floating plate 2, so that the inside and outside of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com