Lithium ion battery and formation method thereof

A technology of lithium ion battery and chemical formation method, which is applied in the field of lithium ion battery and its chemical formation, can solve the problems of low battery capacity and inability to meet high specific energy batteries, affecting the long-term cycle stability of batteries, destroying the stability of electrode structure, etc., so as to improve the cycle Performance and energy density, inhibition of side reactions with pole pieces, inhibition of oxygen escape

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

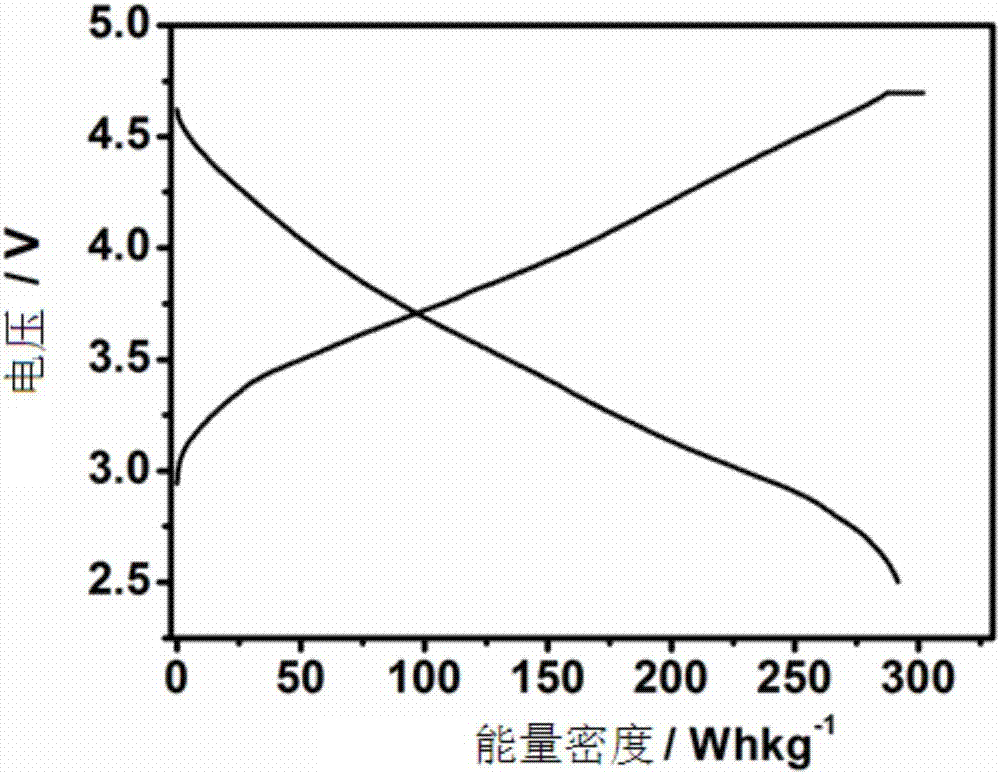

[0044] In this embodiment, the cathode active material adopts lithium-rich manganese-based positive electrode material (Li 1.5 mn 0.75 Ni 0.25 o 2.5 ), the anode active material is prepared into a high-energy soft-packed laminated bare battery cell of about 30Ah with a silicon-carbon composite and a diaphragm, and then the bare battery cell is placed in the formed aluminum-plastic film, and then packaged, dried and injected liquid.

[0045] The battery after liquid injection is formed, and the formation temperature is 25°C. The specific formation process is as follows:

[0046] (1) After charging at a rate of 0.01C for 5 hours, then charge with a constant current at a rate of 0.02C until the voltage is 4.2V, and let it stand for 30 minutes; discharge at a rate of 0.03C until the voltage is 2.5V. Stand still for 30min;

[0047] (2) Carry out constant current charging at a rate of 0.04C until the voltage is 4.2V, and let it stand for 30 minutes; carry out constant current d...

Embodiment 2

[0054] In this embodiment, the cathode active material adopts lithium-rich manganese-based positive electrode material (Li 1.5 mn 0.75 Ni 0.25 o 2.5 ), the anode active material is made of a silicon carbon negative electrode and a separator to form a high-energy soft-packed laminated bare cell of about 30Ah, and then the bare cell is put into the formed aluminum-plastic film, and then packaged, dried and injected liquid.

[0055] The battery after liquid injection is formed, and the formation temperature is 25°C. The specific formation process is as follows:

[0056] (1) After charging at a rate of 0.01C for 10 hours, then charge with a constant current at a rate of 0.03C until the voltage is 4.2V, and let it stand for 30 minutes; discharge at a rate of 0.05C until the voltage is 2.2V. Stand still for 30min;

[0057] (2) Carry out constant current charging at a rate of 0.05C until the voltage is 4.3V, and let it stand for 30 minutes; carry out constant current discharge a...

Embodiment 3

[0062] Repeat the method of Example 1 to prepare a soft-package lithium-ion battery A3, the formation temperature is 25°C, but the difference from Example 1 is that the formation process of this example is as follows:

[0063] (1) After charging at a rate of 0.05C for 2 hours, then charge with a constant current at a rate of 0.05C until the voltage is 4.0V, and let it stand for 30 minutes; discharge at a rate of 0.2C until the voltage is 2.0V. Stand still for 30min;

[0064] (2) Carry out constant current charging at a rate of 0.1C until the voltage is 4.0V, and let it stand for 30 minutes; carry out constant current discharge at a rate of 0.5C until the voltage is 2.0V, and let it stand for 30 minutes;

[0065] (3) Carry out constant current charging at a rate of 0.2C until the voltage is 4.3V, and let it stand for 30 minutes; carry out constant current discharge at a rate of 0.5C until the voltage is 2.0V, and let it stand for 30 minutes;

[0066] (4) Carry out constant cur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com