Anion responsive Pickering emulsion as well as preparation method and application thereof

An anion-responsive technology, applied in the field of anion-responsive Pickering emulsion and its preparation, can solve the problems of inability to impart functionality to materials and inapplicability of temperature-sensitive materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] Example 1 An anion responsive Pickering emulsion (Cl - base)

[0038] The preparation method is as follows:

[0039] 1) Synthesis of hydrolyzed styrene-maleic anhydride copolymer

[0040] Add 150ml of toluene to a 250ml three-necked flask, deoxidize with nitrogen for 30min, then add 5.0g (0.051mol) of maleic anhydride (also known as maleic anhydride), stir until dissolved, then add 5.8ml (0.051mol) of styrene , Azobisisobutyronitrile 0.01g, react at 85℃ for 2h. After the completion of the reaction, it was rinsed with toluene for 3 times, filtered and dried by suction to obtain a white powder as a styrene-maleic anhydride copolymer. Take 10 g of the prepared styrene maleic anhydride copolymer, dissolve it in 90 g of 3 wt% NaOH solution, and stir at 80° C. for 3 hours to obtain a transparent solution that is an aqueous solution (10 wt%) of the styrene-maleic anhydride copolymer after hydrolysis.

[0041] 2) Preparation of phenyl-imidazolinyl Janus hollow sphere

[0042] To 15 mL...

Embodiment 2

[0051] Example 2 Anion responsiveness

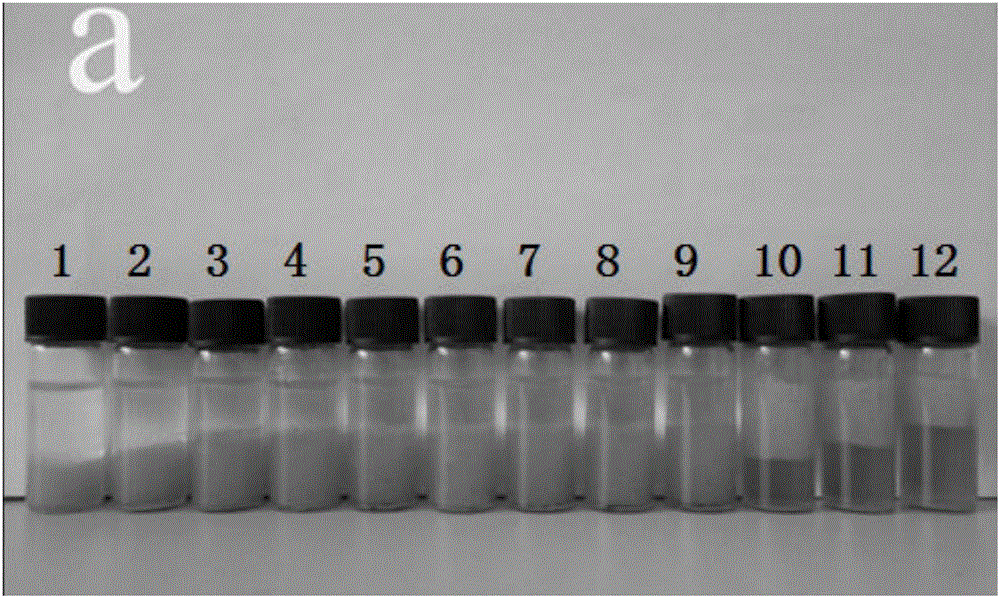

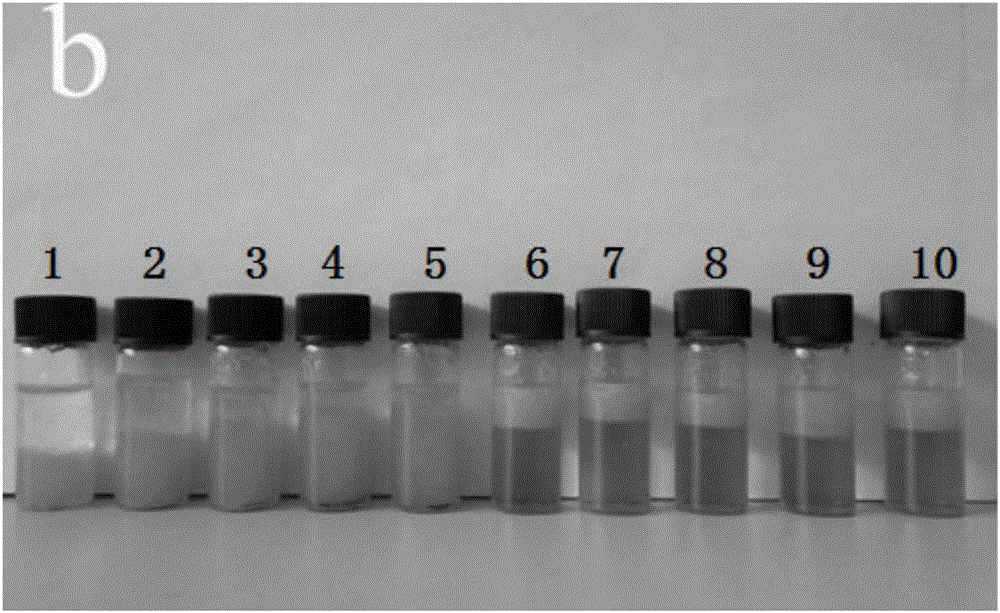

[0052] Take 50mg Cl from step 4) in Example 1 - The Janus nanosheet modified with ionic liquid was ultrasonically dispersed in 25ml of water, and 1mmol of phosphomolybdic acid was added and stirred at room temperature for 2h. The precipitate obtained by centrifugation was washed three times with water, separated by centrifugation and vacuum-dried for 12 hours to obtain a white powder that is a phosphomolybdic acid-based ionic liquid functionalized Janus nanosheet. Take 21 aliquots, each is to ultrasonically disperse 2mg phosphomolybdic acid-based ionic liquid Janus nanosheets in water phase or toluene (total volume is 2ml), and adjust different oil and water ratios to form emulsions. The specific ratio relationship As shown in table 2. After the emulsion is left for 24 hours, the image acquisition results are as follows Figure 2a with Figure 2b Shown.

[0053] Table 1 Types of emulsions formed under different oil-water ratios (Cl - (Janus...

Embodiment 3B

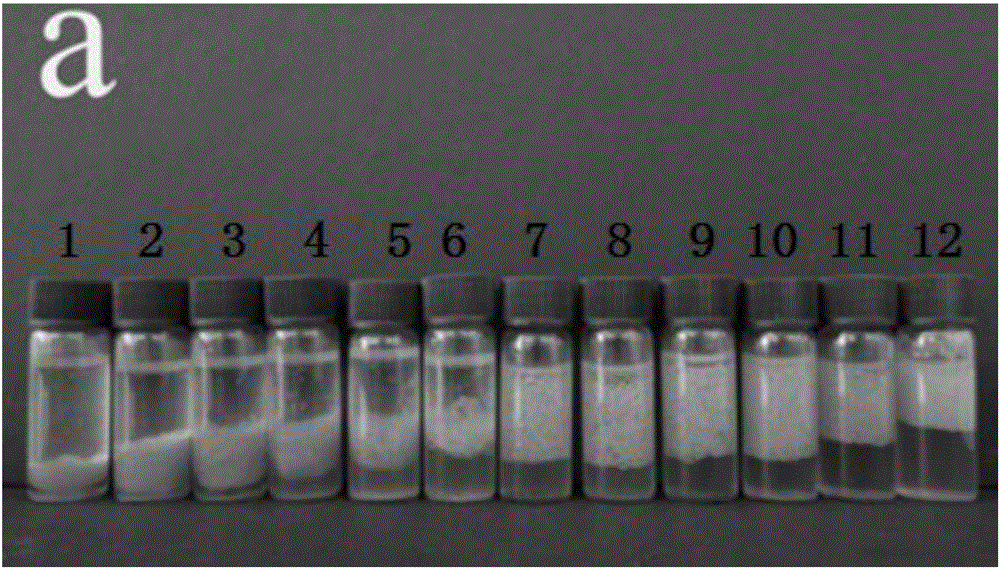

[0065] Example 3Br - , I - , NO 3 - Or HSO 4 - -Based ionic liquid functionalized Janus nanosheet stable anion responsive emulsion

[0066] Take 50mg Cl prepared in step 4) of Example 1 - The Janus nanosheets modified with ionic liquid were dispersed in 25ml water by ultrasonic, and 1mmol NaBr was added to prepare Br - Janus nanosheet modified with ionic liquid; Br - The Janus nanosheets modified with ionic liquids are ultrasonically dispersed in the water or oil phase, and the ratio of oil to water is adjusted to form an anion-responsive Pickering emulsion.

[0067] Take 50mg Cl prepared in step 4) of Example 1 - The Janus nanosheet modified with ionic liquid was dispersed in 25ml of water by ultrasonic, and 1mmol NaI was added to prepare I - Janus nanosheets modified by ionic liquid; I - The Janus nanosheets modified with ionic liquids are ultrasonically dispersed in the water or oil phase, and the ratio of oil to water is adjusted to form an anion-responsive Pickering emulsion.

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com