Patents

Literature

36 results about "Linearity testing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Linearity testing assesses the ability of the dose calibrator to indicate the correct activity over the range of use of the calibrator.

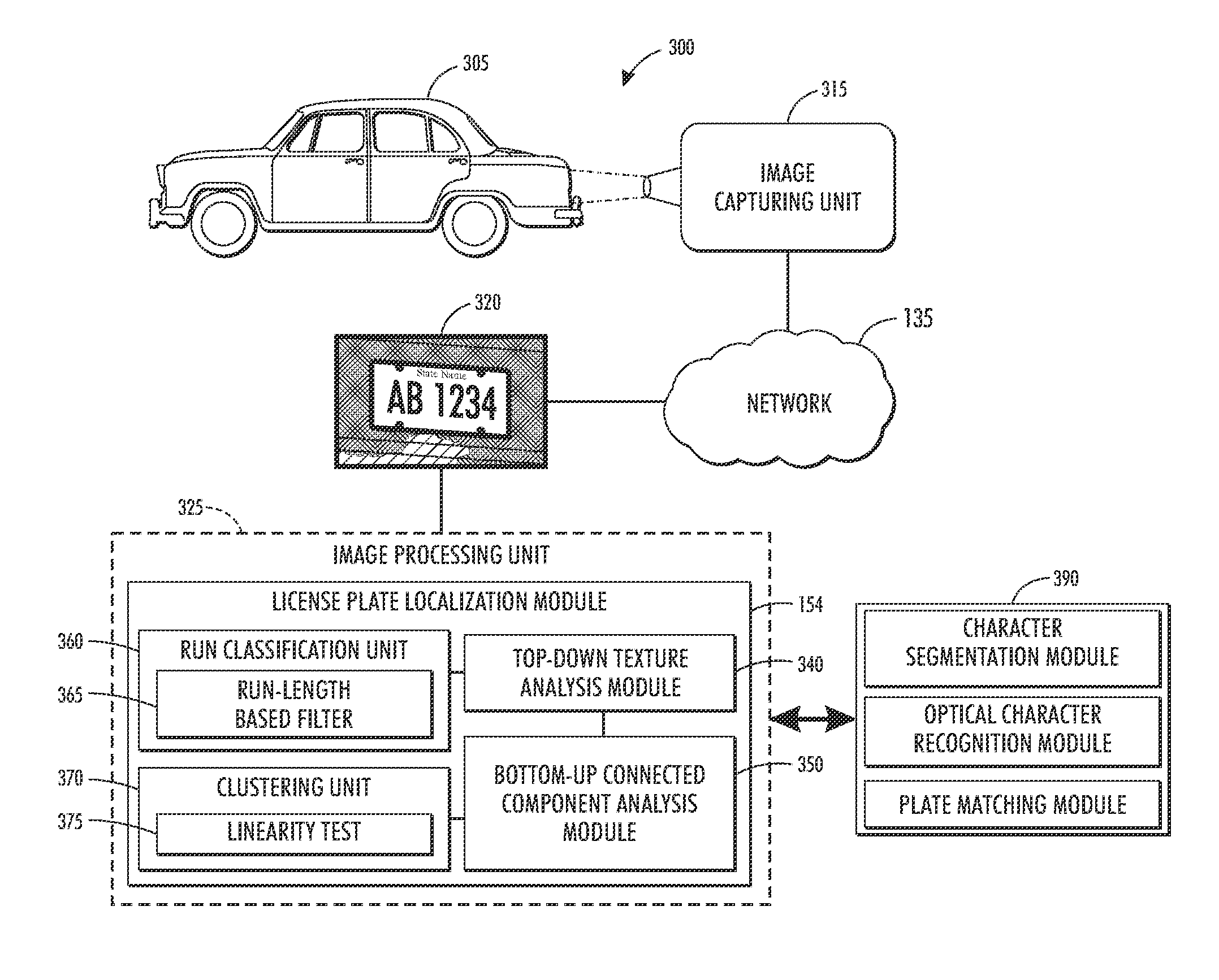

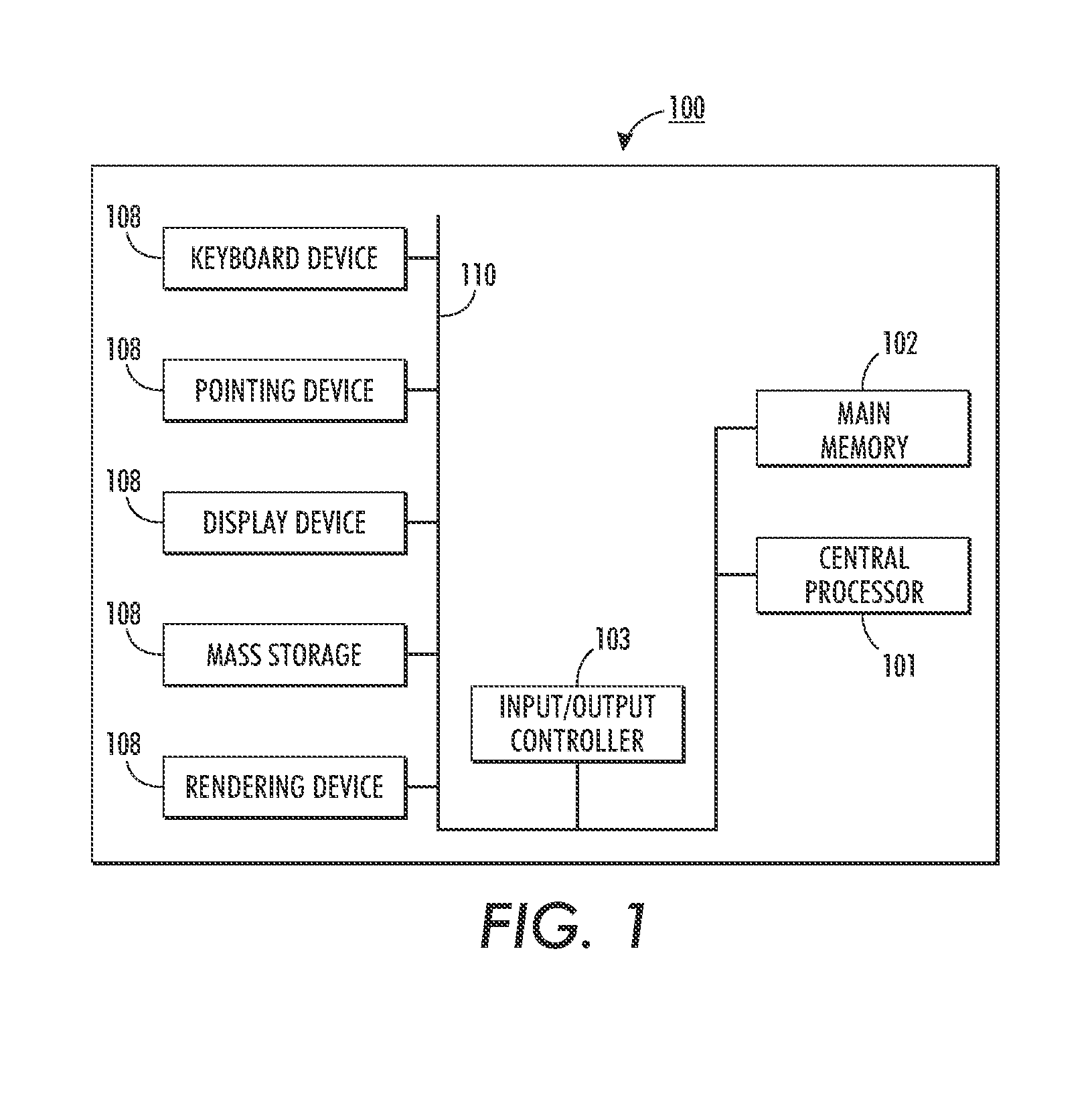

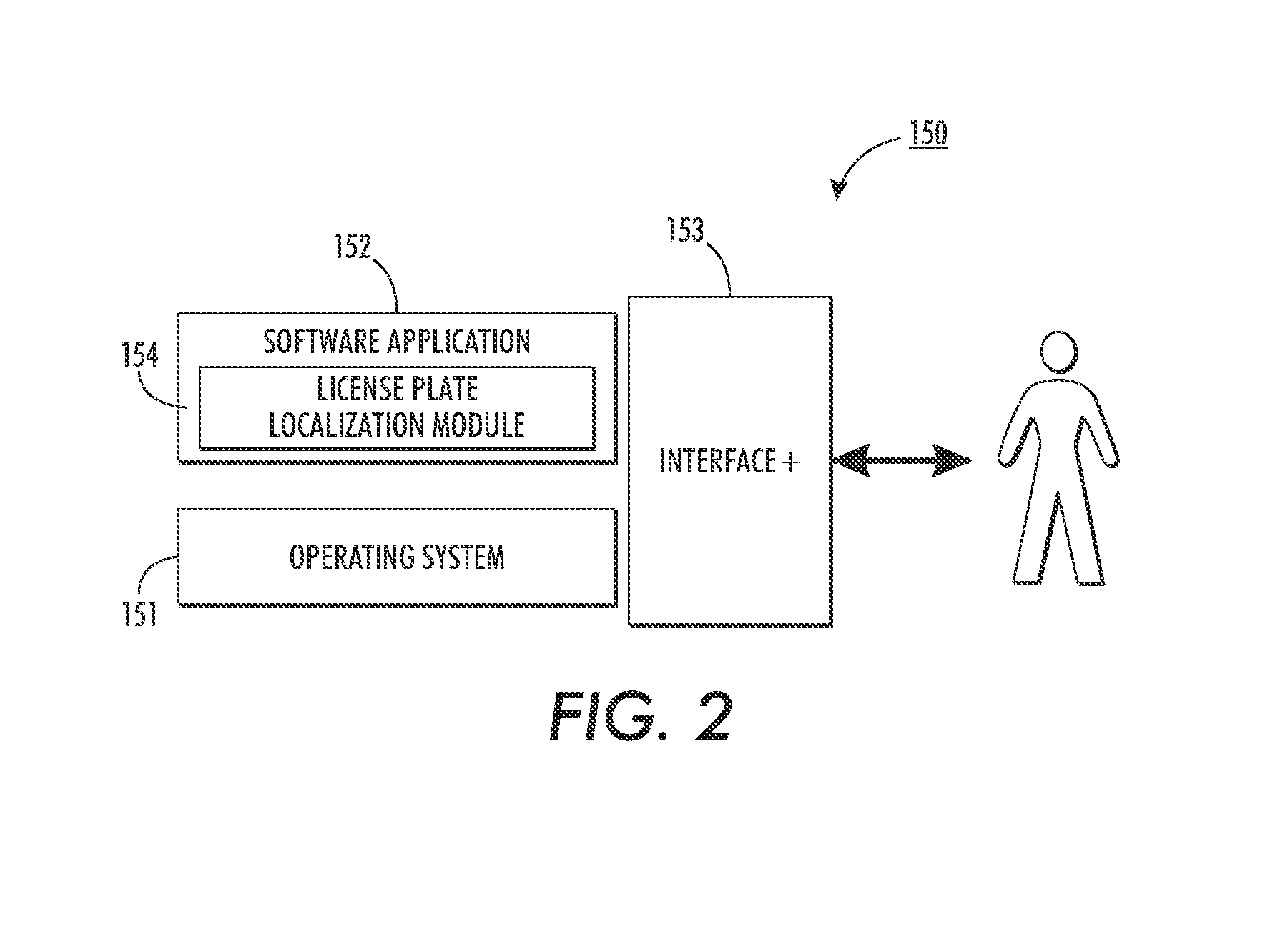

Method and system for identifying a license plate

ActiveUS8792682B2Accurately locating a license plateReduce effortCharacter recognitionPattern recognitionLinearity testing

A license plate localization method and system based on a combination of a top-down texture analysis and a bottom-up connected component. An image with respect to a vehicle captured by an image capturing unit can be processed in order to locate and binarize a busy area. A black run with respect to the binarized image can be analyzed and classified and one or more objects (connected components) can be generated based on the black run classification. The objects can be further classified in accordance with their size utilizing a run-length based filter to filter out a non-text object. The leftover objects can then be spatially clustered and the uniformity and linearity of the clustered objects can be examined based on a linearity test. The clustered objects can be rejected if they fail the linearity test and the detected objects can further be matched with a plate edge characteristic in order to locate a license plate.

Owner:CONDUENT BUSINESS SERVICES LLC

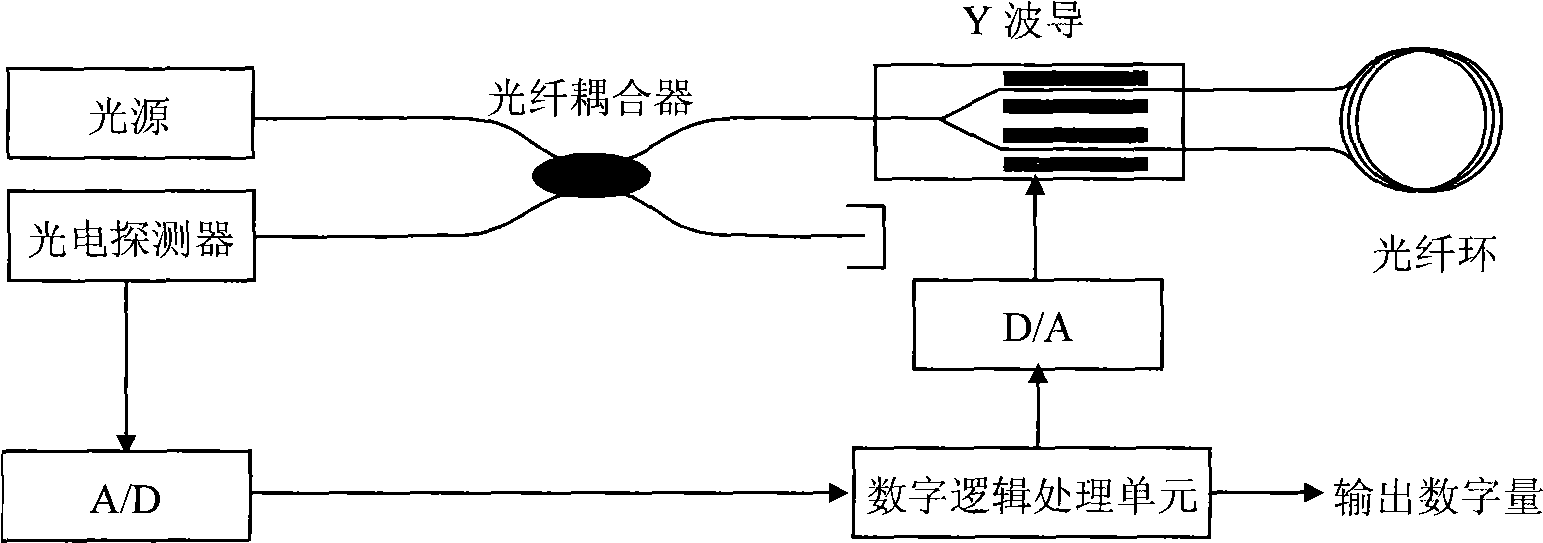

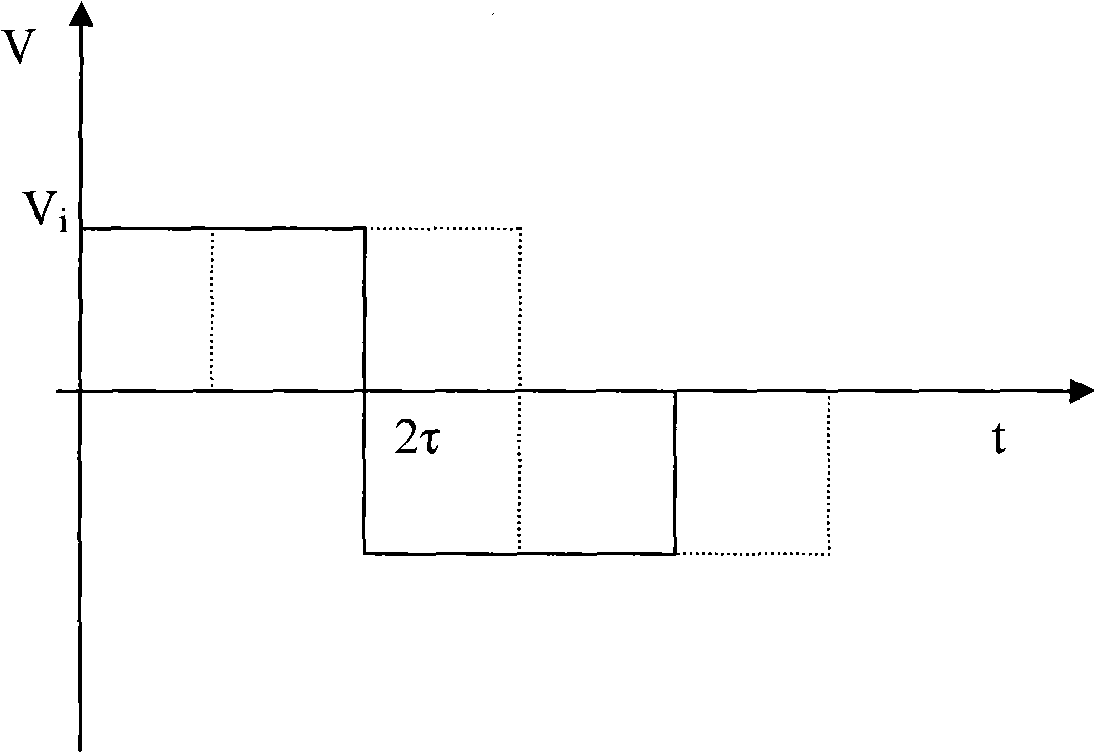

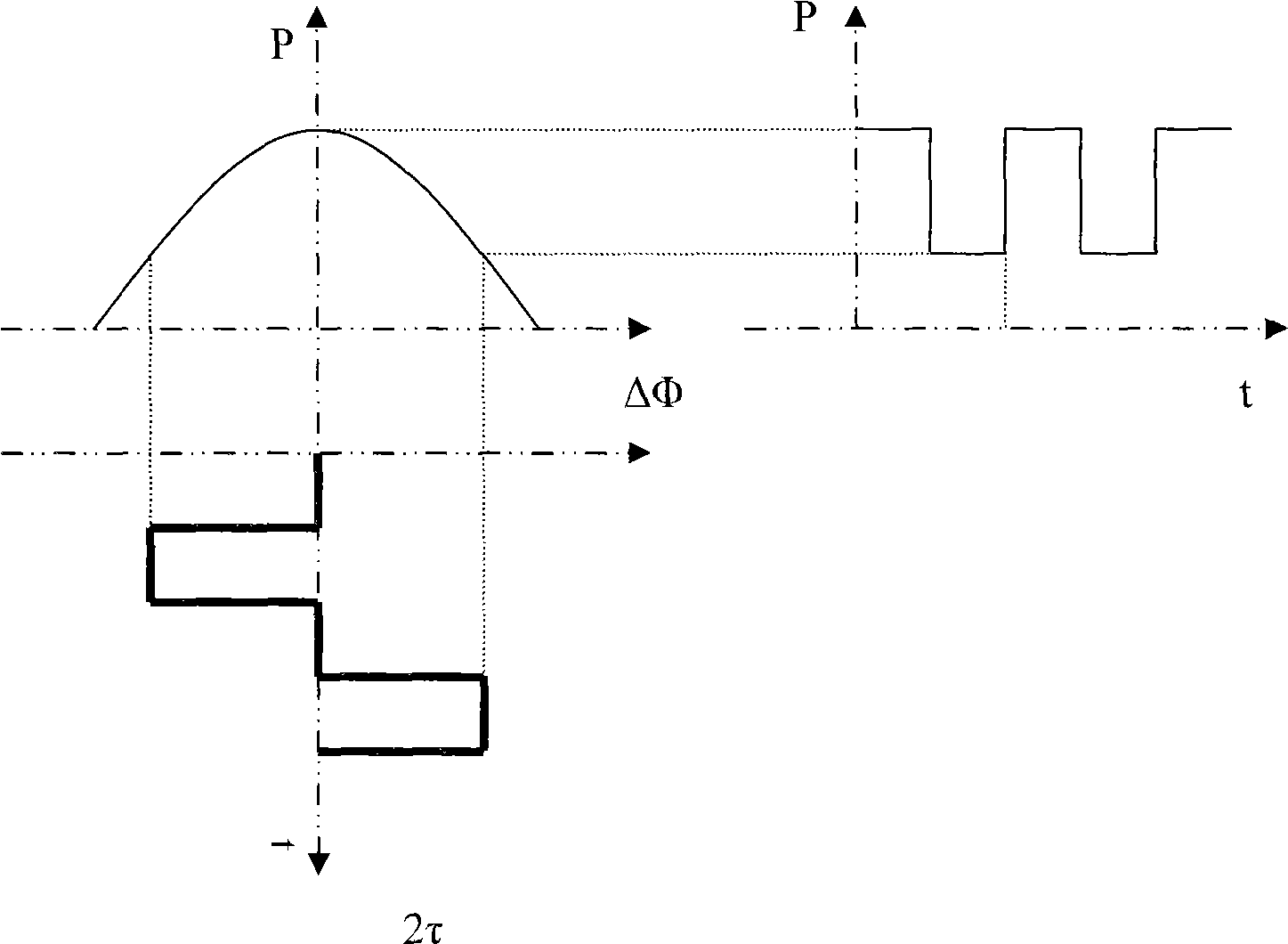

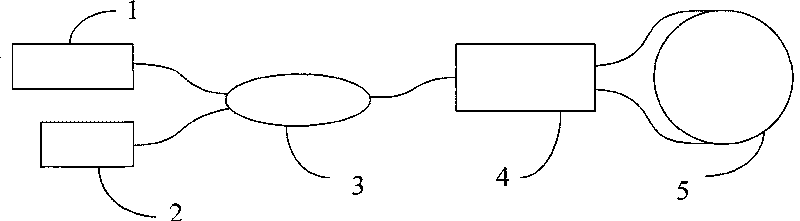

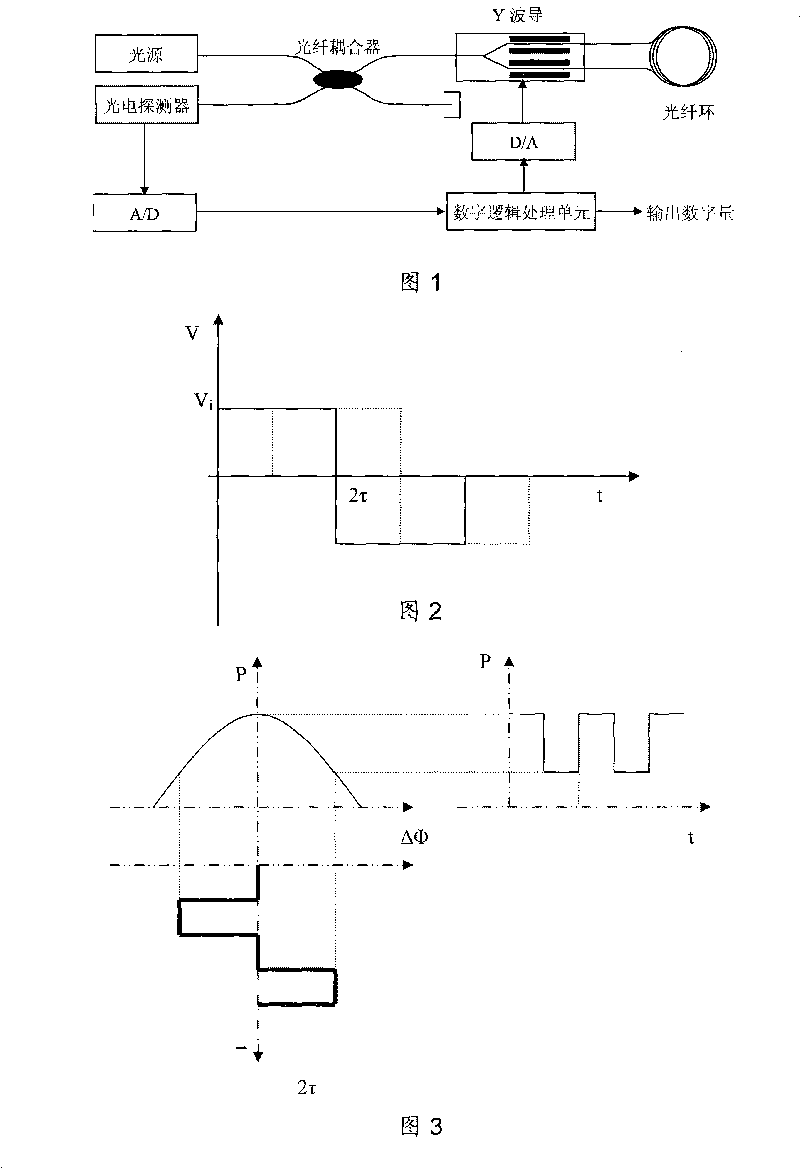

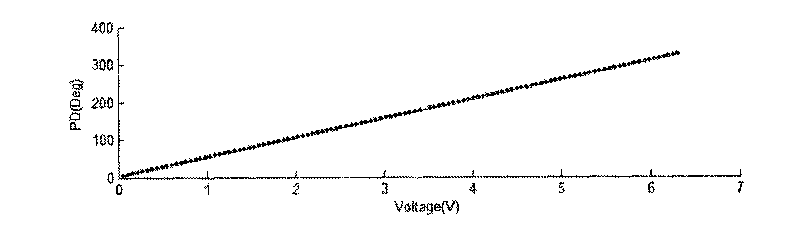

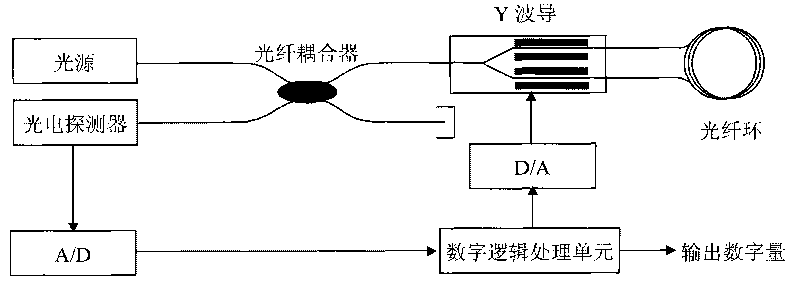

Y waveguide phase modulation linearity test method for optic fiber gyroscope

The invention discloses a gamma waveguide phase modulation linearity testing method used for optical fiber gyro, which comprises: composing a testing system by a light source, a optical fiber coupler, a tested gamma waveguide, a optical fiber ring, a photo detector, an A / D converter, an D / A converter and a digital logic processing unit; the digital logic processing unit sending out line form changeable digital square wave with duty ratio of 1:1 to modulate the tested gamma waveguide; and fitting the phase difference of the tested gamma waveguide by least squares method to achieve the modulated linearity. By adopting the square wave with duty ratio of 1:1 with half of the optical fiber ring eigenfrequency to modulate the tested gamma waveguide, increasing the amplitude linearity, and fitting the tested gamma waveguide by least squares method, the invention increases the precision of optical fiber gyro scale factor; meanwhile, by adopting the high accurate D / A converter and A / D converter to modulate and demodulate, the invention increases the testing precision while the phase difference of the tested gamma waveguide is at pi or 2pi.

Owner:BEIJING AEROSPACE TIMES OPTICAL ELECTRONICS TECH

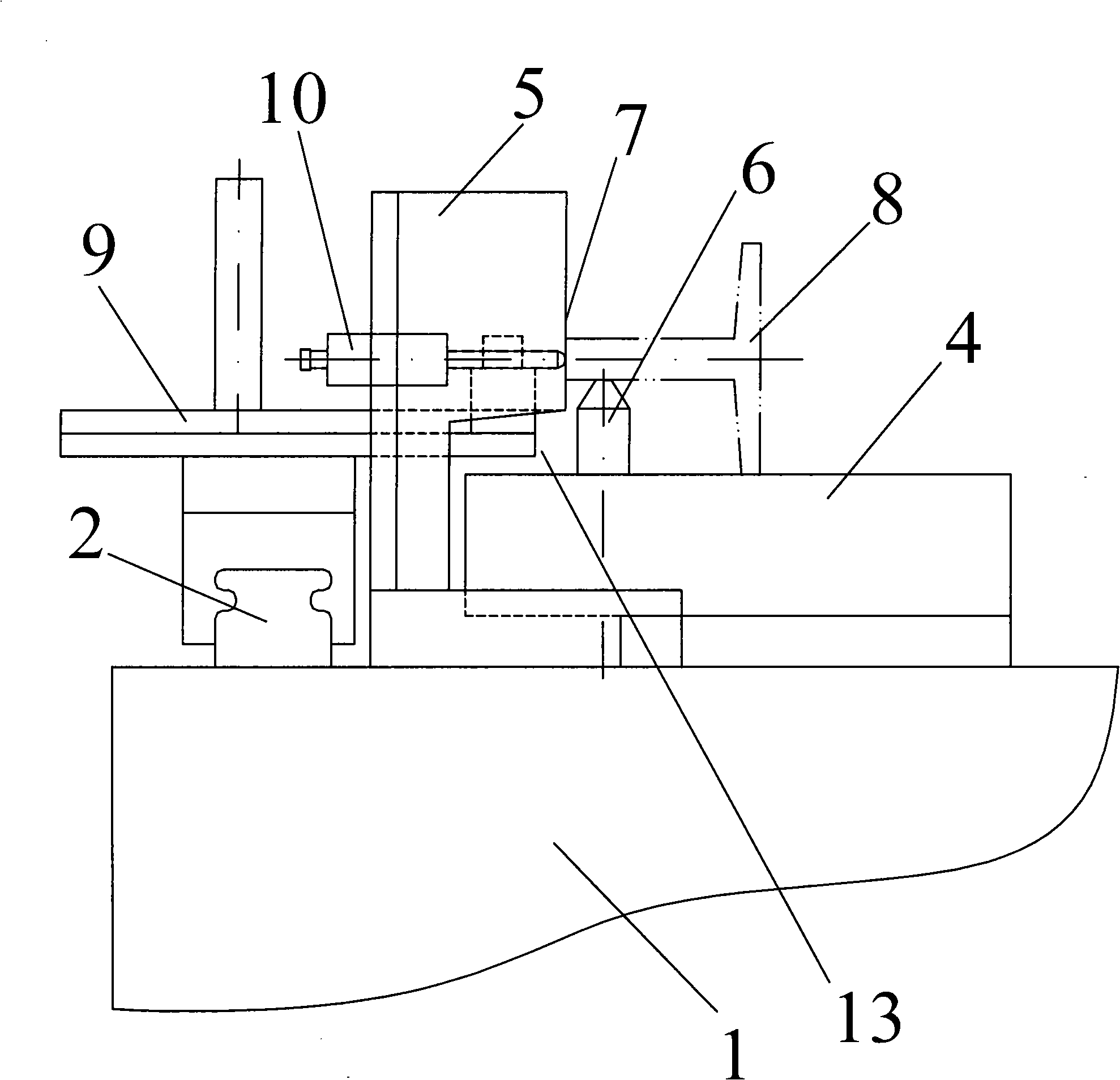

Slide rail linearity testing apparatus

ActiveCN101319869AImprove detection accuracyEasy to operateAngles/taper measurementsLinearity testingIndustrial engineering

Owner:苏州塞维拉上吴电梯轨道系统有限公司

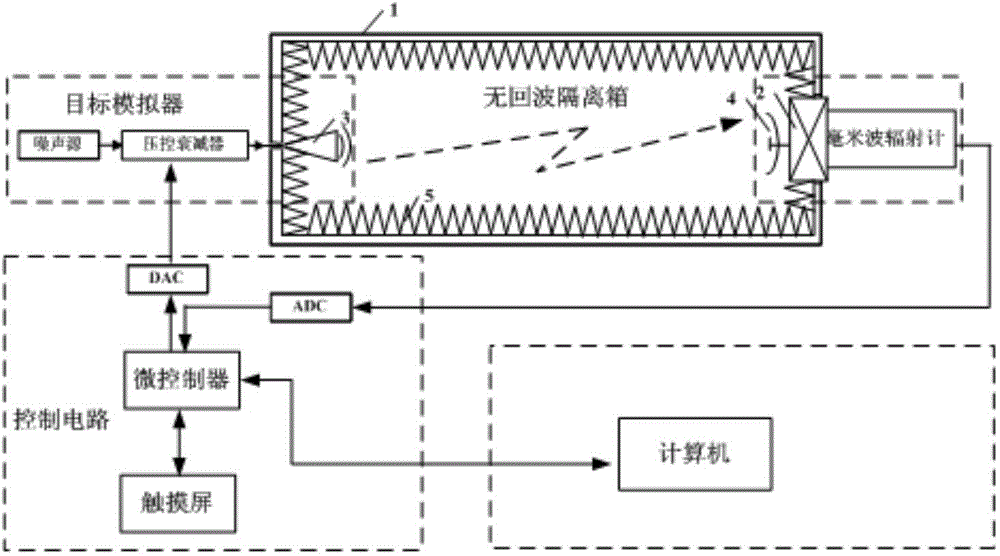

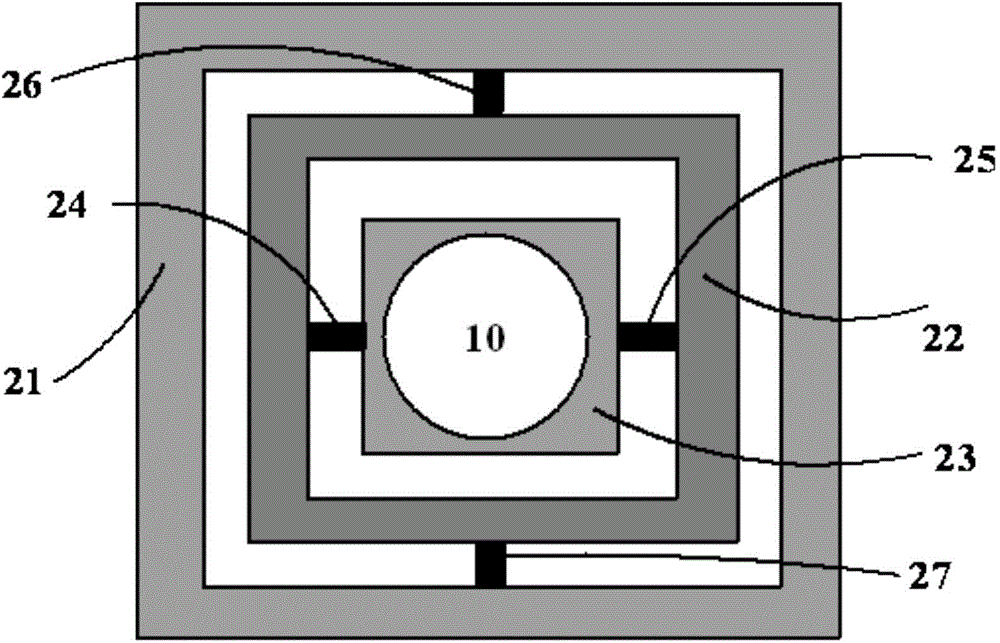

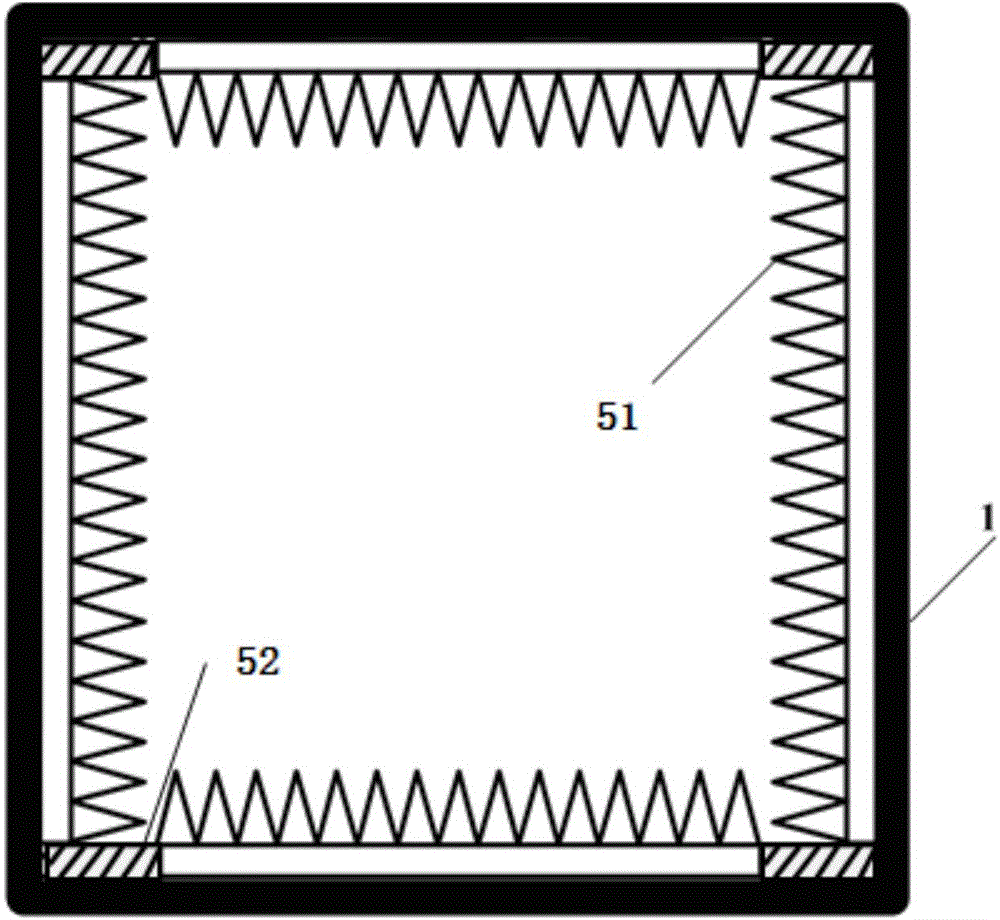

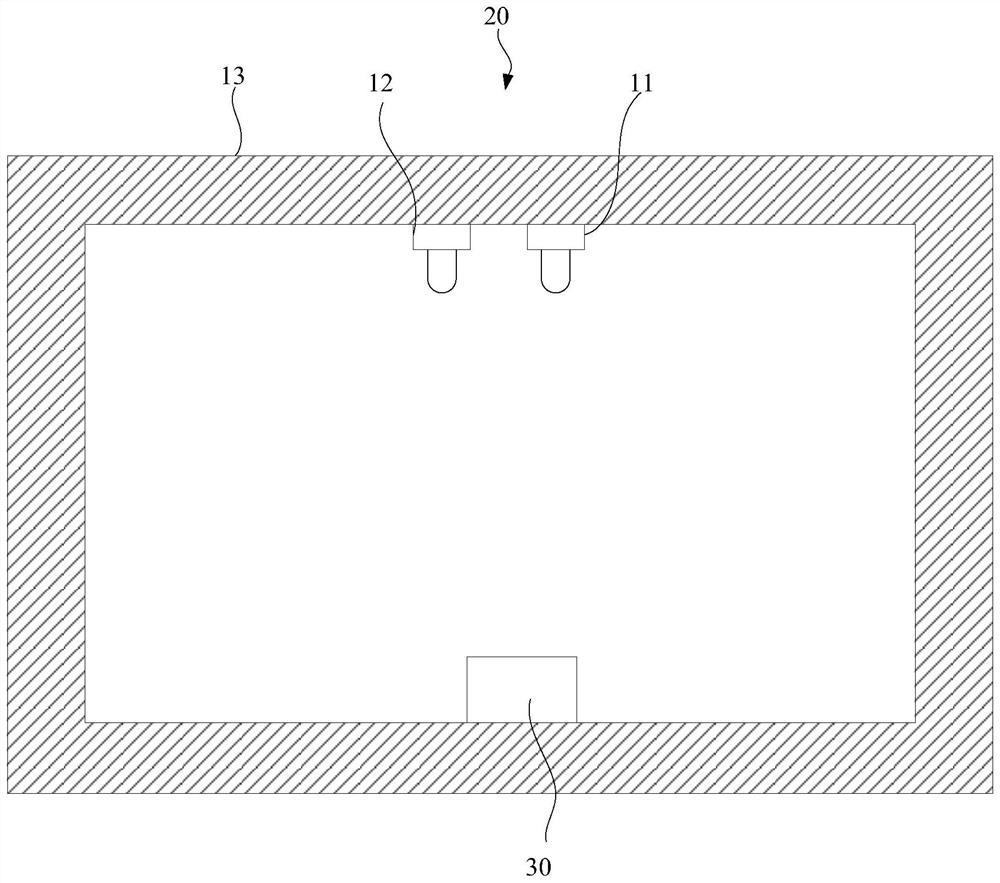

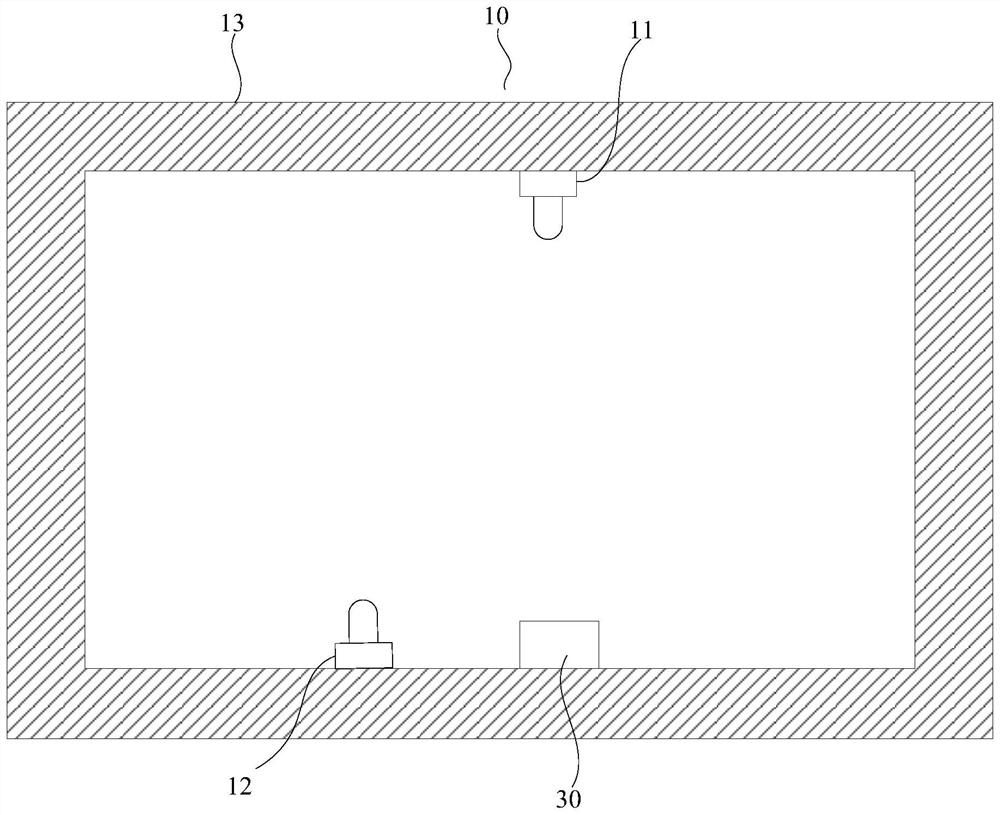

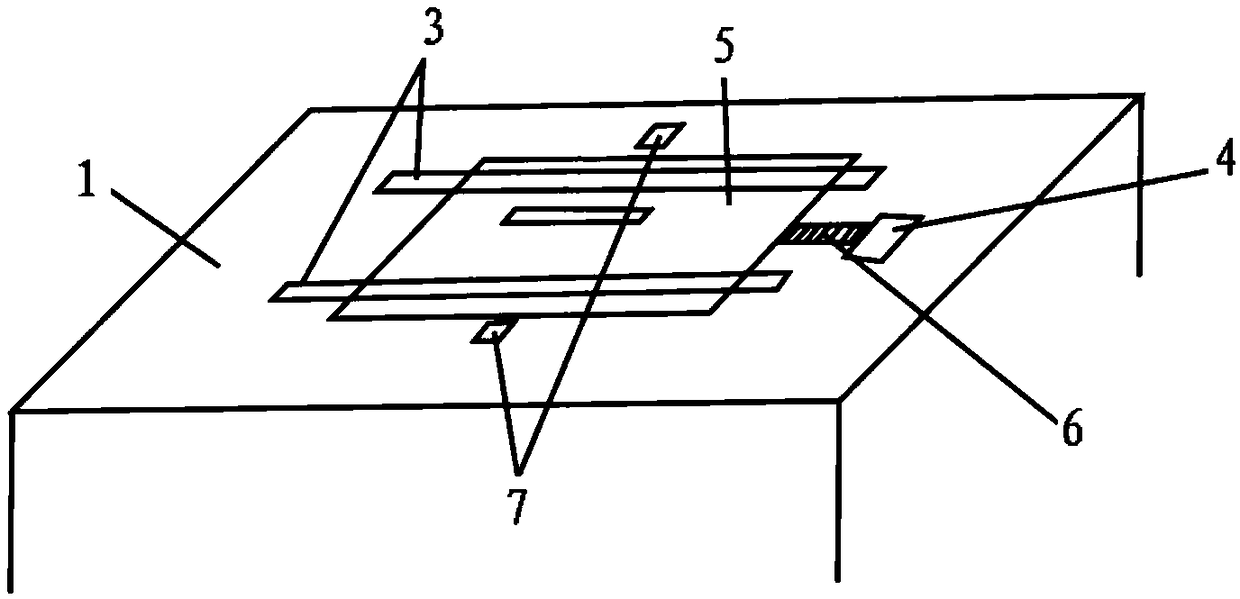

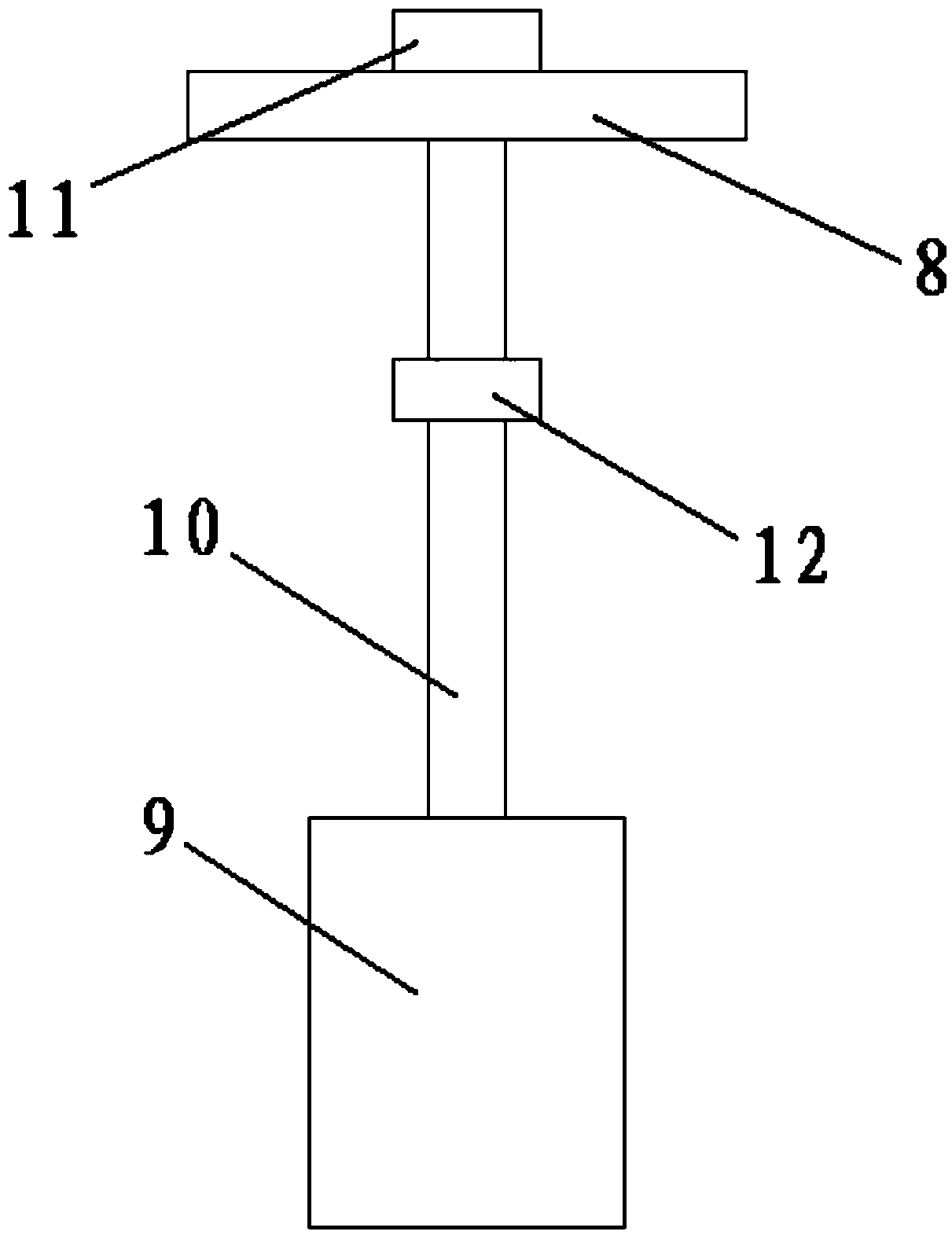

Millimeter wave radiometer semi-physical simulation system, signal generating method and linearity testing method

ActiveCN104635218AGood electromagnetic shieldingImprove simulation accuracyWave based measurement systemsLinearity testingRadiometer

The invention discloses a millimeter wave radiometer semi-physical simulation system, a signal generating method and a linearity testing method. The system comprises an echo-free isolation box, a target simulator, a millimeter wave radiometer, a control circuit and an upper computer. The signal generating method is used for controlling a voltage control attenuator of a target simulator by generating a certain control voltage, and the target simulator can generate a signal for use in the overall dynamic testing and static performance parameter testing of the millimeter wave radiometer. By adopting the millimeter wave radiometer semi-physical simulation system, a good testing environment is provided for the overall testing and signal simulation of a missile-borne millimeter wave alternating current radiometer, and a method is provided for the included angle measurement of a terminal-sensitive projectile millimeter wave alternating current radiometer. The millimeter wave radiometer semi-physical simulation system has the advantages of low cost, small size, convenience in use, high performance, high electromagnetic shielding performance, low external influence, and the like.

Owner:NANJING UNIV OF SCI & TECH

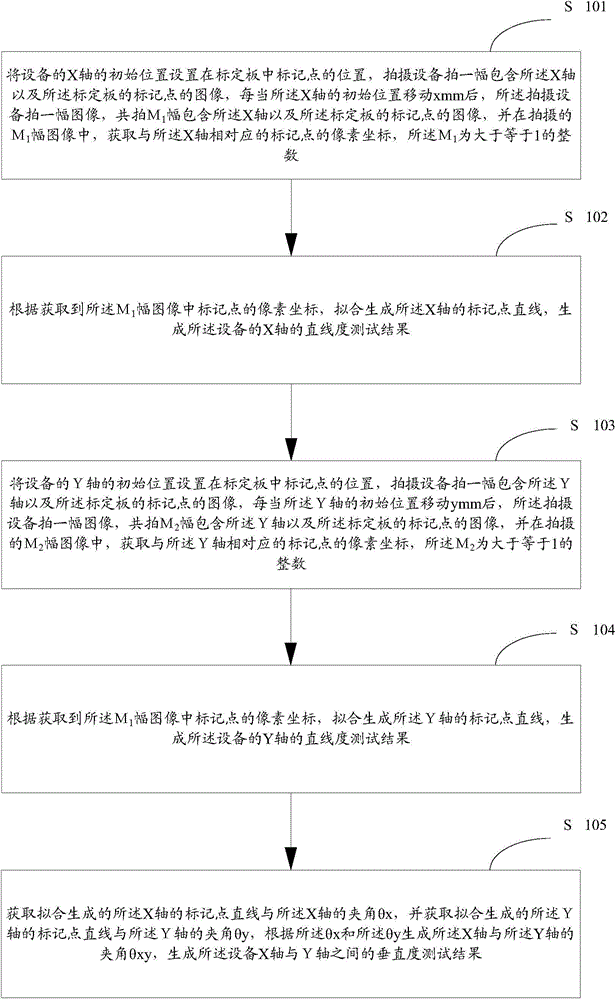

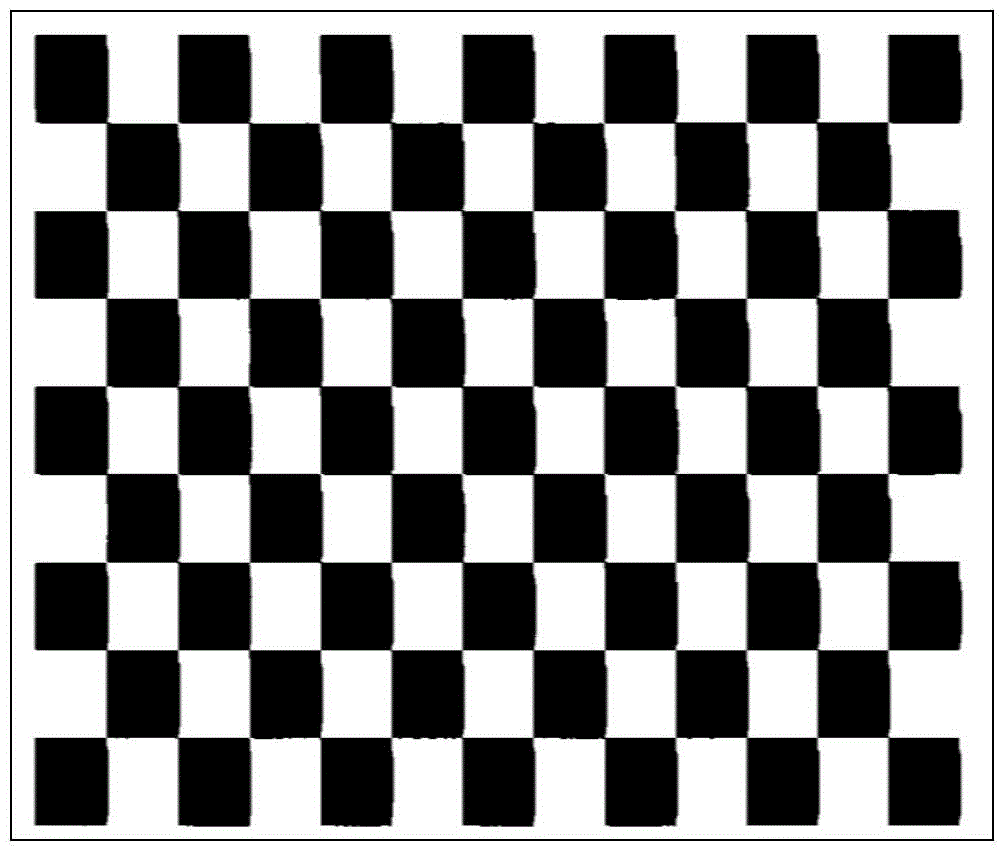

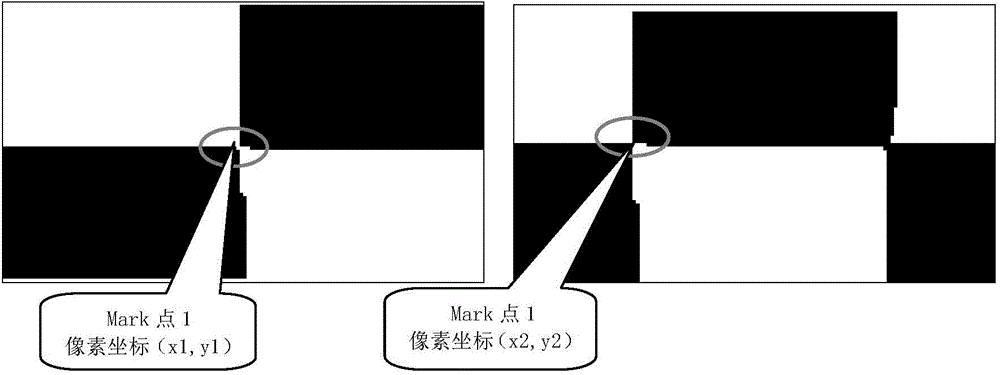

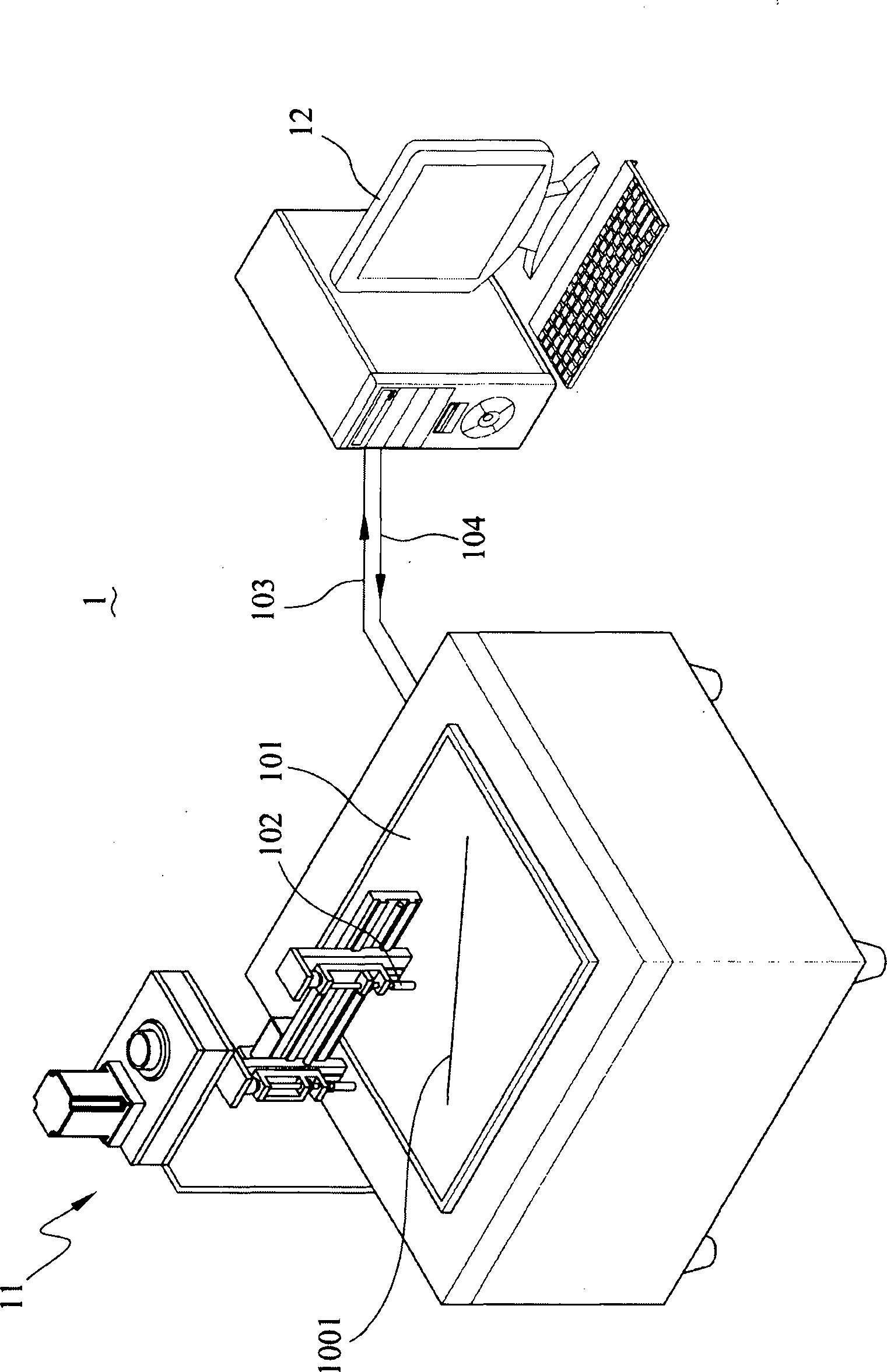

Method and device for detecting linearity and perpendicularity of equipment

InactiveCN104567749ASimplify the measurement stepsImprove detection efficiencyUsing optical meansLinearity testingComputer science

The invention is applied to the technical field of detection, and particularly relates to a method and device for detecting the linearity and perpendicularity of equipment. The method comprises the following steps of fitting and generating a mark point straight line of an X axis according to pixel coordinates of mark points in M1 acquired images, and generating a linearity testing result of the X axis of the equipment; fitting and generating a mark point straight line of a Y axis according to the pixel coordinates of the mark points in the M1 acquired images, and generating a linearity testing result of the Y axis of the equipment; generating an included angle Thetaxy between the X axis and the Y axis according to Thetax and Thetay, and generating a perpendicularity testing result of the X axis and the Y axis of the equipment. According to the method and the device, the existing problems of low equipment linearity and perpendicularity detection efficiency and high cost are solved, the application range of equipment linearity and perpendicularity detection is widened, and the equipment linearity and perpendicularity detection efficiency is improved.

Owner:HANS LASER TECH IND GRP CO LTD +1

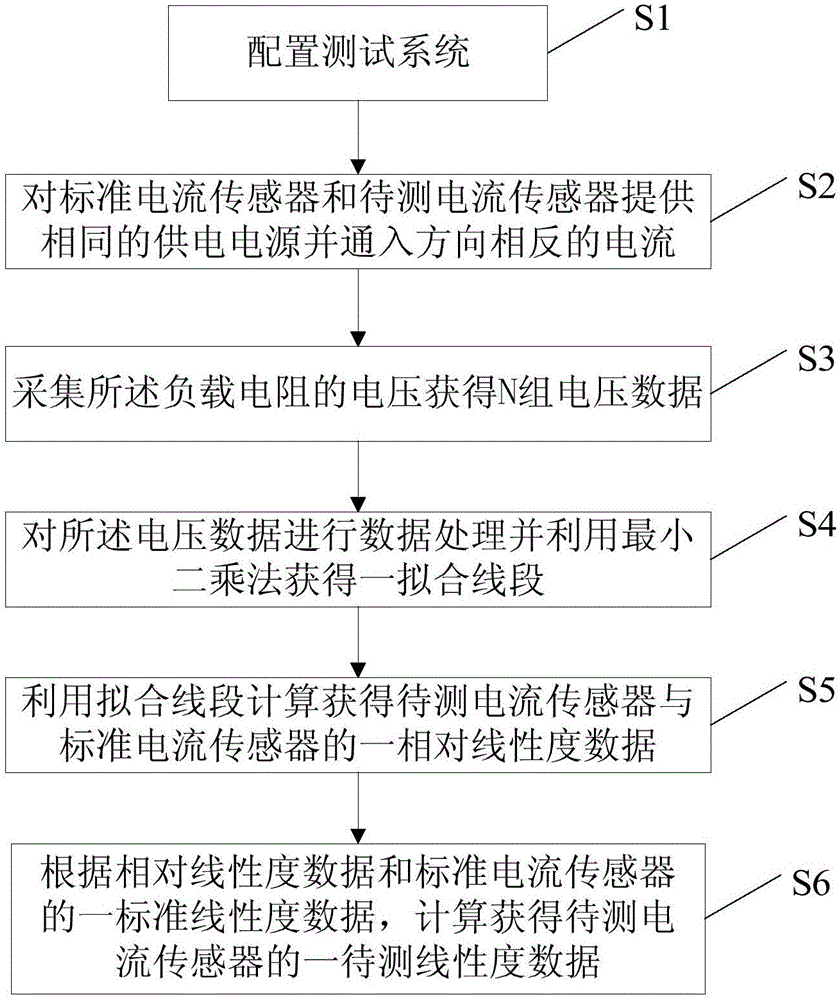

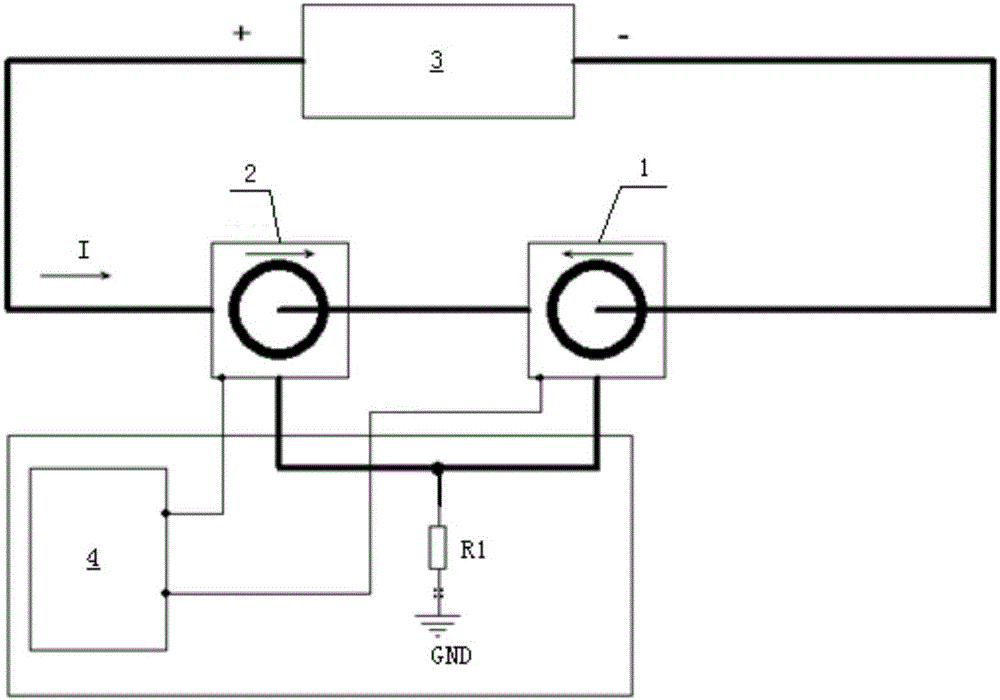

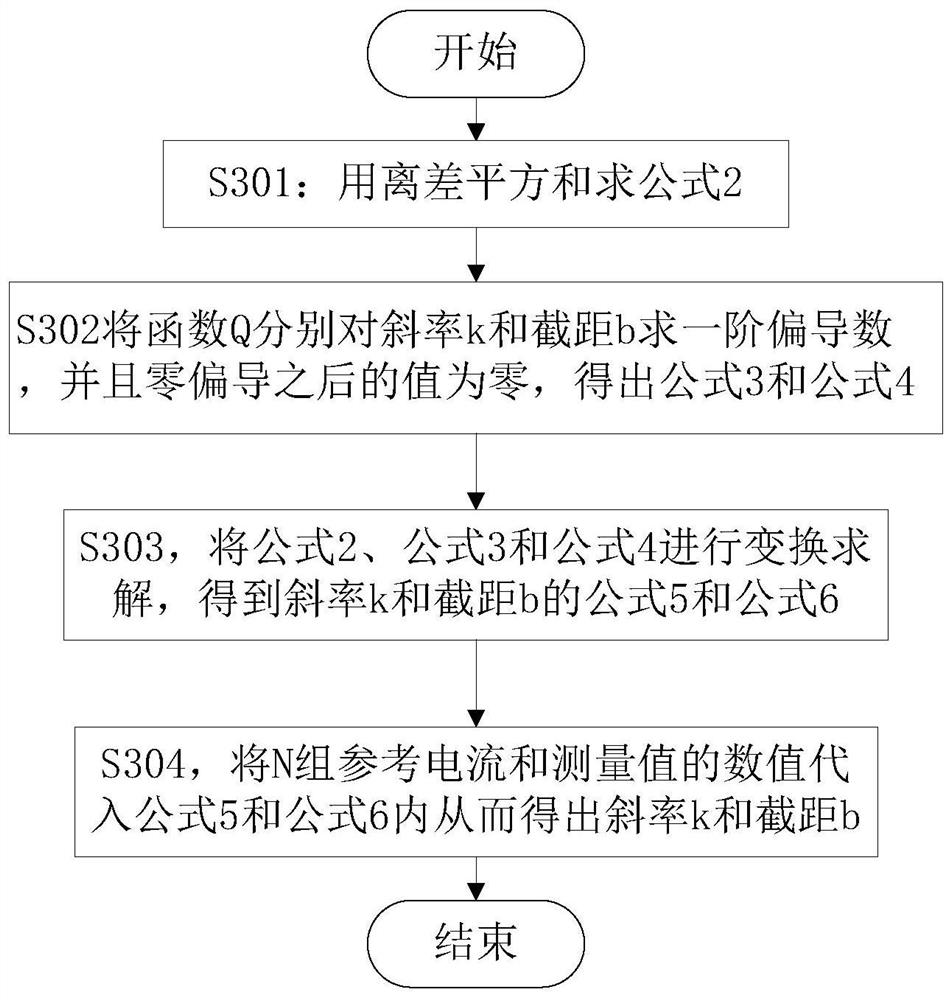

Linearity testing method for current sensor

ActiveCN106443543AEasy to testReduced Linearity RequirementsElectrical measurementsElectrical resistance and conductancePower flow

The invention provides a linearity testing method for a current sensor. The method comprises the steps that 1, a testing system is constructed; 2, a same power supply is provided for a standard current sensor and the to-be-tested current sensor, and currents with the opposite directions are introduced into the standard current sensor and the to-be-tested current sensor respectively; 3, the voltage of a load resistor is collected to obtain N groups of voltage data; 4, data processing is conducted on the voltage data, and a fitting line segment is obtained through a least square method; 5, relative linearity data of the to-be-tested current sensor and the standard current sensor is obtained through calculation; 6, the to-be-tested linearity data of the to-be-tested current sensor is obtained through calculation. According to the linearity testing method for the current sensor, the linearity requirement on a direct-current source is reduced in the testing process, resistance value errors and temperature errors of the load resistor are avoided, the requirements on the precision and the linearity of experimental equipment are greatly reduced, and the advantages of being high in precision and convenient to operate are achieved.

Owner:SHANGHAI INST OF APPLIED PHYSICS - CHINESE ACAD OF SCI +1

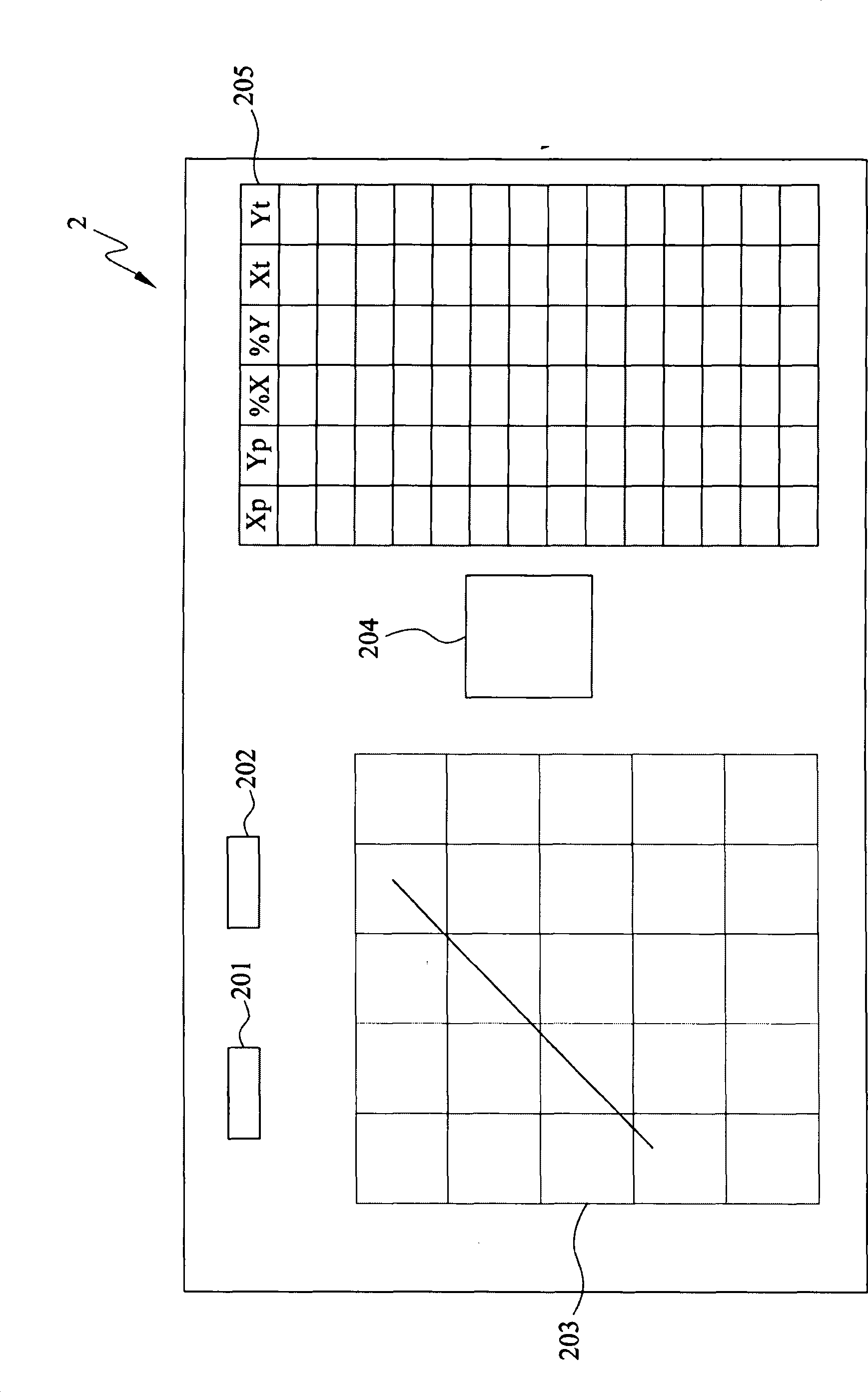

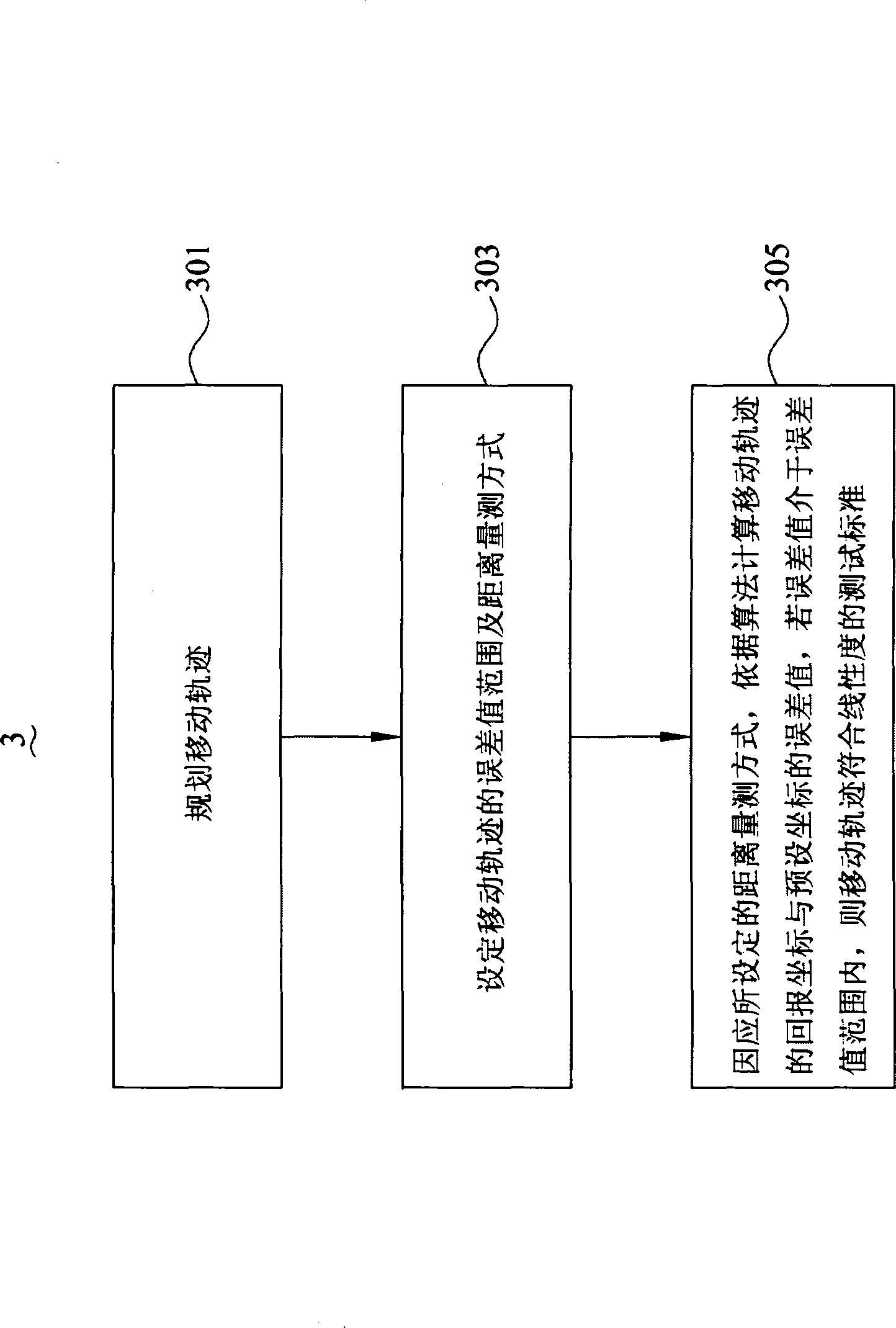

Linearity testing device and method

InactiveCN103383600AElectrical testingInput/output processes for data processingLinearity testingControl signal

The invention discloses a linearity testing device which comprises a controlled module and a control module, wherein the controlled module receives a control signal, reads a feedback coordinate of a mobile track produced on an object to-be-tested according to a preset coordinate, and generates a feedback signal according to the feedback coordinate; the control module receives the feedback signal, and compares the feedback signal with the control signal by the Pythagorean theorem or the normal theorem algorithm to calculate the error value between the feedback coordinate and the preset coordinate, so as to test the mobile track linearity. The invention further discloses a linearity testing method which comprises the following steps: planning the mobile track, and / or setting the error value range and the distance measuring way of the mobile track, and / or calculating the error value between the feedback coordinate of the mobile track and the preset coordinate according to the Pythagorean theorem or the normal theorem algorithm on the basis of the set distance measurement way, and if the error value is within the error value range, the mobile track meets the linearity testing standard.

Owner:杨志沅

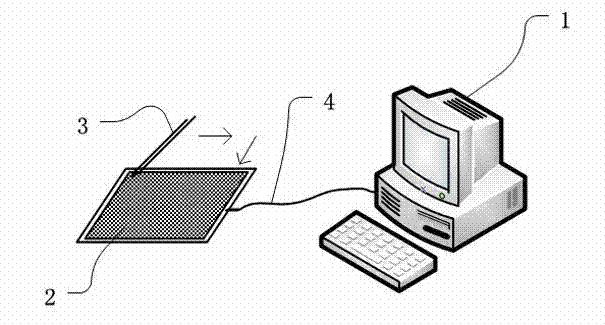

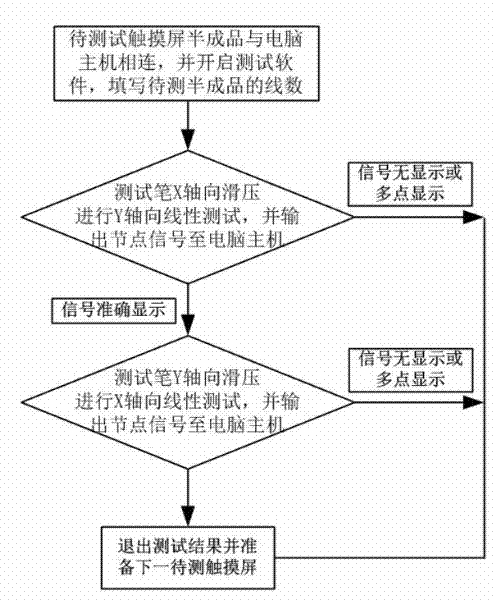

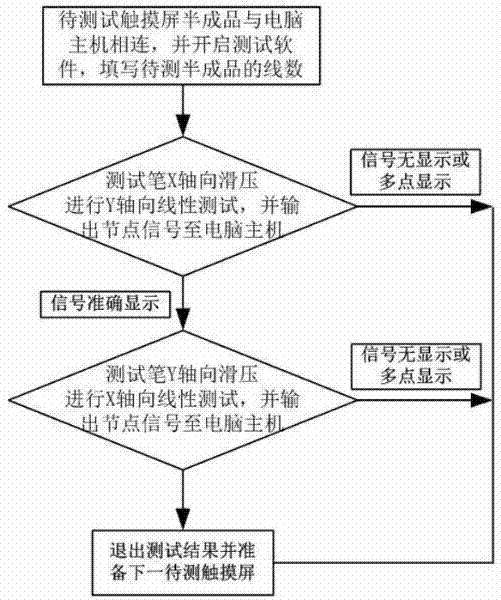

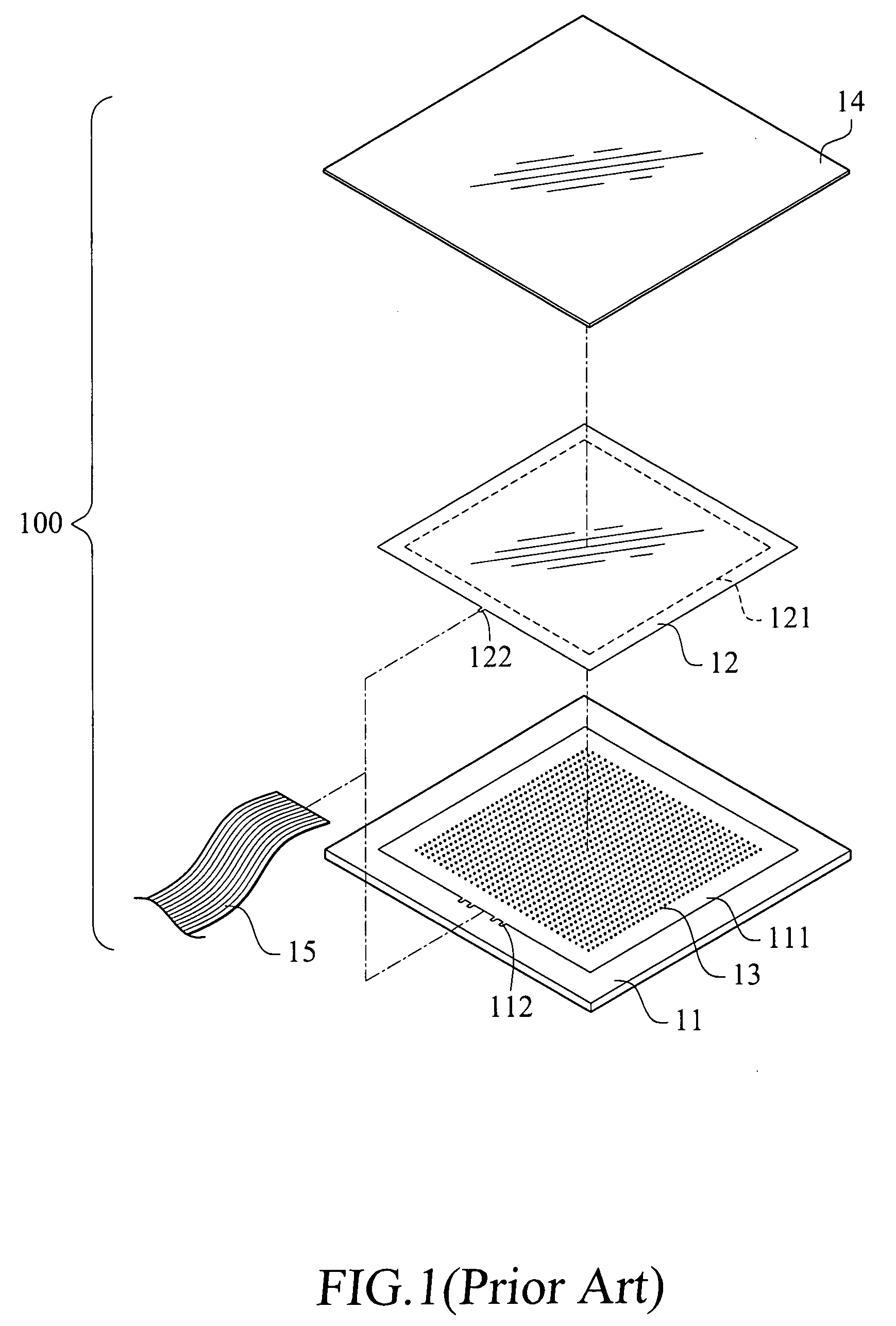

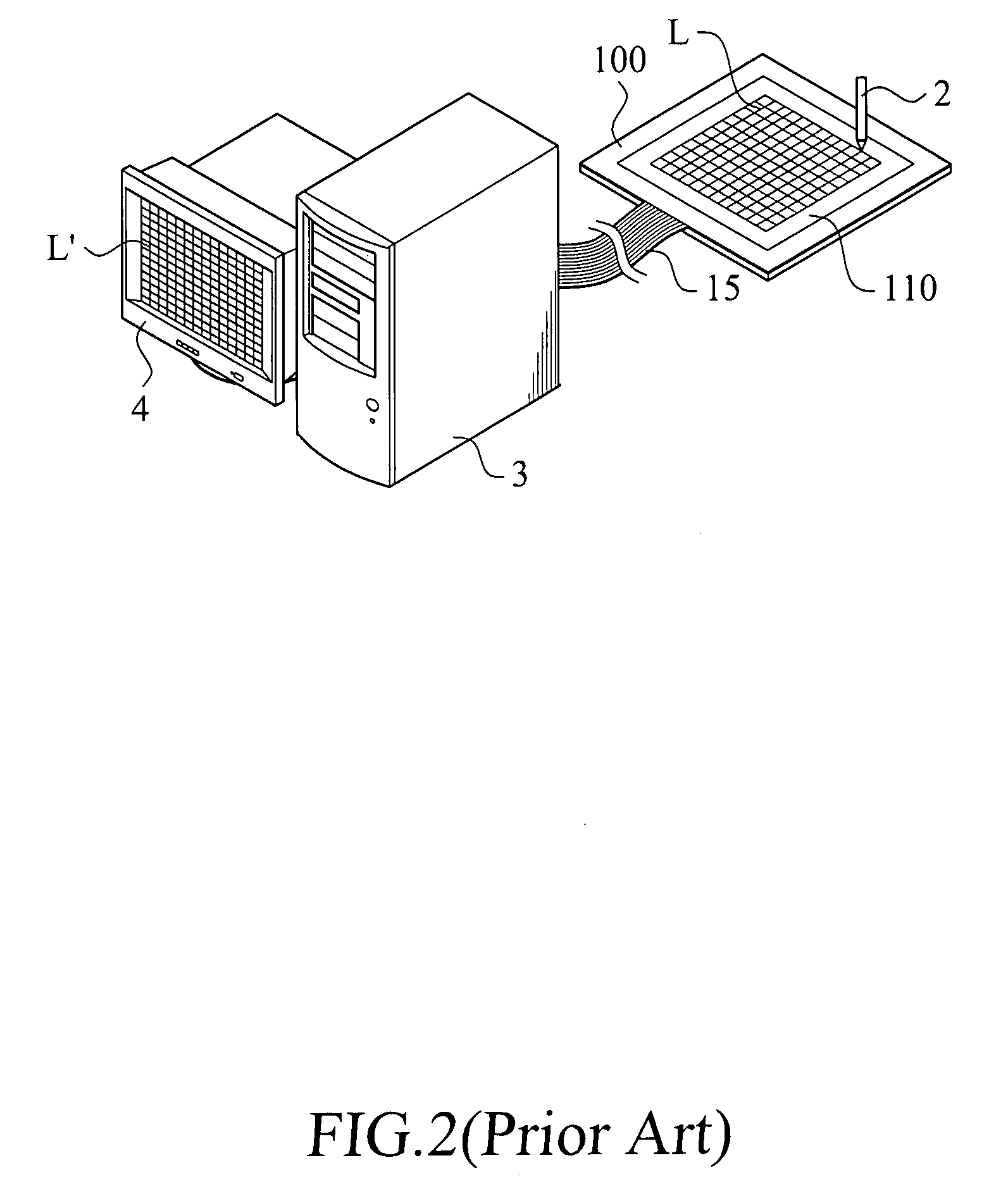

Linear testing method for piezoelectric type touch screen

InactiveCN102331880AShorten the timeIncrease productivityDetecting faulty computer hardwareInput/output processes for data processingTest efficiencyLinearity testing

The invention relates to a linear testing method for a piezoelectric type touch screen. The linear testing method comprises the following steps: during a manufacturing process of a touch screen, testing connectivity of a Y axial wiring by unilaterally sliding and pressing an X axial wiring and testing connectivity of the X axial wiring by unilaterally sliding and pressing the Y axial wiring; after traversing X1, XN, Y1 or YM, confirming the piezoelectric type touch screen to be a qualified product according to a node signal displayed on a computer if the X axial wiring and the Y axial wiring are both connected; and confirming the piezoelectric type touch screen to be a rejected product, if one or both of the X and Y axial wirings are in bad connectivity. Compared with the prior art, the linear testing method has the advantages that the costs of labor and working hour are reduced and the testing efficiency is greatly improved.

Owner:利信光学(苏州)有限公司

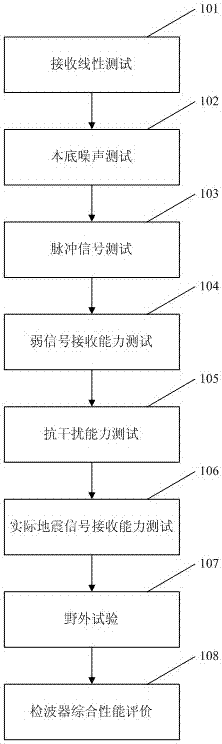

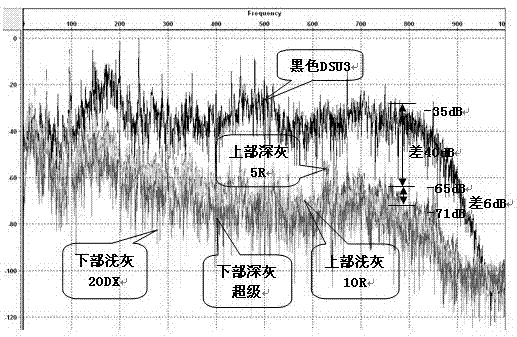

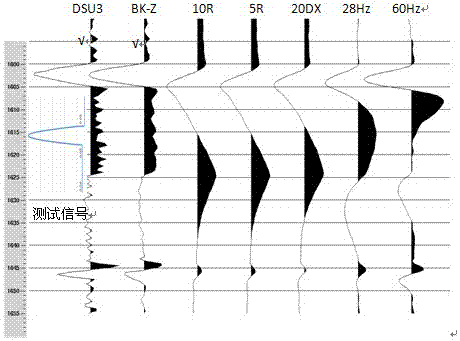

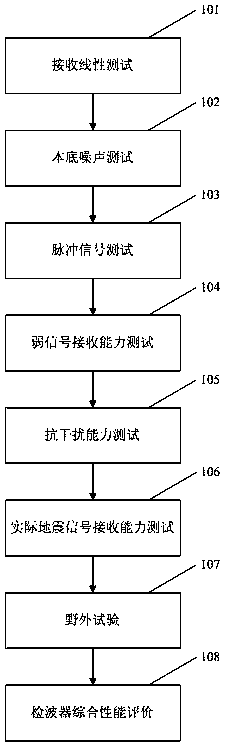

Detector dynamic performance integrated testing and evaluating method

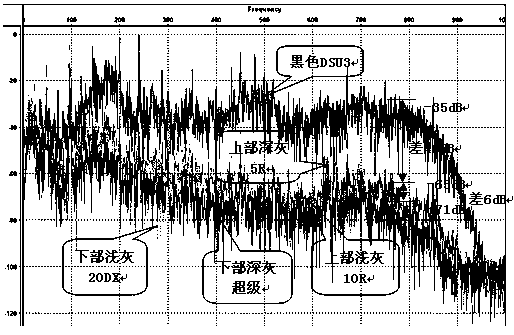

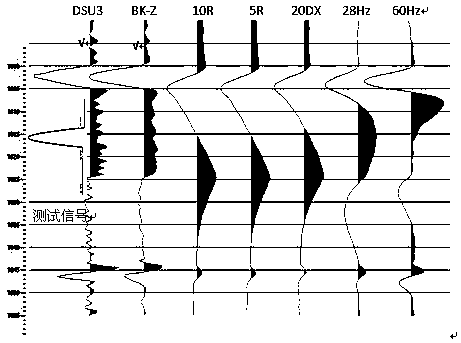

ActiveCN107153224ASolve test problemsSolve evaluation problemsGeological measurementsCombined testLinearity testing

The invention provides a detector dynamic performance integrated testing and evaluating method. The detector dynamic performance integrated testing and evaluating method comprises steps of 1, performing the reception linear test and the ground noise test; 2, performing the pulse signal test and the weak signal reception ability test; 3, performing the anti-interference capability test and the actual seismic signal reception capability test; 4, performing the field test to verify the reception performance of the detector by comparing actual seismic tests; and 5, performing the integrated performance evaluation of the detector. The detector dynamic performance integrated testing and evaluating method is closely integrated with the actual data, and the effect is more obvious. It is an effective method to preferably select the detector according to the seismic exploration demand.

Owner:中石化石油工程技术服务有限公司 +1

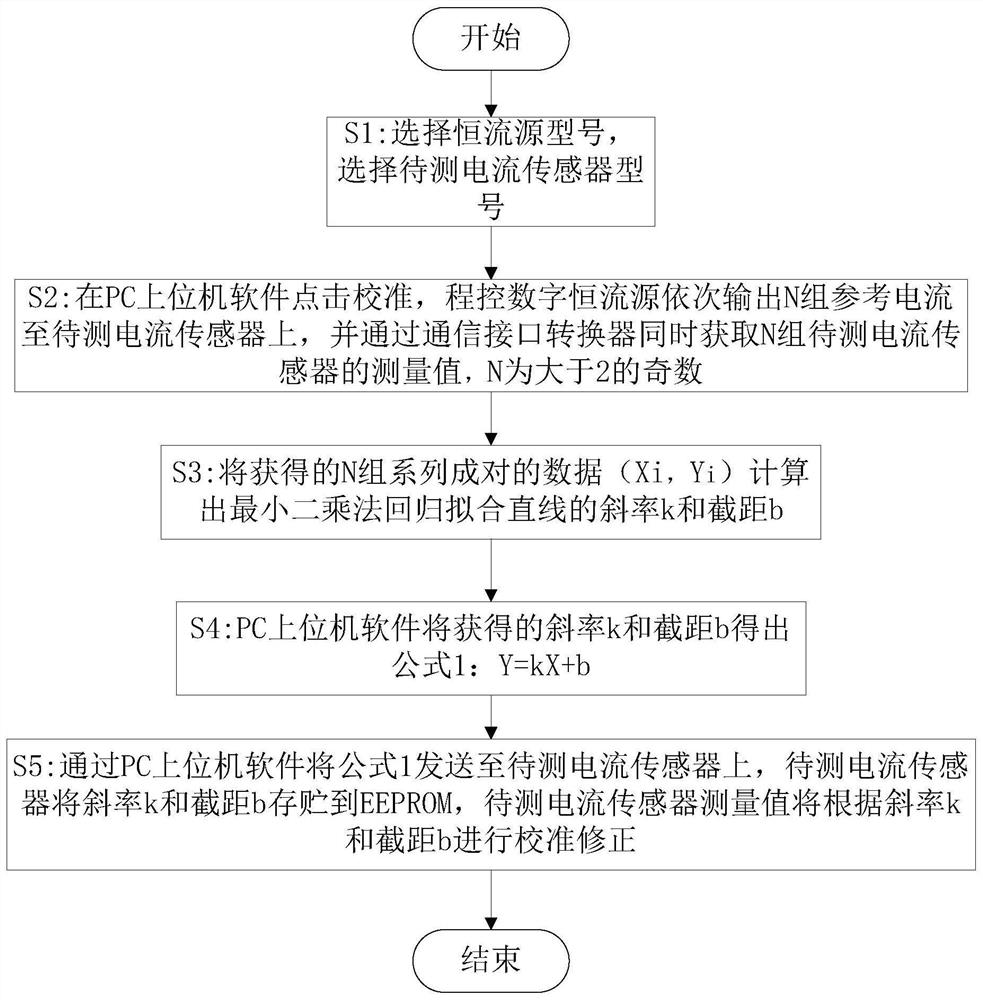

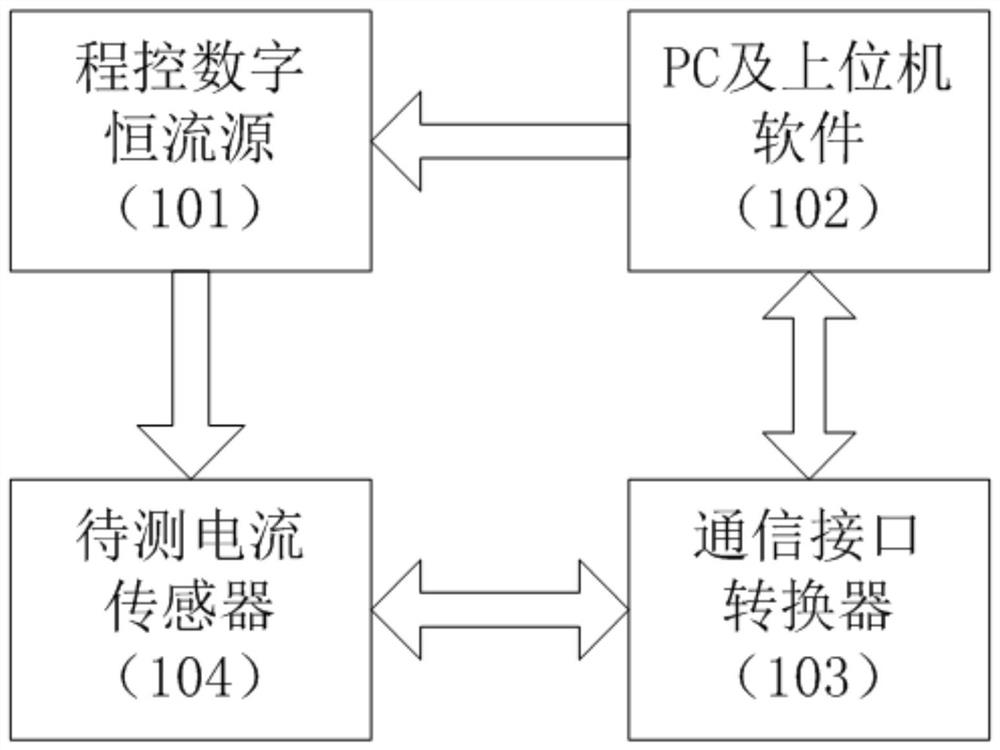

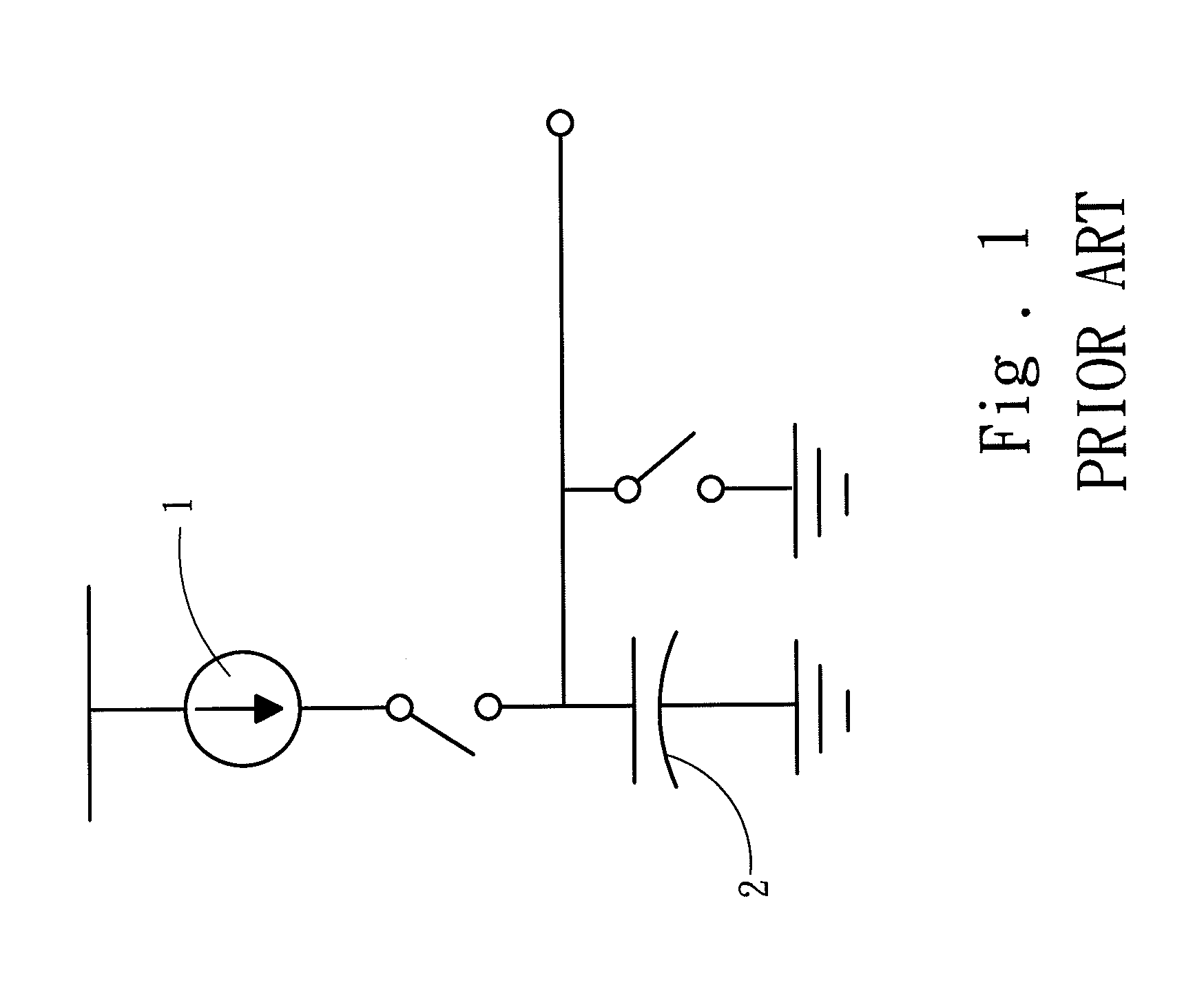

Current sensor linearity test system and calibration method

PendingCN112415458AImprove linearityIncrease productivityElectrical measurementsLinearity testingReference current

A current sensor linearity test system and a calibration method are provided. The system comprises a program-controlled digital constant current source and a PC upper computer, the program-controlleddigital constant current source is used for providing reference current Yi of constant current output for a current sensor to be calibrated, and the PC upper computer is electrically connected with the program-controlled digital constant current source and used for setting output parameters for the program-controlled digital constant current source. And the PC upper computer is also electrically connected with the current sensor to be calibrated and is used for acquiring the current working current and carrying out linearity calibration on the current working current.

Owner:唐新颖

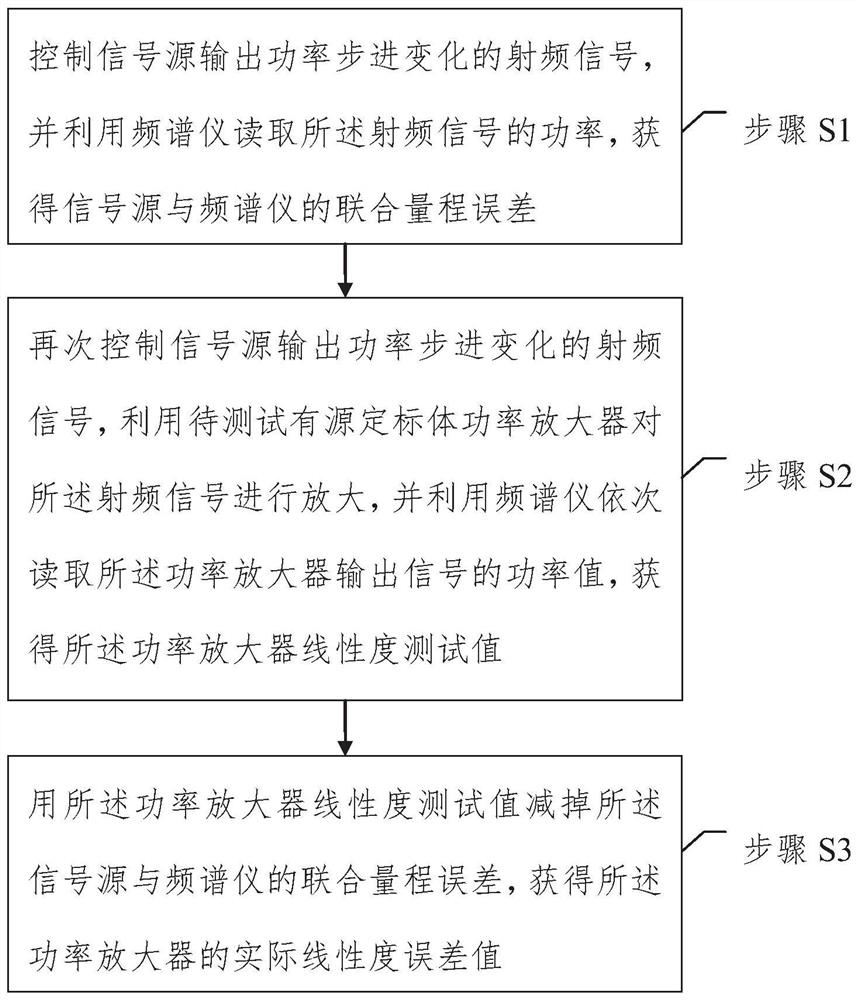

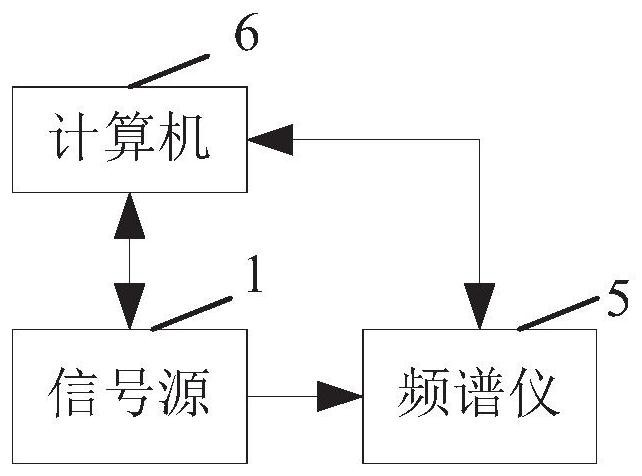

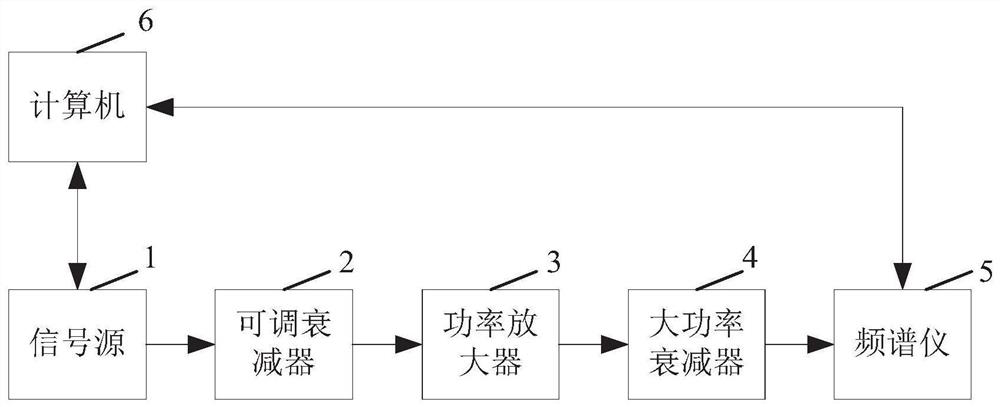

Linearity test method and device of active calibration body power amplifier

ActiveCN112946461ARealize large dynamic range linearity testElectronic circuit testingTest powerLinearity testing

The invention relates to a linearity test technology of a ground active calibration body power amplifier. The linearity test method of the active calibration body power amplifier comprises the following steps: S1, controlling a signal source to output a radio-frequency signal with stepped power change, and reading the power of the radio-frequency signal by using a frequency spectrograph to obtain a combined range error of the signal source and the frequency spectrograph; S2, controlling the signal source again to output the radio frequency signal with the power changing step by step, amplifying the radio frequency signal through the to-be-tested power amplifier, reading the power value of the output signal of the power amplifier through the frequency spectrograph, and obtaining the linearity test value of the power amplifier; and S3, calculating the actual linearity error value of the power amplifier by using the test results of the steps S1 and S2. According to the linearity test device of the active calibration body power amplifier, the computer is connected with the signal source and the frequency spectrograph, and the signal source, the adjustable attenuator, the power amplifier to be tested, the high-power attenuator and the frequency spectrograph are connected in sequence.

Owner:BEIJING INST OF ENVIRONMENTAL FEATURES

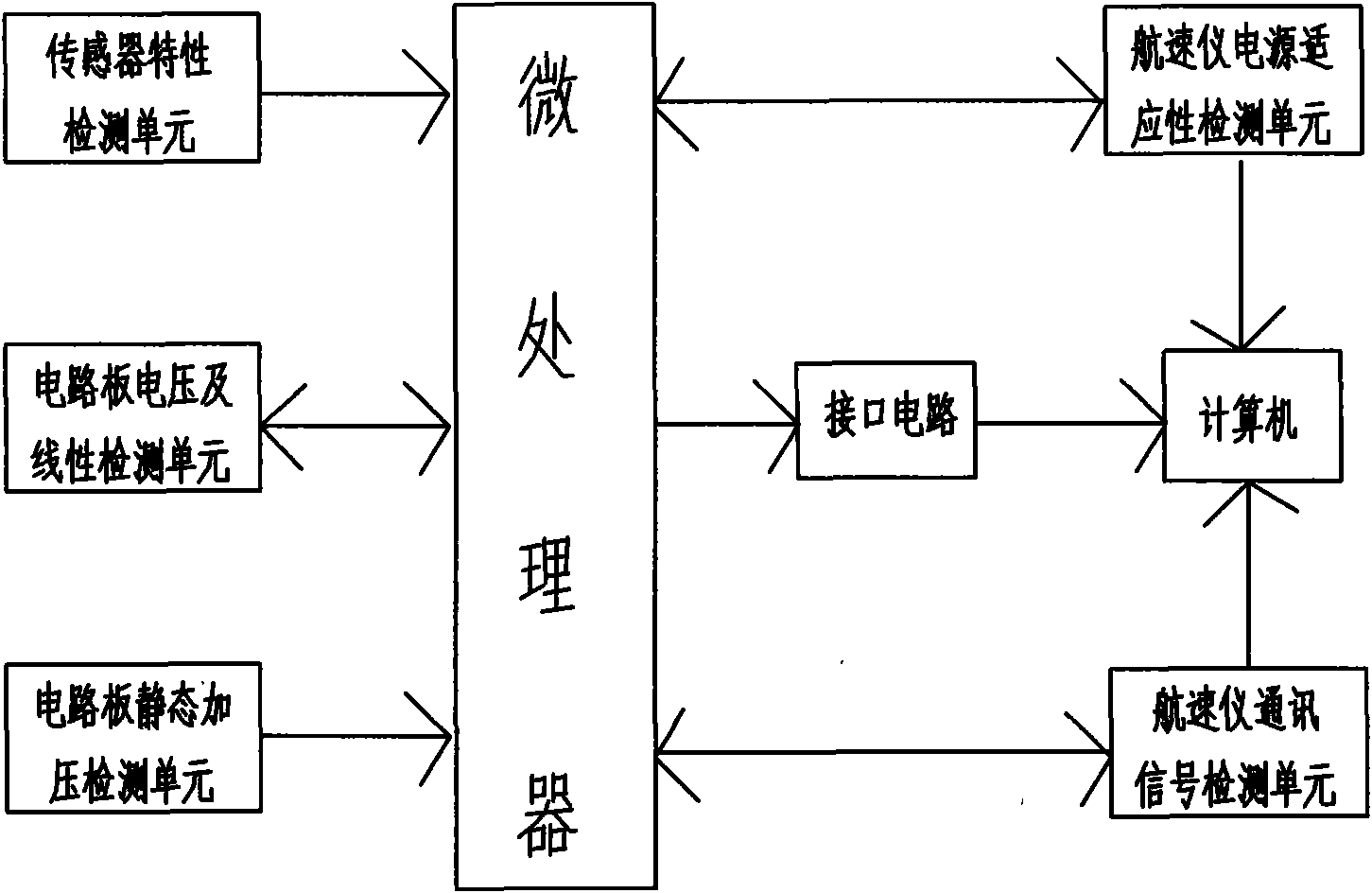

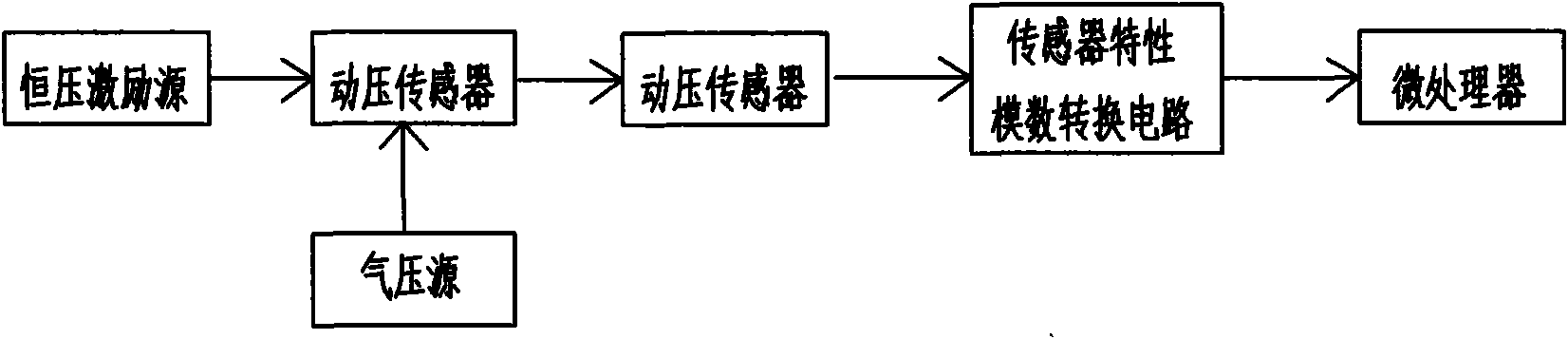

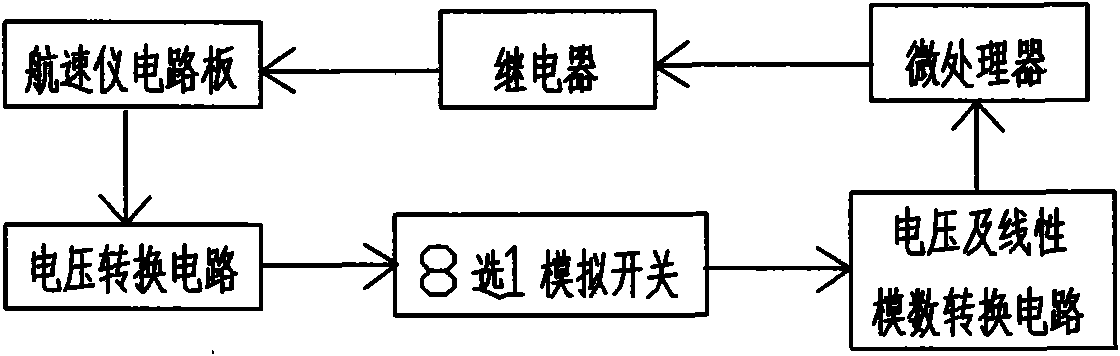

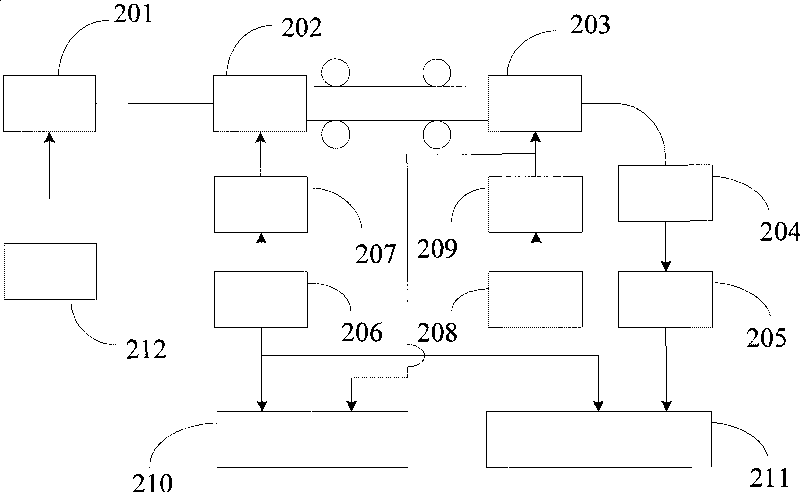

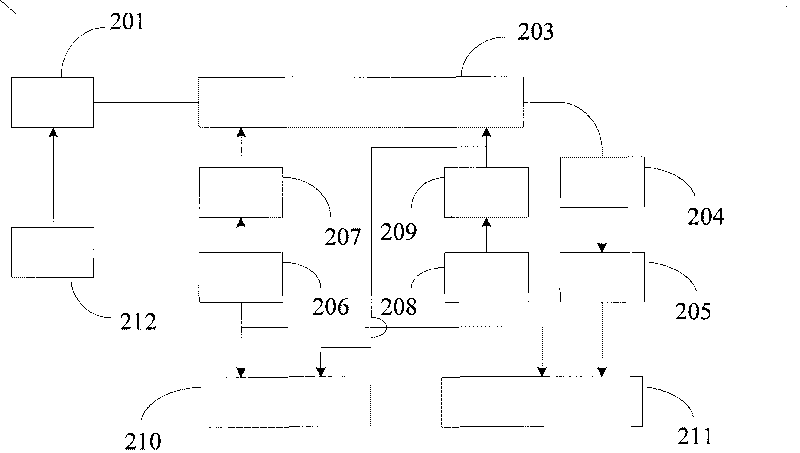

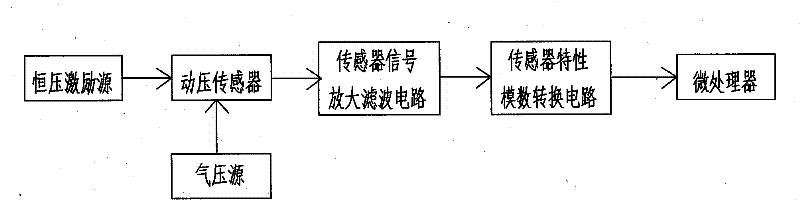

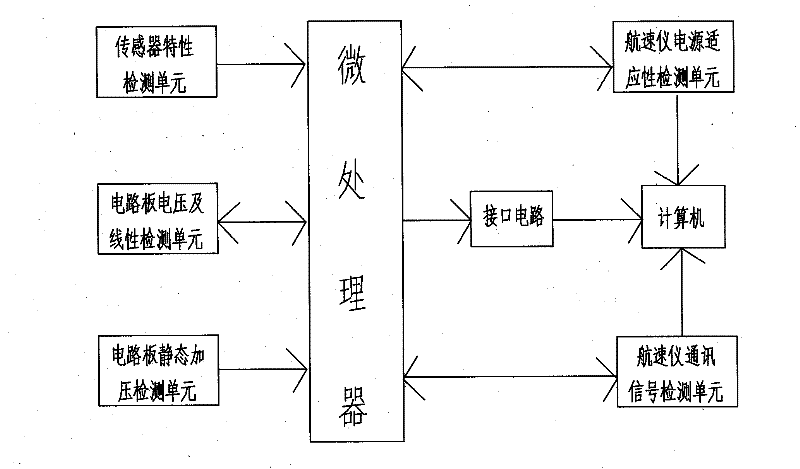

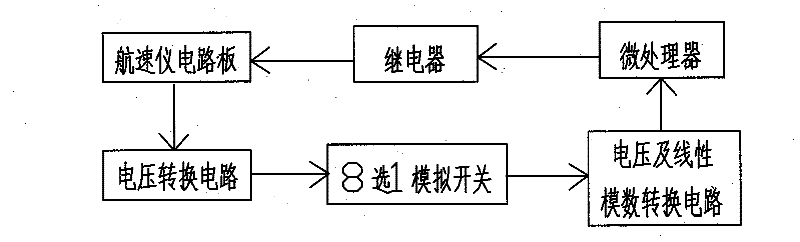

Waterlog comprehensive testing system and waterlog comprehensive testing platform thereof

ActiveCN101893646AImprove product qualityHigh degree of automationTesting/calibration of speed/acceleration/shock measurement devicesCombined testProduct inspection

The invention discloses a waterlog comprehensive testing system and a waterlog comprehensive testing platform thereof. The waterlog comprehensive testing system consists of a sensor property testing unit, a circuit board voltage and linearity testing unit, a circuit board static pressurization testing unit, a waterlog communication signal testing unit, a waterlog power supply adaptability testing unit, a microprocessor and a computer. The upper case body of the waterlog comprehensive testing platform is provided with a gas valve switch, a waterlog testing passage, a waveband switch, a toggle switch, a voltage indicating lamp and an interface connector from left to right in sequence; and the top panel of a middle case body is provided with a motion axis tool, a sensor testing tool and a waterlog circuit board tool. The system is a set of testing equipment for detecting the performance state and the delivery inspection in a waterlog production process, and has the advantages of ensuring product quality and high automation degree, improving the efficiency of product inspection, possibly reducing human operation and detection errors, and effectively avoiding inspection errors caused by objective factors of humans.

Owner:江西省智成测控技术研究所有限责任公司

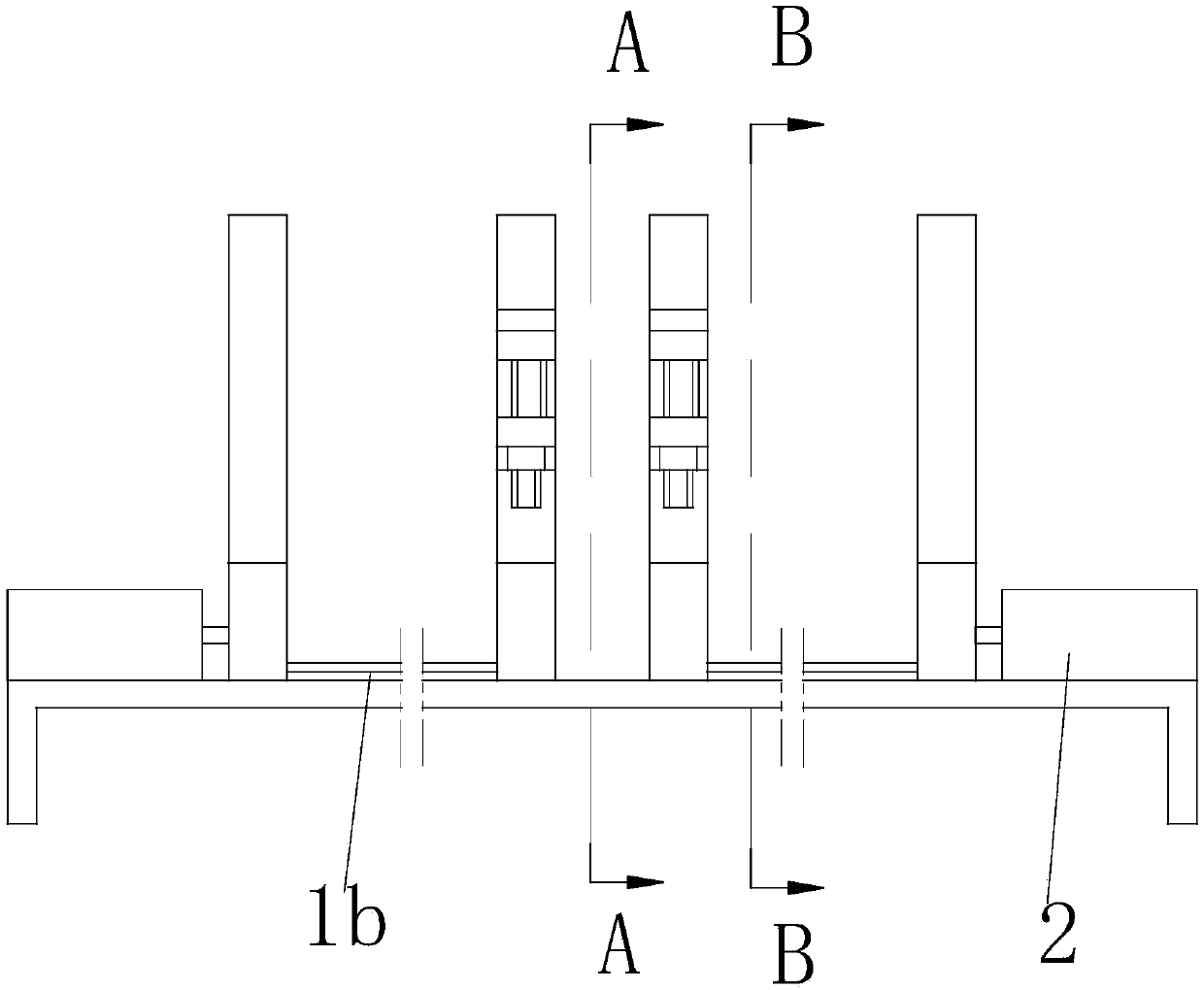

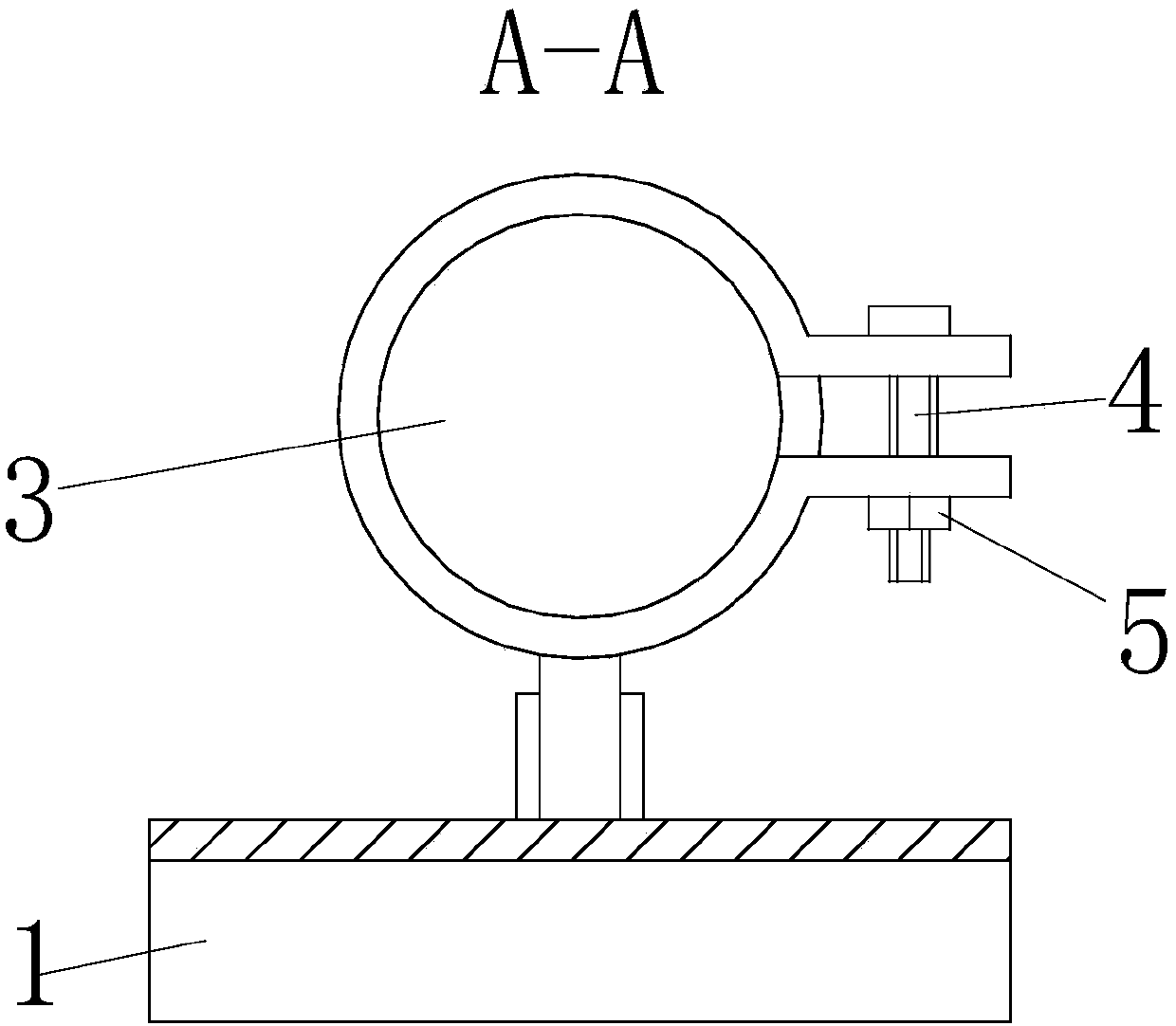

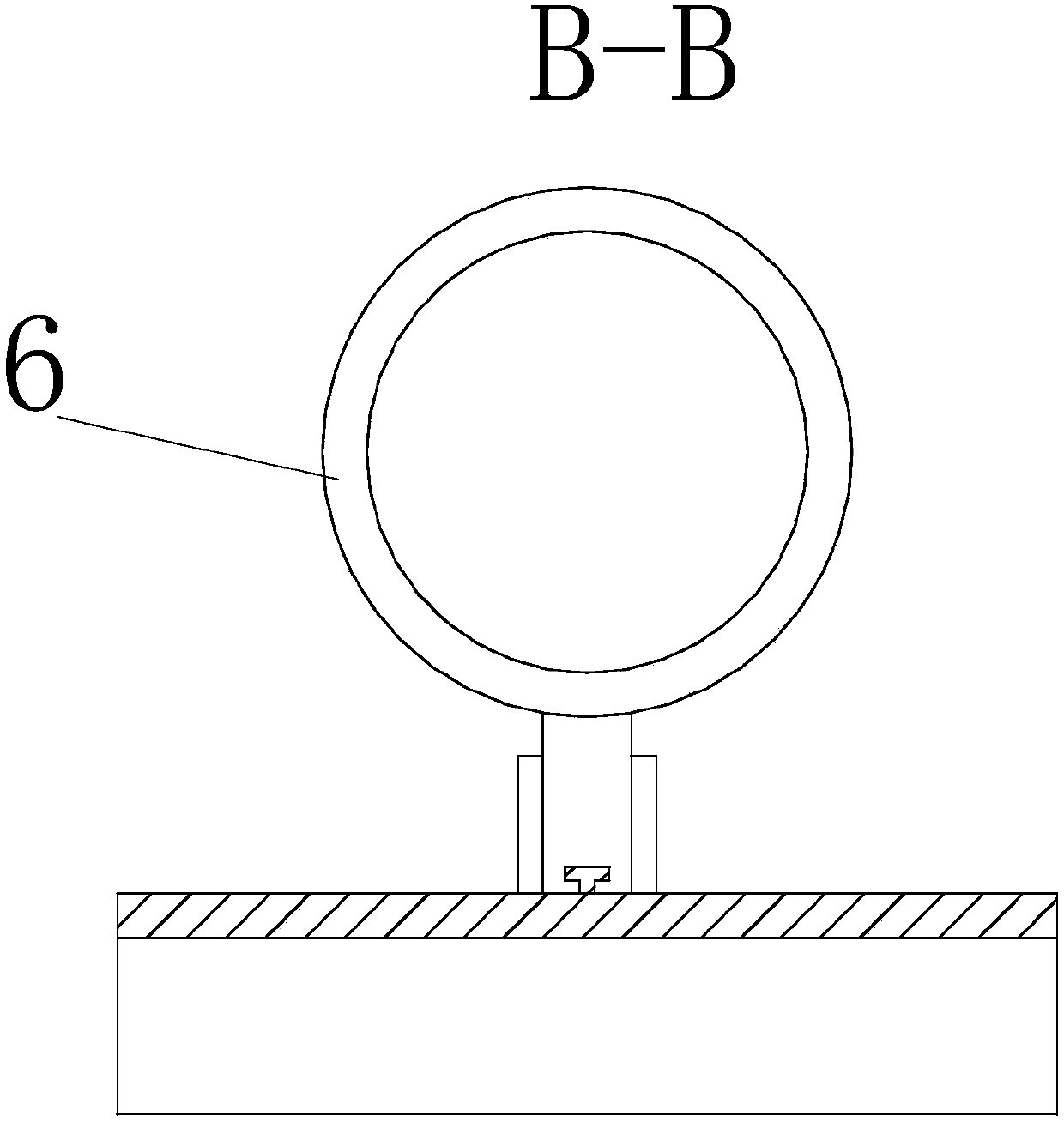

Steel pipe linearity testing fixture

InactiveCN107917653AEasy to useAutomatic convenience detectionAngles/taper measurementsHydraulic cylinderLinearity testing

The invention relates to a steel pipe linearity testing fixture. The steel pipe linearity testing fixture includes a workbench, wherein two steel pipe mounting devices are fixedly arranged on the center of the workbench; the left side and the right side on the workbench are each equipped with a guide rail; a circular ring rack is arranged on each guide rail in a sliding manner; and each circular ring rack is connected with a hydraulic cylinder which is fixedly arranged on the workbench. The steel pipe linearity testing fixture is convenient to use, and can achieve the effect of automatically and conveniently detecting the linearity of the steel pipes by controlling horizontal sliding of the each circular ring rack, on the basis of compressing and fixing the steel pipes through screw threads.

Owner:ANHUI XINRONG STEEL STRUCTURE

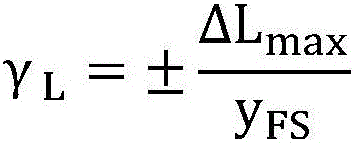

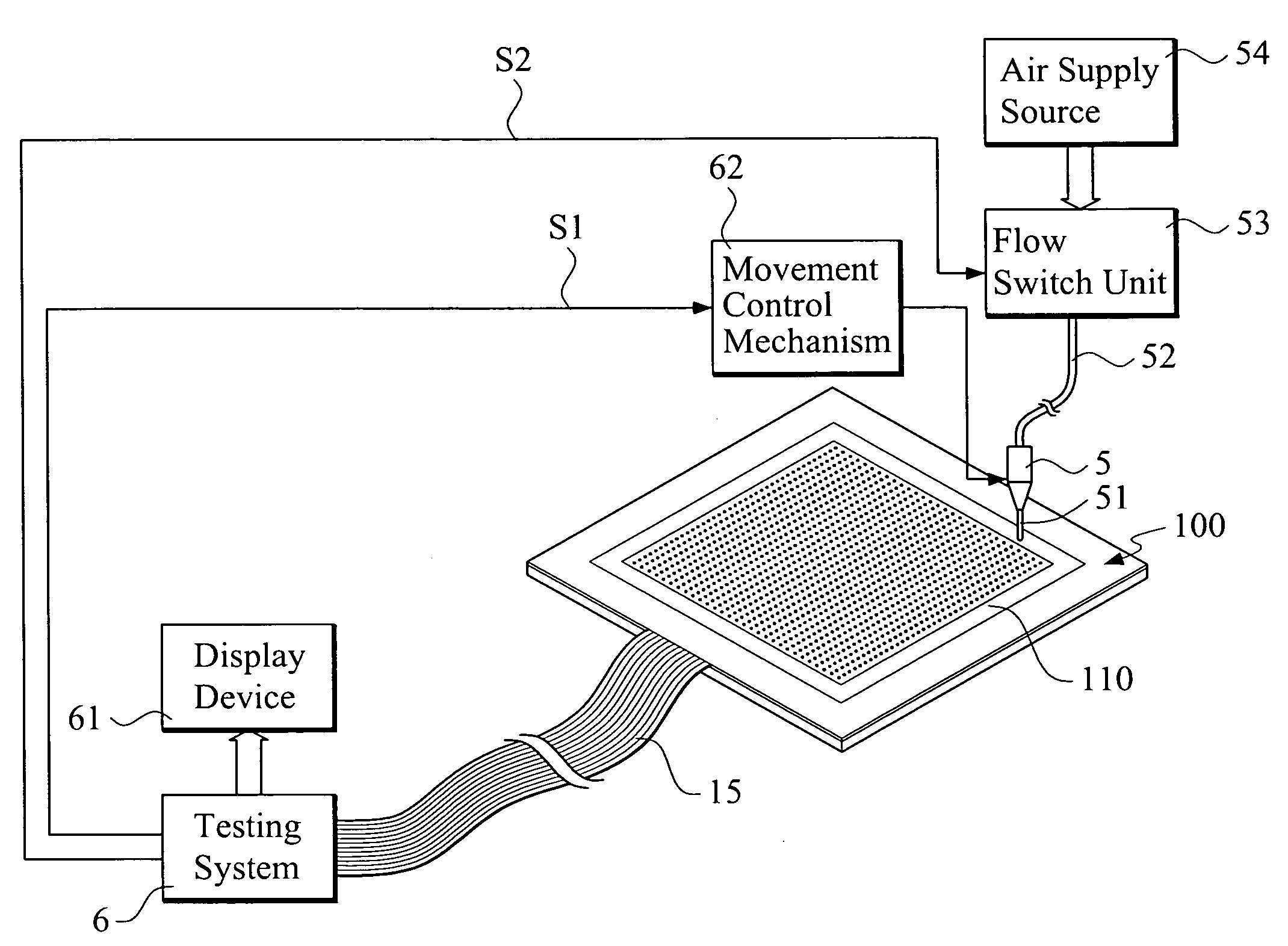

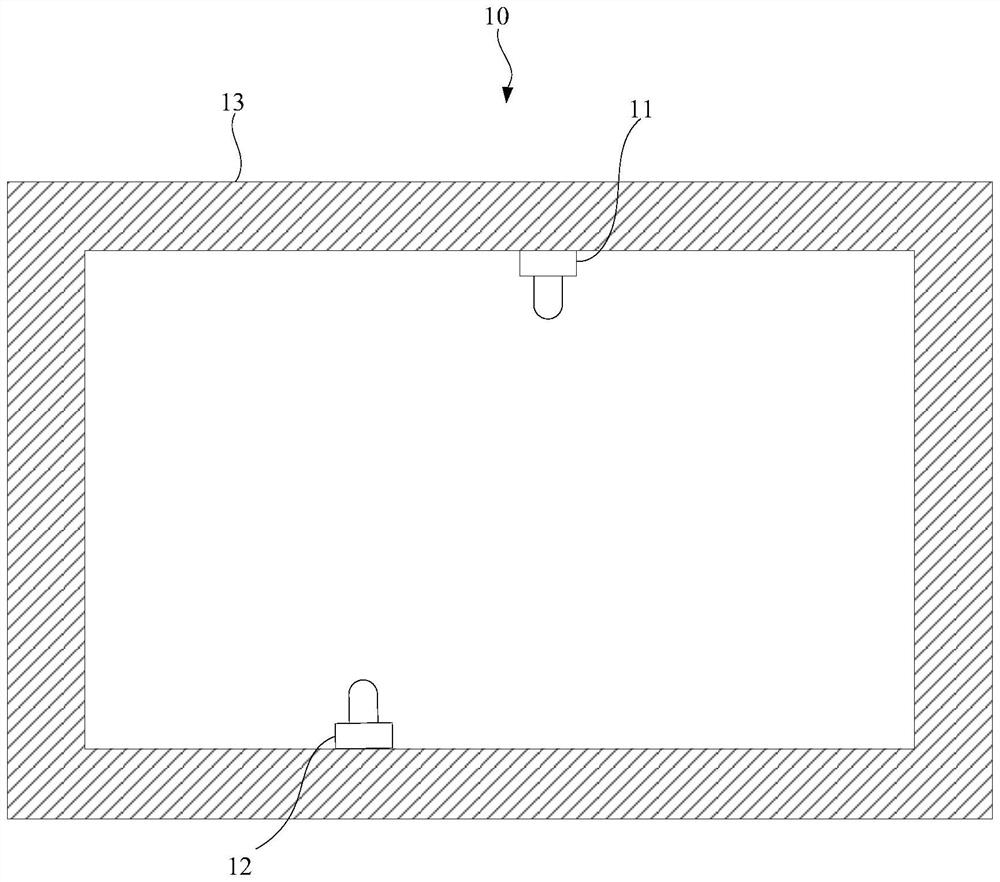

Method and system for carrying out non-contact testing of touch panel

InactiveUS20090002330A1Easy to testHigh yieldElectrical testingInput/output processes for data processingTouchpadEngineering

Disclosed are a system and a method for carrying out non-contact testing of a touch panel. An air nozzle is arranged above the touch panel with a predetermined distance set between an air jet orifice of the air nozzle and a surface of the touch pane. Air is supplied to the air nozzle to cause the air jet orifice to generate an air jet toward the touch panel. Under the control of a test device, the air nozzle is driven to move along a predetermined testing route on the surface of the touch panel and the touch panel generates touch signals corresponding to the movement of the air nozzle along the route. The test device receives the touch signals and determines if the touch panel satisfies the linearity test.

Owner:TRENDON TOUCH TECHNOLOGY CORPORATION

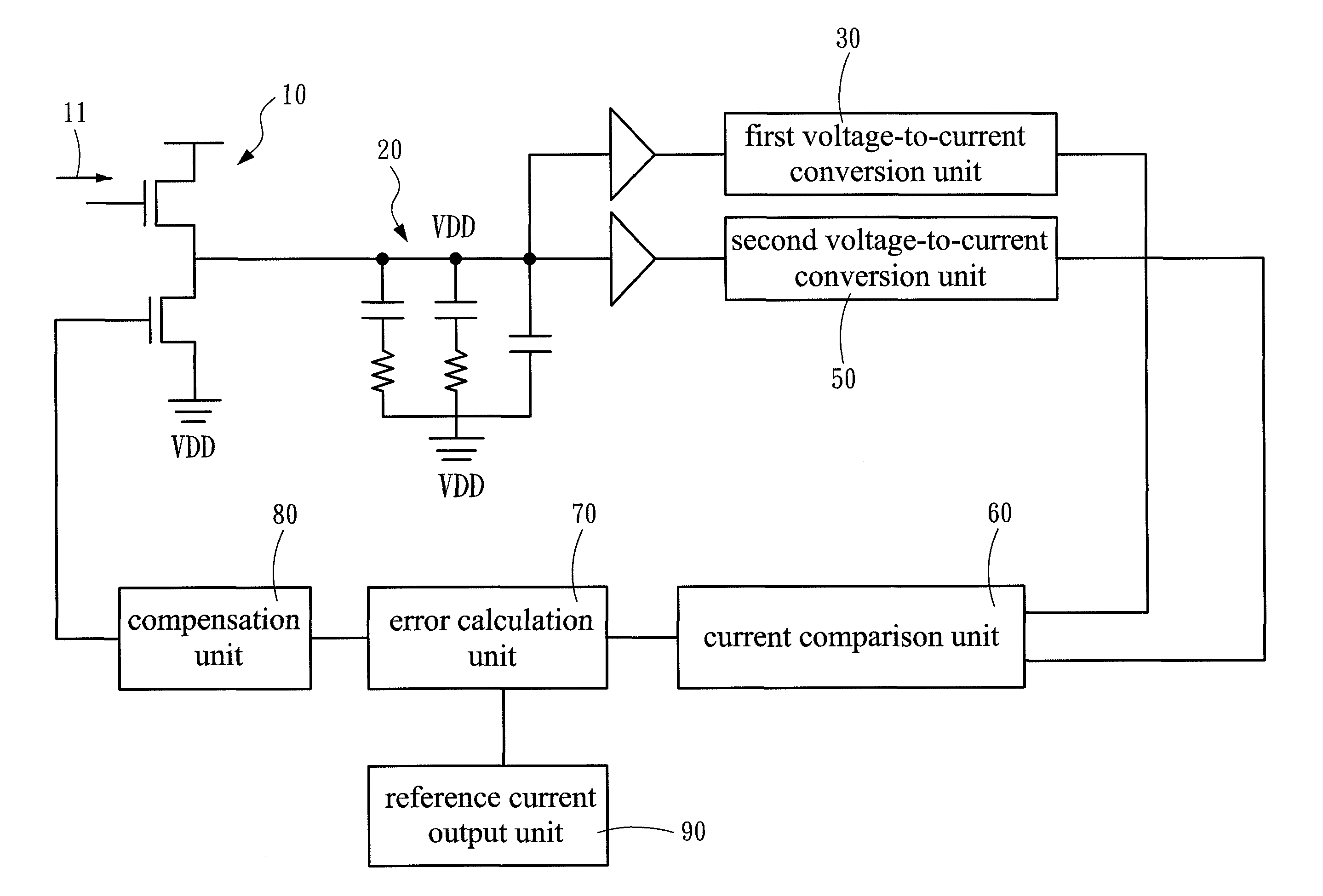

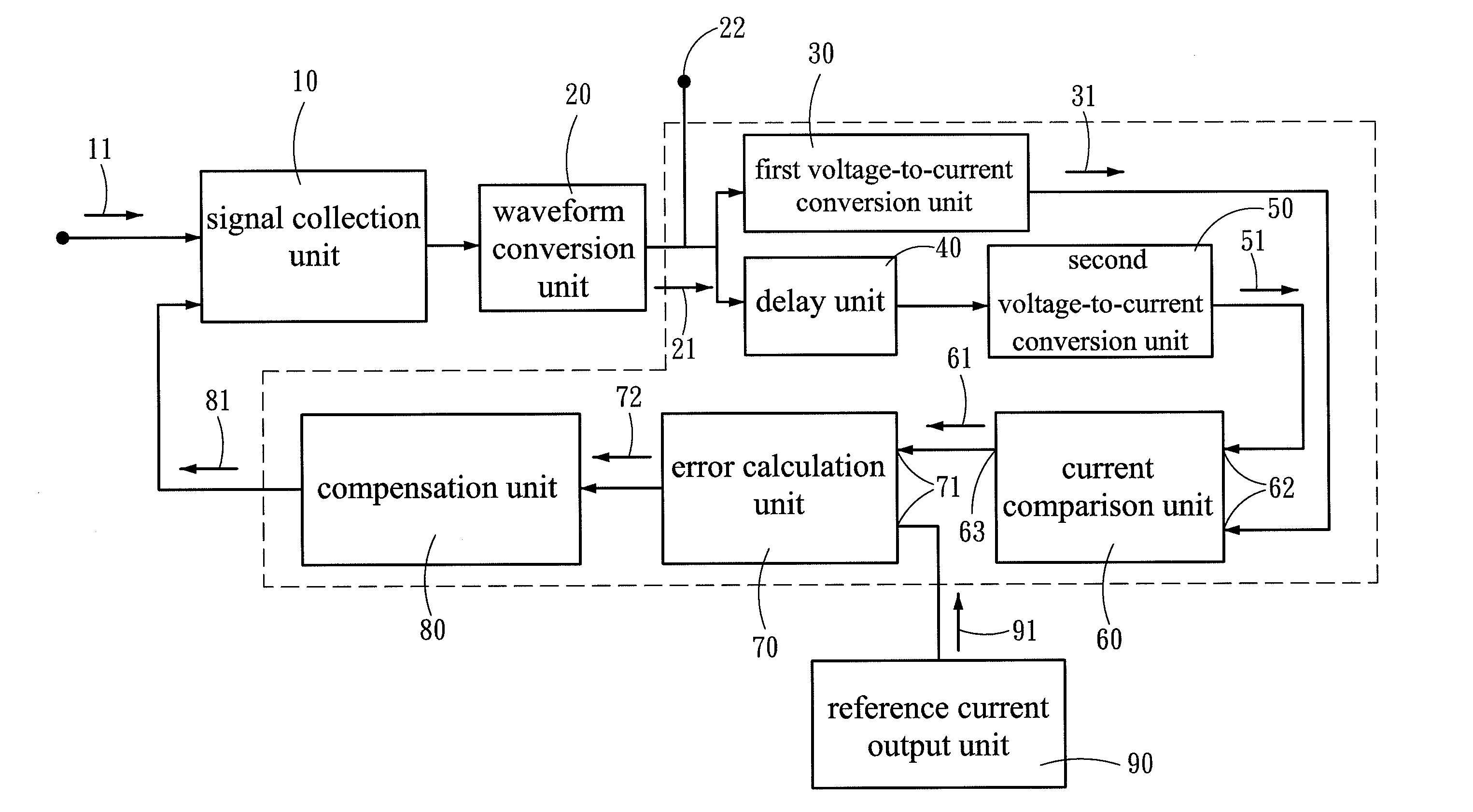

High-linearity testing stimulus signal generator

InactiveUS8542053B2Reduce high costArbitary function generatorsTime-delay networksPower flowLinearity testing

A high-linearity testing stimulus signal generator comprises a signal collection unit receiving an input current signal, a waveform conversion unit connecting with the signal collection unit, a first voltage-to-current conversion unit connecting with the waveform conversion unit, a delay unit connecting with the waveform conversion unit, a second voltage-to-current conversion unit connecting with the delay unit, a current comparison unit connecting respectively with the first voltage-to-current conversion unit and the second voltage-to-current conversion unit, an error calculation unit connecting with the current comparison unit, and a compensation unit connecting with the error calculation unit. The above-mentioned structure forms a feedback mechanism to perform compensation adjustment to promote the linearity of the output signals. Thus, the present invention can generate high-accuracy testing stimulus signals.

Owner:NATIONAL YUNLIN UNIVERSITY OF SCIENCE AND TECHNOLOGY

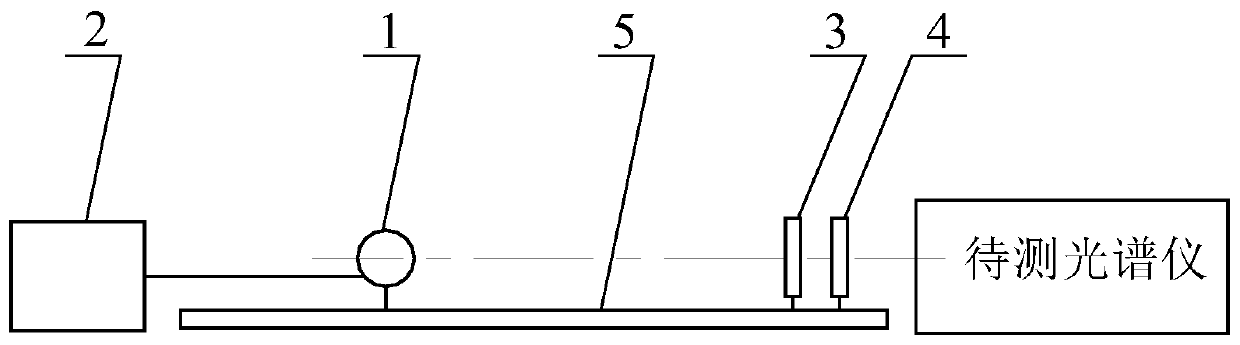

Wide-range linearity testing device and method of ultraviolet spectrum remote sensing instrument

InactiveCN111323121ALarge measuring rangeMeasuring equipment is simpleRadiation pyrometrySpectrum investigationLinearity testingOptical spectrometer

The invention discloses a wide-range linearity testing device of an ultraviolet spectrum remote sensing instrument. The wide-range linearity testing device comprises an ultraviolet light source, an ignition power supply, a neutral dimming sheet, a diffusion plate, a guide rail and a testing module, wherein the ultraviolet light source, the neutral dimming sheet and the diffusion plate are mountedon the guide rail, and the diffusion plate is mounted at one end, close to a spectrograph to be detected, of the guide rail; the neutral dimming sheet is arranged between the ultraviolet light sourceand the diffusion plate and is close to the diffusion plate; the ultraviolet light source is used for providing ultraviolet radiation required by a linearity test of the spectrograph; the neutraldimming sheet is used for reducing radiation intensity of the ultraviolet light source and expanding alinear test range of the spectrograph; the diffusion plate is used for converting light emitted by theultraviolet light source into an area light source so as to fill the field of view of the spectrograph; the test module is used for recording signal output in aspectral band of the spectrograph to betested and drawing a spectral intensity curve when the ultraviolet light source and the diffusion plate are located at different positions; and whether the spectrograph to be testedis linear or not isdetermined according to the spectral intensity curve.

Owner:NAT SPACE SCI CENT CAS

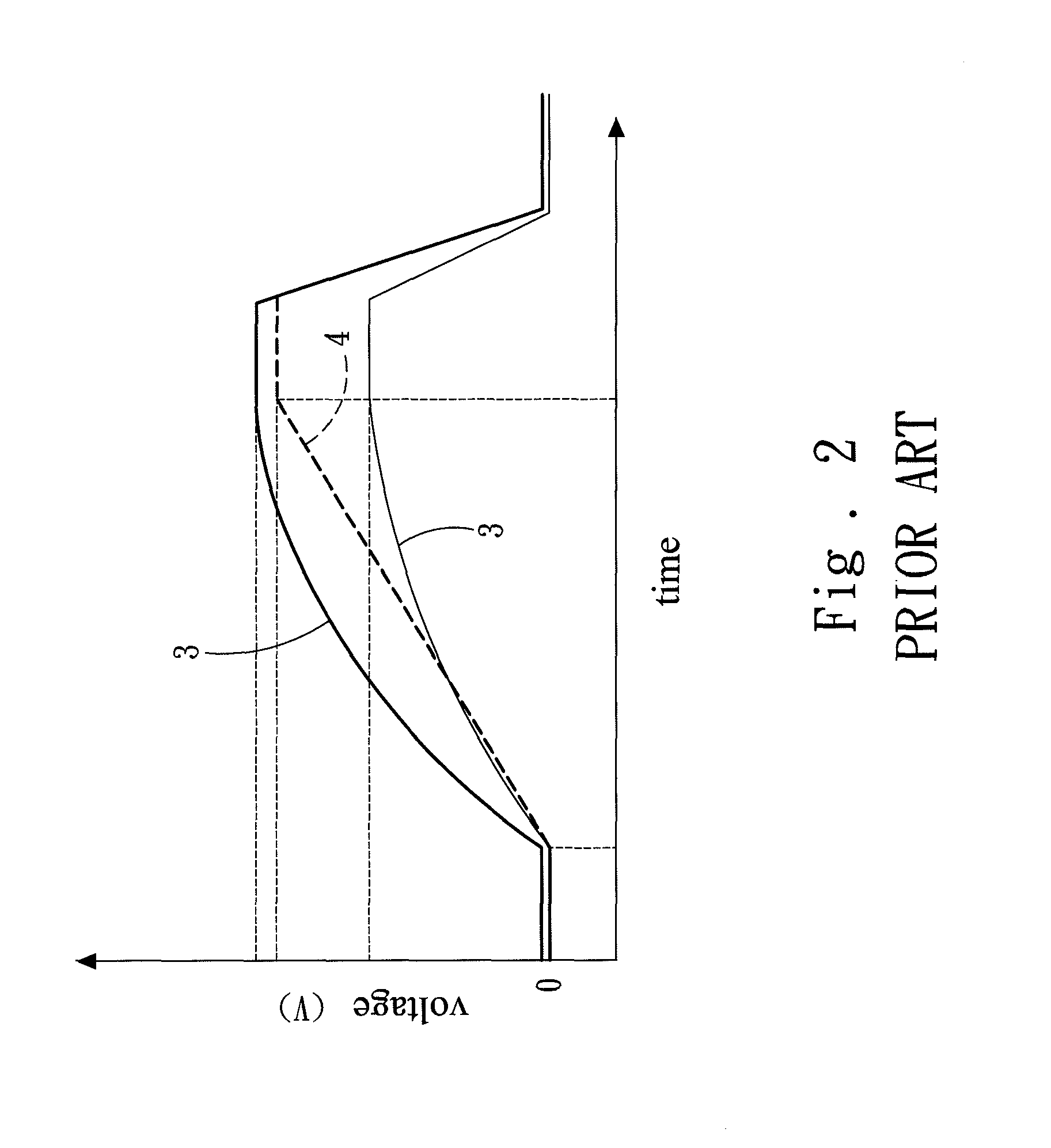

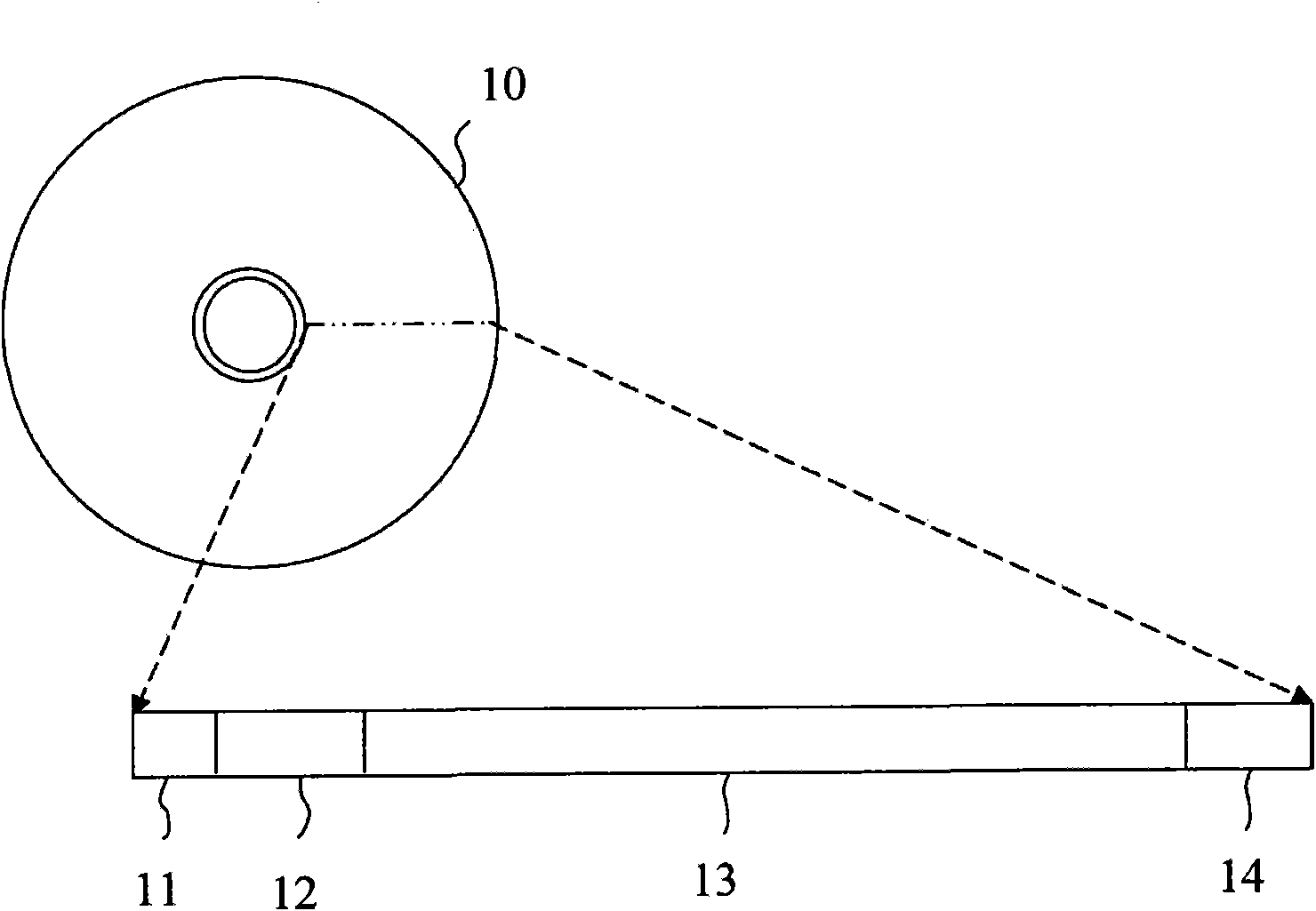

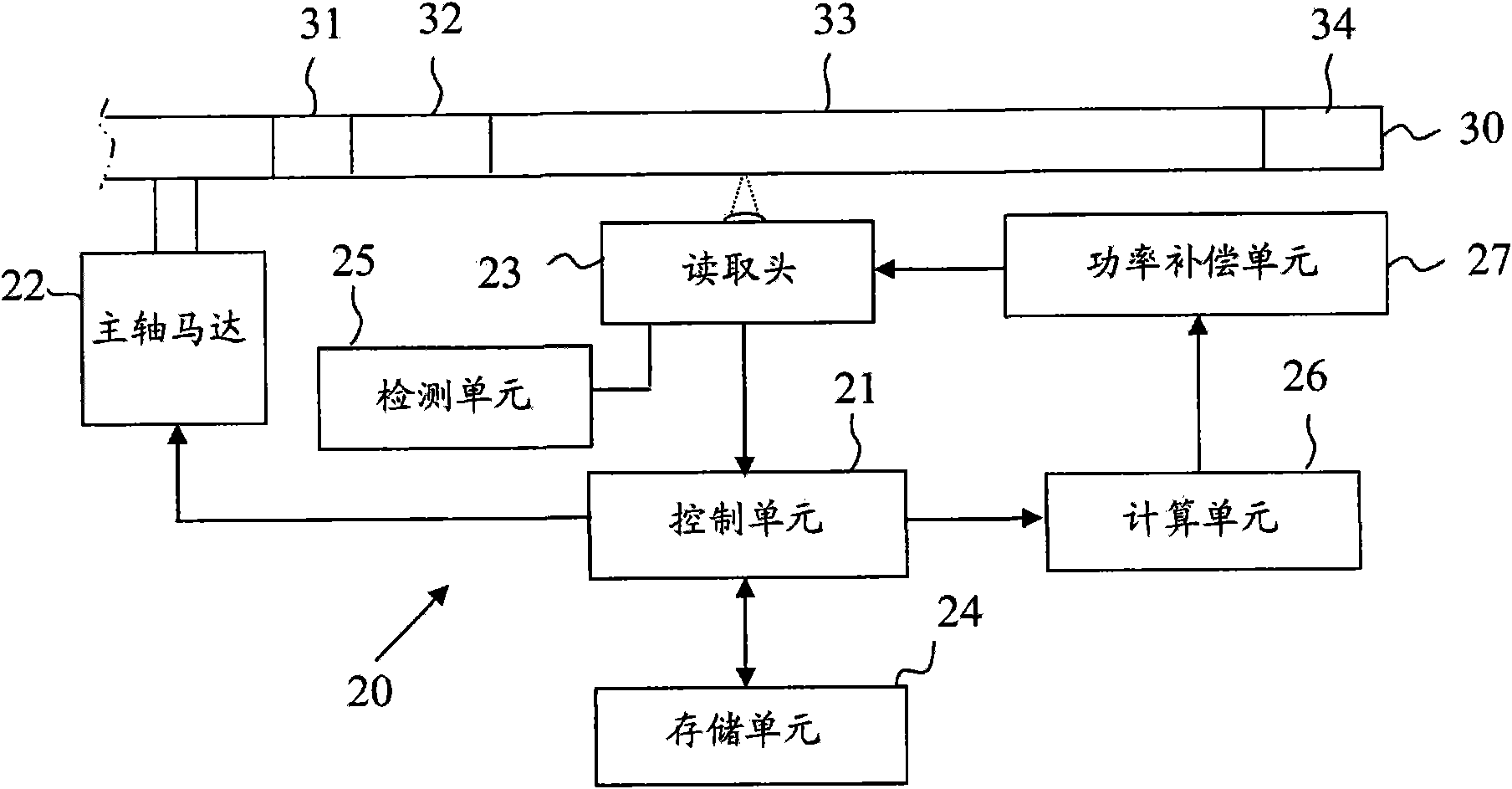

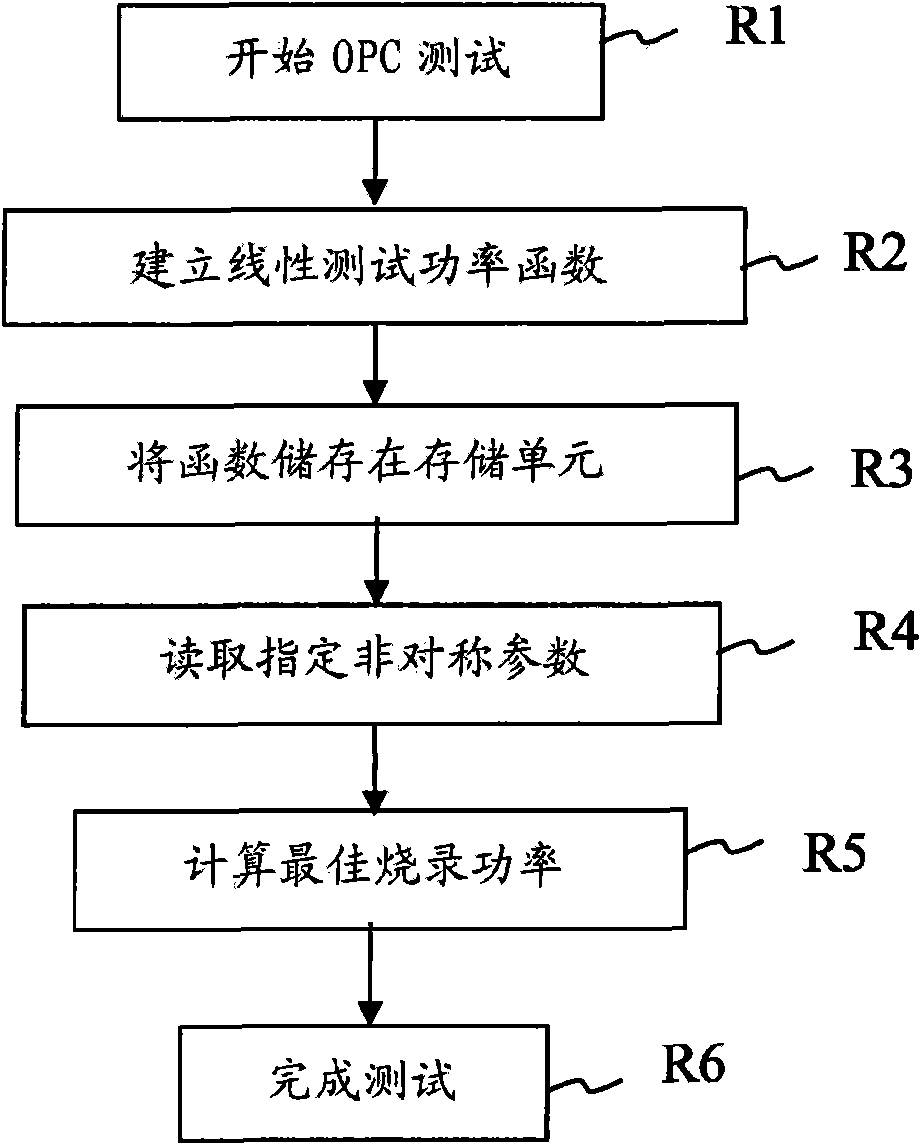

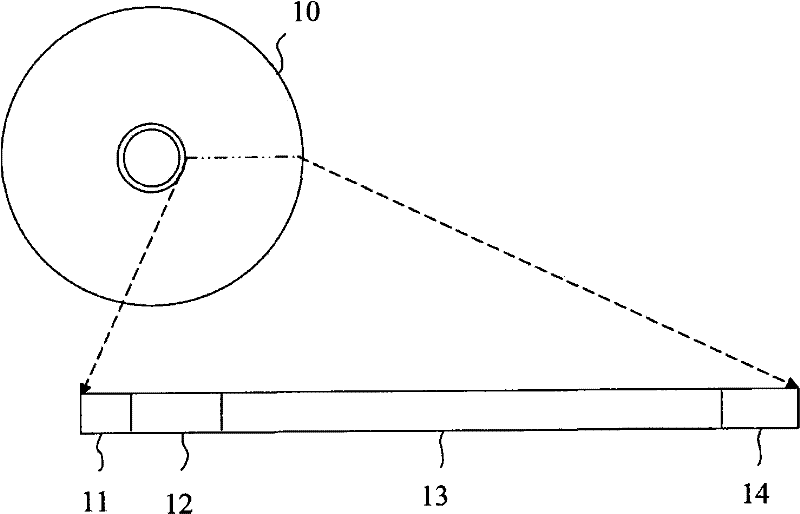

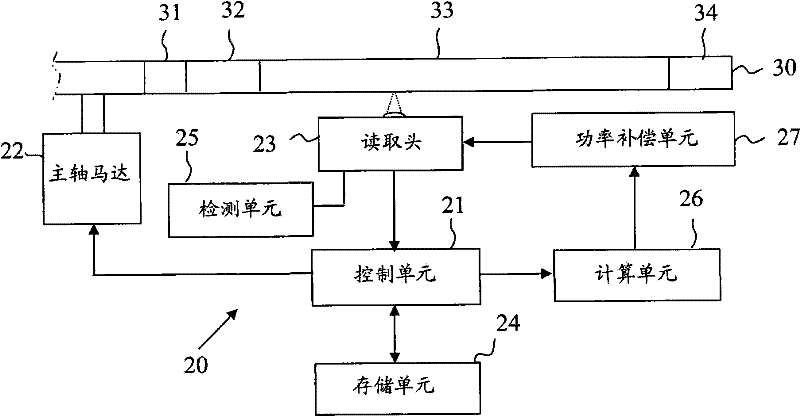

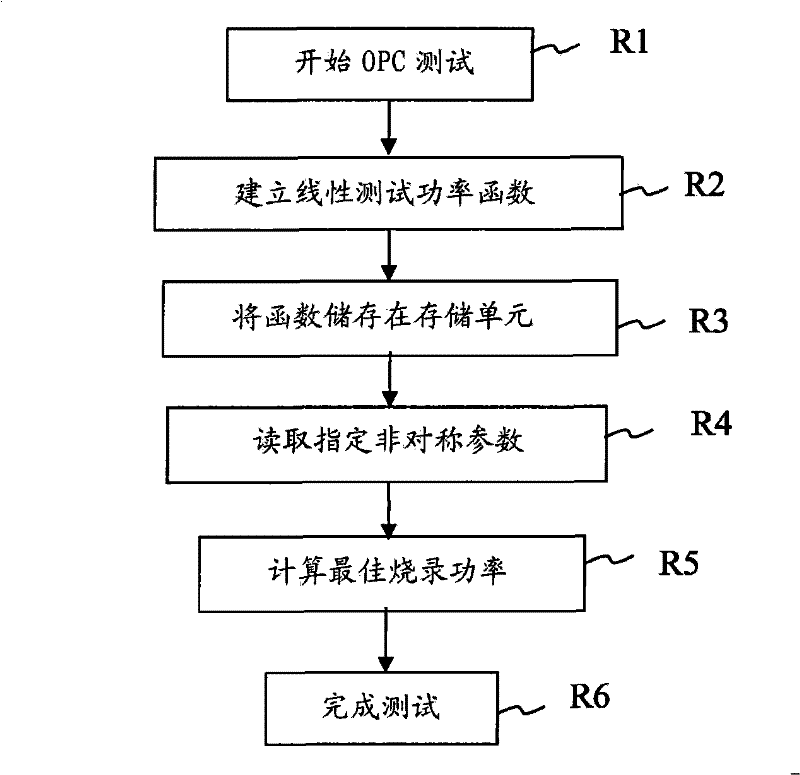

Recording power compensating system and method

InactiveCN101770786AAccurate programming powerImprove burning qualityOptical beam sourcesRecord information storageTest powerPower compensation

The invention relates to a recording power compensating system and a recording power compensating method. A best power test is controlled by a control unit; a calculating unit is used for approximating test power and a corresponding asymmetry parameter into a linear test power function and calculating a difference value of the asymmetry parameter tested by a test unit and corresponding power compensation amount; and a power compensating unit makes use of the power compensation amount to adjust laser beam power so as to improve the recording quality.

Owner:QUANTA STORAGE INC

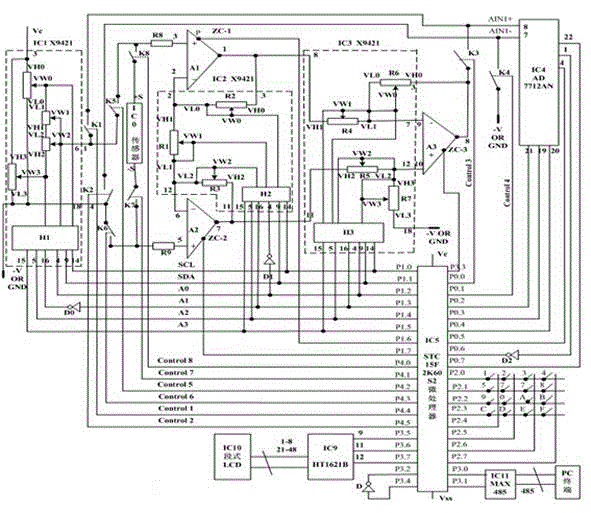

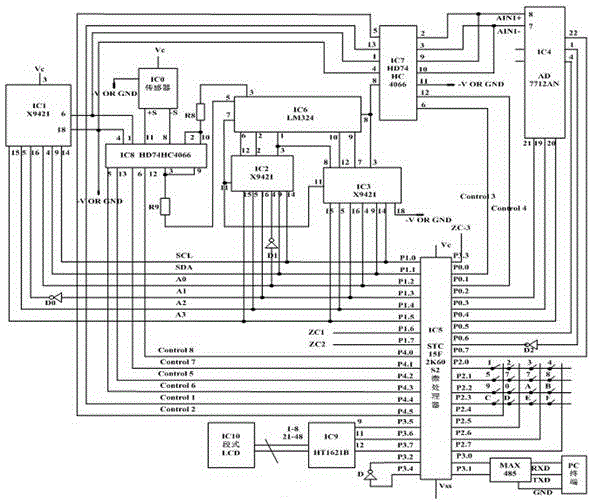

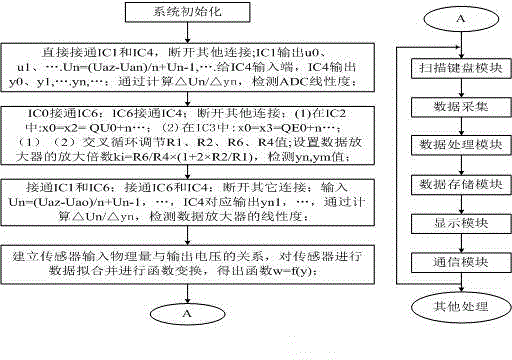

Automatic debugging device of intelligent data collection instrument

InactiveCN104567976AShorten the development cycleImprove stabilityMeasurement devicesLinearity testingElectronic switch

The invention relates to an automatic debugging device of an intelligent data collection instrument. The automatic debugging device comprises an X9241 type digital potentiometer, an operational amplifier LM324, a data amplifier composed of an operational amplifier A1, an operational amplifier A2 and an operational amplifier A3 and a processor STC15F2KS2. The processor STC15F2KS2 controls an electronic switch in an HD74HC4066 to be connected and disconnected, one of two paths of signals output by a sensor IC0 or a sensor IC1 is selected to be sent to the data amplifier, one of two paths of signals output by the A3 or the IC1 is selected to be sent to an AD7712AN, the IC1 is used for outputting high-precision linear voltages to detect the linearity of the data amplifier and the linearity of an ADC of a sample machine, a standard part full range loaded on the sensor IC0 and values output by an IC4 in the no-load process are tested, a standard part is loaded on the IC0 many times, the IC4 outputs the corresponding digital quantity, therefore, experimental data are obtained, and a function relationship of the data is built. According to the device, the development period of the intelligent data collection instrument is shortened, labor intensity of development personnel is reduced, and the stability of the intelligent data collection instrument is improved.

Owner:XUZHOU NORMAL UNIVERSITY

Device for testing linearity of electro-optical modulator

ActiveCN101408477BReduced Linearity RequirementsLittle influence on measurement accuracyTesting optical propertiesLinearity testingHemt circuits

The invention discloses a testing device for linearity of an electro-optical modulator. If the electro-optical modulator to be tested is an intensity modulator, an optical wave from an optical sourceis sent to the electro-optical modulator to be tested, a modulation signal generator generates a modulation signal and sends the modulation signal to the electro-optical modulator to be tested, a first demodulator circuit and a second demodulator circuit; a test signal generator generates a test signal and sends the test signal to the electro-optical modulator to be tested and the first demodulator circuit. In the electro-optical modulator to be tested, the modulation signal causes the two optical waves to generate modulation phase difference, the test signal causes the two optical waves to generate test phase difference, the two optical waves are interfered and sent to a detector, and sent to the second demodulation circuit after photoelectric conversion, the first demodulation circuit obtains the size of the test signal, and the second demodulation circuit obtains the test phase difference; if the electro-optical modulator to be tested is a Y-waveguide integrated optical device, theoptical wave of the optical source is sent to the electro-optical modulator to be tested by an electro-optical modulator for modulation, the modulation signal from the modulation signal generator is sent to the electro-optical modulator for modulation, the test signal from the test signal generator is sent to the tested electro-optical modulator, and the other structures are not changed.

Owner:BEIJING AEROSPACE TIMES OPTICAL ELECTRONICS TECH

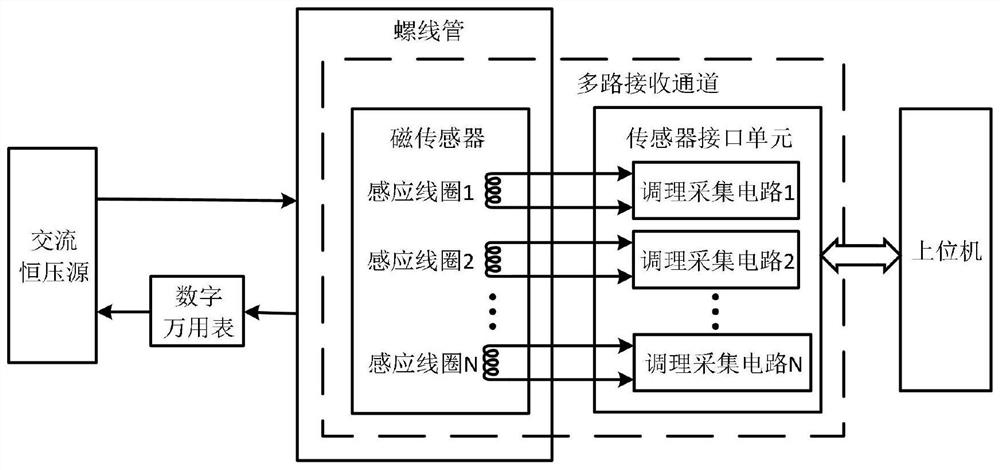

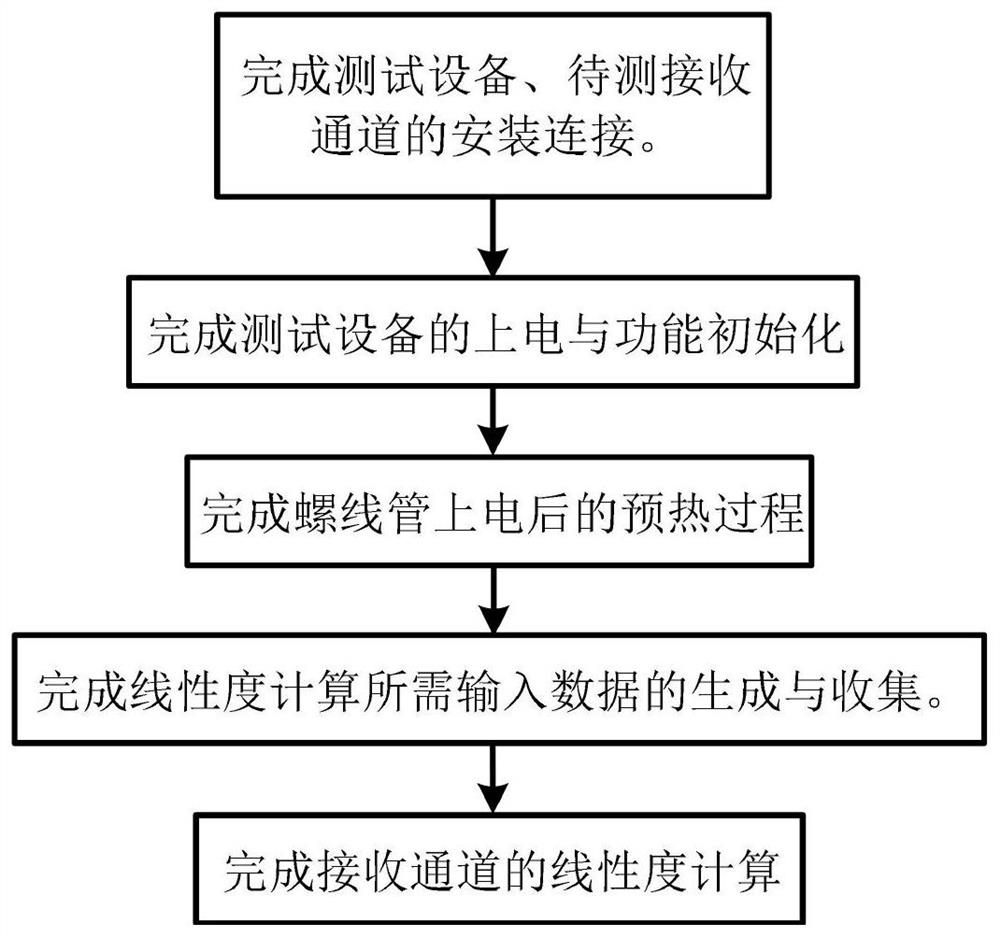

Method for testing linearity of receiving channel in alternating current electromagnetic tracking equipment

ActiveCN112924914ANo stringent requirementsFast and accurate measurement acquisitionElectrical measurementsDriving currentLinearity testing

The invention provides a method for testing linearity of a receiving channel in alternating current electromagnetic tracking equipment. Test equipment comprises an alternating current constant voltage source, a solenoid, a digital multimeter and an upper computer. The effective value of the driving current of the solenoid and the output amplitude of the receiving channel are collected to form the calibration curve of the receiving channel, then the fitting straight line of the receiving channel is obtained by adopting the least square principle, and finally the linearity index of the receiving channel to be measured is obtained through calculation. The method adopts an integrated form, is convenient to operate and low in test cost, has no strict requirements on sites, and has good repeatability.

Owner:BEIJING HUAHANG RADIO MEASUREMENT & RES INST

High-linearity testing stimulus signal generator

InactiveUS20120268192A1Reduce high costArbitary function generatorsTime-delay networksPower flowLinearity testing

A high-linearity testing stimulus signal generator comprises a signal collection unit receiving an input current signal, a waveform conversion unit connecting with the signal collection unit, a first voltage-to-current conversion unit connecting with the waveform conversion unit, a delay unit connecting with the waveform conversion unit, a second voltage-to-current conversion unit connecting with the delay unit, a current comparison unit connecting respectively with the first voltage-to-current conversion unit and the second voltage-to-current conversion unit, an error calculation unit connecting with the current comparison unit, and a compensation unit connecting with the error calculation unit. The above-mentioned structure forms a feedback mechanism to perform compensation adjustment to promote the linearity of the output signals. Thus, the present invention can generate high-accuracy testing stimulus signals.

Owner:NATIONAL YUNLIN UNIVERSITY OF SCIENCE AND TECHNOLOGY

Recording power compensating system and method

InactiveCN101770786BAccurate programming powerImprove burning qualityOptical beam sourcesRecord information storageTest powerPower compensation

The invention relates to a recording power compensating system and a recording power compensating method. A best power test is controlled by a control unit; a calculating unit is used for approximating test power and a corresponding asymmetry parameter into a linear test power function and calculating a difference value of the asymmetry parameter tested by a test unit and corresponding power compensation amount; and a power compensating unit makes use of the power compensation amount to adjust laser beam power so as to improve the recording quality.

Owner:QUANTA STORAGE INC

Photoelectric detector testing device and testing method

PendingCN114323567AIncrease light intensityLow costOptical apparatus testingPhotovoltaic detectorsIlluminance

The invention relates to a photoelectric detector testing device and method, and the method comprises the steps: converting a relation curve between the input optical power of a photoelectric detector and a conversion current into a relation curve between the input current of a second light source and the conversion current of the photoelectric detector, so that the linearity test of the photoelectric detector does not depend on the optical power value of the light source any more; therefore, the use of light source calibration equipment is omitted in the test process, the evaluation of the linearity of the photoelectric detector is realized under the condition that the light source calibration equipment is not used, and the cost of evaluating the linearity of the photoelectric detector is remarkably reduced. Besides, the first light source and the second light source are simultaneously arranged in the photoelectric detector testing device provided by the invention, so that the first light source shares the optical power originally required to be provided by the second light source on the premise that the light sources are utilized to provide the same illumination for the photoelectric detector; the problem that the second light source is prone to light attenuation when working at high light power is avoided, and the accuracy of linearity testing is improved.

Owner:SHENZHEN JUFEI OPTOELECTRONICS CO LTD

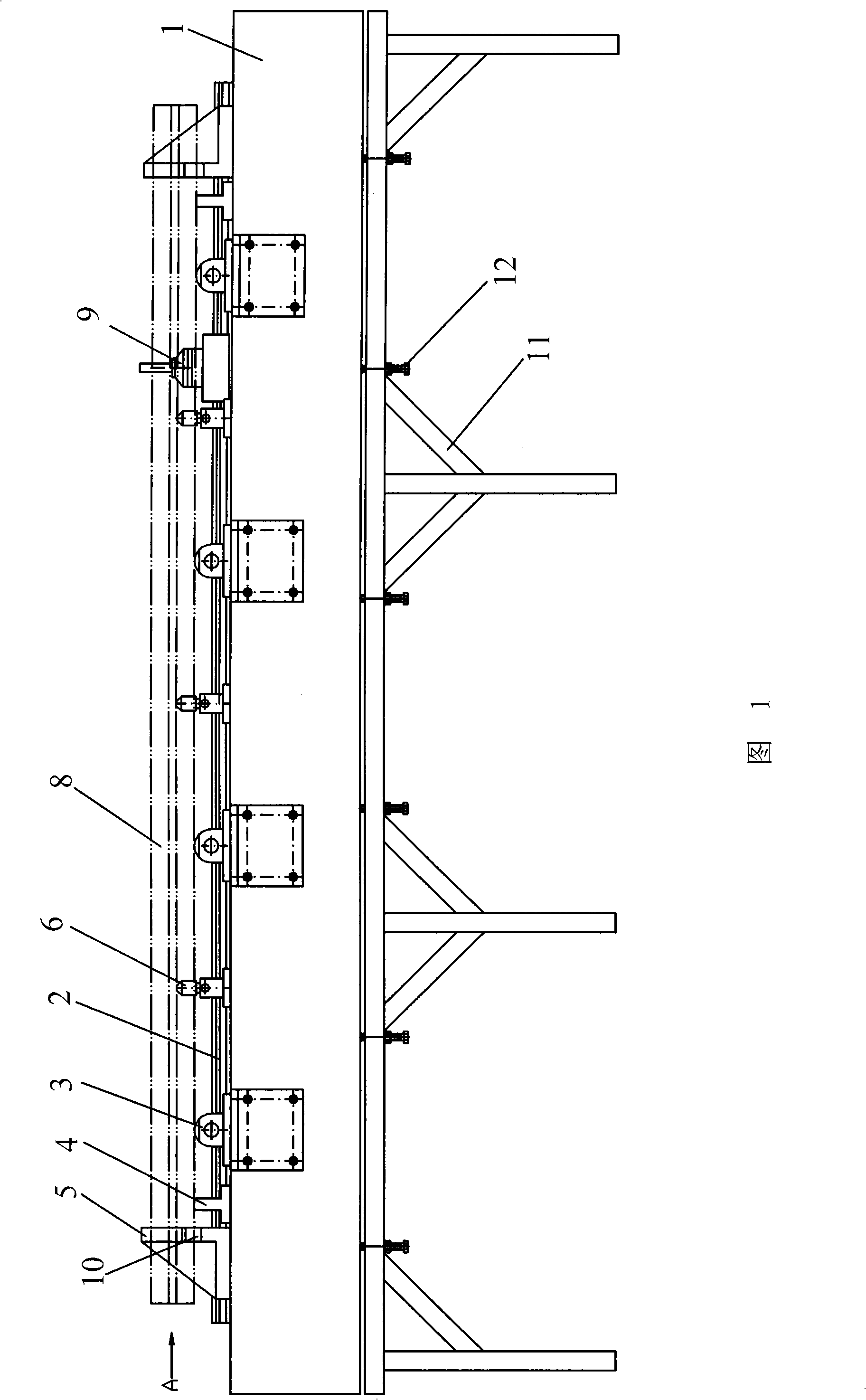

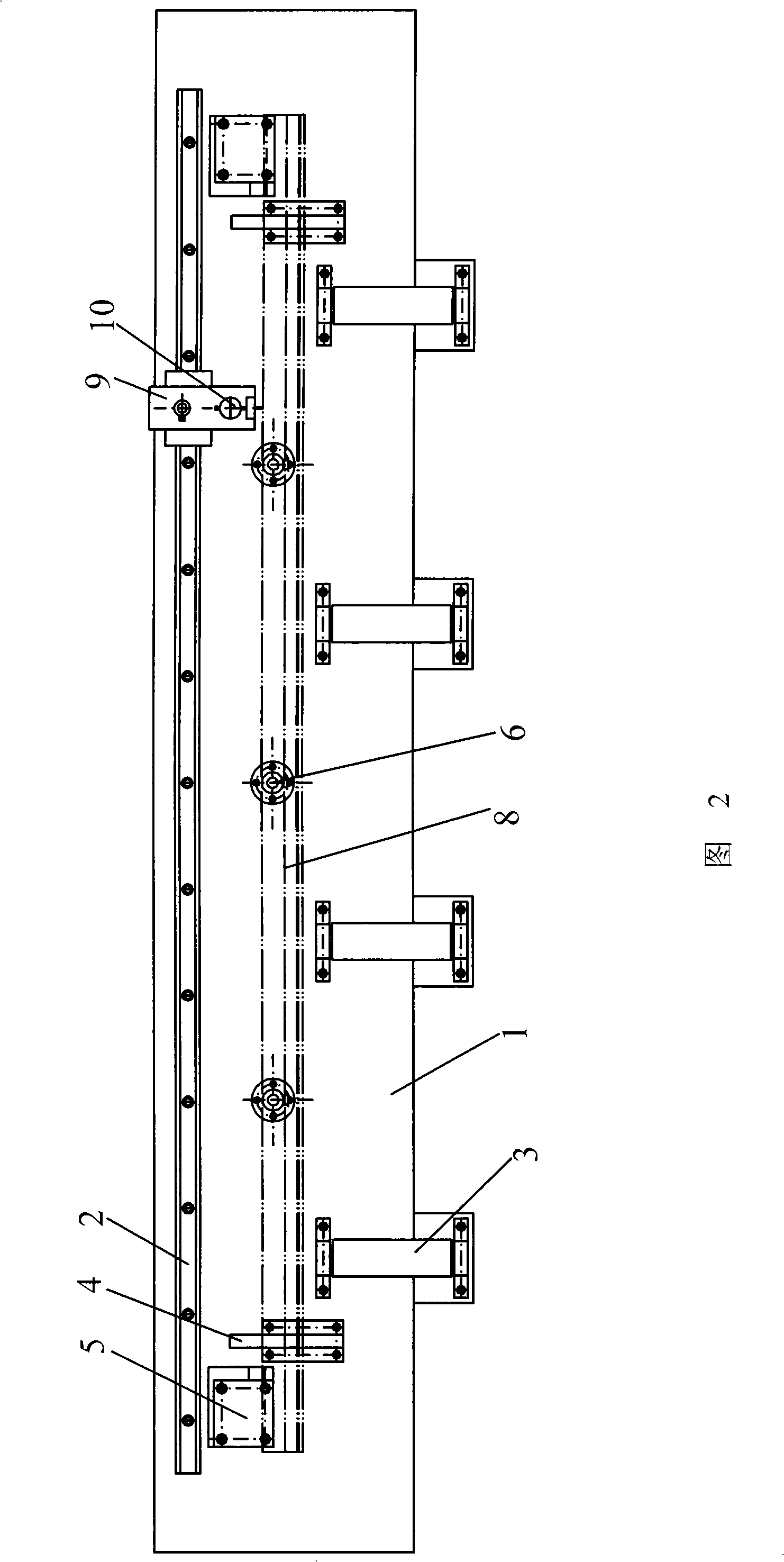

A device and method for detecting and determining the straightness of the width of a square guide rail

ActiveCN105698739BJudgment of flatnessEasy to operateMeasurement devicesMeasurement deviceLinearity testing

The invention discloses a device and method for detecting and determining the straightness of the width of a square guide rail, including a workbench, a controller, a double linear guide rail and a transmission motor. Connected by a ball screw, a measuring device is installed on the workbench at the front and rear sides of the detection platform, the measuring device and the transmission motor are connected with the controller, the controller is connected with a data processor, each measuring device is connected with the data processing connected to the device. The beneficial effects of the present invention are: by using two measuring devices to detect the two surfaces of the square guide rail at the same time, the flatness of the two surfaces of the square guide rail can be quickly judged, and the width of the square guide rail can also be detected at the same time, which is convenient for judgment Regarding the straightness or curvature of the square guide rail, the present invention also has the advantages of wide application range, easy operation, high detection accuracy and high efficiency.

Owner:浙江泰燊传动科技有限公司

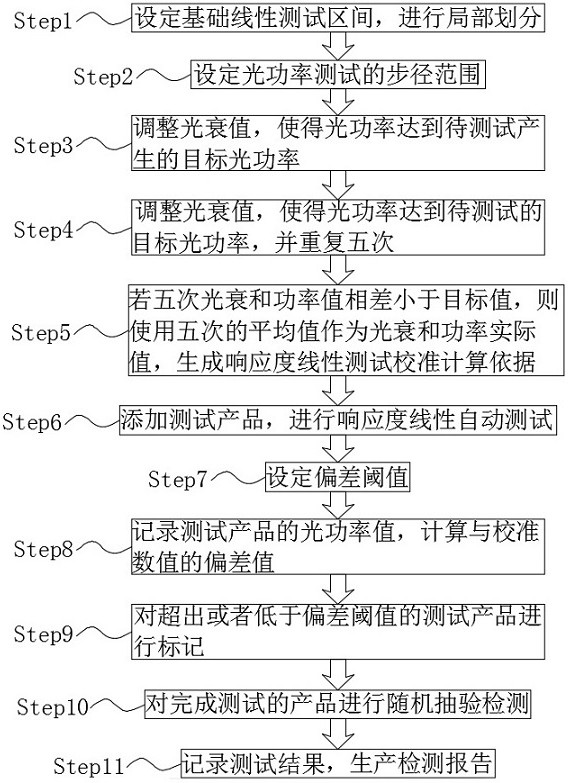

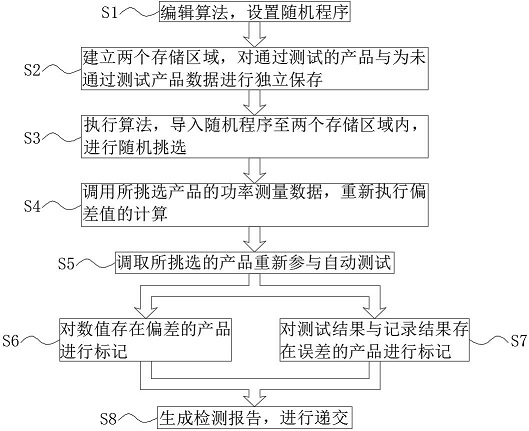

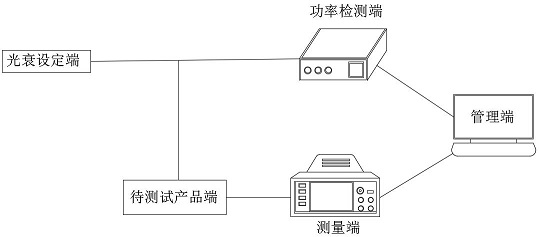

Test method for automatically testing linearity

PendingCN114812653AFacilitates automated testingImprove test efficiencyPhotometry using electric radiation detectorsTest efficiencyLinearity testing

The invention relates to the field of linearity testing, and discloses a testing method for automatically testing linearity, which comprises the following steps: Step 1, setting a basic linearity testing interval, and carrying out local division; step 2, setting a step diameter range of an optical power test; 3, the light attenuation value is adjusted, so that the light power reaches the target light power generated by the test; step 4, adjusting the light attenuation value to enable the light power to reach the target light power to be tested, and repeating for five times; and Step 5, if the difference between the five times of light attenuation and the power value is smaller than the target value, the average value of the five times is used as the actual light attenuation and power value, and a responsivity linear test calibration calculation basis is generated. By adding a scheme capable of automatically testing the product linearity, the method is high in testing efficiency, can well adapt to mass production, is low in production cost, can provide convenient calibration measures, is convenient for a user to complete automatic testing by programming light attenuation and light power, can verify the testing accuracy, and guarantees the qualified rate of finished products.

Owner:浙江光特科技有限公司

Waterlog comprehensive testing system and waterlog comprehensive testing platform thereof

ActiveCN101893646BImprove product qualityHigh degree of automationTesting/calibration of speed/acceleration/shock measurement devicesProduct inspectionCombined test

The invention discloses a waterlog comprehensive testing system and a waterlog comprehensive testing platform thereof. The waterlog comprehensive testing system consists of a sensor property testing unit, a circuit board voltage and linearity testing unit, a circuit board static pressurization testing unit, a waterlog communication signal testing unit, a waterlog power supply adaptability testingunit, a microprocessor and a computer. The upper case body of the waterlog comprehensive testing platform is provided with a gas valve switch, a waterlog testing passage, a waveband switch, a toggle switch, a voltage indicating lamp and an interface connector from left to right in sequence; and the top panel of a middle case body is provided with a motion axis tool, a sensor testing tool and a waterlog circuit board tool. The system is a set of testing equipment for detecting the performance state and the delivery inspection in a waterlog production process, and has the advantages of ensuringproduct quality and high automation degree, improving the efficiency of product inspection, possibly reducing human operation and detection errors, and effectively avoiding inspection errors caused by objective factors of humans.

Owner:江西省智成测控技术研究所有限责任公司

Comprehensive Test and Evaluation Method of Geophone Dynamic Performance

ActiveCN107153224BSolve test problemsSolve evaluation problemsGeological measurementsCombined testLinearity testing

The invention provides a detector dynamic performance integrated testing and evaluating method. The detector dynamic performance integrated testing and evaluating method comprises steps of 1, performing the reception linear test and the ground noise test; 2, performing the pulse signal test and the weak signal reception ability test; 3, performing the anti-interference capability test and the actual seismic signal reception capability test; 4, performing the field test to verify the reception performance of the detector by comparing actual seismic tests; and 5, performing the integrated performance evaluation of the detector. The detector dynamic performance integrated testing and evaluating method is closely integrated with the actual data, and the effect is more obvious. It is an effective method to preferably select the detector according to the seismic exploration demand.

Owner:中石化石油工程技术服务有限公司 +1

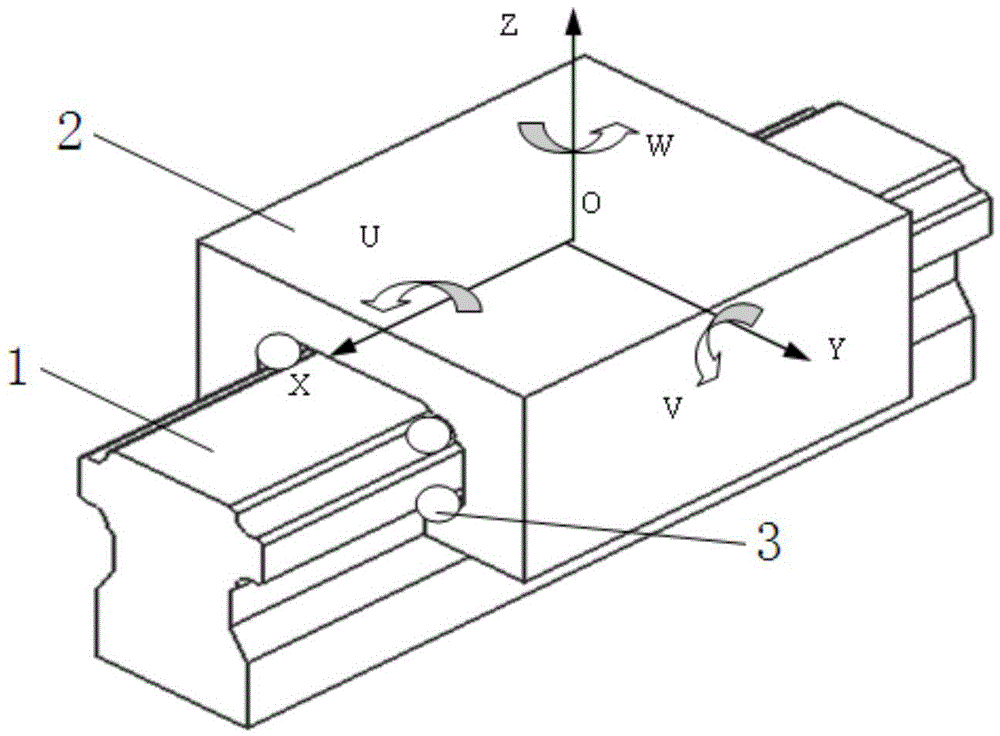

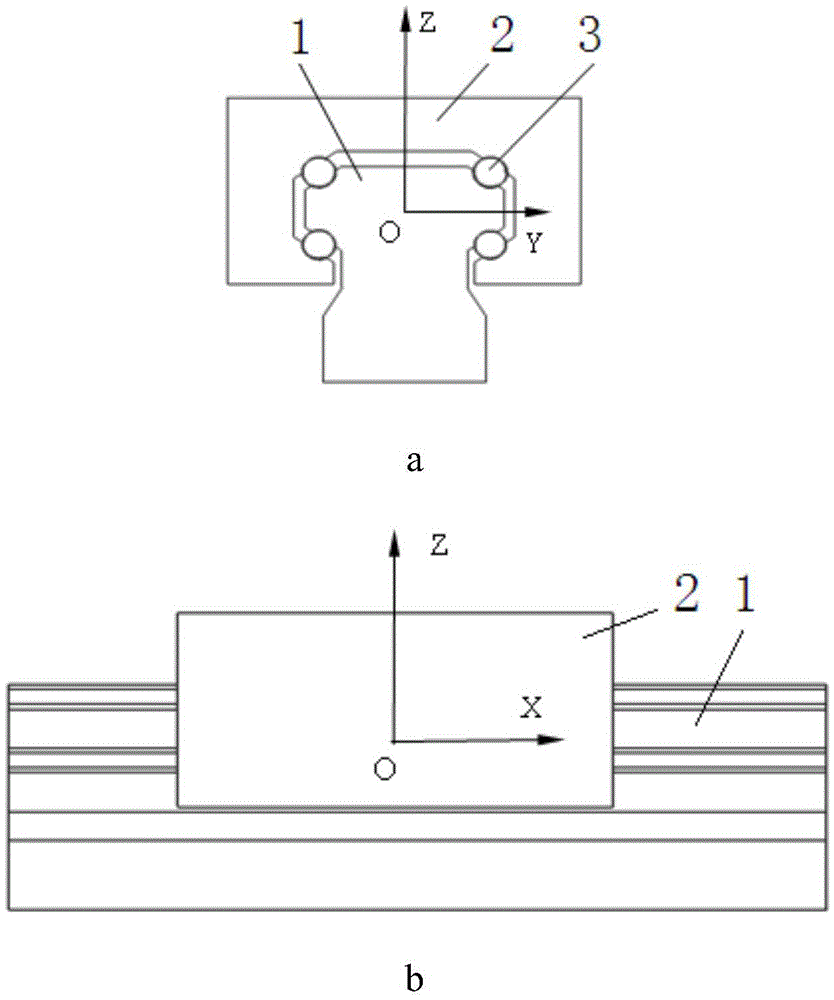

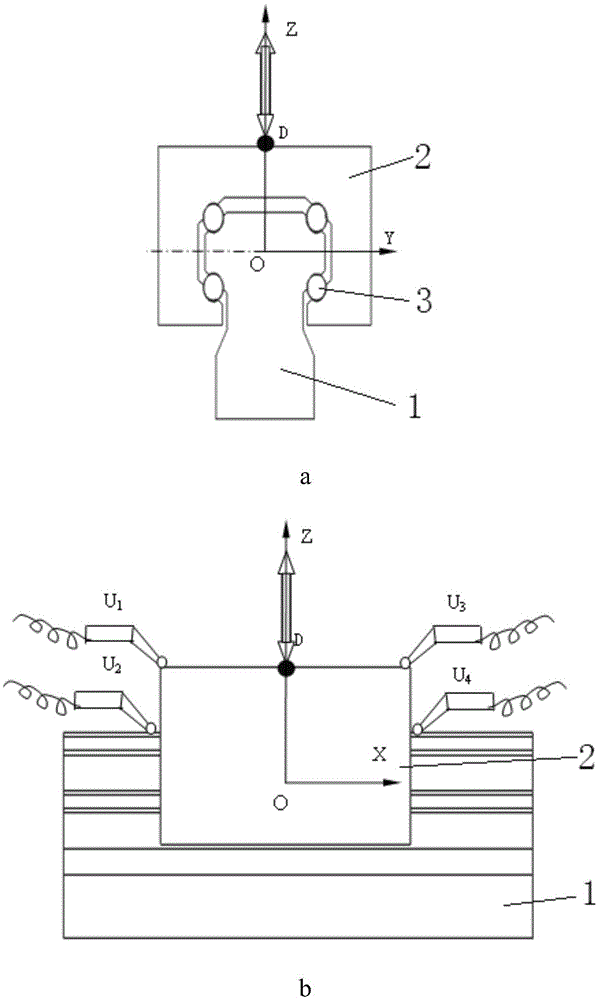

A static stiffness testing device and method for joints of rolling linear guide rail pairs

ActiveCN104062114BEasy to controlMachine part testingStrength propertiesAxis–angle representationLinearity testing

The invention discloses a static stiffness testing device for the joint part of a rolling linear guide rail. Three positioning holes A, B and C are arranged on the bridge type box body; Stiffness test loading; fix the tensile load loading mechanism in the positioning hole A, and perform normal tensile stiffness test loading; fix the pressure load loading mechanism in the positioning hole B, and perform lateral stiffness test loading; fix the torque loading mechanism in the positioning In hole A, carry out angular stiffness test loading around the Z axis; fix the torque loading mechanism in positioning hole B, and carry out angular stiffness test loading around the Y axis; fix the torque loading mechanism in positioning hole D on the front panel of the bridge box , to carry out angular stiffness test loading around the X axis. The invention also discloses a method for testing the static stiffness of the joint part of the rolling linear guide rail pair. The device and method of the present invention adopt a modular structure design, which can meet the requirements of stiffness testing of guide rails of different specifications.

Owner:XIAN UNIV OF TECH

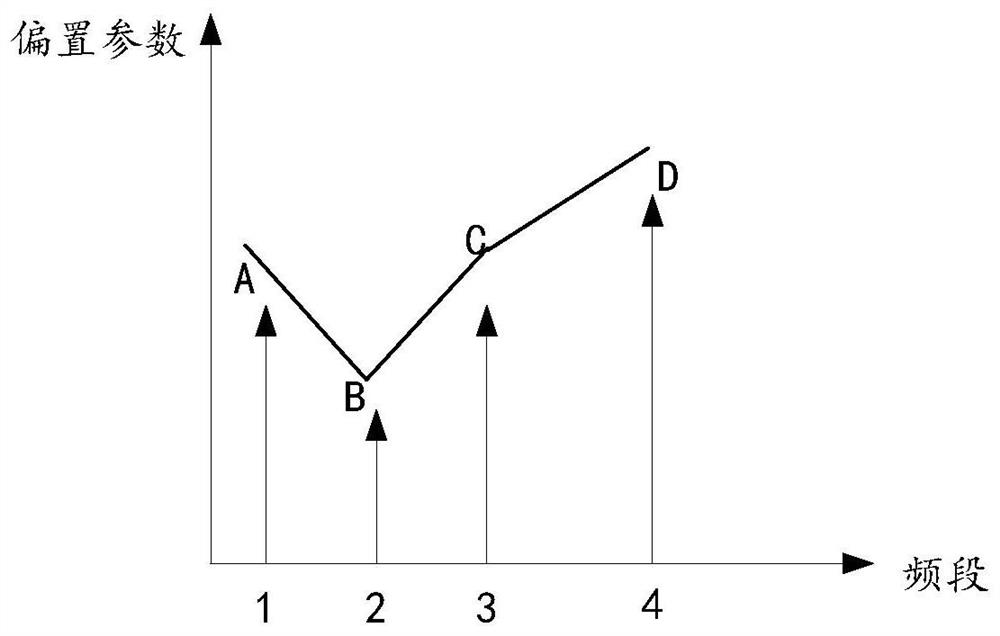

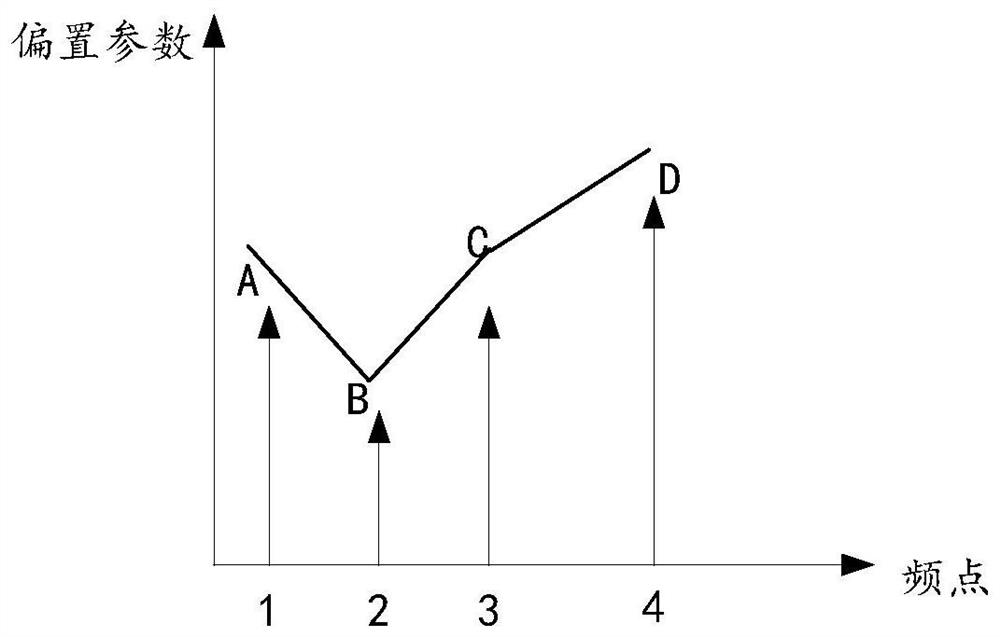

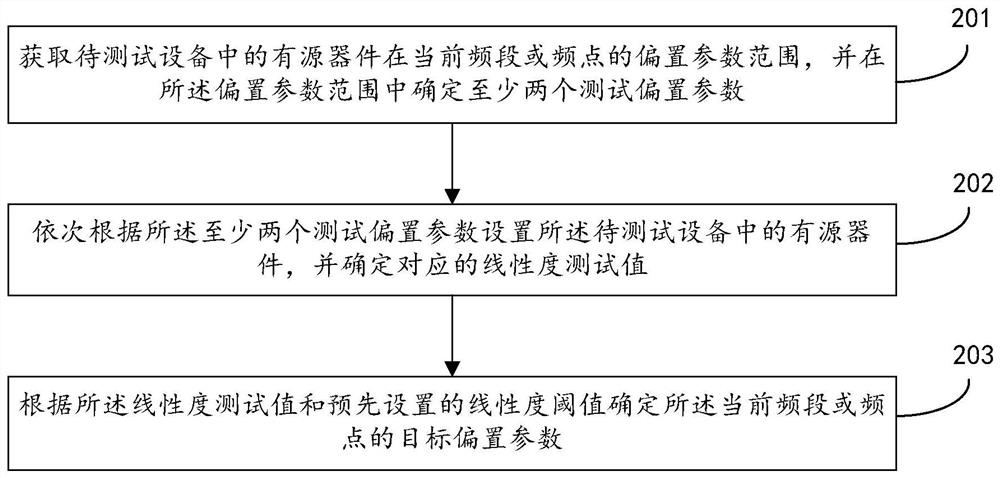

Active device bias parameter determination method, device, storage medium and electronic equipment

InactiveCN108802589BConvenience guaranteedAddressing Performance DifferencesElectrical testingLinearity testingControl engineering

The embodiment of the invention discloses a determination method and apparatus of offset parameters of an active device, a storage medium and electronic equipment. The determination method of offset parameters of an active device includes the steps: obtaining an offset parameter range of the active device in the equipment to be tested at the current frequency range or frequency point, and determining at least two test offset parameters in the offset parameter range; according to the at least two test offset parameters, setting the active device in the equipment to be tested, and determining acorresponding linearity test value; and according to the linearity test value and the preset linearity threshold, determining a target offset parameter of the current frequency range or frequency point. Through the above technical scheme, the determination method of offset parameters of an active device performs a linearity test on each equipment to be tested under a plurality of test offset parameters, according to the linearity test value fed back from the linearity test, determines the target offset parameter of the active device of each equipment to be tested, thus guaranteeing excellent performance of each equipment to be tested, and solves the performance difference problem caused by applying the same group of offset parameters to the active devices of the same type of equipment, thus improving consistence of performance of the equipment.

Owner:GUANGDONG OPPO MOBILE TELECOMM CORP LTD

Y waveguide phase modulation linearity test method for optic fiber gyroscope

Owner:BEIJING AEROSPACE TIMES OPTICAL ELECTRONICS TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com