Automatic debugging device of intelligent data collection instrument

A technology for smart meters and data acquisition, applied in measuring devices, instruments, etc., can solve the problems of low accuracy and stability of technical parameters, long development cycle of data acquisition smart meters, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

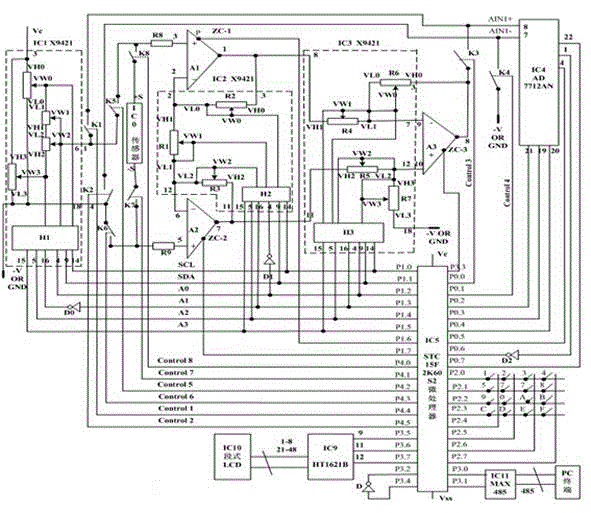

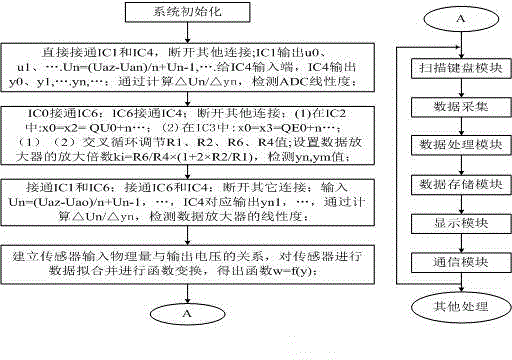

[0051] 1. Circuit connection instructions. exist figure 1 Among them, the three dotted boxes IC1, IC2, and IC3 are three chips of the model X9241, the internal structure of the chip and the pin connection, each chip has four digital potentiometers POT0, POT1, POT2, POT3, POT0 of IC2 , POT1 and POT2 are respectively represented by R2, R1 and R3, POT0, POT1, POT2 and POT3 in IC3 are represented by R6, R4, R5 and R7 respectively, H1, H2 and H3 represent the control and data of IC1, IC2 and IC3 respectively Register; K1-K8 consists of IC7 and IC8 chips with model number HD74HC4066;

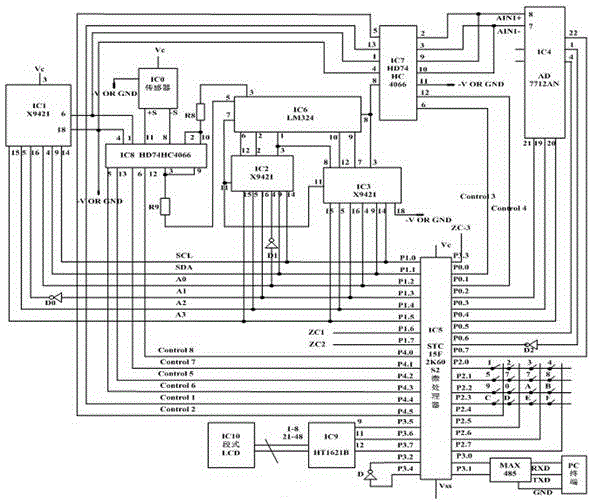

[0052] exist figure 2In IC1, pin 3 is connected to pin 17 and then Vc, pin 1 is connected to pin 7, pin 2 is connected to pin 18 and then connected to -VOR GND, pin 6 is connected to pin 13 and then the common center tap VW12 is connected, pin 8 is connected to pin 12, pin 11 Pin 19, pin 10 -VOR GND, pin 20, pin 3 Vc; P1.0, P1.1, P1.2, P1.3 negate, P1.4, P1.5 of IC5 are connected to IC1 The 15, 5...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com