Test method for automatically testing linearity

A technology of automatic testing and testing methods, applied in the direction of photometry and instruments using electric radiation detectors, can solve the problems of lack of verification test accuracy measures, lack of automatic test solutions, and inability to provide calibration measures, etc., to achieve convenient calibration measures, high test efficiency and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

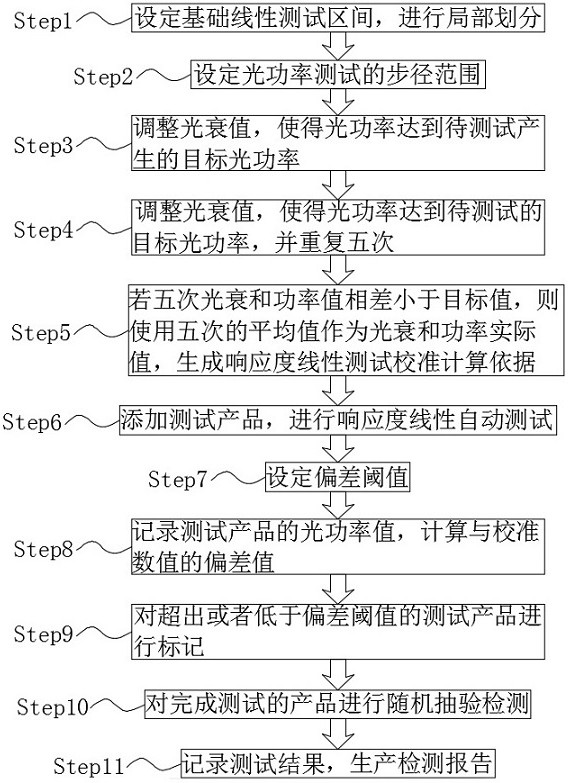

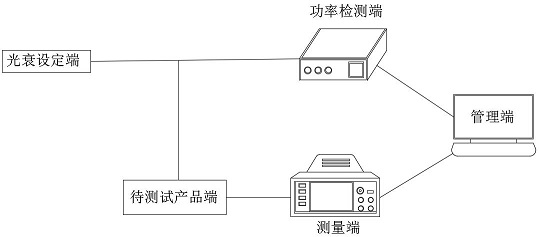

[0051] A test method for automatically testing linearity of the present embodiment, such as figure 1 and image 3 shown, including the following steps:

[0052] Step1: Set the basic linear test interval and perform local division;

[0053] Step2: Set the step range of the optical power test;

[0054] Step3: Adjust the optical attenuation value so that the optical power reaches the target optical power to be tested;

[0055] Step4: Adjust the optical attenuation value so that the optical power reaches the target optical power to be tested, and repeat five times;

[0056] Step5: If the difference between the five optical attenuation and power value is less than the target value, the average value of the five optical attenuation and power value is used as the actual value of optical attenuation and power, and the calculation basis for the responsivity linearity test calibration is generated;

[0057] Step6: Add test products and perform linear automatic test of responsivity; ...

Embodiment 2

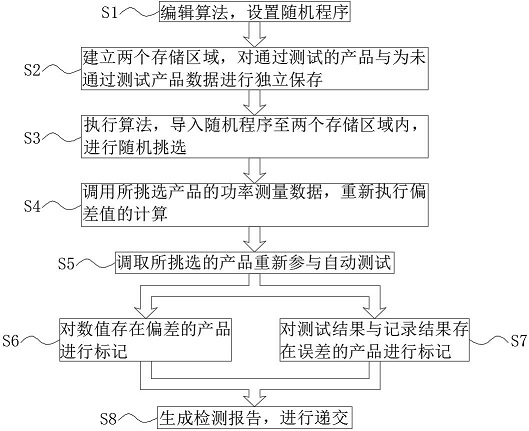

[0067] This embodiment also provides a random sampling detection process, such as figure 2 shown, the following steps:

[0068] S1: Edit the algorithm, set the random program;

[0069] S2: Establish two storage areas to independently save the data of products that pass the test and those that fail the test;

[0070] S3: Execute the algorithm, import the random program into the two storage areas, and perform random selection;

[0071] S4: Call the power measurement data of the selected product, and re-execute the calculation of the deviation value;

[0072] S5: Recall the selected product to participate in the automatic test again;

[0073] S6: Mark products with deviations in value;

[0074] S7: Mark the products with errors between the test results and the recorded results;

[0075] S8: Generate a test report and submit it.

[0076] like figure 2 As shown, the random program in the step S1 uses uniform random bits as auxiliary input to guide its own behavior, and the...

Embodiment 3

[0083] In this embodiment, as figure 1 shown, as figure 1 shown in the step 5, the responsivity is a physical quantity describing the photoelectric conversion capability of the device, and the responsivity is related to the device material and light wavelength, the unit is R, and its size is the average output current Ip of the photodetector and the light The ratio of the average input power Po of the detector, that is, the ratio of the output electrical signal current to the input optical signal power;

[0084] The formula is expressed as:

[0085] R=Ip / Po, the unit is A / W.

[0086] like figure 1 As shown, the calibration calculation basis in the described step Step5, as an important measurement basis for the product quality value, is based on the premise that the measured input amount is in a stable state, and under specified conditions, the calibration calculation basis and the actual calculation data The maximum deviation.

[0087] To sum up, the present invention has ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com