Linear testing method for piezoelectric type touch screen

A test method and touch screen technology, applied in the direction of electrical digital data processing, faulty computer hardware detection, data processing input/output process, etc., can solve the problem of long working hours, complicated testing process, affecting the overall efficiency of touch screen manufacturing, etc. Problems, to achieve the effect of improving production efficiency and shortening the time spent

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

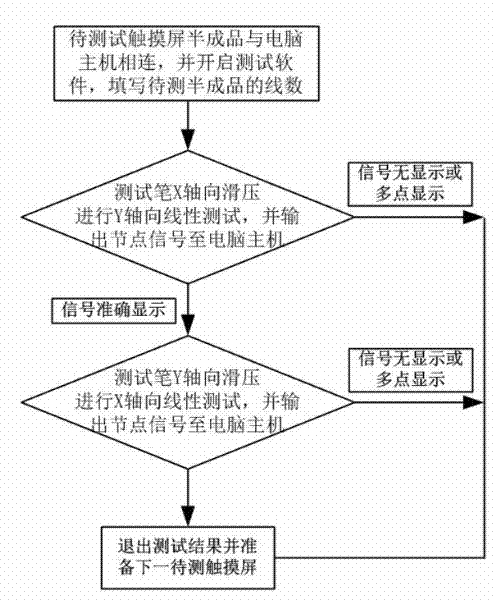

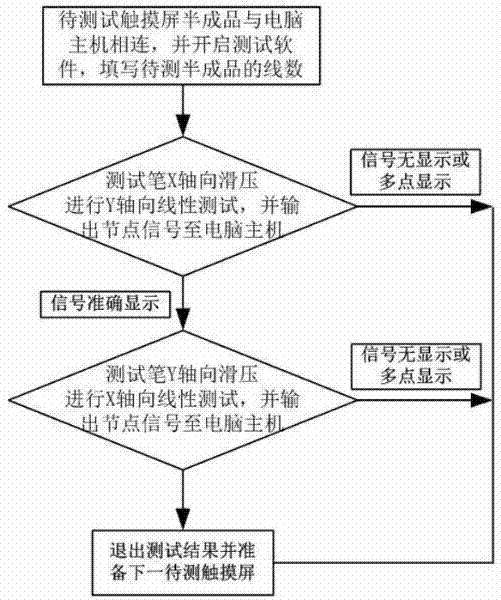

[0014] In the following, the specific implementation manners of the present invention will be further described in detail in conjunction with the accompanying drawings of the embodiments, so as to make the technical solution of the present invention easier to understand and grasp.

[0015] It can be seen from the conventional understanding that the piezoelectric touch screen is one of many types of touch screens, which includes an ITO film with N X-axis wiring X1~XN on the upper layer and an ITO glass with M Y-axis wiring Y1~YM on the lower layer. , the two layers of wiring are vertically interlaced to form M×N nodes. In the case of use, the user touches and presses the surface to make one or more nodes contact and connect, and recognizes the user's control requirements according to the pre-programmed conduction rules, and performs corresponding manipulations.

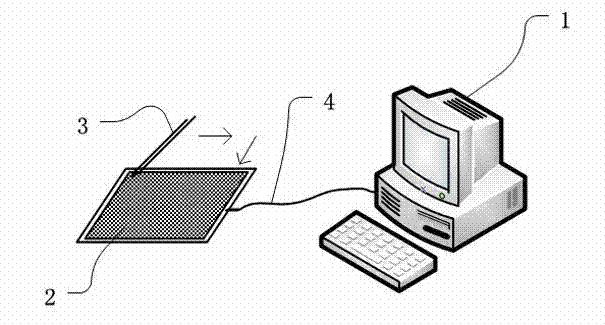

[0016] and see attached figure 1 As shown, when the linearity test is to be performed on the semi-finished touch sc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com