Slide rail linearity testing apparatus

A detection device and straightness technology, applied in the direction of angle/taper measurement, etc., can solve the problem of low detection accuracy and achieve the effect of high detection accuracy and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

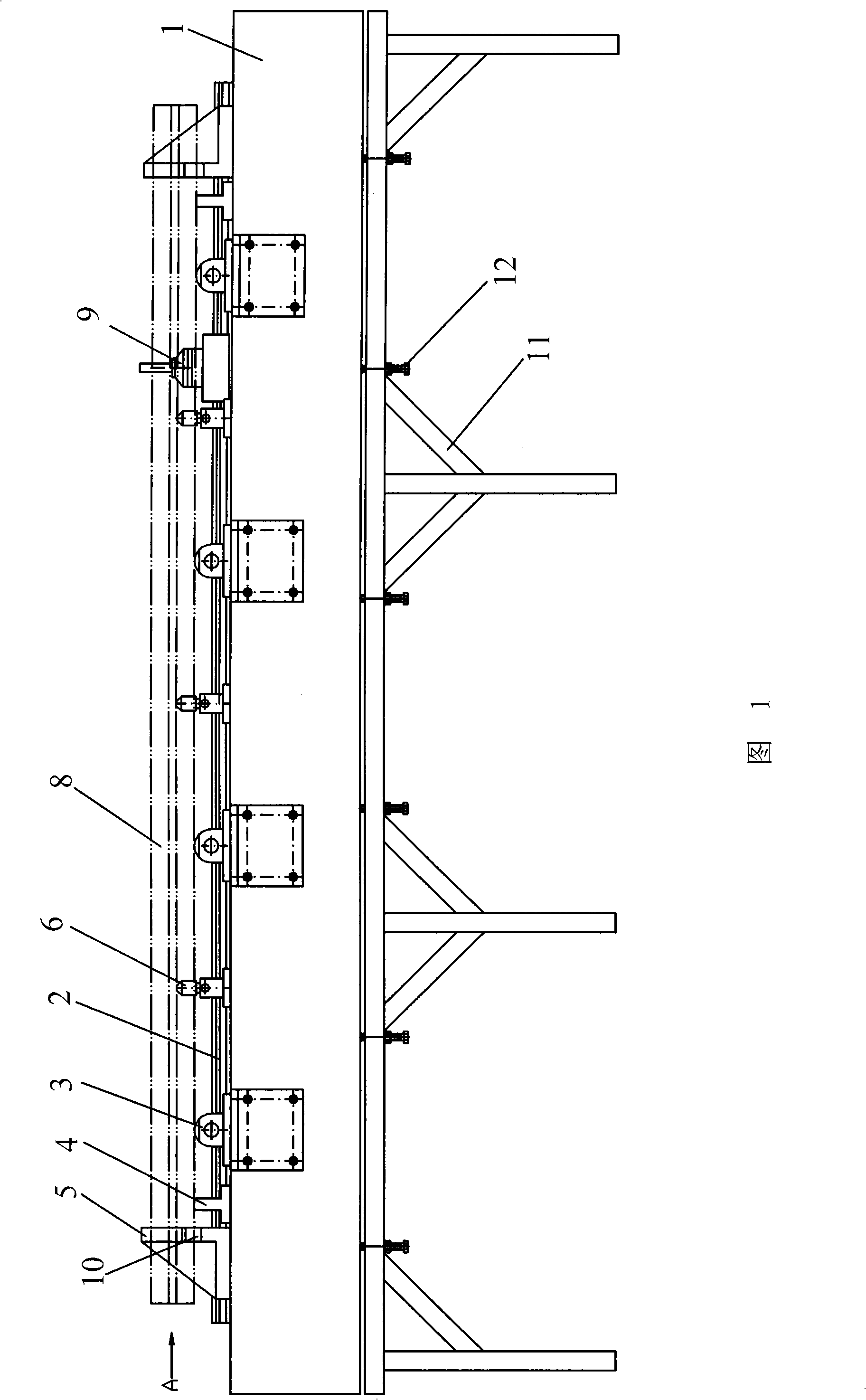

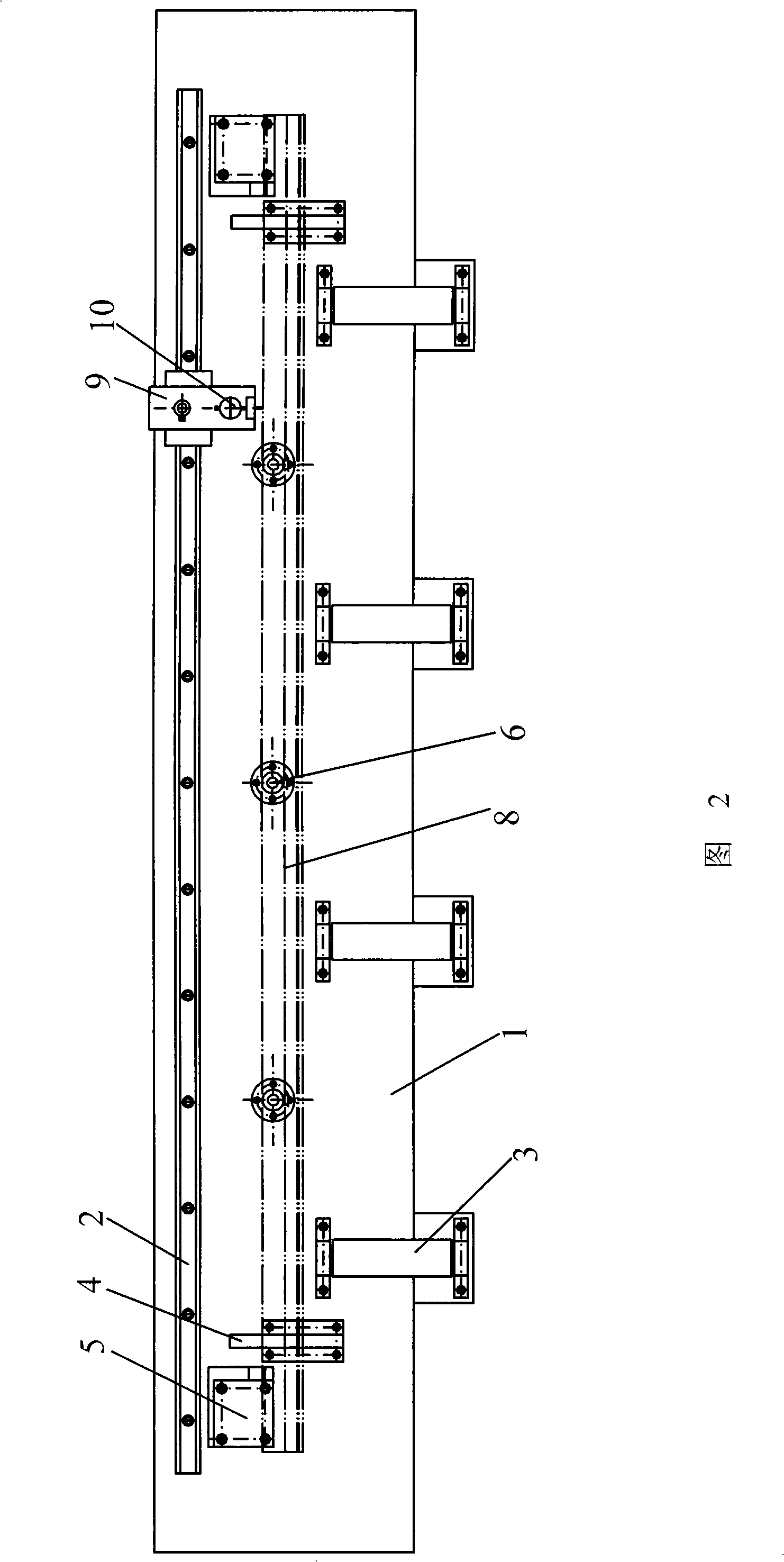

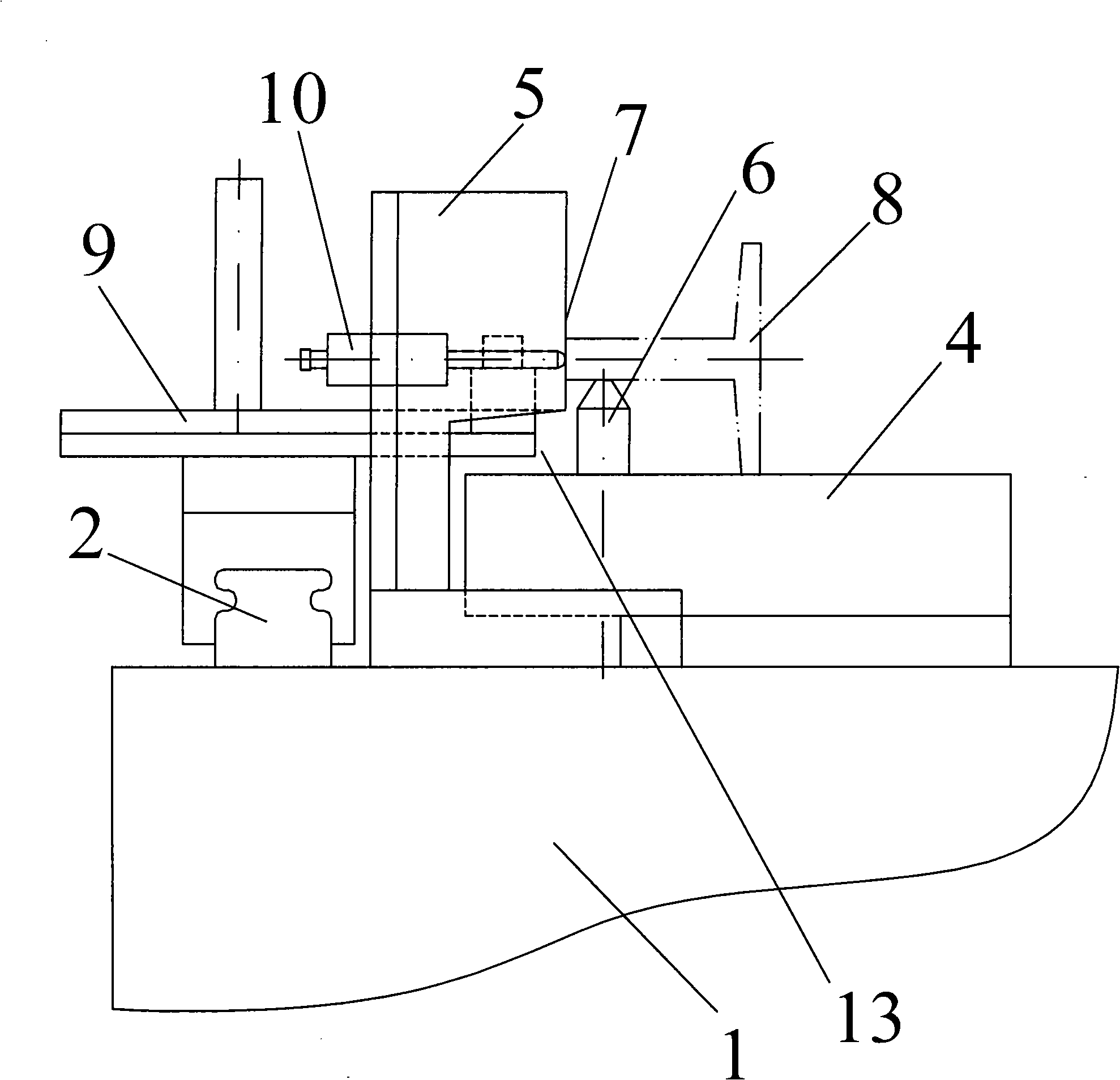

[0012] Embodiment: Fig. 1, Fig. 2 and image 3 As shown, a guide rail straightness detection device includes a working platform 1, the working platform 1 is placed on a frame 11, and a leveling screw 12 is provided between the frame 11 and the working platform 1, and the leveling screw 12 is adjusted by twisting 12 can adjust the levelness of the working platform 1 to ensure that the table of the working platform 1 is parallel to the horizontal plane; the table of the working platform 1 is provided with a bottom positioning part 4, a side positioning part 5 and a lifting movable top 6, and the bottom positioning part 4 1. Each of the side positioning parts 5 includes at least two distributed along the length direction of the working platform 1; a linear track 2 is installed on one side of the working platform 1 along the length direction of the working platform 1, and a moving track 2 is slidably fitted on the linear track 2. Table base 9, measuring device 10 dial indicator is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com