Method for determining stress of sapphire single crystal material by using X-ray diffraction method

A single crystal material, sapphire technology, applied in material analysis using radiation diffraction, material analysis using wave/particle radiation, material analysis, etc., can solve the problems of poor measurement accuracy and accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

[0048] Specific embodiment one: the present embodiment measures the method for sapphire single crystal material stress with X-ray diffraction method, comprises the following steps:

[0049] Step 1. Select the sapphire crystal rod material, and use a diamond tool to cut the sapphire crystal rod into a sapphire single crystal substrate, and polish the sapphire single crystal substrate;

[0050] Step 2. Measure the azimuth and ψ:

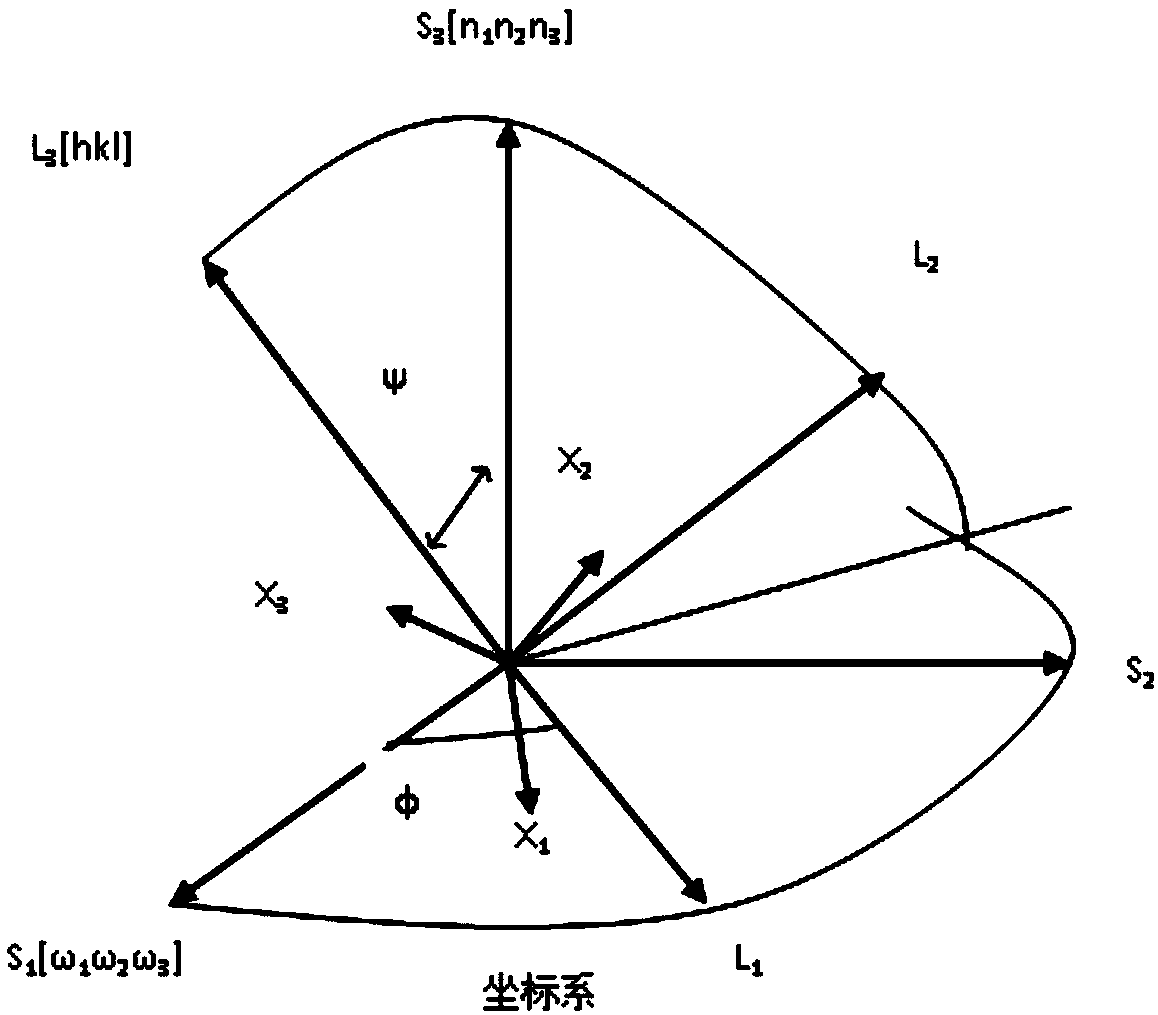

[0051] For the sapphire single crystal substrate sample after step 1 polishing, the pole figure is measured by X-ray diffraction method, and the spatial azimuth angle is further obtained through the pole figure and ψ; where is the angle rotated by the pole around the normal of the characteristic surface, and ψ is the inclination angle of the diffraction vector relative to the normal of the sample surface;

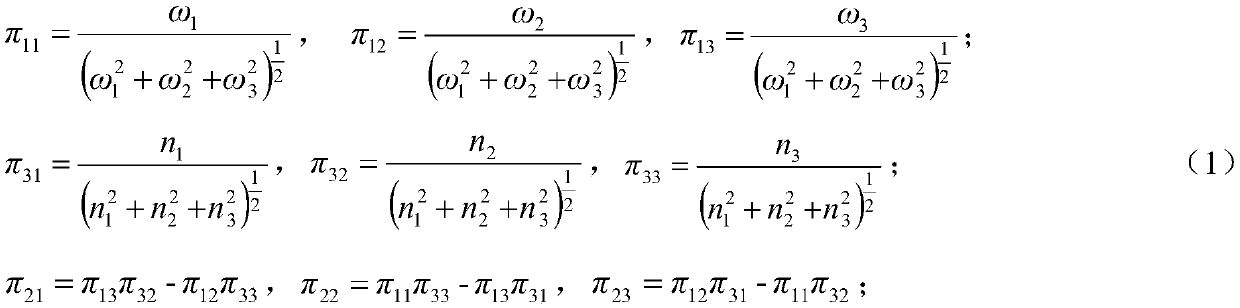

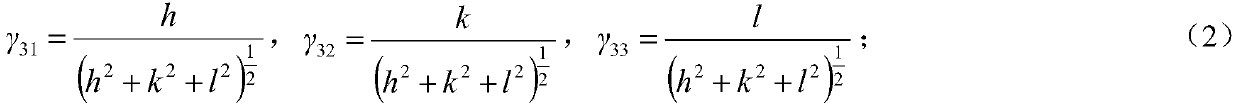

[0052] Step 3, establish a relational coordinate system and perform single crystal orientation, give the sample coordinate system S, the labo...

specific Embodiment approach 2

[0077] Embodiment 2: The difference between this embodiment and Embodiment 1 is that in step 1, the sapphire ingot material obtained by the cold-heart shouldering micro-pulling method is selected. Others are the same as in the first embodiment.

specific Embodiment approach 3

[0078] Specific embodiment three: the difference between this embodiment and specific embodiment one is: in step one, the specific method of polishing the sapphire single crystal substrate is:

[0079] The flaky single crystal sample is polished until the surface roughness of the sapphire single crystal sample is Ra0.2-0.4nm to obtain a polished sapphire single crystal sheet. Others are the same as in the first embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com