Composite material laminate optical fiber impact position identification method based on strain nonlinear weighting

A non-linear weighting and composite material layer technology, which is applied in the direction of analyzing materials, using one-time impact force to test the strength of materials, measuring devices, etc., can solve the problems of susceptibility to electromagnetic interference and cumbersome process, and achieve strong anti-electromagnetic interference ability and processing Simple, simple layout effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

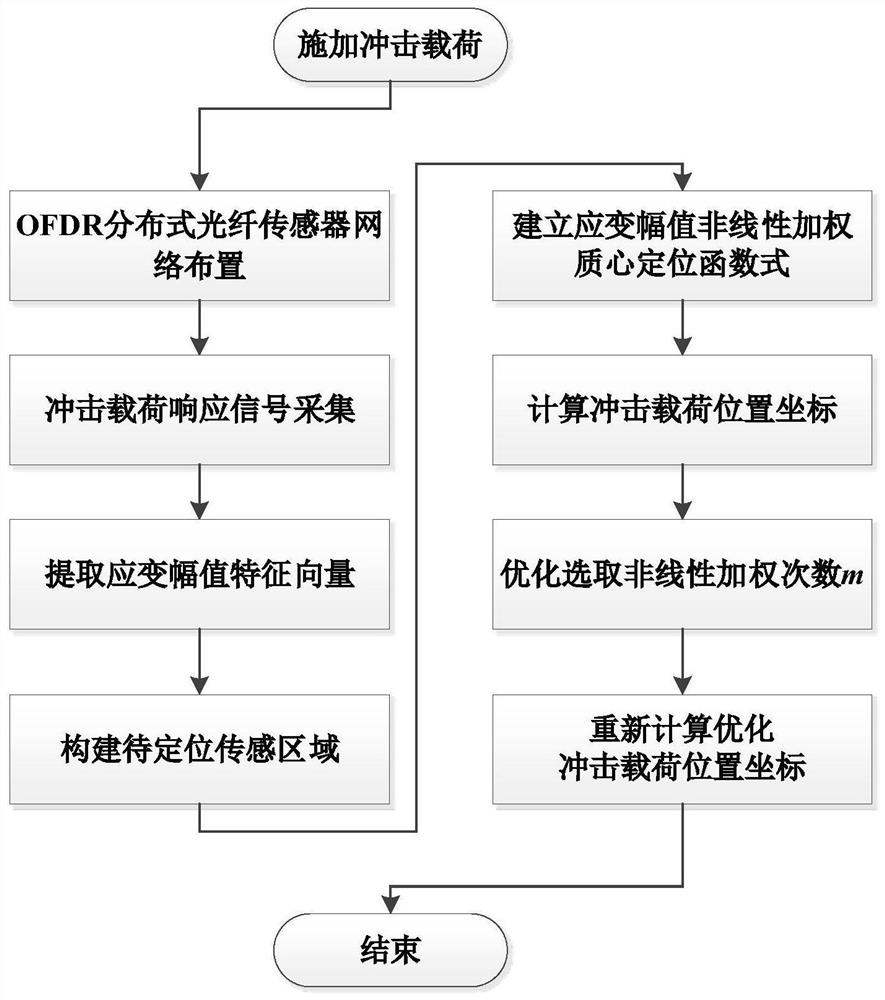

[0043] The technical solution of the present invention will be further described in detail below in conjunction with the accompanying drawings.

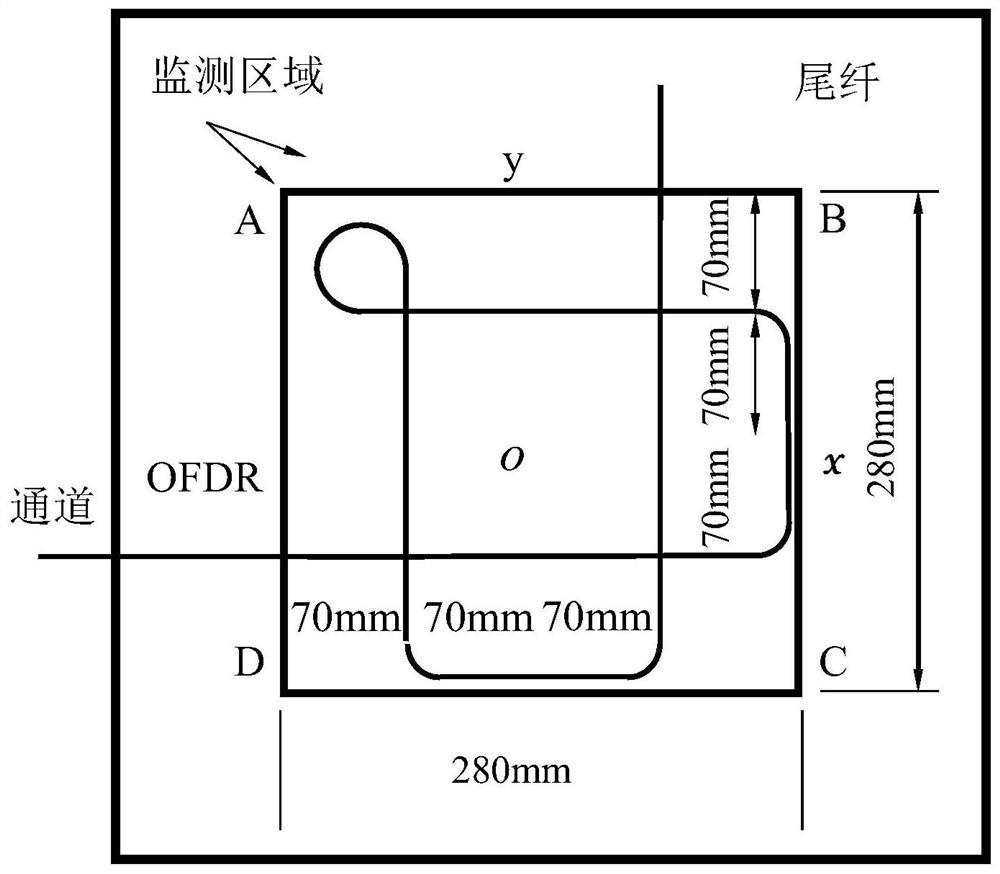

[0044] Step 1: OFDR distributed fiber optic sensor network layout

[0045] Step a: Construct a square monitoring area ABCD at the center of the four-sided fixed-supported composite plate structure, where point A is located in the upper left corner, and points A, B, C, and D are the vertices of the square arranged in a clockwise direction; a two-dimensional right-angle Coordinate system, select the central position of the area to be monitored of the composite material plate structure as the coordinate origin O, define the X axis parallel to the AB direction, and the Y axis parallel to the AD direction;

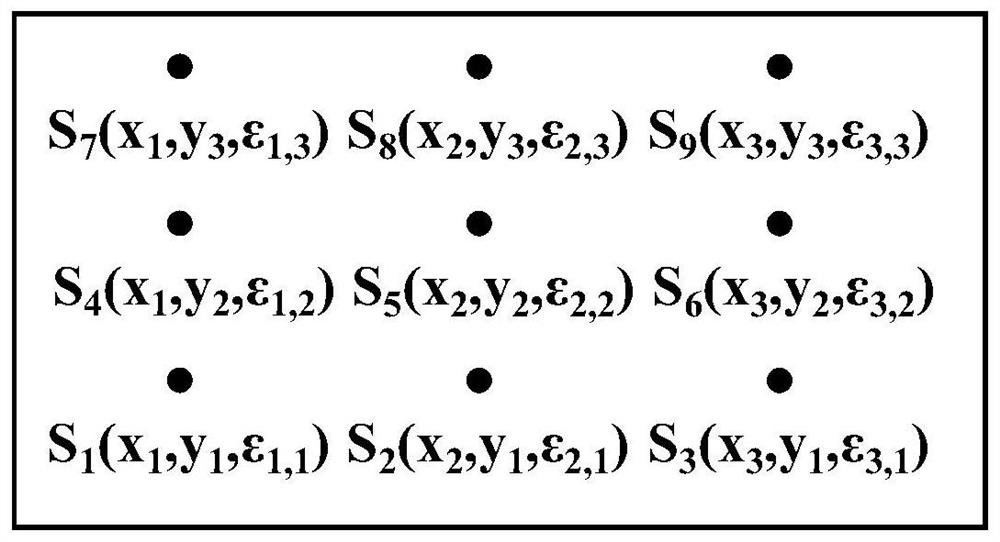

[0046] Step b: Select three rows of OFDR distributed optical fiber sensor paste paths parallel to the X-axis direction in the monitoring area, and name them as the first, second, and third row of sensor paths from bottom to top. The f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com