A method for calculating the influence of a low-temperature economizer on the heat consumption rate of a steam turbine unit

A low-temperature economizer and calculation method technology, applied in the direction of calculation, instrument, data processing application, etc., can solve the problem that there is no calculation method yet

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0102] The technical solution of the present invention will be further described below in conjunction with the accompanying drawings.

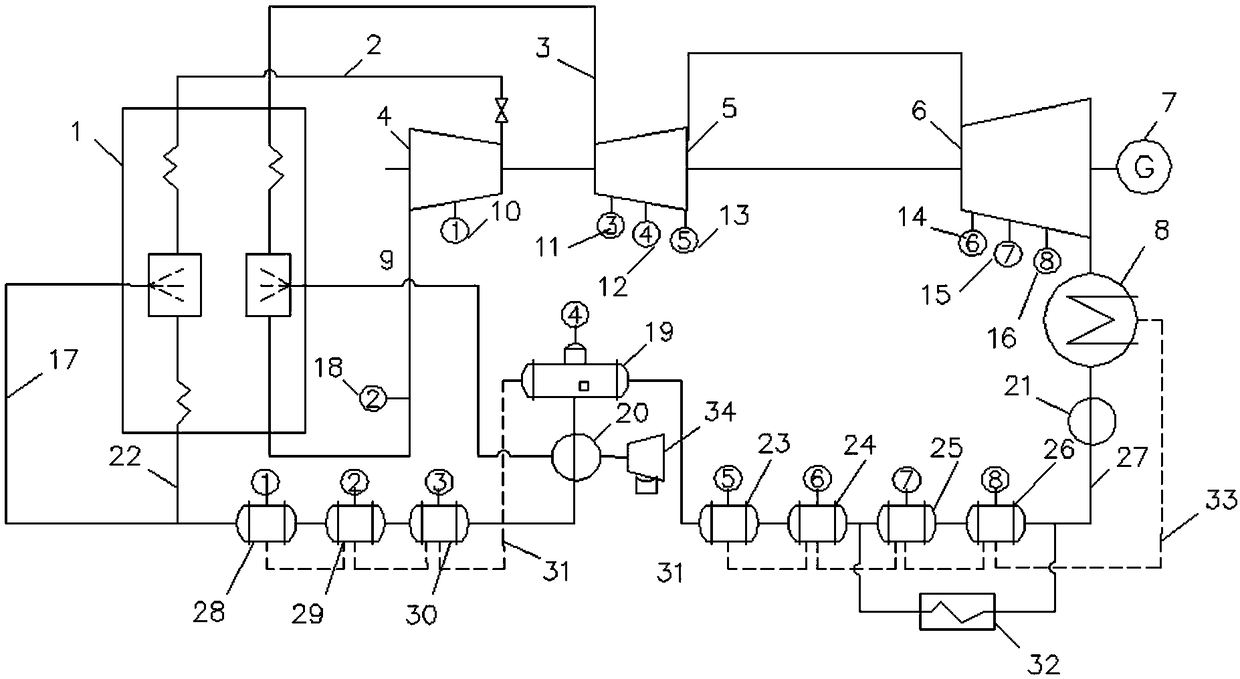

[0103] In order to facilitate the understanding of the calculation method of the present invention, as follows figure 1 Shown is a home-made intermediate reheating, single-shaft, two-cylinder, two-exhaust, condensing steam turbine, the feedwater reheating system is 3 high plus 1 deaeration + 4 low plus, and it is equipped with a steam-driven feedwater pump The unit is described for the column.

[0104] figure 1 Shown is a reheat unit with 8 stages of regenerative extraction. Its thermal system is mainly composed of boiler 1, main steam (main steam pipeline) 2, reheat steam (reheat steam pipeline) 3, high pressure cylinder 4, medium pressure cylinder 5, low pressure cylinder 6, generator 7, condensing steam 8, and then reduce the water 9. And one draw 10, two draws 18, three draws 11, four draws 12, five draws 13, six draws 14, seven draws ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com