Intelligent layer-burning boiler extinguishing boundary detecting system

An intelligent detection and boundary technology, applied in the direction of combustion chamber safety devices, combustion chambers, combustion methods, etc., can solve the problems of curved surface imaging deformation, affecting the accuracy of extinguishing point monitoring, etc. Small amount of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

[0030] An intelligent detection system for the extinguishment limit of a floor-fired boiler, including an image acquisition subsystem, an extinguishment limit calibration subsystem, an image processing subsystem, and a host computer 11;

[0031] The image acquisition subsystem acquires real-time images in the layer-fired boiler;

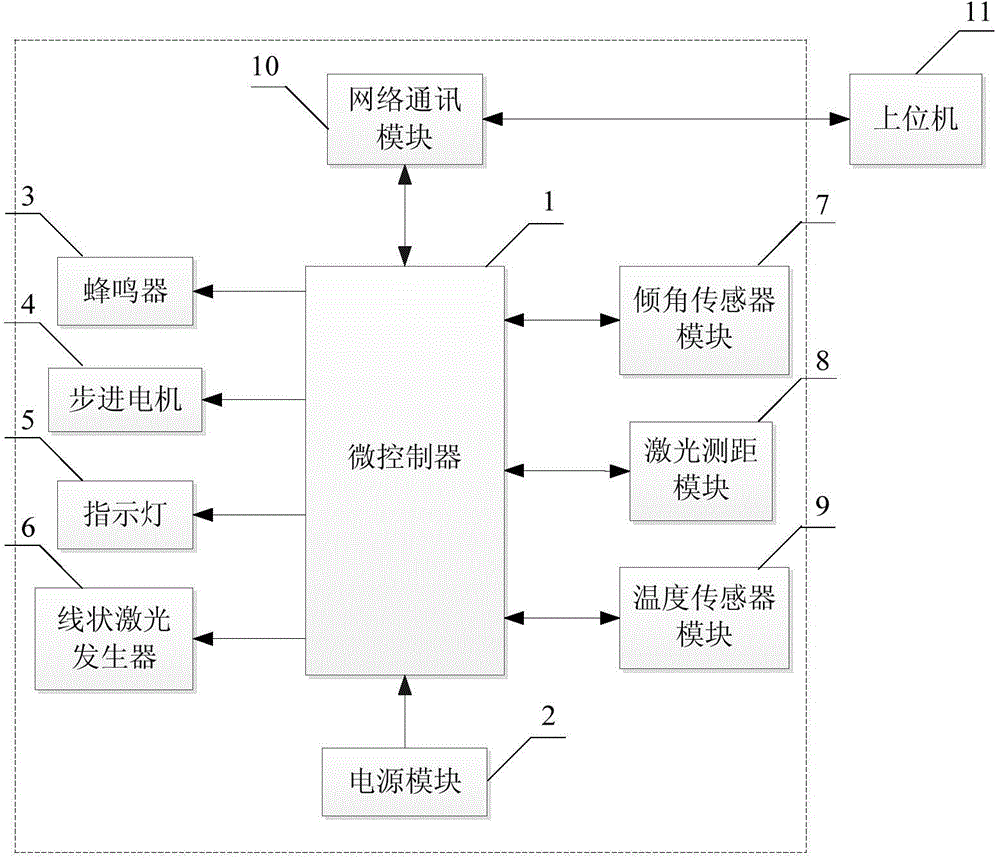

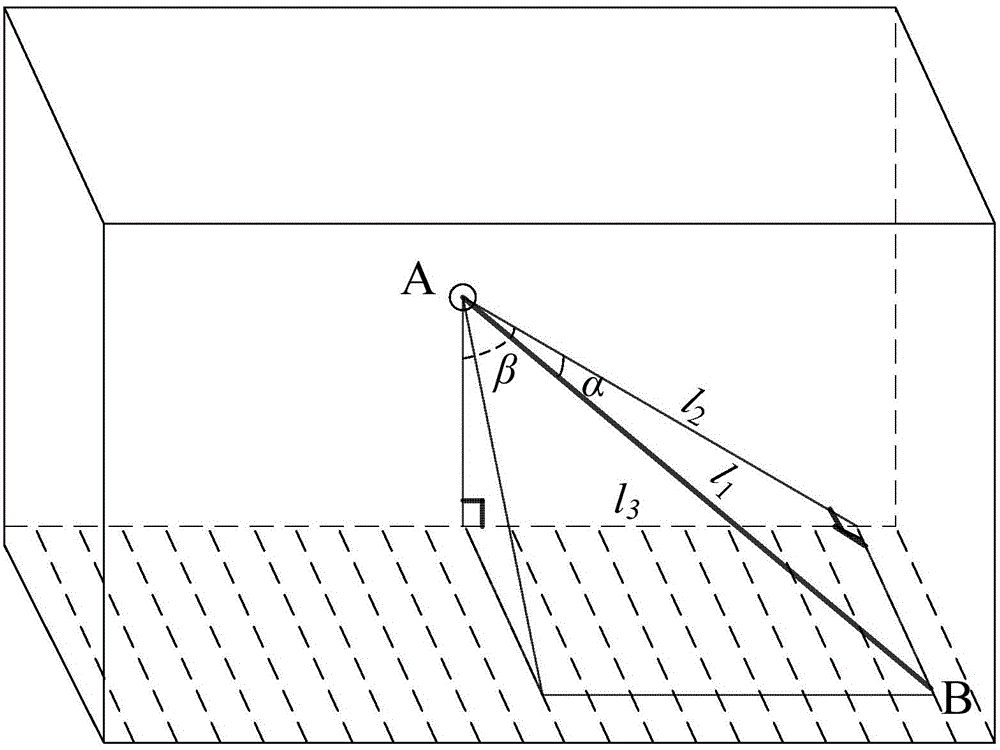

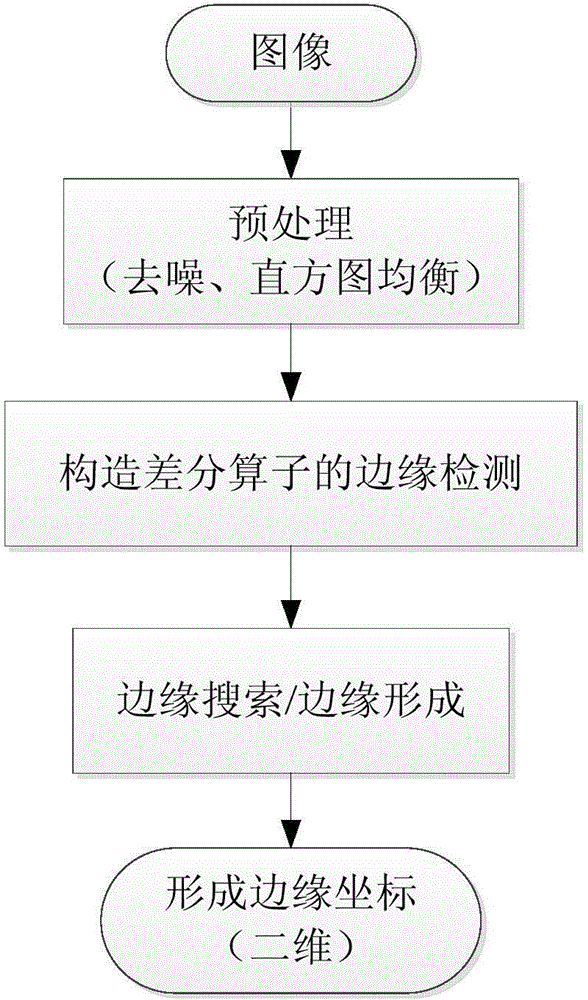

[0032] refer to Figure 2-3 The extinguishing limit calibration subsystem includes: a microcontroller 1, a stepper motor 4, a linear laser generator 6, an inclination sensor module 7 and a laser ranging module 8; After the scanning command of the , generate pulse and direction signal, control the speed, direction and angular displacement of the stepper motor 4 rotation, thereby controlling the rotation of the linear laser generator 6; the linear laser generator 6 rotates every A reference line perpendicular to the f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com