Centering method for stepped shaft and hole assembling process

A technology of assembly process and stepped axis, which is applied in the direction of measuring device, optical device, image data processing, etc., can solve the problems of not considering the fitting error, not considering the unique characteristics of the stepped axis, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0071] Embodiments of the present invention are described in detail below, and the embodiments are exemplary and intended to explain the present invention, but should not be construed as limiting the present invention.

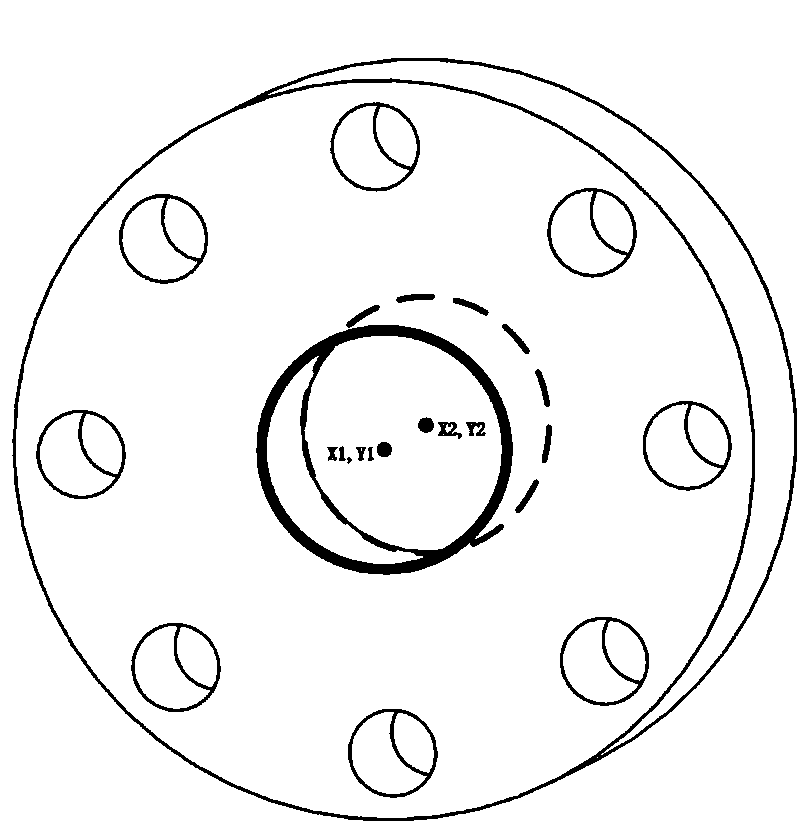

[0072] The purpose of the present invention is to realize real-time monitoring and feedback on the alignment of the stepped shaft and the hole, and therefore proposes a centering method for the assembly process of the stepped shaft and the hole, which includes the following steps.

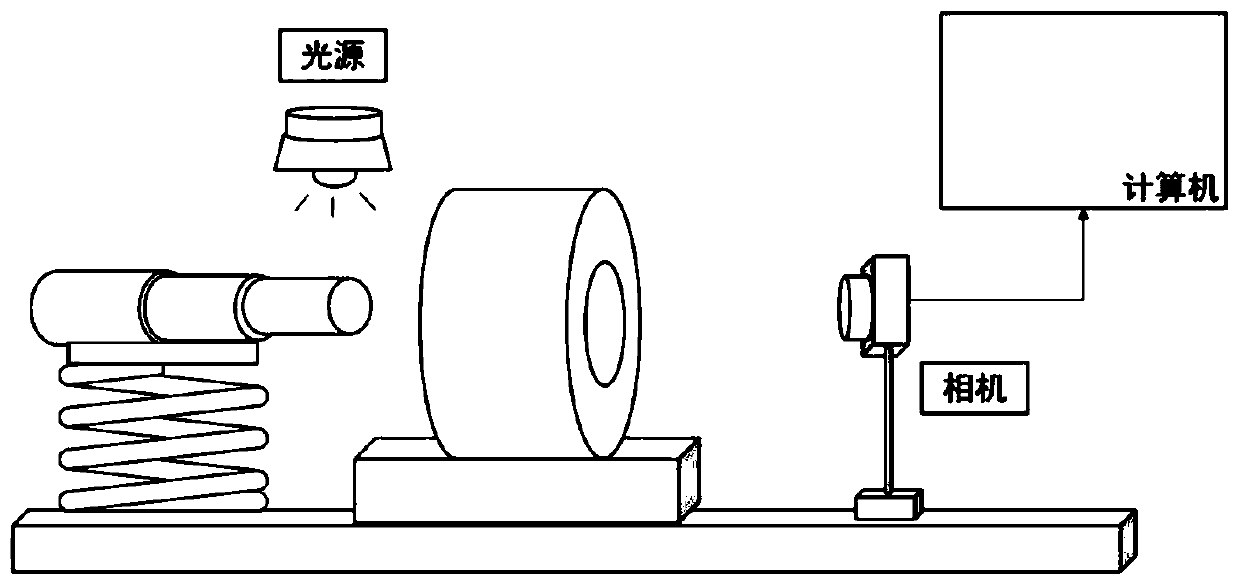

[0073] Step 1: Fix the calibrated industrial camera, fix the hole parts to be assembled in front of the camera, and install the light source to illuminate the through holes of the hole parts.

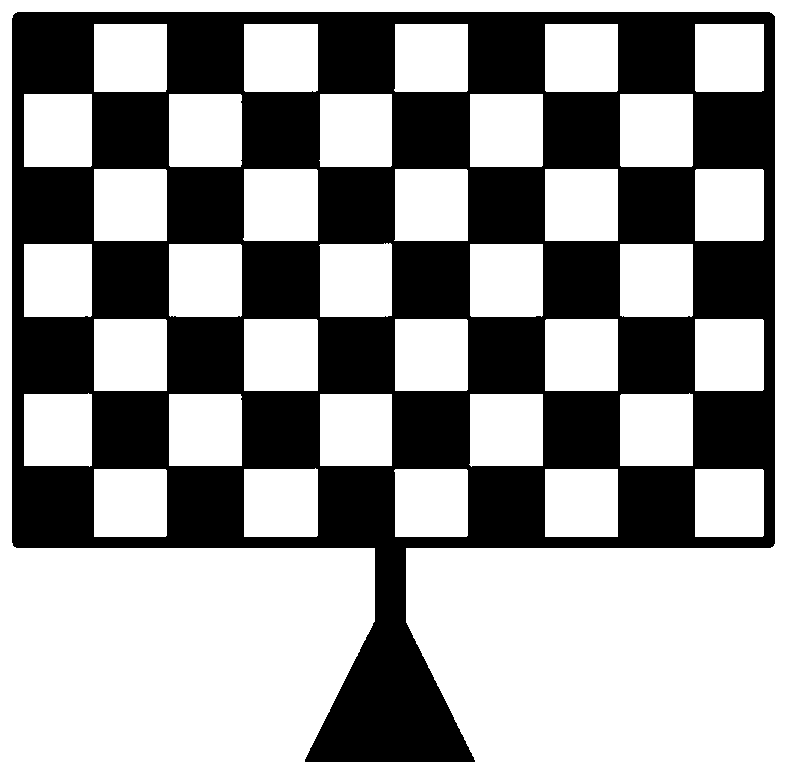

[0074] In the application of machine vision, in order to correct the distortion of the lens and determine the conversion relationship between the physical size and the pixel in reality, the industrial camera is calibrated using the chessboard pattern Ti-times CG-076-T. Such as figure 2 sho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com