Marine blow-throwing bait feeder for pound

A technology for fish ponds and boats, applied in the field of feeders, can solve problems such as fish deaths, water pollution, water quality deterioration, etc., and achieve the effect of solving uniformity problems and preventing malignant accidents.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

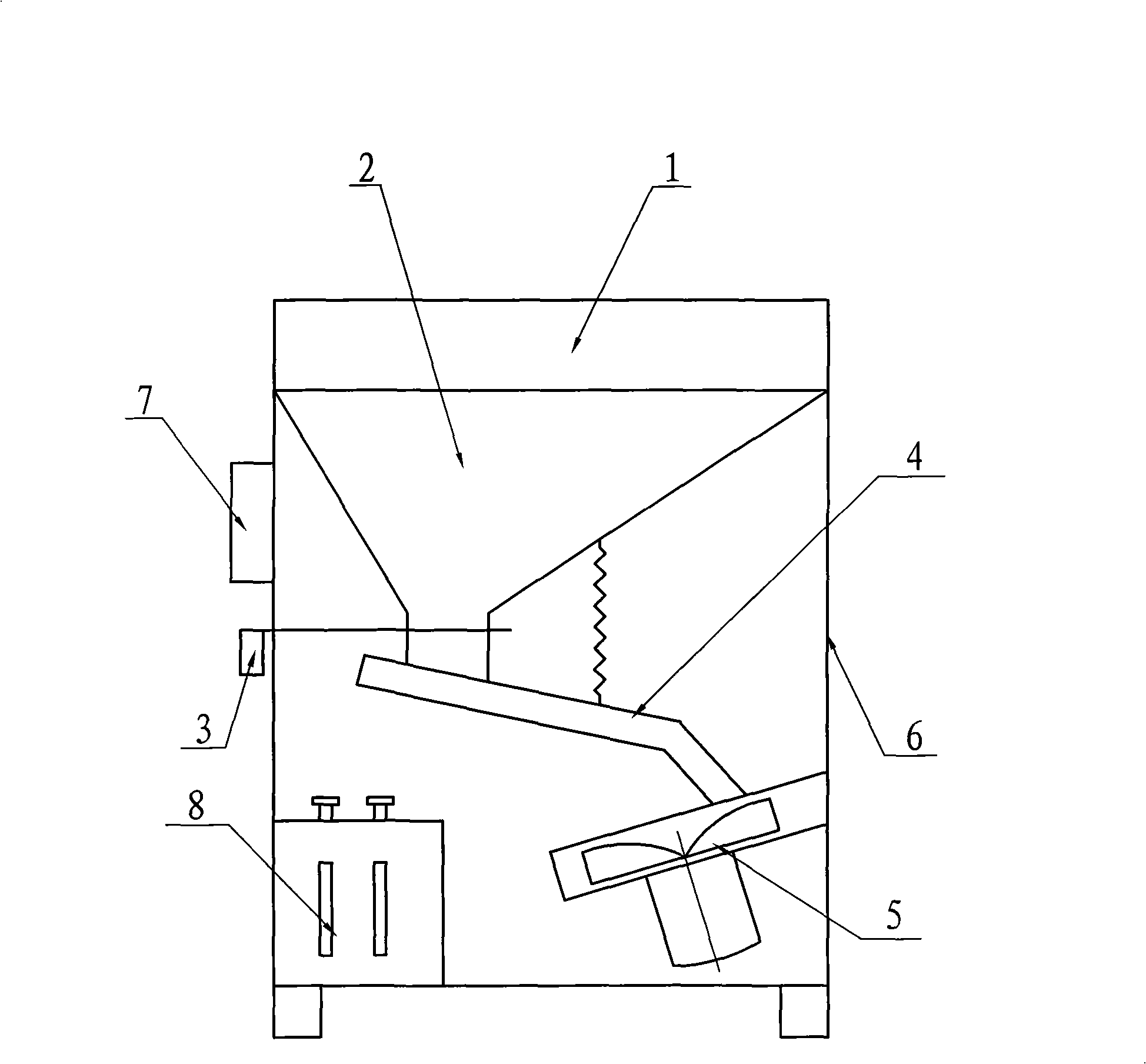

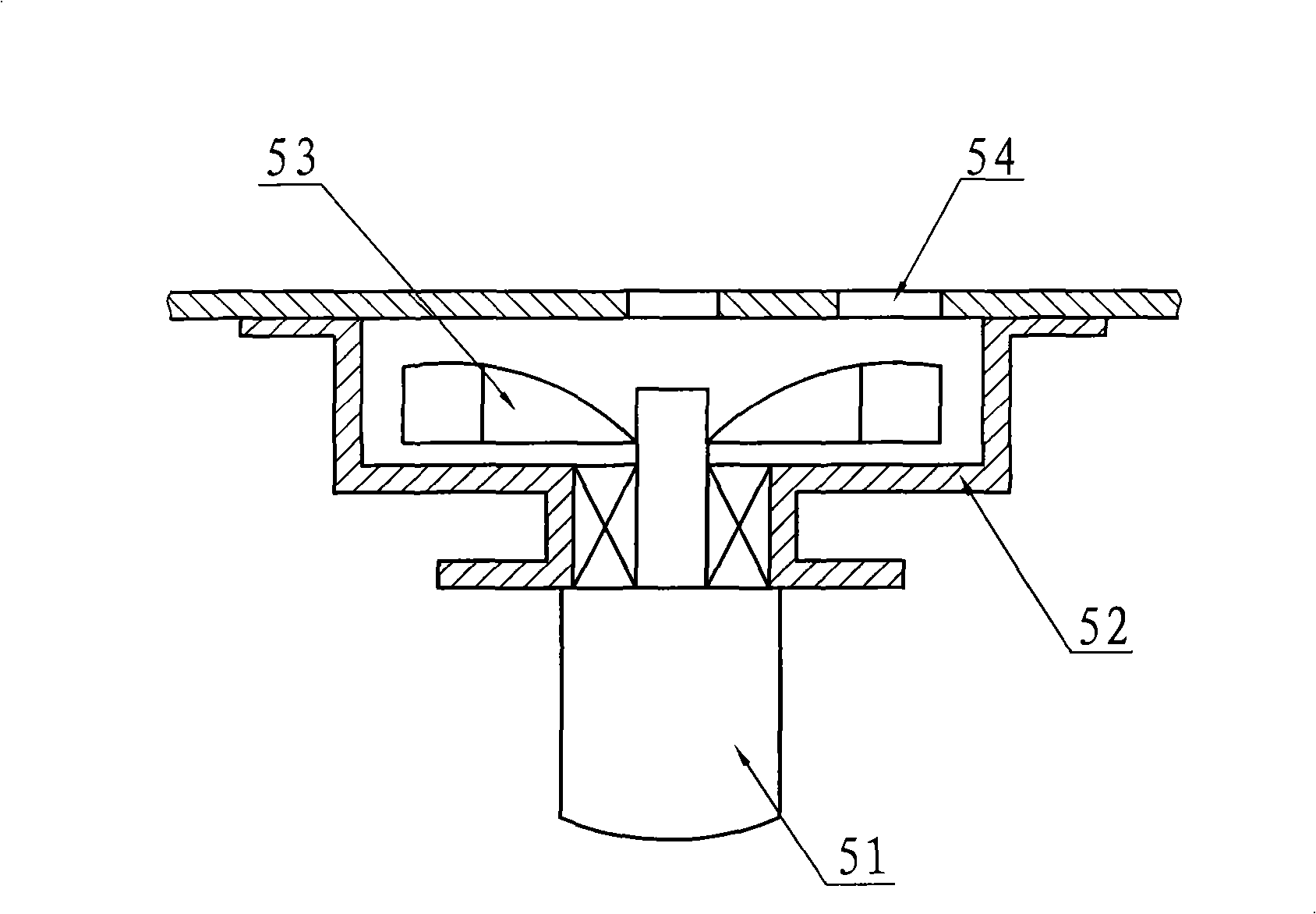

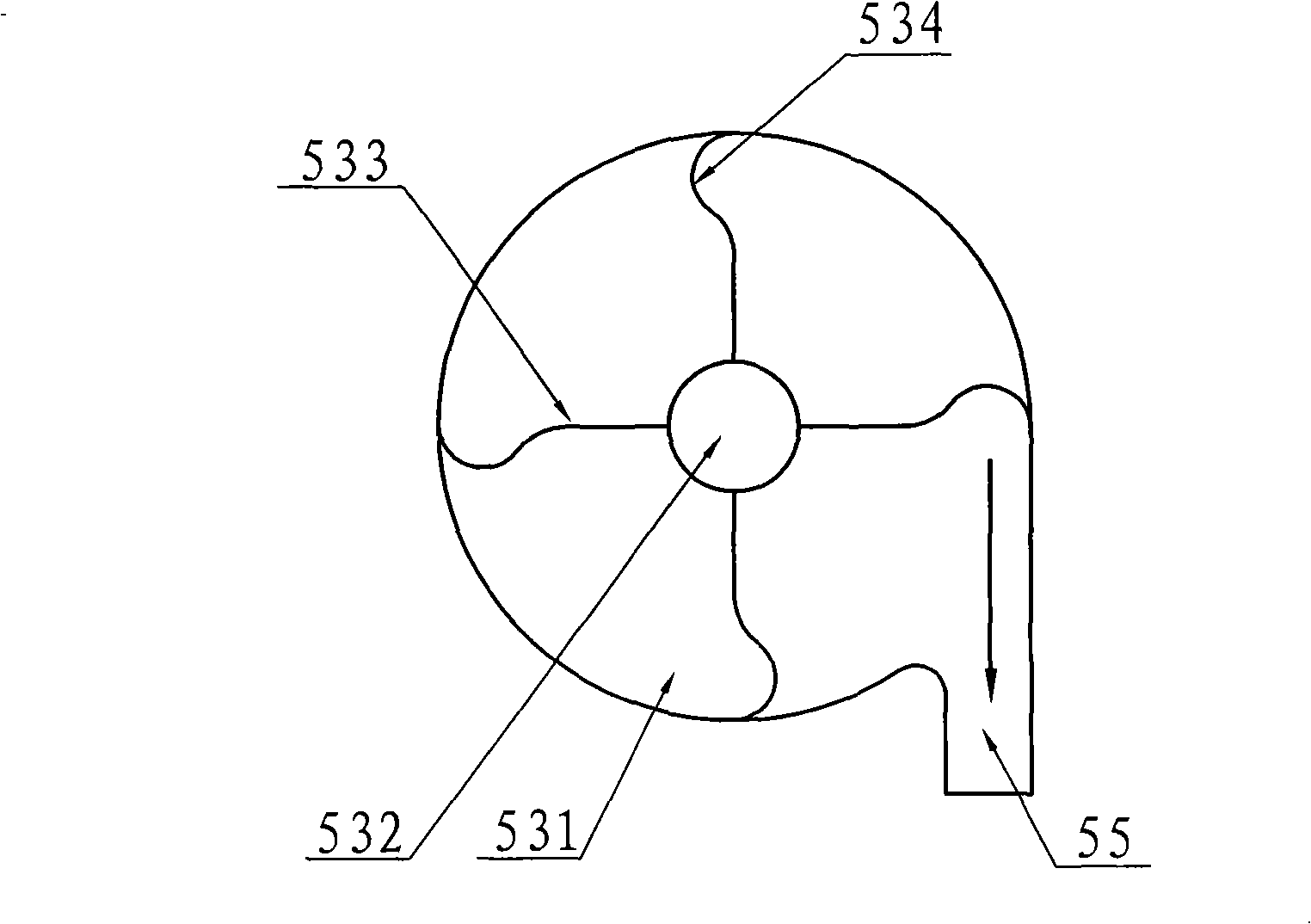

[0013] Embodiment 1: The blowing and throwing type erbium throwing machine for the marine fish pond is as figure 1 As shown, it includes a box cover 1, a hopper 2, a feed adjustment plate 3, a vibrating feed trough 4, a throwing tray 5, a frame 6, a DC control setting box 7 and a battery 8, and a DC control setting box 7 The input wire is electrically connected with the storage battery 8, and the output wire of the DC control setting box 7 is electrically connected with the DC motor of the vibratory feeding trough 4 and the DC motor 51 in the throwing tray 5; the throwing tray 5 is electrically connected by the DC motor 51. Housing 52, throwing and blowing impeller 53 and blanking port 54. The housing 52 is fixed on the frame 6. The DC motor 51 is fixed on the housing 52. The throwing and blowing impeller 53 is fixed on the output of the DC motor 51. axis, such as figure 2 As shown; the throwing and blowing impeller 53 is composed of a base plate 531, an impeller seat 532, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com