Winch heave compensation device of marine floating drilling platform

A technology for drilling platform and heave compensation, which is applied to winches, drilling equipment, drill pipes, etc., can solve the problems of low control accuracy, high energy consumption, and high installed power, and achieves improved control accuracy, long wire rope life, and high response. fast effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

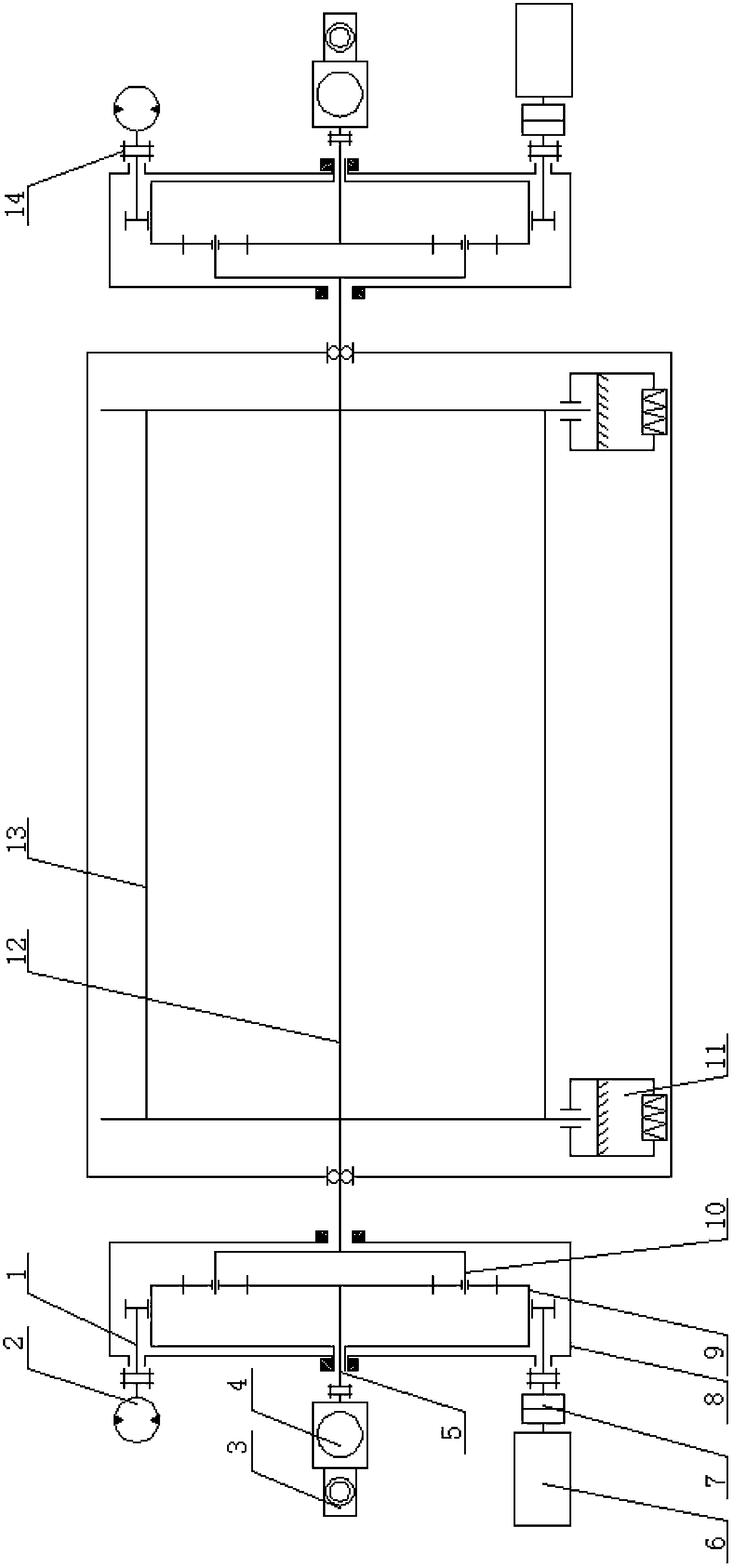

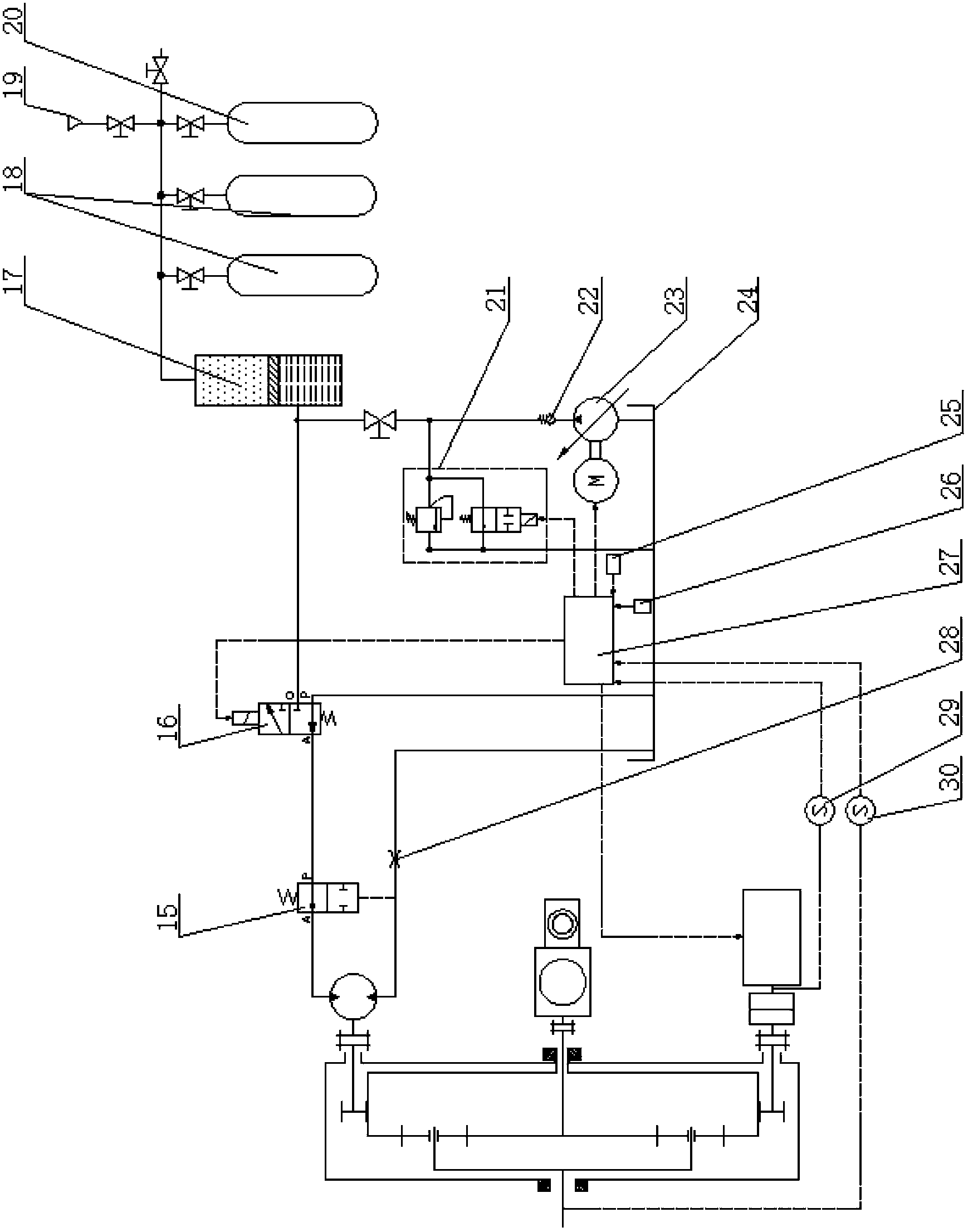

[0022] Such as figure 1 , 2 As shown, the heave compensation device of the drawworks of the offshore floating drilling platform is arranged symmetrically along the two ends of the drawworks drum 13, mainly including the passive compensation hydraulic motor 2, the active compensation motor 6 and its variable frequency drive system, the differential planetary reducer 8, and the drilling motor 3. Winch shaft 12 and winch drum 13. During installation, the active compensation motor 6 and the passive compensation hydraulic motor 2 are connected with the outer ring gear pinion of the differential planetary reducer 8 through the clutch 7 and the shaft coupling 14, and are arranged along the circumferential direction of the outer ring gear 9; The cycloid reducer 4 and the shaft coupling 14 are connected to the sun gear power input shaft 5 of the differential reducer 8; the planet carrier 10 is connected to the winch shaft 12 through a key. The acceleration sensor 25 is fixedly connec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com