Centrifugal fly claw ratchet wheel braking locker and contact net compensation device

A catenary compensation, flying claw ratchet technology, applied in overhead lines and other directions, can solve the problems of heavy weight, poor locking reliability, large volume, etc., and achieve the effect of simple structure and reliable use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

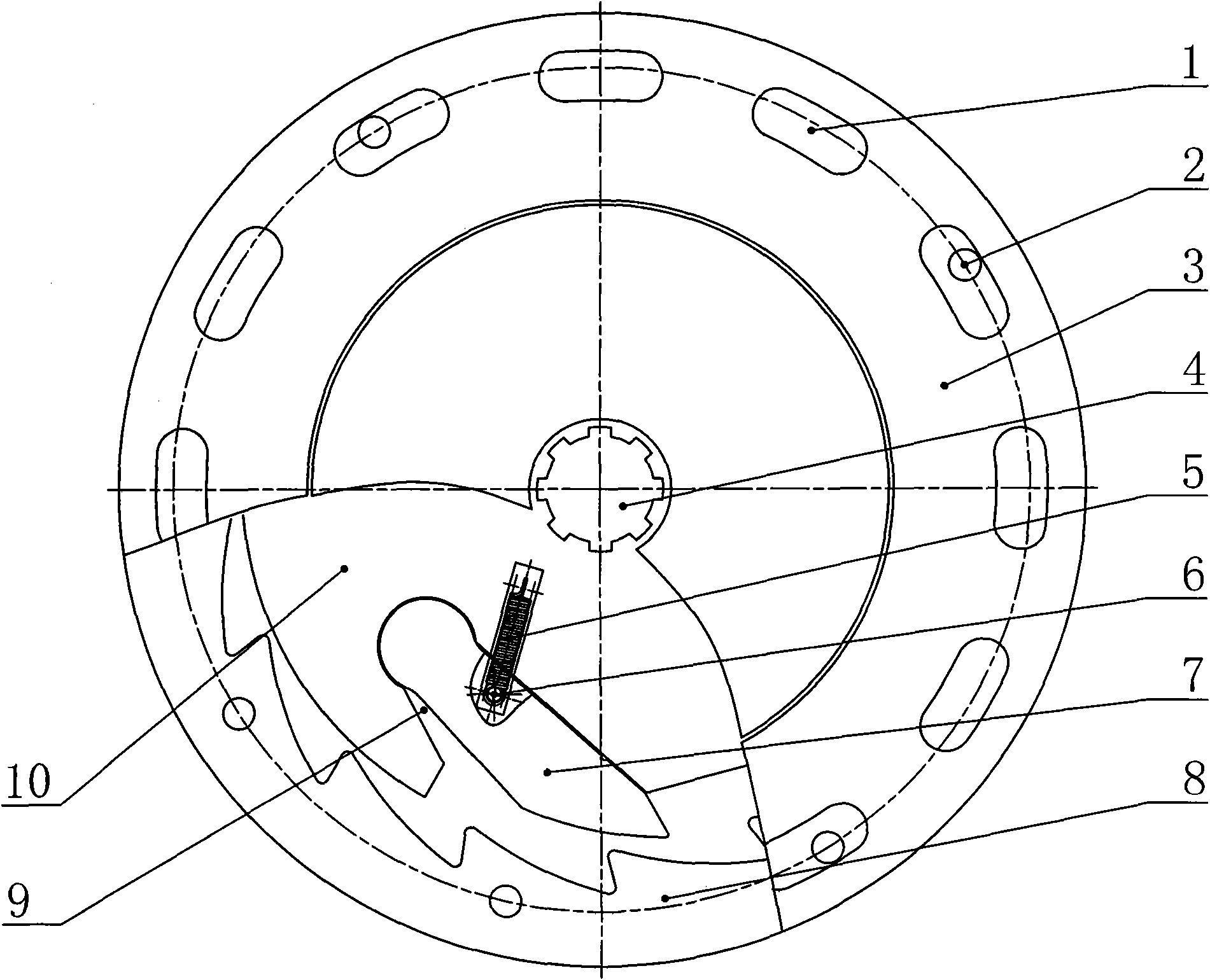

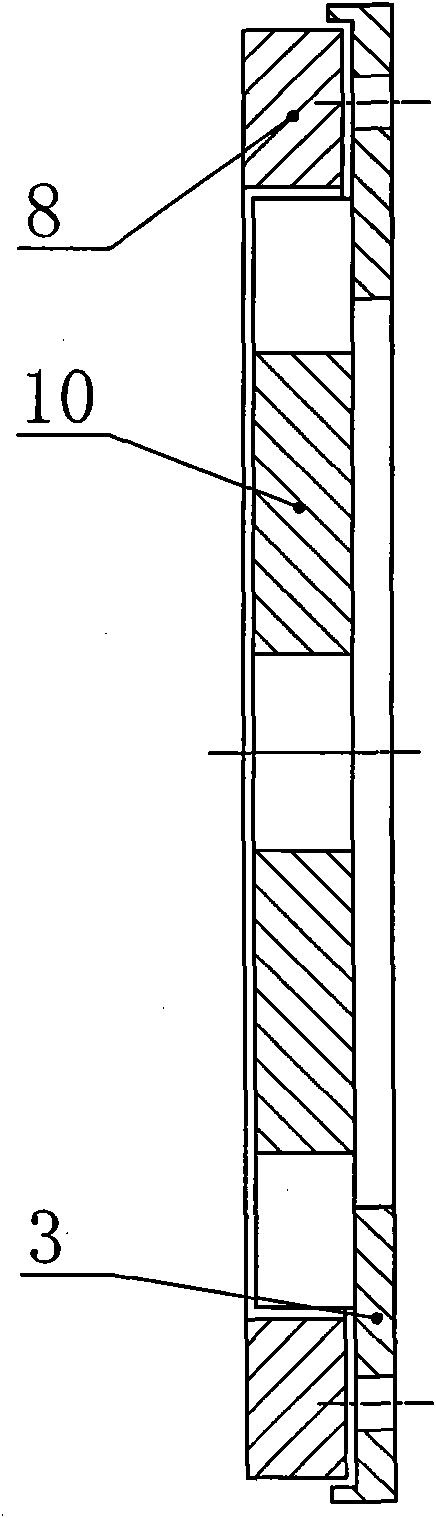

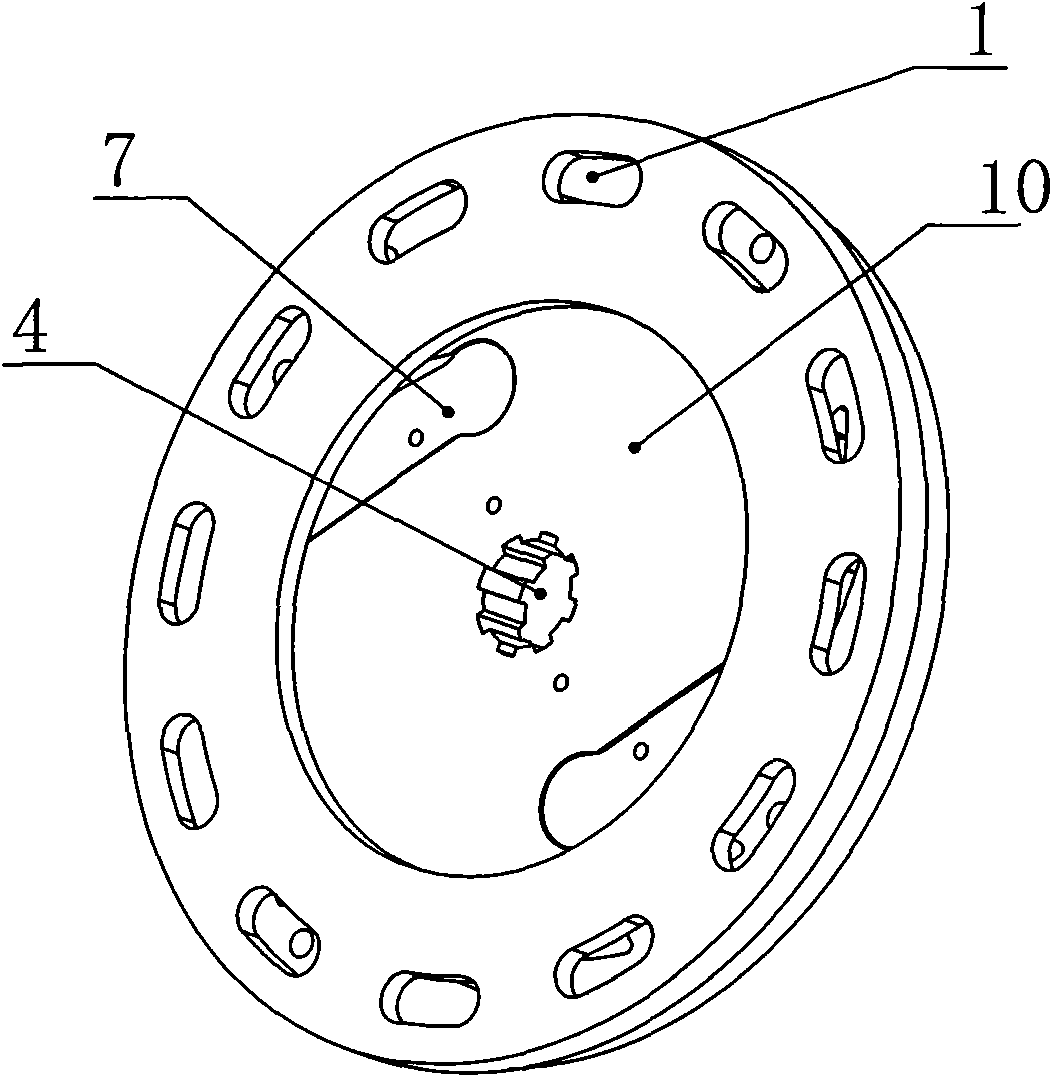

[0033] Such as Figure 1-4 As shown, it is a centrifugal fly paw ratchet brake locker, its structure mainly includes an internal tooth ratchet 8, a fly pawl 7 and a flywheel 10, the internal tooth ratchet 8 is set on the flywheel 10, and there is a gap between the two Clearance, the outer circumference of the flywheel 10 is symmetrically provided with two flying claw grooves 9 along the center of the flywheel shaft, the flying claws 7 are inserted into the flying claw grooves 9, and there is a gap between the flying claws 7 and the flywheel 10 to drive the flying claws to shrink. Elastic mechanism in claw groove, this elastic mechanism is extension spring 5, is provided with extension spring fixing screw 6 on fly claw 7, is provided with extension spring installation groove on flywheel 10, extension spring 5 one ends are fixed in extension spring installation groove, and the other One end is connected to the extension spring fixing screw 6, and the end of the flying claw 7 cor...

Embodiment 2

[0037] Such as Figure 5 As shown, it is a catenary compensation device, including a constant tension spring compensation device 20, on the main shaft 18a of the constant tension spring compensation device 20, a centrifugal fly paw ratchet brake locker 17 as in embodiment 1 is fixedly installed, the The internal tooth ratchet of the centrifugal fly paw ratchet brake locker 17 is fixedly connected to the side plate 21 of the constant tension spring compensation device, and the flywheel of the centrifugal fly pawl ratchet brake locker 17 is connected to the main shaft of the constant tension spring compensation device 18a is fixedly connected.

Embodiment 3

[0039] Such as Figure 6-7 As shown, it is a catenary pendant compensation device equipped with a centrifugal flying claw ratchet brake locker as shown in Embodiment 1. Its structure mainly includes a bracket 11 arranged on an electric pole 12. The rotating main shaft 18 is provided with a large-diameter tension wire pulley 16 and one or two small-diameter tension wire pulleys 19 linked to each other on the main shaft 18. The large-diameter tension wire pulley 16 is wound with a steel wire rope 13a, and the lower end of the steel wire rope 13a is suspended A pendant 14 is hung, a small-diameter tensioning wire wheel 19 is wound around a steel wire rope 13b with a connecting wire or a load-bearing cable, and the centrifugal flying claw ratchet brake locker 17 is arranged on the main shaft 18. The centrifugal flying claw ratchet system The internal tooth ratchet 8 of the dynamic locking device 17 is connected with the fixed outer plate of the bracket 11, and the flywheel 10 of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com