Integrated double-main-cylinder line control braking system

A brake-by-wire and dual-master cylinder technology, applied in brakes, brake transmissions, transportation and packaging, etc., can solve the problems of increased brake pipeline length, slow brake pressure response, low modularization, etc., to achieve The effect of reducing the quality of the assembly, reducing the frequency of use, and reducing the working time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

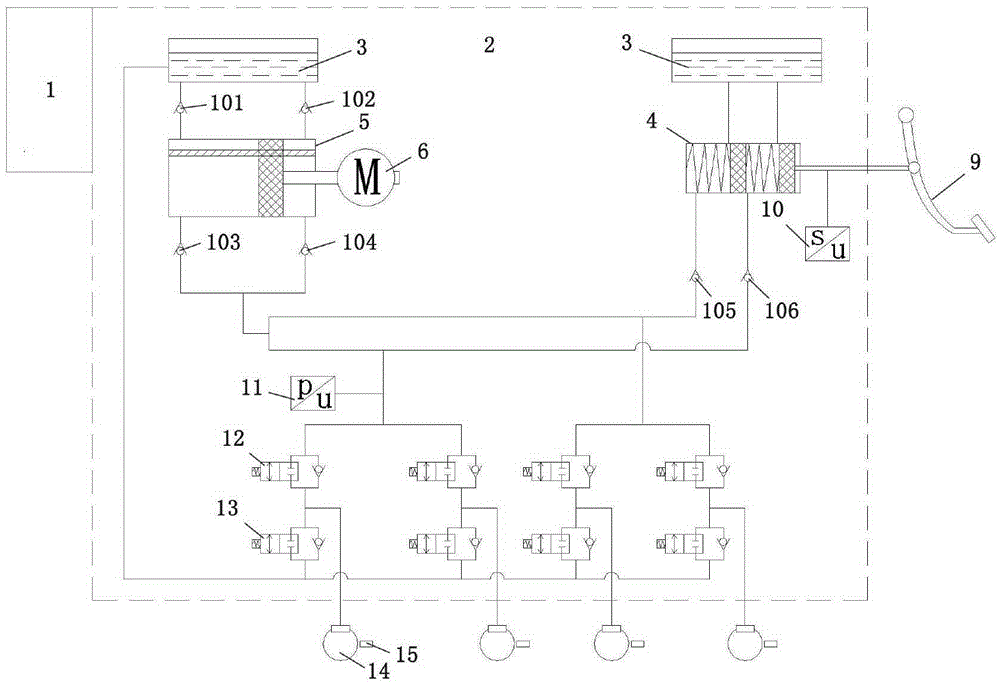

[0035] Such as figure 1 As shown, the present embodiment consists of ECU electronic control unit 1, oil pot 3, first master cylinder 4, second master cylinder 5, motor 6, electronic pedal 9, pedal displacement sensor 10, pressure sensor 11, normally open valve 12, Normally closed valve 13, wheel cylinder 14, wheel speed sensor 15, screw rod (not shown in the figure), first check valve 101, second check valve 102, third check valve 103, fourth check valve 104 , the fifth one-way valve 105, and the sixth one-way valve 106.

[0036] Wherein the oil pot 3, the first master cylinder 4, the check valve, the pressure sensor 11, the normally open valve 12, and the wheel cylinder 14 are sequentially connected to form the first brake passage, and the wheel cylinder 14 is also connected with a wheel speed sensor 15. Specifically, such as figure 1 As shown, the first master cylinder 4 is composed of a cylinder body, a piston push rod, two pistons and two return springs, and the two pist...

Embodiment 2

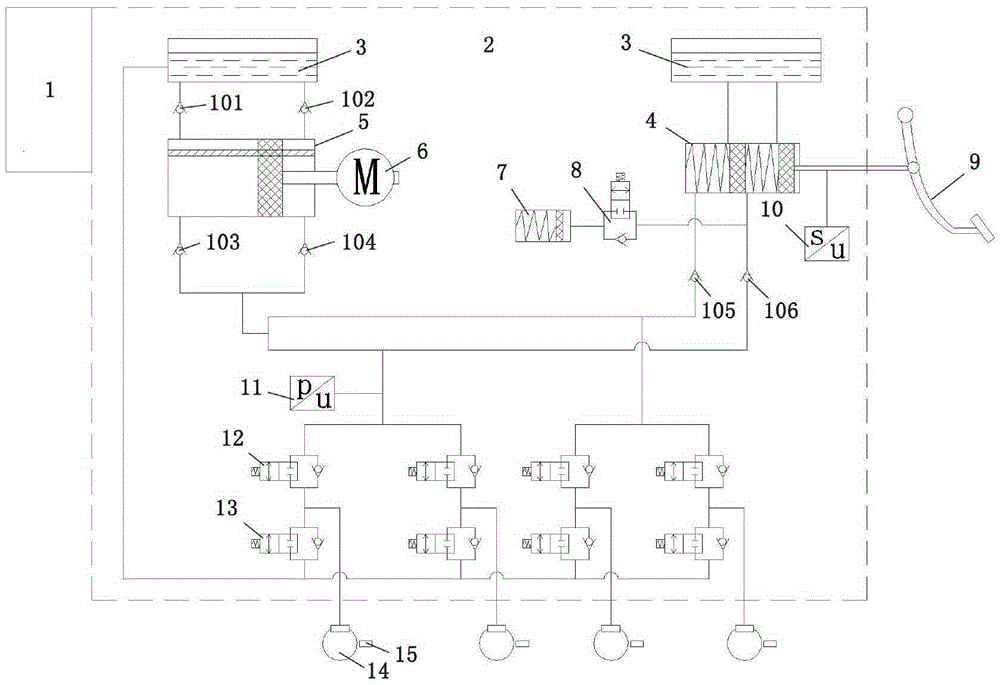

[0059] This embodiment is similar to Embodiment 1, except that this embodiment also includes a pedal feeling simulator 7 and an isolation valve 8 , and the pedal feeling simulator 7 is connected to the first master cylinder 4 through the isolation valve 8 .

[0060] In this embodiment, oil pot 3, first master cylinder 4, second master cylinder 5, motor 6, lead screw, pressure sensor 11, pedal simulator 7, one-way valve, isolation valve 8, normally open valve 12, The normally closed valves 13 are all integrated into the hydraulic adjustment unit 2 .

[0061] The specific braking process in this embodiment is as follows:

[0062] 1. Conventional braking:

[0063] When the driver depresses the electronic pedal 9, the piston push rod pushes the piston in the first master cylinder 4 to press the brake fluid into the four wheel cylinders 14 through the fifth one-way valve 105 and the sixth one-way valve 106 , the brake fluid pushes the wheel cylinder piston, and the piston pushes ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com