Device capable of adjusting vertical loads of four wheels of automobile

A vertical load and adjustable technology, applied in the direction of the body, vehicle parts, streamlined body, etc., can solve problems such as slippage, large vehicle roll, and vertical load that cannot be controlled independently, so as to suppress the body roll and increase the cornering speed , Improve the effect of handling stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

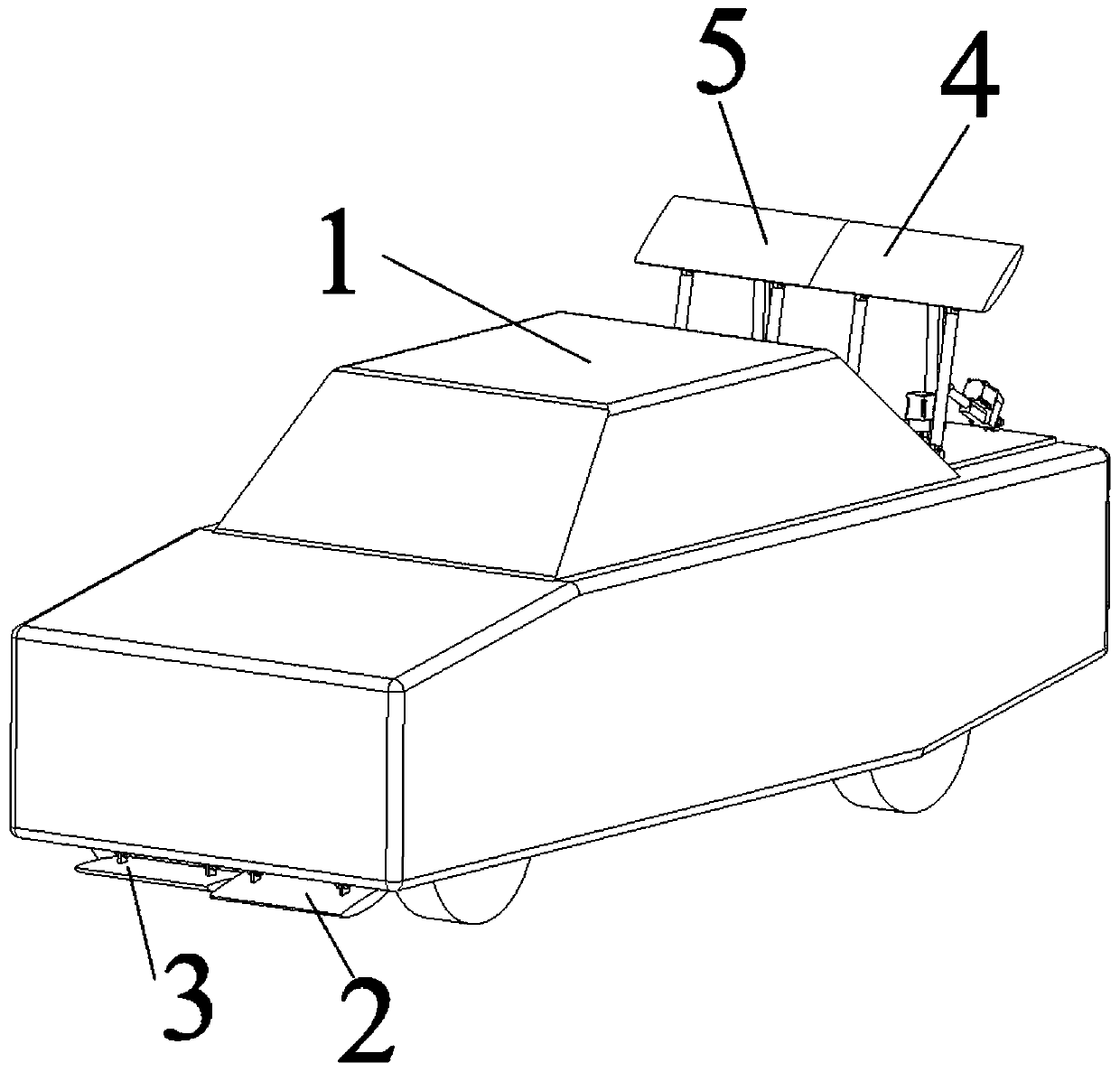

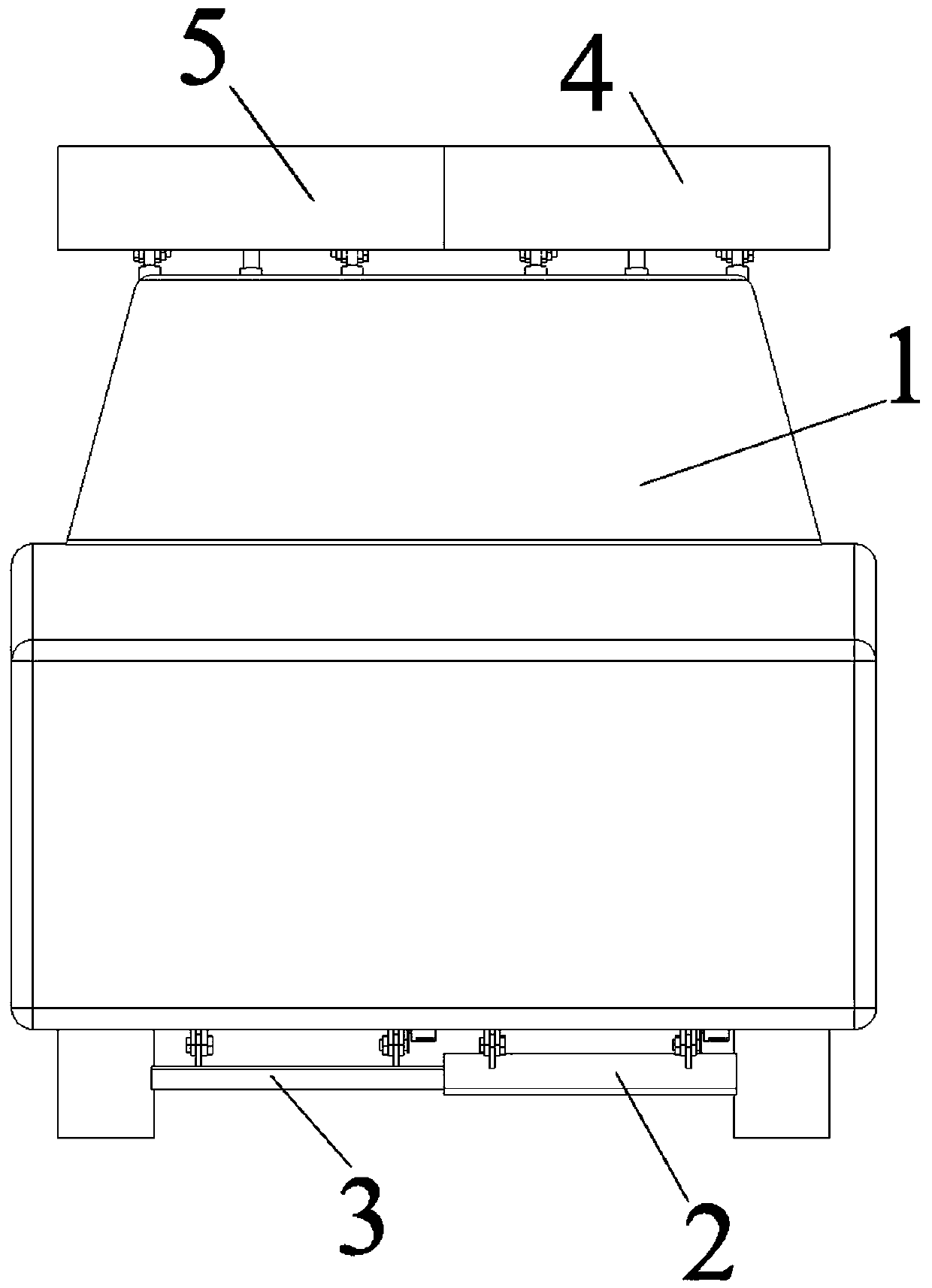

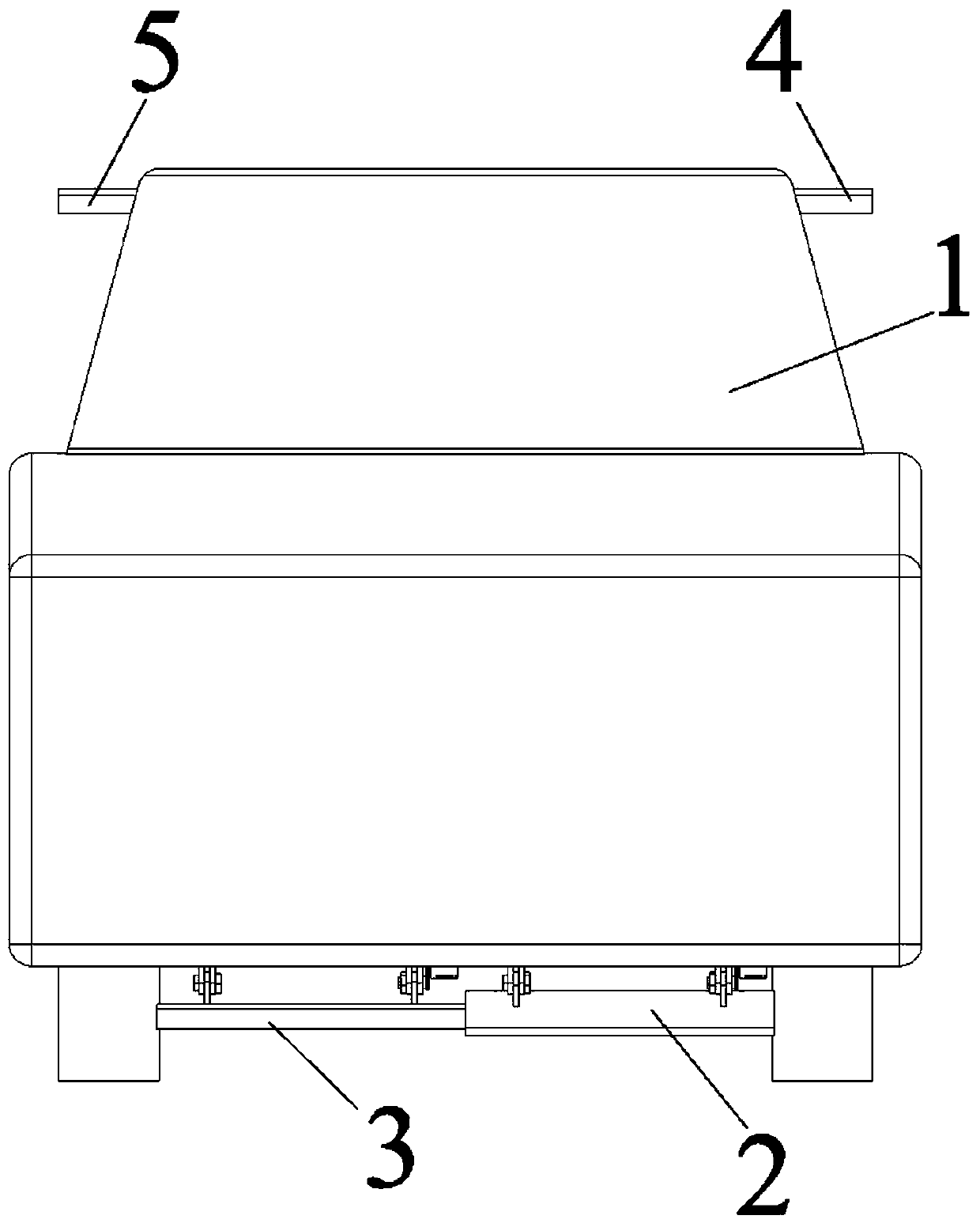

[0033] Such as Figure 1-8Shown, a kind of adjustable automobile four-wheel vertical load device, described device comprises front left wing plate 2, front right wing plate 3, rear left wing plate 4, rear right wing plate 5, wing plate attitude adjustment mechanism and vehicle-mounted ECU; The left wing and the front right wing are located at the front of the vehicle body 1 and in front of the front wheels at the lower end of the chassis. The front left wing and the front right wing are respectively adjacent to the left front wheel and the right front wheel; on the left and right sides of the rear of the vehicle body; the wing plate attitude adjustment mechanism is connected with the front left wing plate and the front right wing plate to adjust the angle of attack; the vehicle-mounted ECU is connected with the wing plate attitude adjustment mechanism; the wing plate attitude adjustment mechanism is connected with the rear wing plate The left wing plate and the rear right wing...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com